1

/

of

9

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

JC/T 977-2005 English PDF (JC/T977-2005)

JC/T 977-2005 English PDF (JC/T977-2005)

Regular price

$160.00

Regular price

Sale price

$160.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

JC/T 977-2005: Chemically strengthened glass

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click JC/T 977-2005 (Self-service in 1-minute)

Historical versions (Master-website): JC/T 977-2005

Preview True-PDF (Reload/Scroll-down if blank)

JC/T 977-2005

JC

BUILDING MATERIALS INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 81.040.20

Q 33

Record No.. 15249-2005

Chemically strengthened glass

ISSUED ON. FEBRUARY 14, 2005

IMPLEMENTED ON. JULY 1, 2005

Issued by. National Development and Reform Commission

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Classification and marks... 5

5 Technical requirements ... 5

6 Test methods ... 11

7 Inspection rules ... 15

8 Package, marks, transport and storage ... 17

Appendix A ... 18

Appendix B ... 21

Foreword

This Standard was modified on the basis of European standard EN 12337-

1.2000 Glass in Building - Chemically Strengthened Soda Lime Silicate Glass

- Part 1. Definition and Description.

Compared with EN 12337-1.2000, the main technical differences are as follows.

- Deleted measurement method for squareness of planar rectangular

products; added requirements for diagonal difference;

- Added requirements and measurement methods for surface stress and

compressive stress layer depth by referring to ASTM C1422-99 Standard

Specification for Chemically Strengthened Flat Glass.

Appendix A of this Standard is normative. Appendix B is informative.

This Standard was proposed by China Building Materials Industry Association.

This Standard shall be under the jurisdiction of National Technical Committee

on Building Glass of Standardization Administration of China.

Main drafting organization of this Standard. Glass Science Institute of China

Building Materials Academy.

Drafting organizations of this Standard. China Southern Glass Technology

Holdings (Group) Co., Ltd., Beijing Gelin Jingfeng Fireproof Glass Co., Ltd..

Main drafters of this Standard. Yang Jianjun, Wang Rui, Gong Shuyi, Zhang

Baojun, Xiong Wei, Song Li, Shi Xinyong, Mo Jiao, Wu Huiting, Hu Yue.

This Standard was issued for the first time.

Chemically strengthened glass

1 Scope

This Standard specifies the term and definition, classification and marks,

technical requirements, test methods, inspection rules, package, marks,

transport and storage of chemically strengthened glass.

This Standard is applicable to flat chemically strengthened glass.

2 Normative references

The following standards contain the provisions which, through reference in this

Standard, constitute the provisions of this Standard. For dated references,

subsequent amendments (excluding corrections) or revisions do not apply to

this Standard. However, the parties who enter into agreement based on this

Standard are encouraged to investigate whether the latest versions of these

documents are applicable. For undated reference documents, the latest

versions apply to this Standard.

GB/T 1216 Micrometers

GB/T 5137.1-2002 Test Methods of Safety Glazing Materials Used on Road

Vehicle

GB 11614-1999 Float glass

GB/T 18144 Test method for measurement of stress in glass

JB/T 8788 Feeler gauges

3 Terms and definitions

The following terms and definitions apply to this document.

Chemically strengthened glass

Glass of which alkali metal ions of glass surface are replaced by other alkali

metal ions in molten salt, so as to improve mechanical strength.

Stain trace,

smog

There shall be no obvious stain trace, smog on the surface of chemically

tempered glass.

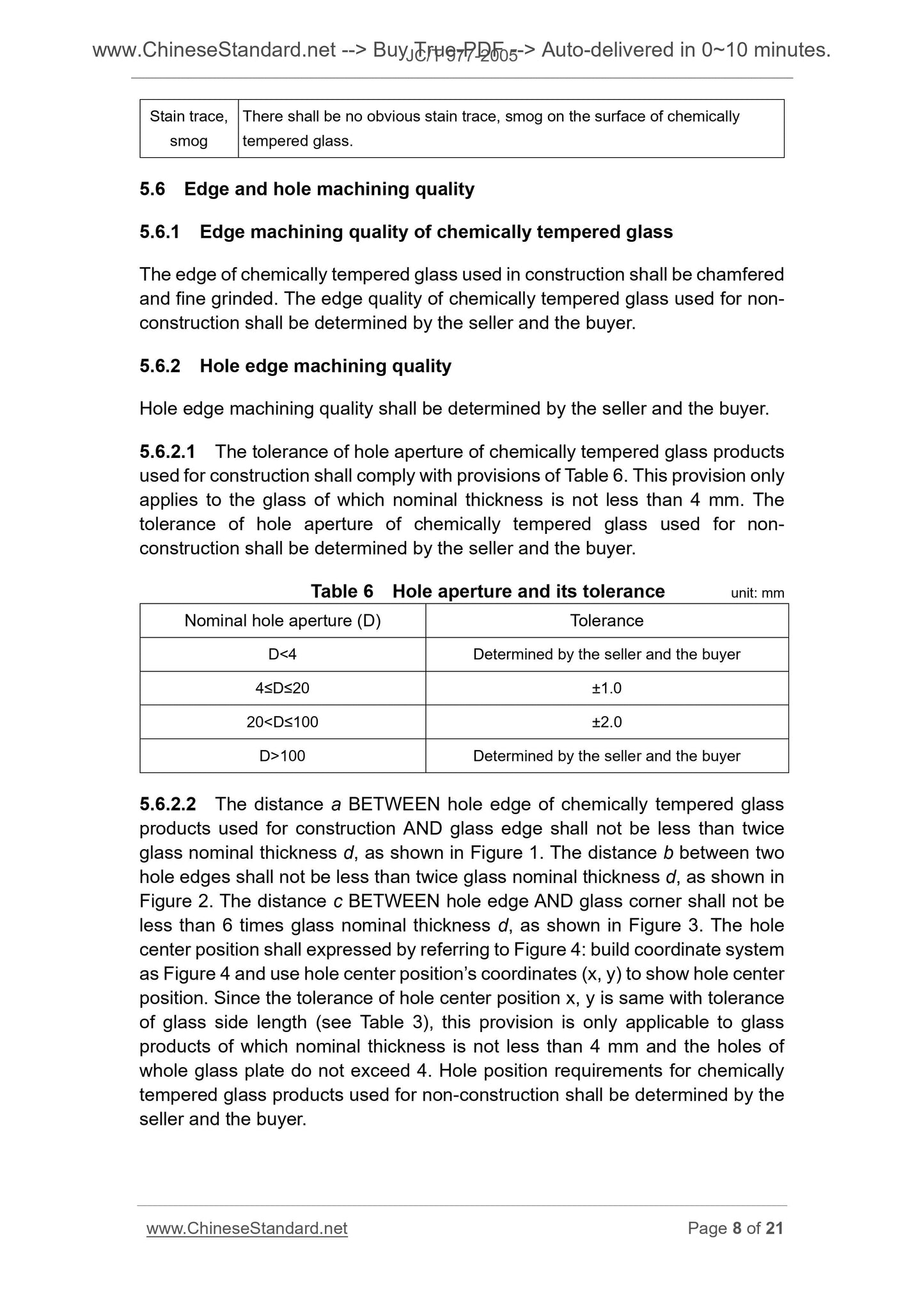

5.6 Edge and hole machining quality

5.6.1 Edge machining quality of chemically tempered glass

The edge of chemically tempered glass used in construction shall be chamfered

and fine grinded. The edge quality of chemically tempered glass used for non-

construction shall be determined by the seller and the buyer.

