1

/

of

8

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

JJG 1149-2022 English PDF

JJG 1149-2022 English PDF

Regular price

$260.00

Regular price

Sale price

$260.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

JJG 1149-2022: Off-board Chargers for Electric Vehicles(for Trial Implementation)

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click JJG 1149-2022 (Self-service in 1-minute)

Historical versions (Master-website): JJG 1149-2022

Preview True-PDF (Reload/Scroll-down if blank)

JJF 1149-2022

JJF

NATIONAL METROLOGICAL VERIFICATION REGULATIONS

OF THE PEOPLE’S REPUBLIC OF CHINA

JJG 1149-2022

Off-board Chargers for Electric Vehicles (for Trial

Implementation)

ISSUED ON: JUNE 28, 2022

IMPLEMENTED ON: DECEMBER 28, 2022

Issued by: State Administration for Market Regulation

Table of Contents

Introduction ... 5

1 Scope ... 6

2 Normative references ... 6

3 Terms ... 6

4 Overview ... 7

5 Metrology performance requirements ... 8

5.1 Operate error ... 8

5.2 Clock time error ... 9

6 General technical requirements ... 9

6.1 Identification ... 9

6.2 Testing interface ... 10

6.3 Constant ... 10

6.4 Minimum power variable ... 10

6.5 Display of charging energy ... 10

7 Measuring instrument control ... 10

7.1 First verification, follow-up verification and in-use inspection ... 10

7.2 Verification conditions ... 10

7.3 Verification items and verification methods ... 11

7.4 Processing of verification results ... 16

7.5 Verification period ... 17

Annex A Format for original record of verification ... 18

Annex B Format for inner page of verification certificate/ verification result notification

(Page 2) ... 21

Annex C Format for inner page of verification certificate/ verification result notification

(Page 3) ... 22

Verification Regulation of Off-board Chargers for Electric

Vehicles (for Trial Implementation)

1 Scope

This Regulation applies to the first verification, follow-up verification and in-use

inspection for off-board chargers for electric vehicles.

The verification of off-board chargers for electric vehicles based on statistical sampling

methods can be carried out in accordance with this Regulation.

2 Normative references

This Regulation refers to the following documents:

JJG 842-2017, Electronic Meters for Measuring Direct-current Electrical Energy

JJF 1139, Principle and method for determination verification period of measuring

instruments

NB/T 33001-2018, Specification for electric vehicle off-board conductive charger

For the dated documents, only the versions with the dates indicated are applicable to

this Regulation; for the undated documents, only the latest version (including all the

amendments) is applicable to this Regulation.

3 Terms

The following terms and definitions apply to this document.

3.1 off-board charger

A special device that is fixedly connected to an AC or DC power source, converts its

electrical energy into DC electrical energy, charges the power battery of an electric

vehicle by means of conduction, and has the functions of measuring, storing, and

providing results to users.

3.2 connection point

A connection point that the off-board charger is connected to the electric vehicle.

NOTE: If the output cable is a fixed part of the off-board charger, this point is defined as the

connector at the end of the cable. Otherwise, the connection point is defined as the cable insertion

point of the off-board charger.

3.3 real load test method

A method of verification using the actual operating load.

3.4 virtual load test method

A method that uses the virtual load provided by the charger verification device to verify.

3.5 constant-current charge

A way that the battery is charged with a controlled constant current when the charging

voltage is within the working range.

3.6 constant voltage charge

A way when the charging current is within the working range, the battery is charged

with a controlled constant voltage.

3.7 operate error

DC energy measurement errors of off-board chargers under working conditions.

3.8 test output

A device that provides pulses corresponding to the DC energy measured by off-board

chargers.

3.9 constant

A numerical value representing the relationship between the electric energy recorded

by the off-board charger and the corresponding test output value.

4 Overview

An off-board chargers for electric vehicles (hereinafter referred to as charger) is a

metrology device that provides DC power for electric vehicles. It is mainly composed

of rectification and chopper control unit, display interface or data transmission interface,

metrology module, connection device for conductive charging and other parts. The

schematic diagram of the charger is shown in Figure 1.

