1

/

of

10

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

JC/T 973-2005 English PDF (JCT973-2005)

JC/T 973-2005 English PDF (JCT973-2005)

Regular price

$160.00 USD

Regular price

Sale price

$160.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click JC/T 973-2005

Historical versions: JC/T 973-2005

Preview True-PDF (Reload/Scroll if blank)

JC/T 973-2005: Natural stone protector for building decoration

JC/T 973-2005

BUILDING MATERIAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 91.100.20

Q 21

Registration number: 15245-2005

Natural stone protector for building decoration

ISSUED ON: FEBRUARY 14, 2005

IMPLEMENTED ON: JULY 01, 2005

Issued by: National Development and Reform Commission of PRC

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Product classification and naming marks ... 5

5 Technical requirements ... 7

6 Test methods ... 8

7 Inspection rules ... 9

8 Marking, packaging, storage, transportation ... 10

9 Safety coating and protection ... 10

Appendix A (Normative) Test method of waterproofness ... 12

Appendix B (Normative) Test method of stain resistance ... 14

Appendix C (Normative) Test method for reduction rate of cement’s bond

strength ... 16

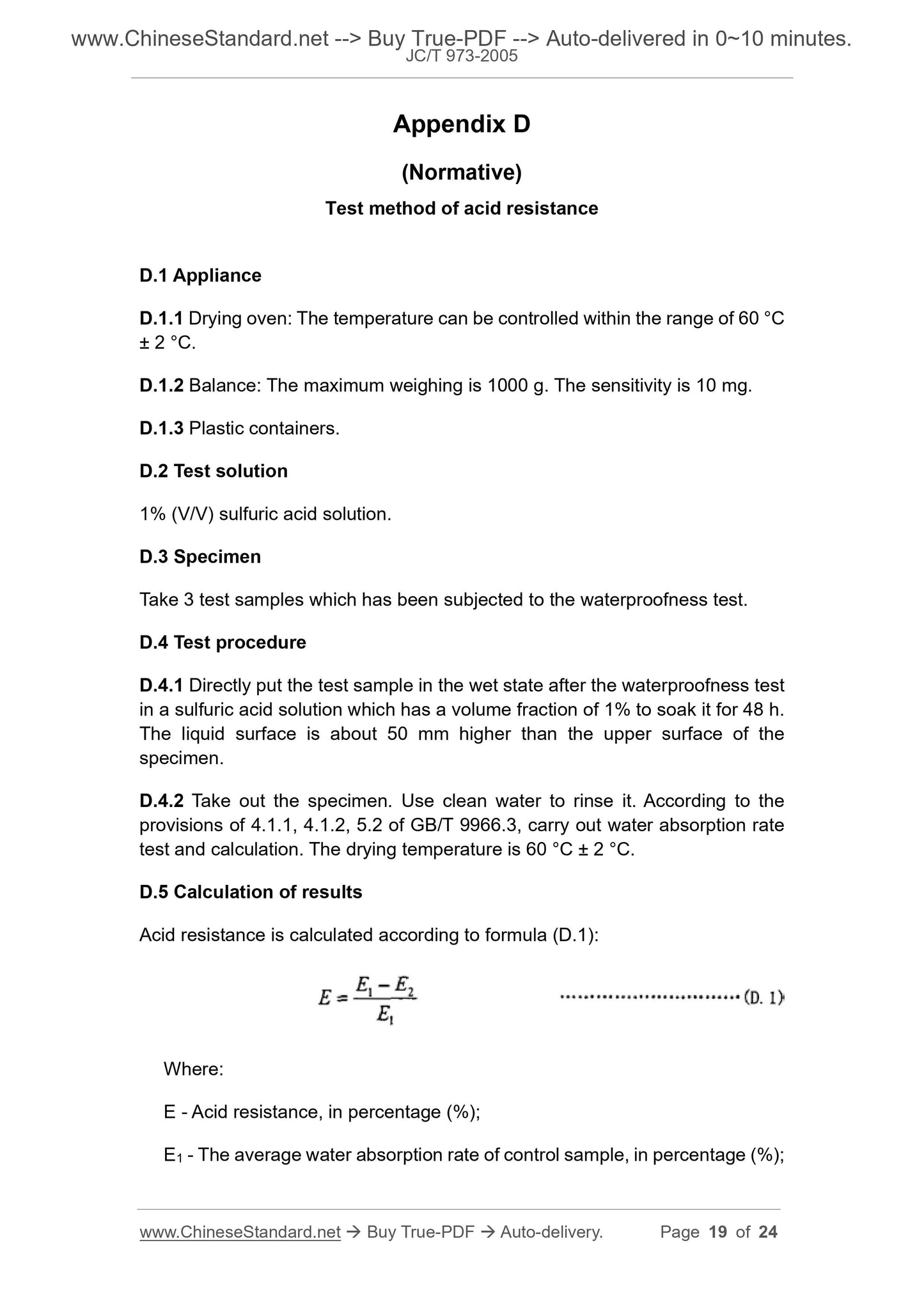

Appendix D (Normative) Test method of acid resistance ... 19

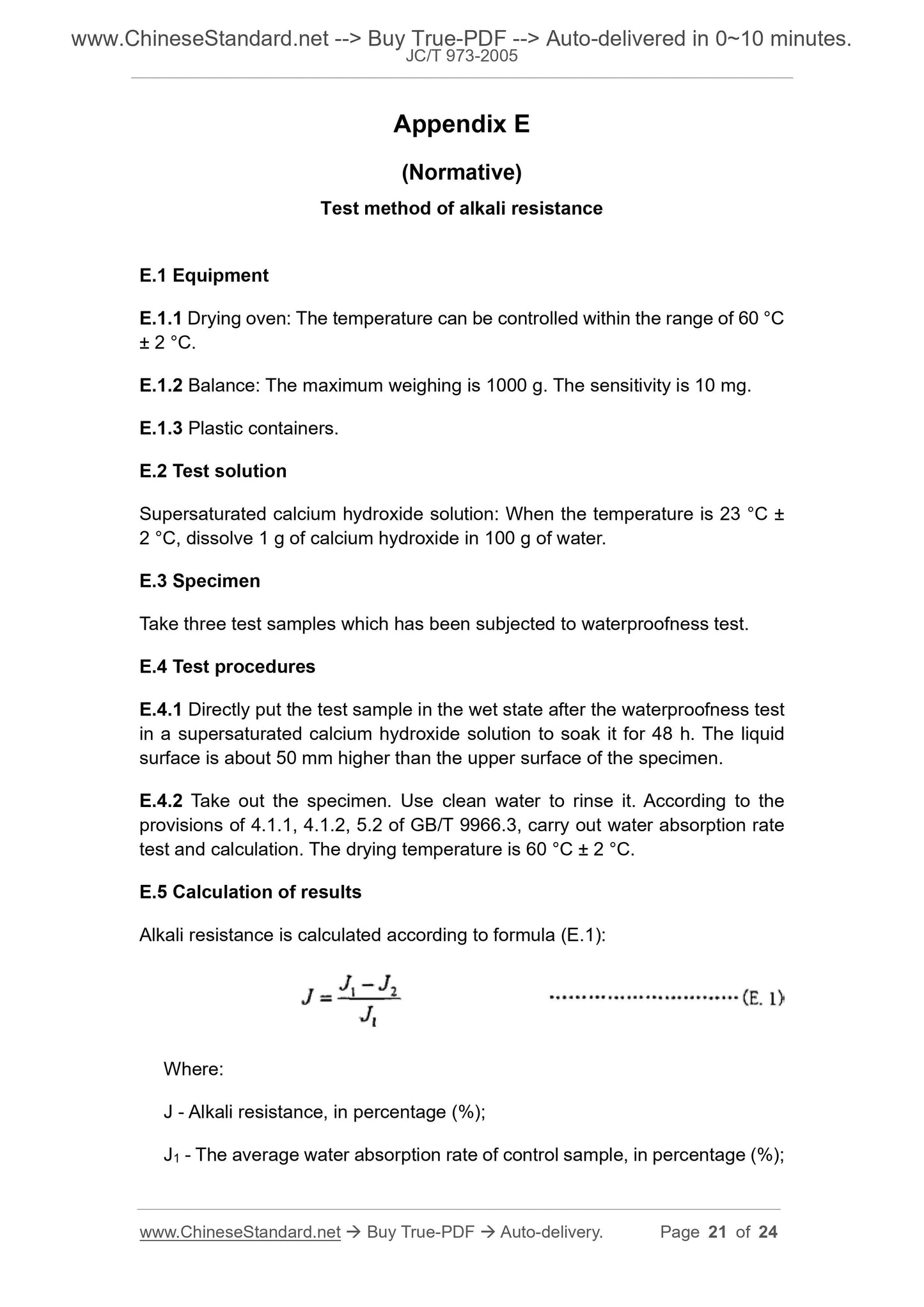

Appendix E (Normative) Test method of alkali resistance ... 21

Appendix F (Normative) Test method of UV-aging resistance ... 23

Natural stone protector for building decoration

1 Scope

This standard specifies the terms and definitions, classification and naming

marks, technical requirements, test methods, inspection rules, marking,

packaging, storage and transportation, safe coating and protection of natural

stone protectors.