5.6.2 Hole edge machining quality

Hole edge machining quality shall be determined by the seller and the buyer.

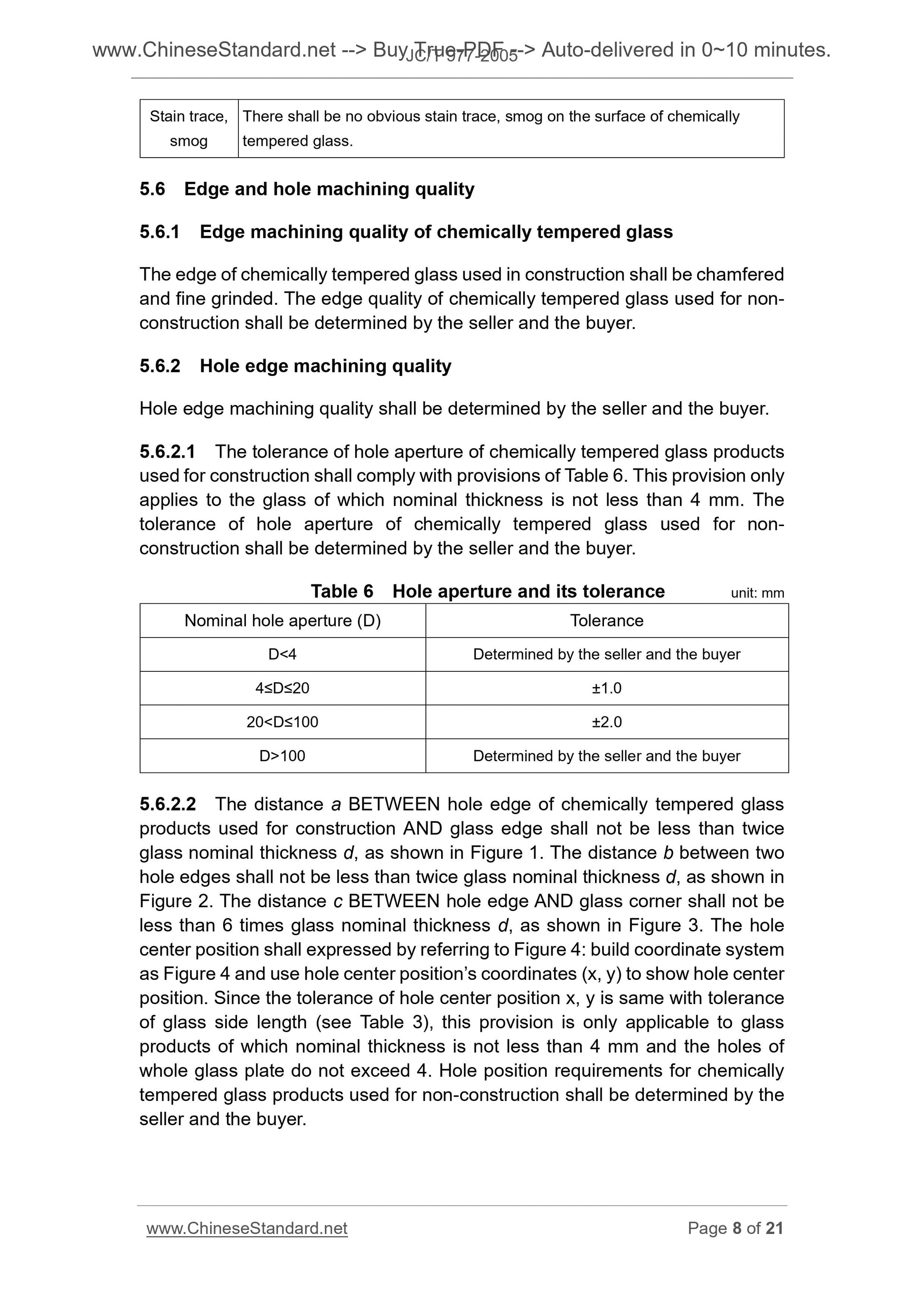

5.6.2.1 The tolerance of hole aperture of chemically tempered glass products

used for construction shall comply with provisions of Table 6. This provision only

applies to the glass of which nominal thickness is not less than 4 mm. The

tolerance of hole aperture of chemically tempered glass used for non-

construction shall be determined by the seller and the buyer.

Table 6 Hole aperture and its tolerance unit. mm

Nominal hole aperture (D) Tolerance

D< 4 Determined by the seller and the buyer

4≤D≤20 ±1.0

20< D≤100 ±2.0

D>100 Determined by the seller and the buyer

5.6.2.2 The distance a BETWEEN hole edge of chemically tempered glass

products used for construction AND glass edge shall not be less than twice

glass nominal thickness d, as shown in Figure 1. The distance b between two

hole edges shall not be less than twice glass nominal thickness d, as shown in

Figure 2. The distance c BETWEEN hole edge AND glass corner shall not be

less than 6 times glass nominal thickness d, as shown in Figure 3. The hole

center position shall expressed by referring to Figure 4. build coordinate system

as Figure 4 and use hole center position’s coordinates (x, y) to show hole center

position. Since the tolerance of hole center position x, y is same with tolerance

of glass side length (see Table 3), this provision is only applicable to glass

products of which nominal thickness is not less than 4 mm and the holes of

whole glass plate do not exceed 4. Hole position requirements for chemically

tempered glass products used for non-construction shall be determined by the

seller and the buyer.