The charger converts AC power into DC power through the rectification and chopper

control unit. The DC power is sent to the electric vehicle through the connection device

for conductive charging to meet the charging demand. The metrology module

completes the measurement of DC electric energy, and outputs the measured quantity

to the display interface or data transmission interface.

not marked, the maximum current value is: rated power/[(Umax+Umin)/2]; the minimum current

value is: 5A.

2 For chargers installed before January 1, 2023, if the accuracy level is not marked, it will be

implemented as level 2.

6.2 Testing interface

The technical indicators of the test output and communication interface of the charger

used for verification shall meet the requirements of relevant standards.

6.3 Constant

The charger shall have a pulse output corresponding to the measured DC energy. It shall

be consistent with the constant marked on the nameplate.

6.4 Minimum power variable

The minimum electric energy variable shall be 0.001kW·h.

6.5 Display of charging energy

The charger shall be able to display the charging energy. The number of digits for

electric energy display shall be no less than 6 digits (including at least 3 decimal places).

For chargers with time-sharing charging function, the resolution of clock time display

is not greater than 1s.

7 Measuring instrument control

7.1 First verification, follow-up verification and in-use inspection

The first verification is for a charger that has not been verified. The follow-up

verification is any verification after the first verification. The repaired charger must be

according to the first verification. In-use inspection is an inspection to find out whether

the verification mark or verification certificate of the charger is valid, and whether the

verified charger has been significantly modified.

7.2 Verification conditions

7.2.1 Ambient conditions for verification

When verifying the charger, the following conditions shall be met:

- Verification conditions and their deviations do not exceed those specified in Table

3.

- There shall be no appreciable shock load. The seal of the charger is complete.

b) Verification operate error

Compare the DC power value measured simultaneously by the verification device

and the charger under test, so as to determine the operate error of the charger

under test.

According to the principle, it can be divided into real load test method and virtual

load test method.

1) Real load test method

Connect the charger calibrator and load composition verification device to the

connection point. Use method I or method II at the selected load point.

Compare the DC power values measured simultaneously by the verification

device and the charger under test, so as to determine the operate error of the

charger under test.

Method I:

When both the charging pile calibrator and the inspected charger are working

continuously, the pulse output by the inspected charger is used to control the

counting of the charging pile calibrator to determine the operate error of the

inspected charger. When using this method, use method Ⅱ to check whether

the charger constant is correct.