This standard applies to the natural stone protector for building decoration.

2 Normative references

The provisions in following documents become the provisions of this standard

through reference in this standard. For the dated references, the subsequent

amendments (excluding corrections) or revisions do not apply to this standard;

however, parties who reach an agreement based on this standard are

encouraged to study if the latest versions of these documents are applicable.

For undated references, the latest edition of the referenced document applies.

GB 3186 Sampling paint products

GB/T 9966.3-2001 Test methods for natural facing stones - Part 3: Test

methods for bulk density, true density, true porosity and water absorption

GB/T 13890 Terms for natural facing stone

GB 18581 Indoor decorating and refurbishing materials - Limit of harmful

substances of solvent based coatings for woodenware

GB 18582 Indoor decorating and refurbishing materials - Limit of harmful

substances of interior architectural coatings

JC/T 902 Silicone hydrophobic agent for construction surfaces

3 Terms and definitions

The terms and definitions as established by GB/T 13890 as well as the following

terms and definitions apply to this standard.

3.1

6 Test methods

6.1 pH

Use a precision pH test paper to make determination.

6.2 Stability

Take two sets of 10 mL of sample. Respectively put it into two test tubes. Place

them on opposite sides of the electric centrifuge. Rotate it at 3000 r/min for 5

min. Take out the test tube, to see if there is delamination, floating oil,

precipitation.

6.3 Waterproofness

See Appendix A.

6.4 Stain resistance

See Appendix B.

6.5 Reduction rate of cement’s bond strength

See Appendix C.

6.6 Acid resistance

See Appendix D.

6.7 Alkali resistance

See Appendix E.

6.8 UV-aging resistance

See Appendix F.

6.9 Impermeability

Flatly place the five 150 mm x 150 mm x 20 mm stones, whose bottom and four

sides are protected according to A.3.1 to A.3.3 in Appendix A, in the top of a

container (wide-edge box which has a volume of 160 mm x 160 mm x 25 mm,

lined with 240 mm x 240 mm plastic film) which contains cement mortar (cement

and sand are prepared in the proportion of 1:2.5 by the use of water). Make its

bottom face downwards. Allow the cement mortar to reach about 1/2 of the

stone’s thickness. Use plastic tape to seal the exposed part at the sides of stone

and the periphery of the container. Let it be standing for seven days. At the

interval of one day, observe the color change and the presence of water mark

7.2 Type inspection

7.2.1 Inspection items

All the items in clause 5 of technical requirements.

7.2.2 Inspection conditions

In one of the following cases, carry out type inspection:

a) When the new product is initially type-finalized;

b) When there is a major change in product’s formulation, process, raw

materials;

c) When the production is restored after suspension for more than half a year;

d) Once a year during normal production;

e) When the national quality supervision agency proposes to carry out type

inspection requirements.

7.2.3 2 Group-batch

Same as exit-factory inspection.

7.2.4 Sampling

Same as exit-factory inspection.

7.2.5 Determination

If one of the test results does not meet the requirements of clause 5, the batch

of products is judged to be unqualified.

8 Marking, packaging, storage, transportation

The marking, packaging, storage, transportation of the product shall be in

accordance with the provisions of clause 7 of JC/T 902.

9 Safety coating and protection

9.1 When applying coating, try to choose the brushing method and carry it

outdoors. If it is indoors, it must be well ventilated.

9.2 When applying coating, the construction personnel shall wear the

necessary protective equipment.

Appendix A

(Normative)

Test method of waterproofness

A.1 Equipment and appliances.

A.1.1 Drying oven: The temperature can be controlled within the range of 60 °C

± 2 °C.

A.1.2 Balance: The maximum weighing is 1000 g. The sensitivity is 10 mg.

A.1.3 Dryer.

A.2 Specimen

Take 14 pieces of natural stone sample of 100 mm x 100 mm x 20 mm (it is

recommended to use the G3503 natural granite).