Category B 25< d≤50

Category C d>50

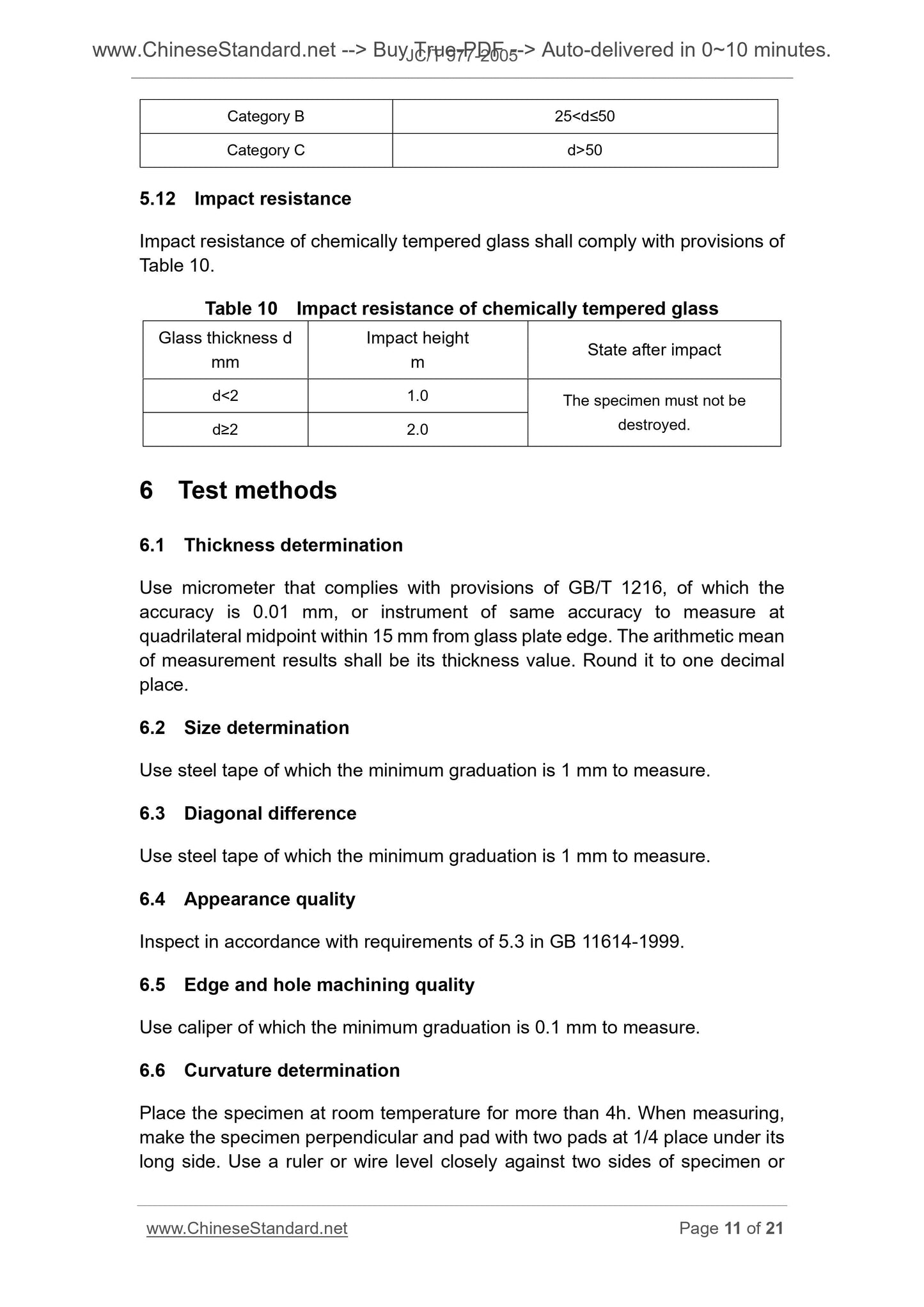

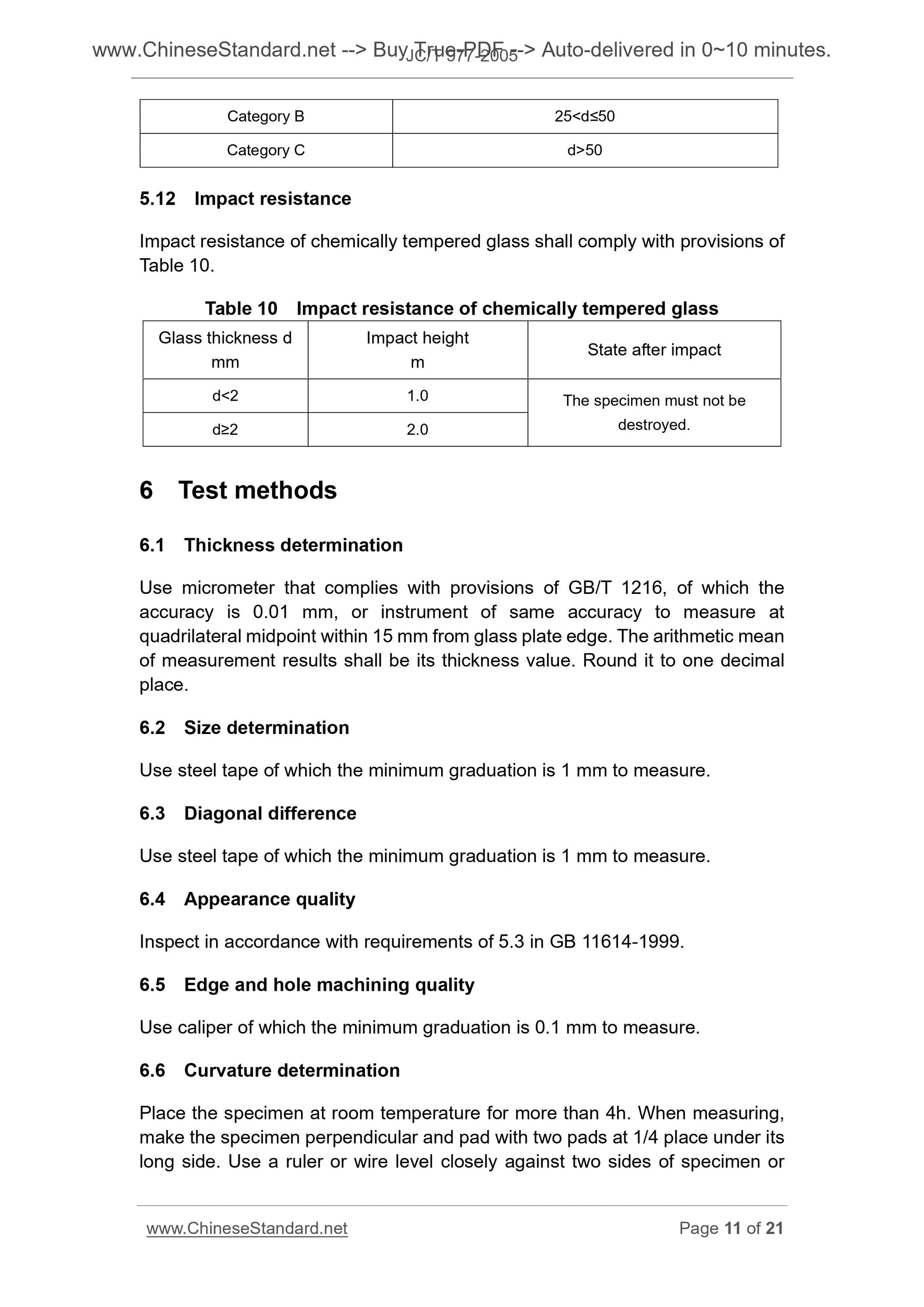

5.12 Impact resistance

Impact resistance of chemically tempered glass shall comply with provisions of

Table 10.

Table 10 Impact resistance of chemically tempered glass

Glass thickness d

mm

Impact height

m State after impact

d< 2 1.0 The specimen must not be

destroyed. d≥2 2.0

6 Test methods

6.1 Thickness determination

Use micrometer that complies with provisions of GB/T 1216, of which the

accuracy is 0.01 mm, or instrument of same accuracy to measure at

quadrilateral midpoint within 15 mm from glass plate edge. The arithmetic mean

of measurement results shall be its thickness value. Round it to one decimal

place.

6.2 Size determination

Use steel tape of which the minimum graduation is 1 mm to measure.

6.3 Diagonal difference

Use steel tape of which the minimum graduation is 1 mm to measure.

6.4 Appearance quality

Inspect in accordance with requirements of 5.3 in GB 11614-1999.

6.5 Edge and hole machining quality

Use caliper of which the minimum graduation is 0.1 mm to measure.

6.6 Curvature determination

Place the specimen at room temperature for more than 4h. When measuring,

make the specimen perpendicular and pad with two pads at 1/4 place under its

long side. Use a ruler or wire level closely against two sides of specimen or

stress.