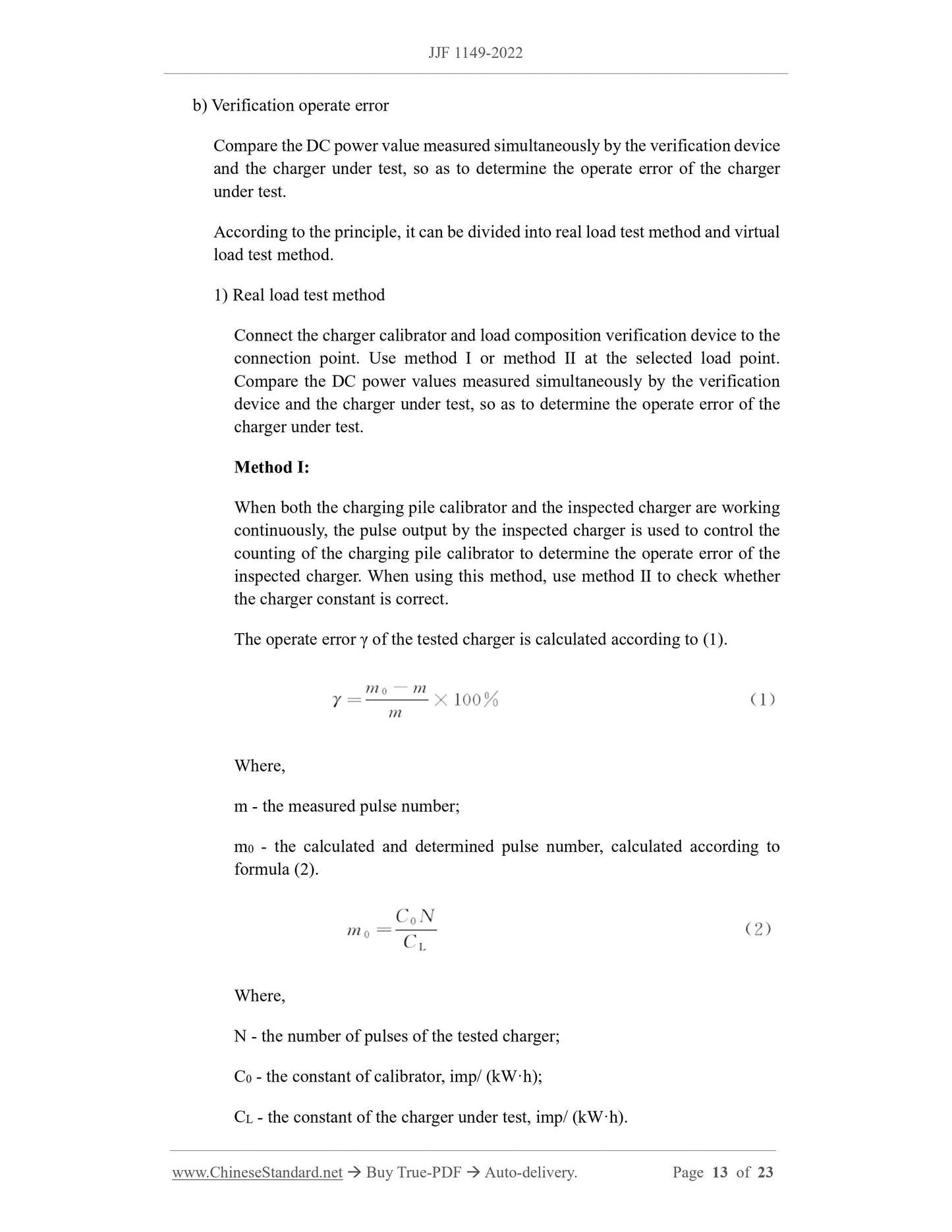

The operate error γ of the tested charger is calculated according to (1).

Where,

m - the measured pulse number;

m0 - the calculated and determined pulse number, calculated according to

formula (2).

Where,

N - the number of pulses of the tested charger;

C0 - the constant of calibrator, imp/ (kW·h);

CL - the constant of the charger under test, imp/ (kW·h).

NOTE: Select the appropriate pulse number N of the tested charger, so that the

quantization error of the calculated pulse number is not greater than 1/10 of the grade

index of the tested charger.

Method II:

When both the charging pile calibrator and the inspected charger are working

continuously, the operate error of the tested charger is determined by using the

output electric energy indication value of the inspected charger and the electric

energy value measured by the charging pile calibrator.