A.3 Test procedures

A.3.1 Prepare the protector according to the protector’s instruction manual or

the requirements of the entrusting organization.

A.3.2 Use 0.25 mm silicon carbide sand to grind the six sides of the specimen

smoothly. Use clean water to rinse it. Place it in a drying oven at 60 °C ± 2 °C

to dry it for 48 h. Take it out. Place it in a desiccator to cool it to room temperature.

Store 5 of them in a desiccator as control samples. Take the other 9 of them as

test samples.

A.3.3 Take 9 test samples. Use a brush which is fully coated with protector to

apply uniform coating for the six surfaces of the test sample. Flatly place it in a

porcelain plate which is paved with glass rod at the bottom. Dry it naturally at

room temperature for 1 h. Place the surface of the stone in contact with the

glass rod upwards. Continue to dry it at room temperature for 1 h. Follow the

procedures above to apply another course of coating. Let it be naturally dried

at room temperature which has a humidity of not more than 60% for 48 h.

A.3.4 Make the control sample and test sample be subjected to the water

absorption rate test and calculation according to the requirements of 4.1.1,

4.1.2, 5.2 of GB/T 9966.3-2001. The drying temperature is 60 °C ± 2 °C.

Respectively calculate the average value of water absorption rate of the control

sample and the test sample.

A.4 Calculation of results

Appendix B

(Normative)

Test method of stain resistance

B.1 Vessel

B.1.1 Drying oven: The temperature can be controlled within the range of 60 °C

± 2 °C.

B.1.2 25 mL dropper bottle.

B.1.3 Dryer.

B.2 Contaminant reagent

B.2.1 Edible vegetable oil.

B.2.2 Blue-black ink.

B.3 Specimen

Take 12 pieces of natural stone sample of 100 mm ...

Get QUOTATION in 1-minute: Click JC/T 973-2005

Historical versions: JC/T 973-2005

Preview True-PDF (Reload/Scroll if blank)

JC/T 973-2005: Natural stone protector for building decoration

JC/T 973-2005

BUILDING MATERIAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 91.100.20

Q 21

Registration number: 15245-2005

Natural stone protector for building decoration

ISSUED ON: FEBRUARY 14, 2005

IMPLEMENTED ON: JULY 01, 2005

Issued by: National Development and Reform Commission of PRC

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Product classification and naming marks ... 5

5 Technical requirements ... 7

6 Test methods ... 8

7 Inspection rules ... 9

8 Marking, packaging, storage, transportation ... 10

9 Safety coating and protection ... 10

Appendix A (Normative) Test method of waterproofness ... 12

Appendix B (Normative) Test method of stain resistance ... 14

Appendix C (Normative) Test method for reduction rate of cement’s bond

strength ... 16

Appendix D (Normative) Test method of acid resistance ... 19

Appendix E (Normative) Test method of alkali resistance ... 21

Appendix F (Normative) Test method of UV-aging resistance ... 23

Natural stone protector for building decoration

1 Scope

This standard specifies the terms and definitions, classification and naming

marks, technical requirements, test methods, inspection rules, marking,

packaging, storage and transportation, safe coating and protection of natural

stone protectors.

This standard applies to the natural stone protector for building decoration.

2 Normative references

The provisions in following documents become the provisions of this standard

through reference in this standard. For the dated references, the subsequent

amendments (excluding corrections) or revisions do not apply to this standard;

however, parties who reach an agreement based on this standard are

encouraged to study if the latest versions of these documents are applicable.

For undated references, the latest edition of the referenced document applies.

GB 3186 Sampling paint products

GB/T 9966.3-2001 Test methods for natural facing stones - Part 3: Test

methods for bulk density, true density, true porosity and water absorption

GB/T 13890 Terms for natural facing stone

GB 18581 Indoor decorating and refurbishing materials - Limit of harmful

substances of solvent based coatings for woodenware

GB 18582 Indoor decorating and refurbishing materials - Limit of harmful

substances of interior architectural coatings

JC/T 902 Silicone hydrophobic agent for construction surfaces

3 Terms and definitions

The terms and definitions as established by GB/T 13890 as well as the following

terms and definitions apply to this standard.

3.1

6 Test methods

6.1 pH

Use a precision pH test paper to make determination.

6.2 Stability

Take two sets of 10 mL of sample. Respectively put it into two test tubes. Place

them on opposite sides of the electric centrifuge. Rotate it at 3000 r/min for 5

min. Take out the test tube, to see if there is delamination, floating oil,

precipitation.