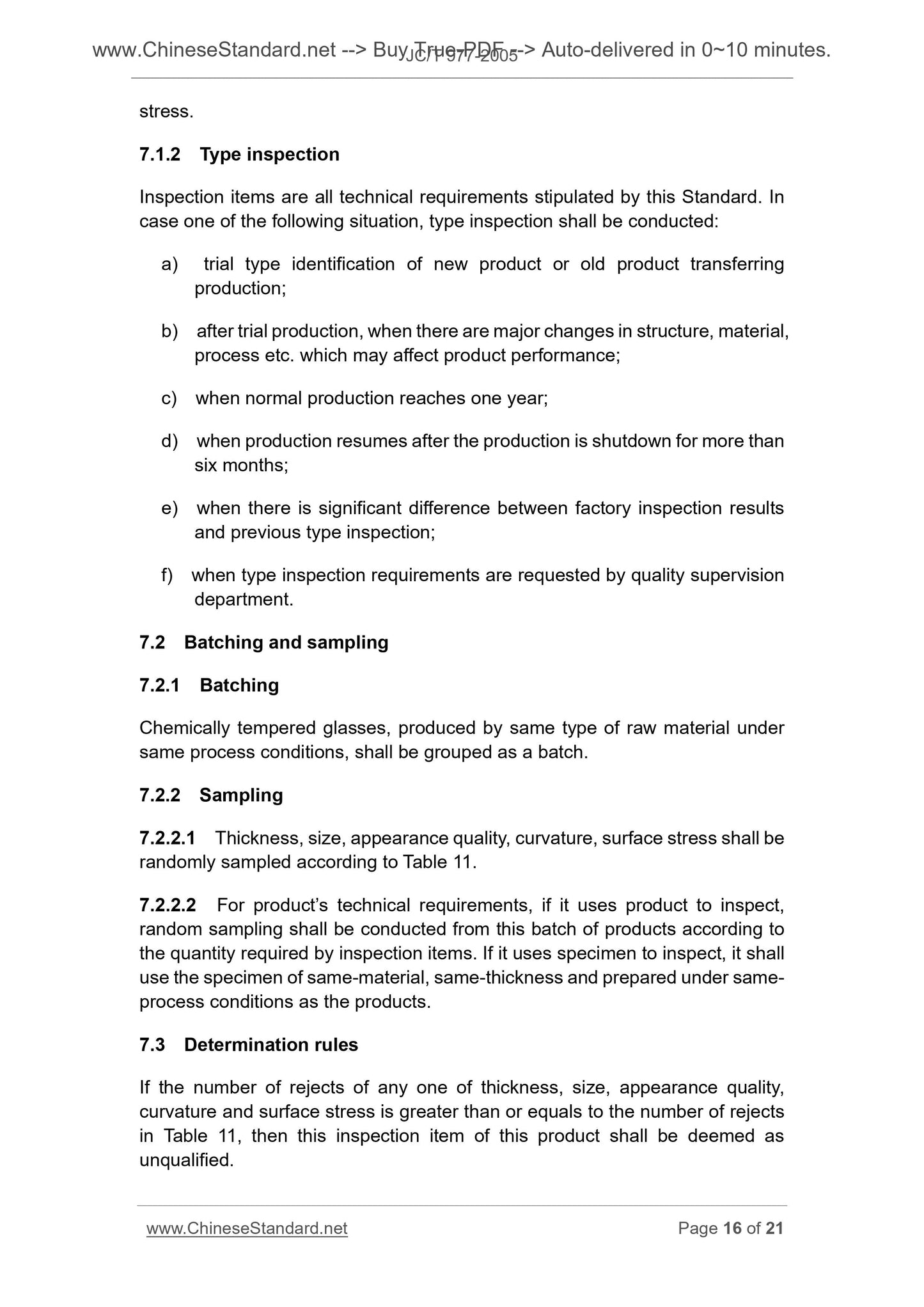

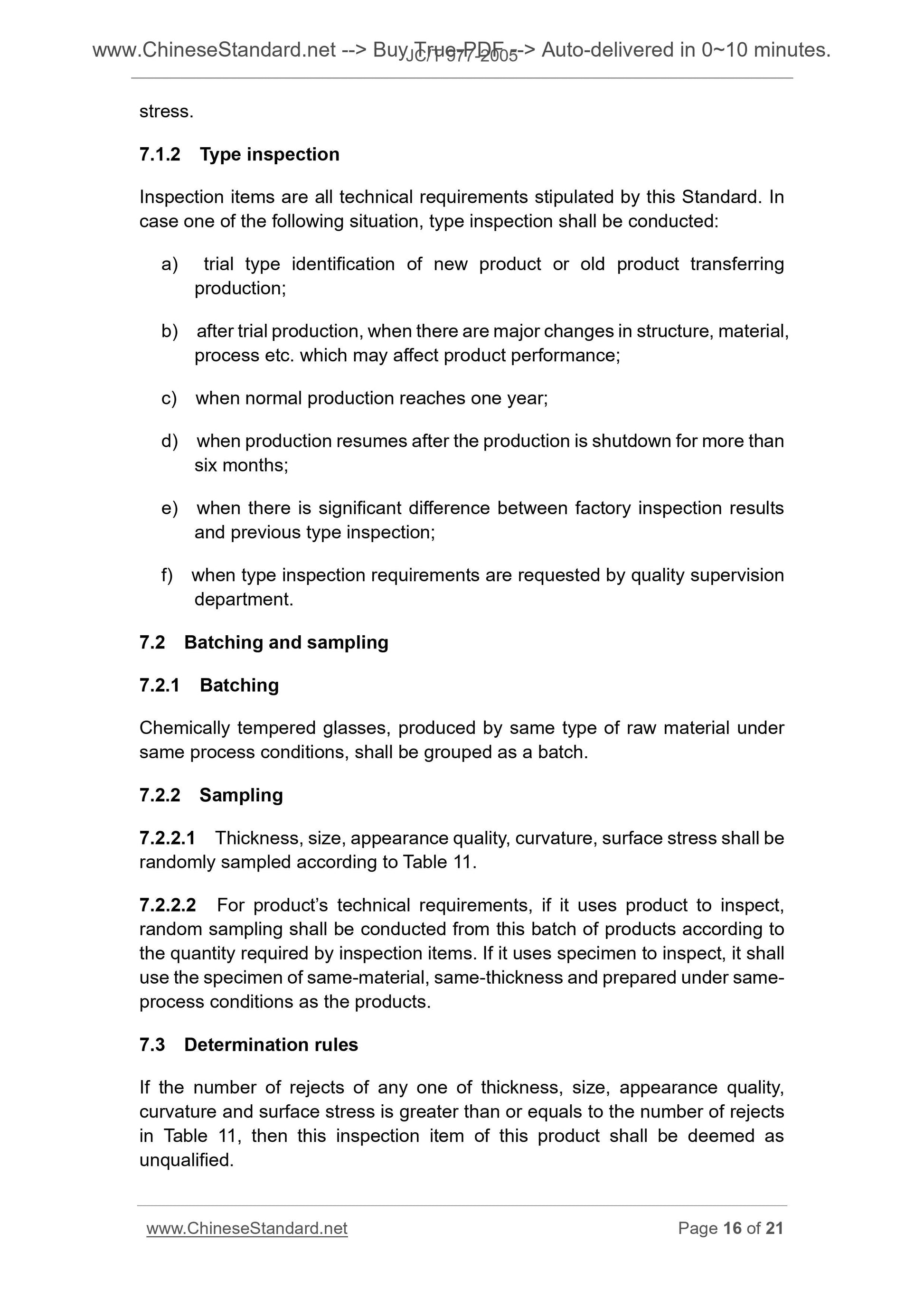

7.1.2 Type inspection

Inspection items are all technical requirements stipulated by this Standard. In

case one of the following situation, type inspection shall be conducted.

a) trial type identification of new product or old product transferring

production;

b) after trial production, when there are major changes in structure, material,

process etc. which may affect product performance;

c) when normal production reaches one year;

d) when production resumes after the production is shutdown for more than

six months;

e) when there is significant difference between factory inspection results

and previous type inspection;

f) when type inspection requirements are requested by quality supervision

department.