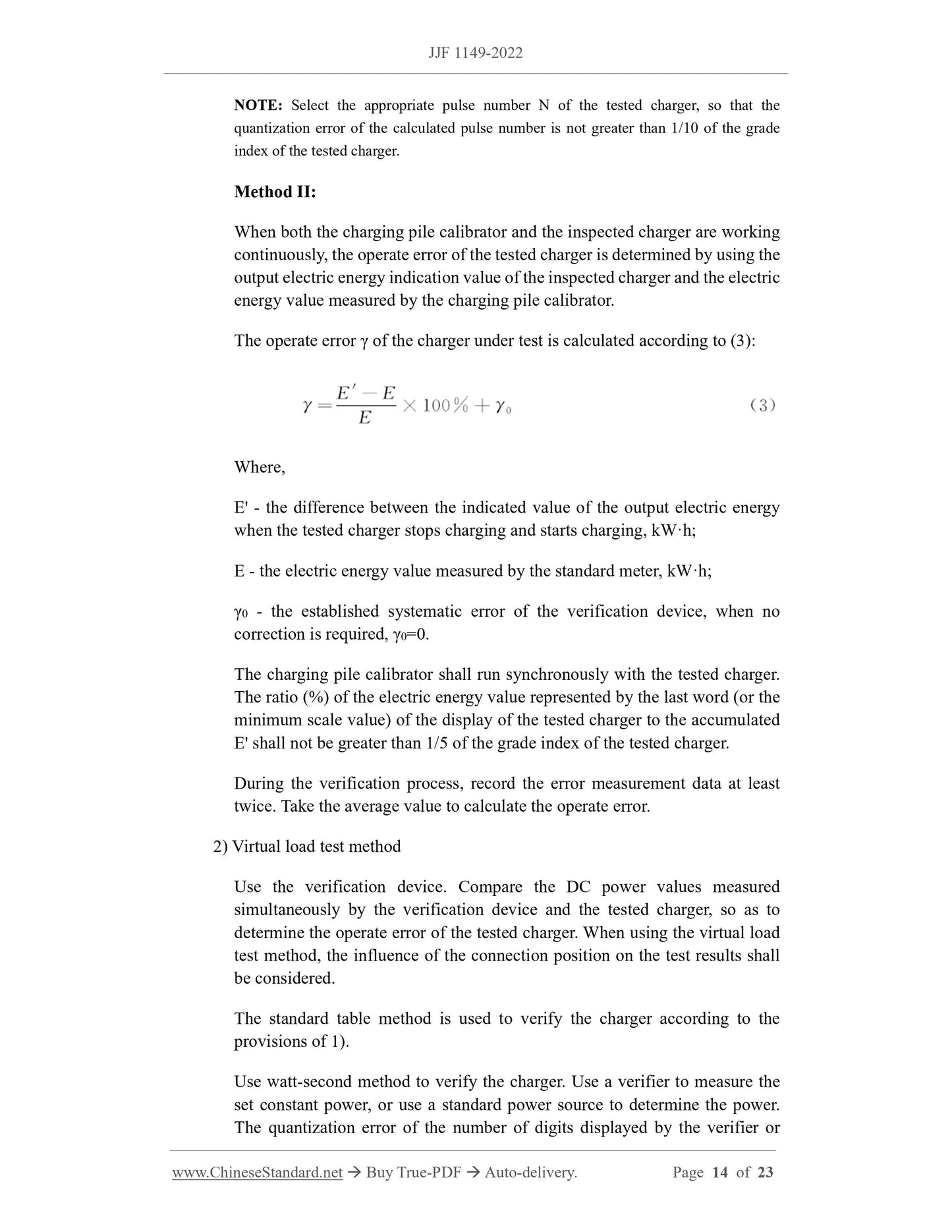

The operate error γ of the charger under test is calculated according to (3):

Where,

E' - the difference between the indicated value of the output electric energy

when the tested charger stops charging and starts charging, kW·h;

E - the electric energy value measured by the standard meter, kW·h;

γ0 - the established systematic error of the verification device, when no

correction is required, γ0=0.

The charging pile calibrator shall run synchronously with the tested charger.

The ratio (%) of the electric energy value represented by the last word (or the

minimum scale value) of the display of the tested charger to the accumulated

E' shall not be greater than 1/5 of the grade index of the tested charger.

During the verification process, record the error measurement data at least

twice. Take the average value to calculate the operate error.

2) Virtual load test method

Use the verification device. Compare the DC power values measured

simultaneously by the verification device and the tested charger, so as to

determine the operate error of the tested charger. When using the virtual load

test method, the influence of the connection position on the test results shall

be considered.

The standard table method is used to verify the charger according to the

provisions of 1).

Use watt-second method to verify the charger. Use a verifier to measure the

set constant power, or use a standard power source to determine the power.

The quantization error of the number of digits displayed by the verifier or

Where,

T - the reference clock display time, ××h××min××s;

T0 - the display time of the charging pile under inspection, ××h××min××s.