6.3 Waterproofness

See Appendix A.

6.4 Stain resistance

See Appendix B.

6.5 Reduction rate of cement’s bond strength

See Appendix C.

6.6 Acid resistance

See Appendix D.

6.7 Alkali resistance

See Appendix E.

6.8 UV-aging resistance

See Appendix F.

6.9 Impermeability

Flatly place the five 150 mm x 150 mm x 20 mm stones, whose bottom and four

sides are protected according to A.3.1 to A.3.3 in Appendix A, in the top of a

container (wide-edge box which has a volume of 160 mm x 160 mm x 25 mm,

lined with 240 mm x 240 mm plastic film) which contains cement mortar (cement

and sand are prepared in the proportion of 1:2.5 by the use of water). Make its

bottom face downwards. Allow the cement mortar to reach about 1/2 of the

stone’s thickness. Use plastic tape to seal the exposed part at the sides of stone

and the periphery of the container. Let it be standing for seven days. At the

interval of one day, observe the color change and the presence of water mark

7.2 Type inspection

7.2.1 Inspection items

All the items in clause 5 of technical requirements.

7.2.2 Inspection conditions

In one of the following cases, carry out type inspection:

a) When the new product is initially type-finalized;

b) When there is a major change in product’s formulation, process, raw

materials;

c) When the production is restored after suspension for more than half a year;

d) Once a year during normal production;

e) When the national quality supervision agency proposes to carry out type

inspection requirements.

7.2.3 2 Group-batch

Same as exit-factory inspection.

7.2.4 Sampling

Same as exit-factory inspection.

7.2.5 Determination

If one of the test results does not meet the requirements of clause 5, the batch

of products is judged to be unqualified.

8 Marking, packaging, storage, transportation

The marking, packaging, storage, transportation of the product shall be in

accordance with the provisions of clause 7 of JC/T 902.

9 Safety coating and protection

9.1 When applying coating, try to choose the brushing method and carry it

outdoors. If it is indoors, it must be well ventilated.

9.2 When applying coating, the construction personnel shall wear the

necessary protective equipment.

Appendix A

(Normative)

Test method of waterproofness

A.1 Equipment and appliances.

A.1.1 Drying oven: The temperature can be controlled within the range of 60 °C

± 2 °C.

A.1.2 Balance: The maximum weighing is 1000 g. The sensitivity is 10 mg.

A.1.3 Dryer.

A.2 Specimen

Take 14 pieces of natural stone sample of 100 mm x 100 mm x 20 mm (it is

recommended to use the G3503 natural granite).

A.3 Test procedures

A.3.1 Prepare the protector according to the protector’s instruction manual or

the requirements of the entrusting organization.

A.3.2 Use 0.25 mm silicon carbide sand to grind the six sides of the specimen

smoothly. Use clean water to rinse it. Place it in a drying oven at 60 °C ± 2 °C

to dry it for 48 h. Take it out. Place it in a desiccator to cool it to room temperature.

Store 5 of them in a desiccator as control samples. Take the other 9 of them as

test samples.

A.3.3 Take 9 test samples. Use a brush which is fully coated with protector to

apply uniform coating for the six surfaces of the test sample. Flatly place it in a

porcelain plate which is paved with glass rod at the bottom. Dry it naturally at

room temperature for 1 h. Place the surface of the stone in contact with the

glass rod upwards. Continue to dry it at room temperature for 1 h. Follow the

procedures above to apply another course of coating. Let it be naturally dried

at room temperature which has a humidity of not more than 60% for 48 h.

A.3.4 Make the control sample and test sample be subjected to the water

absorption rate test and calculation according to the requirements of 4.1.1,

4.1.2, 5.2 of GB/T 9966.3-2001. The drying temperature is 60 °C ± 2 °C.

Respectively calculate the average value of water absorption rate of the control

sample and the test sample.

A.4 Calculation of results

Appendix B

(Normative)

Test method of stain resistance

B.1 Vessel

B.1.1 Drying oven: The temperature can be controlled within the range of 60 °C

± 2 °C.

B.1.2 25 mL dropper bottle.

B.1.3 Dryer.

B.2 Contaminant reagent

B.2.1 Edible vegetable oil.

B.2.2 Blue-black ink.

B.3 Specimen

Take 12 pieces of natural stone sample of 100 mm ...

Share