7.2 Batching and sampling

7.2.1 Batching

Chemically tempered glasses, produced by same type of raw material under

same process conditions, shall be grouped as a batch.

7.2.2 Sampling

7.2.2.1 Thickness, size, appearance quality, curvature, surface stress shall be

randomly sampled according to Table 11.

7.2.2.2 For product’s technical requirements, if it uses product to inspect,

random sampling shall be conducted from this batch of products according to

the quantity required by inspection items. If it uses specimen to inspect, it shall

use the specimen of same-material, same-thickness and prepared under same-

process conditions as the products.

7.3 Determination rules

If the number of rejects of any one of thickness, size, appearance quality,

curvature and surface stress is greater than or equals to the number of rejects

in Table 11, then this inspection item of this product shall be deemed as

unqualified.

Appendix A

(Normative)

Bending strength test method

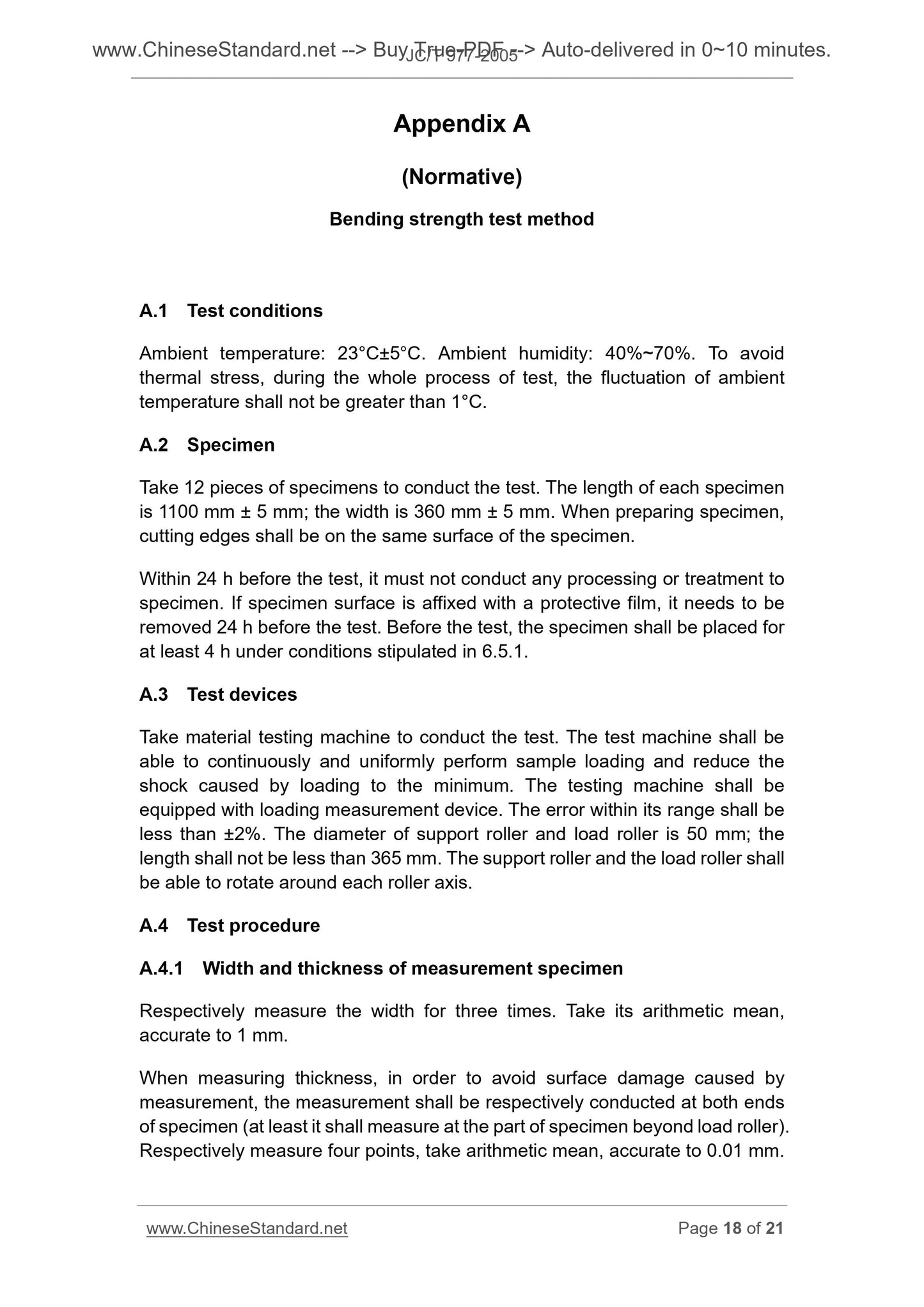

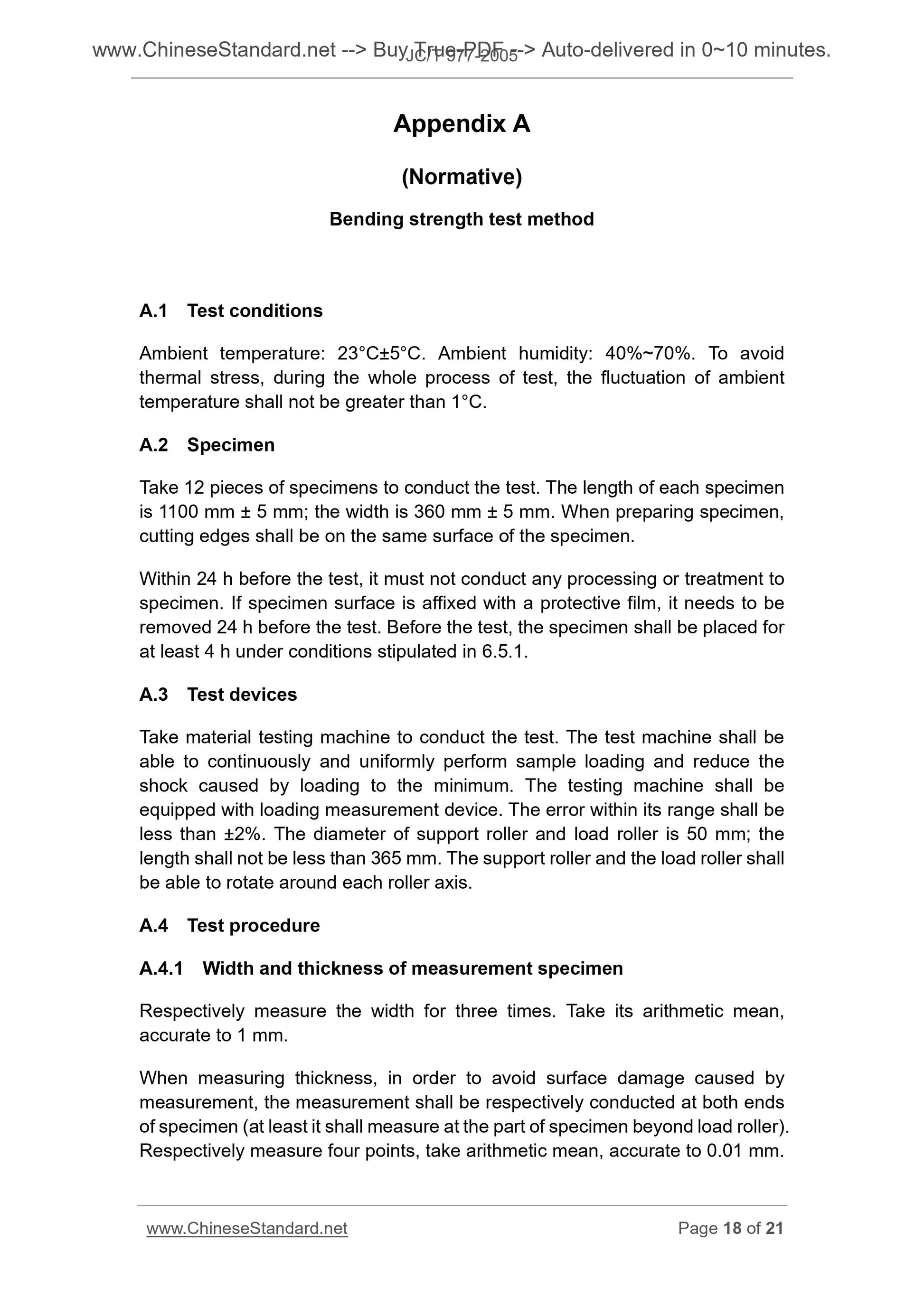

A.1 Test conditions

Ambient temperature. 23°C±5°C. Ambient humidity. 40%~70%. To avoid

thermal stress, during the whole process of test, the fluctuation of ambient

temperature shall not be greater than 1°C.

A.2 Specimen

Take 12 pieces of specimens to conduct the test. The length of each specimen

is 1100 mm ± 5 mm; the width is 360 mm ± 5 mm. When preparing specimen,

cutting edges shall be on the same surface of the specimen.

Within...

JC/T 977-2005

JC

BUILDING MATERIALS INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 81.040.20

Q 33

Record No.. 15249-2005

Chemically strengthened glass

ISSUED ON. FEBRUARY 14, 2005

IMPLEMENTED ON. JULY 1, 2005

Issued by. National Development and Reform Commission

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Classification and marks... 5

5 Technical requirements ... 5

6 Test methods ... 11

7 Inspection rules ... 15

8 Package, marks, transport and storage ... 17

Appendix A ... 18

Appendix B ... 21

Foreword

This Standard was modified on the basis of European standard EN 12337-

1.2000 Glass in Building - Chemically Strengthened Soda Lime Silicate Glass

- Part 1. Definition and Description.

Compared with EN 12337-1.2000, the main technical differences are as follows.

- Deleted measurement method for squareness of planar rectangular

products; added requirements for diagonal difference;

- Added requirements and measurement methods for surface stress and

compressive stress layer depth by referring to ASTM C1422-99 Standard

Specification for Chemically Strengthened Flat Glass.

Appendix A of this Standard is normative. Appendix B is informative.

This Standard was proposed by China Building Materials Industry Association.

This Standard shall be under the jurisdiction of National Technical Committee

on Building Glass of Standardization Administration of China.

Main drafting organization of this Standard. Glass Science Institute of China

Building Materials Academy.

Drafting organizations of this Standard. China Southern Glass Technology

Holdings (Group) Co., Ltd., Beijing Gelin Jingfeng Fireproof Glass Co., Ltd..

Main drafters of this Standard. Yang Jianjun, Wang Rui, Gong Shuyi, Zhang

Baojun, Xiong Wei, Song Li, Shi Xinyong, Mo Jiao, Wu Huiting, Hu Yue.

This Standard was issued for the first time.

Chemically strengthened glass

1 Scope

This Standard specifies the term and definition, classification and marks,

technical requirements, test methods, inspection rules, package, marks,

transport and storage of chemically strengthened glass.

This Standard is applicable to flat chemically strengthened glass.

2 Normative references

The following standards contain the provisions which, through reference in this

Standard, constitute the provisions of this Standard. For dated references,

subsequent amendments (excluding corrections) or revisions do not apply to