The test results shall meet the requirements of 5.2.

7.4 Processing of verification results

7.4.1 Processing of verification results

7.4.1.1 Judging all data shall be subject to the rounded data.

7.4.1.2 The rounding interval of operate error is 1/10 of the accuracy level of the charger.

7.4.1.3 The rounding interval of the clock time error is 1s.

7.4.2 Rounding off method for measurement data

7.4.2.1 Rounding off method when the rounding off interval is 1: The right side of the

reserved digit is for the reserved digit 1. If it is greater than 0.5, add 1 to the reserved

digit. If it is less than 0.5, the reserved digit remains unchanged. If it is equal to 0.5, the

reserved digit remains unchanged when it is an even number. Add 1 when the reserved

digit is odd.

NOTE: "Reserved digit" refers to the number corresponding to the rounding interval. This value is

called a "reserved digit".

7.4.2.2 Rounding method when the rounding interval is n (n≠1): Divide the measured

data by n. Then round off according to the method of 7.4.2.1. After rounding, multiply

by n, which is the final rounding result.

7.4.3 If all items meet the requirements, it is judged as qualified, otherwise it is judged

as unqualified. Chargers that pass the verification will be issued with a verification

certificate (see Annexes B and C for the format of the verification certificate) and a

verification-pass mark.

7.4.4 A verification-pass charger must be sealed at the position of the electric energy

meter or metrology module used inside it. Splitters that are used separately also need to

be sealed.

NOTE: For chargers installed before January 1, 2023, the implementation of shunt seal

requirements will be suspended until December 31, 2027, under special circumstances.

7.4.5 A test result notification will be issued to the unqualified charger (see Annexes B

and C for the format). Cancel the original verification-pass seal or verification-pass

mark.

JJF 1149-2022

JJF

NATIONAL METROLOGICAL VERIFICATION REGULATIONS

OF THE PEOPLE’S REPUBLIC OF CHINA

JJG 1149-2022

Off-board Chargers for Electric Vehicles (for Trial

Implementation)

ISSUED ON: JUNE 28, 2022

IMPLEMENTED ON: DECEMBER 28, 2022

Issued by: State Administration for Market Regulation

Table of Contents

Introduction ... 5

1 Scope ... 6

2 Normative references ... 6

3 Terms ... 6

4 Overview ... 7

5 Metrology performance requirements ... 8

5.1 Operate error ... 8

5.2 Clock time error ... 9

6 General technical requirements ... 9

6.1 Identification ... 9

6.2 Testing interface ... 10

6.3 Constant ... 10

6.4 Minimum power variable ... 10

6.5 Display of charging energy ... 10

7 Measuring instrument control ... 10

7.1 First verification, follow-up verification and in-use inspection ... 10

7.2 Verification conditions ... 10

7.3 Verification items and verification methods ... 11

7.4 Processing of verification results ... 16

7.5 Verification period ... 17

Annex A Format for original record of verification ... 18

Annex B Format for inner page of verification certificate/ verification result notification

(Page 2) ... 21

Annex C Format for inner page of verification certificate/ verification result notification

(Page 3) ... 22

Verification Regulation of Off-board Chargers for Electric

Vehicles (for Trial Implementation)

1 Scope

This Regulation applies to the first verification, follow-up verification and in-use

inspection for off-board chargers for electric vehicles.

The verification of off-board chargers for electric vehicles based on statistical sampling

methods can be carried out in accordance with this Regulation.