this Standard. However, the parties who enter into agreement based on this

Standard are encouraged to investigate whether the latest versions of these

documents are applicable. For undated reference documents, the latest

versions apply to this Standard.

GB/T 1216 Micrometers

GB/T 5137.1-2002 Test Methods of Safety Glazing Materials Used on Road

Vehicle

GB 11614-1999 Float glass

GB/T 18144 Test method for measurement of stress in glass

JB/T 8788 Feeler gauges

3 Terms and definitions

The following terms and definitions apply to this document.

Chemically strengthened glass

Glass of which alkali metal ions of glass surface are replaced by other alkali

metal ions in molten salt, so as to improve mechanical strength.

Stain trace,

smog

There shall be no obvious stain trace, smog on the surface of chemically

tempered glass.

5.6 Edge and hole machining quality

5.6.1 Edge machining quality of chemically tempered glass

The edge of chemically tempered glass used in construction shall be chamfered

and fine grinded. The edge quality of chemically tempered glass used for non-

construction shall be determined by the seller and the buyer.

5.6.2 Hole edge machining quality

Hole edge machining quality shall be determined by the seller and the buyer.

5.6.2.1 The tolerance of hole aperture of chemically tempered glass products

used for construction shall comply with provisions of Table 6. This provision only

applies to the glass of which nominal thickness is not less than 4 mm. The

tolerance of hole aperture of chemically tempered glass used for non-

construction shall be determined by the seller and the buyer.

Table 6 Hole aperture and its tolerance unit. mm

Nominal hole aperture (D) Tolerance

D< 4 Determined by the seller and the buyer

4≤D≤20 ±1.0

20< D≤100 ±2.0

D>100 Determined by the seller and the buyer

5.6.2.2 The distance a BETWEEN hole edge of chemically tempered glass

products used for construction AND glass edge shall not be less than twice

glass nominal thickness d, as shown in Figure 1. The distance b between two

hole edges shall not be less than twice glass nominal thickness d, as shown in

Figure 2. The distance c BETWEEN hole edge AND glass corner shall not be

less than 6 times glass nominal thickness d, as shown in Figure 3. The hole

center position shall expressed by referring to Figure 4. build coordinate system

as Figure 4 and use hole center position’s coordinates (x, y) to show hole center ...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click JC/T 977-2005 (Self-service in 1-minute)

Historical versions (Master-website): JC/T 977-2005

Preview True-PDF (Reload/Scroll-down if blank)

JC/T 977-2005

JC

BUILDING MATERIALS INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 81.040.20

Q 33

Record No.. 15249-2005

Chemically strengthened glass

ISSUED ON. FEBRUARY 14, 2005

IMPLEMENTED ON. JULY 1, 2005

Issued by. National Development and Reform Commission

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Classification and marks... 5

5 Technical requirements ... 5

6 Test methods ... 11

7 Inspection rules ... 15

8 Package, marks, transport and storage ... 17

Appendix A ... 18

Appendix B ... 21

Foreword

This Standard was modified on the basis of European standard EN 12337-

1.2000 Glass in Building - Chemically Strengthened Soda Lime Silicate Glass

- Part 1. Definition and Description.

Compared with EN 12337-1.2000, the main technical differences are as follows.

- Deleted measurement method for squareness of planar rectangular

products; added requirements for diagonal difference;

- Added requirements and measurement methods for surface stress and

compressive stress layer depth by referring to ASTM C1422-99 Standard

Specification for Chemically Strengthened Flat Glass.

Appendix A of this Standard is normative. Appendix B is informative.

This Standard was proposed by China Building Materials Industry Association.

This Standard shall be under the jurisdiction of National Technical Committee

on Building Glass of Standardization Administration of China.

Main drafting organization of this Standard. Glass Science Institute of China

Building Materials Academy.

Drafting organizations of this Standard. China Southern Glass Technology

Holdings (Group) Co., Ltd., Beijing Gelin Jingfeng Fireproof Glass Co., Ltd..

Main drafters of this Standard. Yang Jianjun, Wang Rui, Gong Shuyi, Zhang

Baojun, Xiong Wei, Song Li, Shi Xinyong, Mo Jiao, Wu Huiting, Hu Yue.

This Standard was issued for the first time.

Chemically strengthened glass

1 Scope

This Standard specifies the term and definition, classification and marks,

technical requirements, test methods, inspection rules, package, marks,

transport and storage of chemically strengthened glass.

This Standard is applicable to flat chemically strengthened glass.

2 Normative references

The following standards contain the provisions which, through reference in this

Standard, constitute the provisions of this Standard. For dated references,

subsequent amendments (excluding corrections) or revisions do not apply to

this Standard. However, the parties who enter into agreement based on this

Standard are encouraged to investigate whether the latest versions of these

documents are applicable. For undated reference documents, the latest

versions apply to this Standard.

GB/T 1216 Micrometers

GB/T 5137.1-2002 Test Methods of Safety Glazing Materials Used on Road

Vehicle

GB 11614-1999 Float glass

GB/T 18144 Test method for measurement of stress in glass

JB/T 8788 Feeler gauges

3 Terms and definitions

The following terms and definitions apply to this document.

Chemically strengthened glass

Glass of which alkali metal ions of glass surface are replaced by other alkali

metal ions in molten salt, so as to improve mechanical strength.

Stain trace,

smog

There shall be no obvious stain trace, smog on the surface of chemically

tempered glass.

5.6 Edge and hole machining quality

5.6.1 Edge machining quality of chemically tempered glass

The edge of chemically tempered glass used in construction shall be chamfered

and fine grinded. The edge quality of chemically tempered glass used for non-

construction shall be determined by the seller and the buyer.

5.6.2 Hole edge machining quality

Hole edge machining quality shall be determined by the seller and the buyer.

5.6.2.1 The tolerance of hole aperture of chemically tempered glass products

used for construction shall comply with provisions of Table 6. This provision only

applies to the glass of which nominal thickness is not less than 4 mm. The

tolerance of hole aperture of chemically tempered glass used for non-

construction shall be determined by the seller and the buyer.

Table 6 Hole aperture and its tolerance unit. mm

Nominal hole aperture (D) Tolerance

D< 4 Determined by the seller and the buyer

4≤D≤20 ±1.0

20< D≤100 ±2.0

D>100 Determined by the seller and the buyer

5.6.2.2 The distance a BETWEEN hole edge of chemically tempered glass

products used for construction AND glass edge shall not be less than twice

glass nominal thickness d, as shown in Figure 1. The distance b between two

hole edges shall not be less than twice glass nominal thickness d, as shown in

Figure 2. The distance c BETWEEN hole edge AND glass corner shall not be

less than 6 times glass nominal thickness d, as shown in Figure 3. The hole

center position shall expressed by referring to Figure 4. build coordinate system

as Figure 4 and use hole center position’s coordinates (x, y) to show hole center

position. Since the tolerance of hole center position x, y is same with tolerance

of glass side length (see Table 3), this provision is only applicable to glass

products of which nominal thickness is not less than 4 mm and the holes of

whole glass plate do not exceed 4. Hole position requirements for chemically

tempered glass products used for non-construction shall be determined by the

seller and the buyer.

Category B 25< d≤50

Category C d>50

5.12 Impact resistance

Impact resistance of chemically tempered glass shall comply with provisions of

Table 10.

Table 10 Impact resistance of chemically tempered glass

Glass thickness d

mm

Impact height

m State after impact

d< 2 1.0 The specimen must not be

destroyed. d≥2 2.0

6 Test methods

6.1 Thickness determination

Use micrometer that complies with provisions of GB/T 1216, of which the

accuracy is 0.01 mm, or instrument of same accuracy to measure at

quadrilateral midpoint within 15 mm from glass plate edge. The arithmetic mean

of measurement results shall be its thickness value. Round it to one decimal

place.

6.2 Size determination

Use steel tape of which the minimum graduation is 1 mm to measure.

6.3 Diagonal difference

Use steel tape of which the minimum graduation is 1 mm to measure.

6.4 Appearance quality

Inspect in accordance with requirements of 5.3 in GB 11614-1999.

6.5 Edge and hole machining quality

Use caliper of which the minimum graduation is 0.1 mm to measure.

6.6 Curvature determination

Place the specimen at room temperature for more than 4h. When measuring,

make the specimen perpendicular and pad with two pads at 1/4 place under its

long side. Use a ruler or wire level closely against two sides of specimen or

stress.

7.1.2 Type inspection

Inspection items are all technical requirements stipulated by this Standard. In

case one of the following situation, type inspection shall be conducted.

a) trial type identification of new product or old product transferring

production;

b) after trial production, when there are major changes in structure, material,

process etc. which may affect product performance;

c) when normal production reaches one year;

d) when production resumes after the production is shutdown for more than

six months;

e) when there is significant difference between factory inspection results

and previous type inspection;

f) when type inspection requirements are requested by quality supervision

department.

7.2 Batching and sampling

7.2.1 Batching

Chemically tempered glasses, produced by same type of raw material under

same process conditions, shall be grouped as a batch.

7.2.2 Sampling

7.2.2.1 Thickness, size, appearance quality, curvature, surface stress shall be

randomly sampled according to Table 11.

7.2.2.2 For product’s technical requirements, if it uses product to inspect,

random sampling shall be conducted from this batch of products according to

the quantity required by inspection items. If it uses specimen to inspect, it shall

use the specimen of same-material, same-thickness and prepared under same-

process conditions as the products.

7.3 Determination rules

If the number of rejects of any one of thickness, size, appearance quality,

curvature and surface stress is greater than or equals to the number of rejects

in Table 11, then this inspection item of this product shall be deemed as

unqualified.

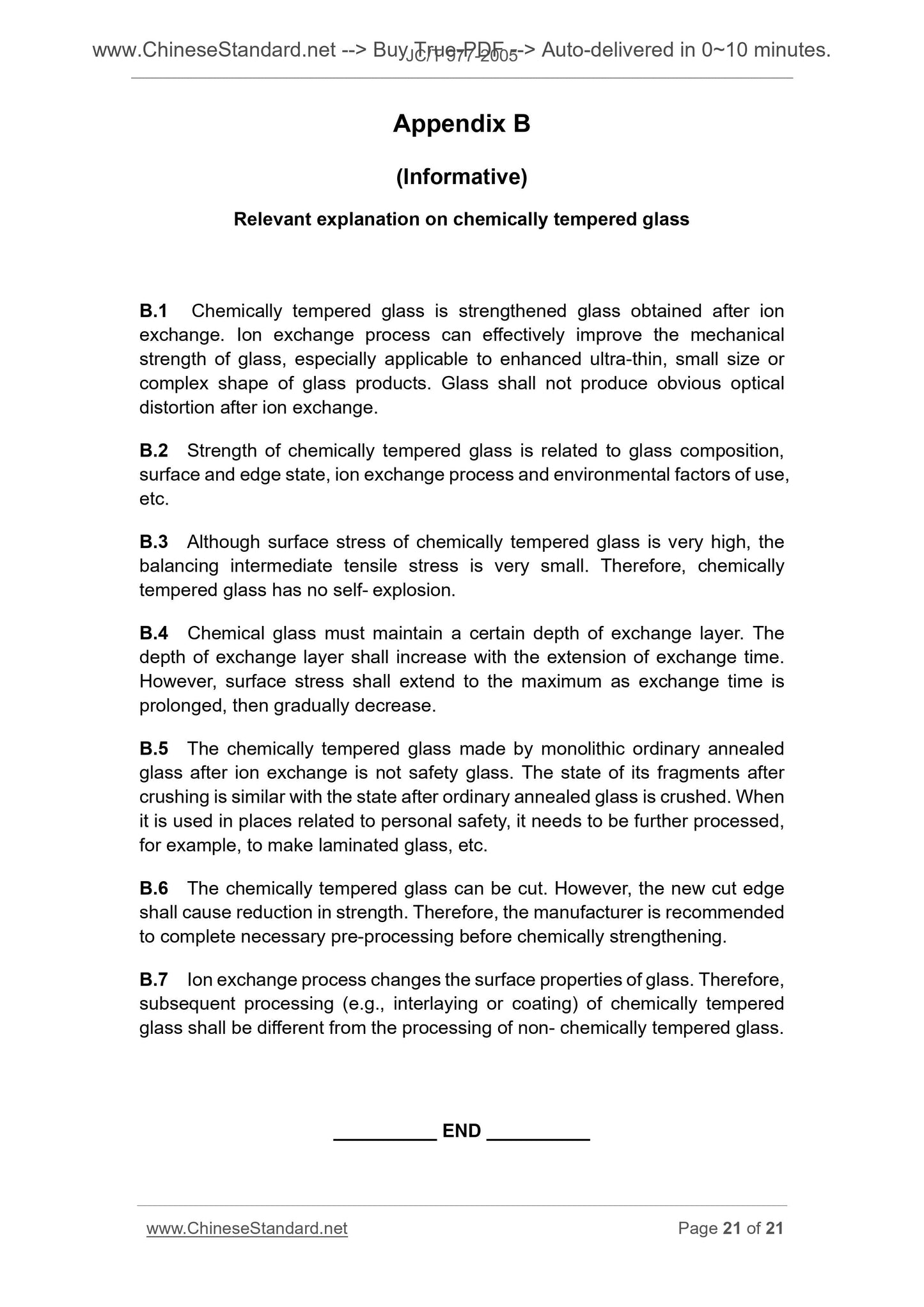

Appendix A

(Normative)

Bending strength test method

A.1 Test conditions

Ambient temperature. 23°C±5°C. Ambient humidity. 40%~70%. To avoid

thermal stress, during the whole process of test, the fluctuation of ambient

temperature shall not be greater than 1°C.

A.2 Specimen

Take 12 pieces of specimens to conduct the test. The length of each specimen

is 1100 mm ± 5 mm; the width is 360 mm ± 5 mm. When preparing specimen,

cutting edges shall be on the same surface of the specimen.

Within...

JC/T 977-2005

JC

BUILDING MATERIALS INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 81.040.20

Q 33

Record No.. 15249-2005

Chemically strengthened glass

ISSUED ON. FEBRUARY 14, 2005

IMPLEMENTED ON. JULY 1, 2005

Issued by. National Development and Reform Commission

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Classification and marks... 5

5 Technical requirements ... 5

6 Test methods ... 11

7 Inspection rules ... 15

8 Package, marks, transport and storage ... 17

Appendix A ... 18

Appendix B ... 21

Foreword

This Standard was modified on the basis of European standard EN 12337-

1.2000 Glass in Building - Chemically Strengthened Soda Lime Silicate Glass

- Part 1. Definition and Description.

Compared with EN 12337-1.2000, the main technical differences are as follows.

- Deleted measurement method for squareness of planar rectangular

products; added requirements for diagonal difference;

- Added requirements and measurement methods for surface stress and

compressive stress layer depth by referring to ASTM C1422-99 Standard

Specification for Chemically Strengthened Flat Glass.

Appendix A of this Standard is normative. Appendix B is informative.

This Standard was proposed by China Building Materials Industry Association.

This Standard shall be under the jurisdiction of National Technical Committee

on Building Glass of Standardization Administration of China.

Main drafting organization of this Standard. Glass Science Institute of China

Building Materials Academy.

Drafting organizations of this Standard. China Southern Glass Technology

Holdings (Group) Co., Ltd., Beijing Gelin Jingfeng Fireproof Glass Co., Ltd..

Main drafters of this Standard. Yang Jianjun, Wang Rui, Gong Shuyi, Zhang

Baojun, Xiong Wei, Song Li, Shi Xinyong, Mo Jiao, Wu Huiting, Hu Yue.

This Standard was issued for the first time.

Chemically strengthened glass

1 Scope

This Standard specifies the term and definition, classification and marks,

technical requirements, test methods, inspection rules, package, marks,

transport and storage of chemically strengthened glass.

This Standard is applicable to flat chemically strengthened glass.

2 Normative references

The following standards contain the provisions which, through reference in this

Standard, constitute the provisions of this Standard. For dated references,

subsequent amendments (excluding corrections) or revisions do not apply to

this Standard. However, the parties who enter into agreement based on this

Standard are encouraged to investigate whether the latest versions of these

documents are applicable. For undated reference documents, the latest

versions apply to this Standard.

GB/T 1216 Micrometers

GB/T 5137.1-2002 Test Methods of Safety Glazing Materials Used on Road

Vehicle

GB 11614-1999 Float glass

GB/T 18144 Test method for measurement of stress in glass

JB/T 8788 Feeler gauges

3 Terms and definitions

The following terms and definitions apply to this document.

Chemically strengthened glass

Glass of which alkali metal ions of glass surface are replaced by other alkali

metal ions in molten salt, so as to improve mechanical strength.

Stain trace,

smog

There shall be no obvious stain trace, smog on the surface of chemically

tempered glass.

5.6 Edge and hole machining quality

5.6.1 Edge machining quality of chemically tempered glass

The edge of chemically tempered glass used in construction shall be chamfered

and fine grinded. The edge quality of chemically tempered glass used for non-

construction shall be determined by the seller and the buyer.

5.6.2 Hole edge machining quality

Hole edge machining quality shall be determined by the seller and the buyer.

5.6.2.1 The tolerance of hole aperture of chemically tempered glass products

used for construction shall comply with provisions of Table 6. This provision only

applies to the glass of which nominal thickness is not less than 4 mm. The

tolerance of hole aperture of chemically tempered glass used for non-

construction shall be determined by the seller and the buyer.

Table 6 Hole aperture and its tolerance unit. mm

Nominal hole aperture (D) Tolerance

D< 4 Determined by the seller and the buyer

4≤D≤20 ±1.0

20< D≤100 ±2.0

D>100 Determined by the seller and the buyer

5.6.2.2 The distance a BETWEEN hole edge of chemically tempered glass

products used for construction AND glass edge shall not be less than twice

glass nominal thickness d, as shown in Figure 1. The distance b between two

hole edges shall not be less than twice glass nominal thickness d, as shown in

Figure 2. The distance c BETWEEN hole edge AND glass corner shall not be

less than 6 times glass nominal thickness d, as shown in Figure 3. The hole

center position shall expressed by referring to Figure 4. build coordinate system

as Figure 4 and use hole center position’s coordinates (x, y) to show hole center ...

Share