2 Normative references

This Regulation refers to the following documents:

JJG 842-2017, Electronic Meters for Measuring Direct-current Electrical Energy

JJF 1139, Principle and method for determination verification period of measuring

instruments

NB/T 33001-2018, Spec...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click JJG 1149-2022 (Self-service in 1-minute)

Historical versions (Master-website): JJG 1149-2022

Preview True-PDF (Reload/Scroll-down if blank)

JJF 1149-2022

JJF

NATIONAL METROLOGICAL VERIFICATION REGULATIONS

OF THE PEOPLE’S REPUBLIC OF CHINA

JJG 1149-2022

Off-board Chargers for Electric Vehicles (for Trial

Implementation)

ISSUED ON: JUNE 28, 2022

IMPLEMENTED ON: DECEMBER 28, 2022

Issued by: State Administration for Market Regulation

Table of Contents

Introduction ... 5

1 Scope ... 6

2 Normative references ... 6

3 Terms ... 6

4 Overview ... 7

5 Metrology performance requirements ... 8

5.1 Operate error ... 8

5.2 Clock time error ... 9

6 General technical requirements ... 9

6.1 Identification ... 9

6.2 Testing interface ... 10

6.3 Constant ... 10

6.4 Minimum power variable ... 10

6.5 Display of charging energy ... 10

7 Measuring instrument control ... 10

7.1 First verification, follow-up verification and in-use inspection ... 10

7.2 Verification conditions ... 10

7.3 Verification items and verification methods ... 11

7.4 Processing of verification results ... 16

7.5 Verification period ... 17

Annex A Format for original record of verification ... 18

Annex B Format for inner page of verification certificate/ verification result notification

(Page 2) ... 21

Annex C Format for inner page of verification certificate/ verification result notification

(Page 3) ... 22

Verification Regulation of Off-board Chargers for Electric

Vehicles (for Trial Implementation)

1 Scope

This Regulation applies to the first verification, follow-up verification and in-use

inspection for off-board chargers for electric vehicles.

The verification of off-board chargers for electric vehicles based on statistical sampling

methods can be carried out in accordance with this Regulation.

2 Normative references

This Regulation refers to the following documents:

JJG 842-2017, Electronic Meters for Measuring Direct-current Electrical Energy

JJF 1139, Principle and method for determination verification period of measuring

instruments

NB/T 33001-2018, Specification for electric vehicle off-board conductive charger

For the dated documents, only the versions with the dates indicated are applicable to

this Regulation; for the undated documents, only the latest version (including all the

amendments) is applicable to this Regulation.

3 Terms

The following terms and definitions apply to this document.

3.1 off-board charger

A special device that is fixedly connected to an AC or DC power source, converts its

electrical energy into DC electrical energy, charges the power battery of an electric

vehicle by means of conduction, and has the functions of measuring, storing, and

providing results to users.

3.2 connection point

A connection point that the off-board charger is connected to the electric vehicle.

NOTE: If the output cable is a fixed part of the off-board charger, this point is defined as the

connector at the end of the cable. Otherwise, the connection point is defined as the cable insertion

point of the off-board charger.

3.3 real load test method

A method of verification using the actual operating load.

3.4 virtual load test method

A method that uses the virtual load provided by the charger verification device to verify.

3.5 constant-current charge

A way that the battery is charged with a controlled constant current when the charging

voltage is within the working range.

3.6 constant voltage charge

A way when the charging current is within the working range, the battery is charged

with a controlled constant voltage.

3.7 operate error

DC energy measurement errors of off-board chargers under working conditions.

3.8 test output

A device that provides pulses corresponding to the DC energy measured by off-board

chargers.

3.9 constant

A numerical value representing the relationship between the electric energy recorded

by the off-board charger and the corresponding test output value.

4 Overview

An off-board chargers for electric vehicles (hereinafter referred to as charger) is a

metrology device that provides DC power for electric vehicles. It is mainly composed

of rectification and chopper control unit, display interface or data transmission interface,

metrology module, connection device for conductive charging and other parts. The

schematic diagram of the charger is shown in Figure 1.

The charger converts AC power into DC power through the rectification and chopper

control unit. The DC power is sent to the electric vehicle through the connection device

for conductive charging to meet the charging demand. The metrology module

completes the measurement of DC electric energy, and outputs the measured quantity

to the display interface or data transmission interface.

not marked, the maximum current value is: rated power/[(Umax+Umin)/2]; the minimum current

value is: 5A.

2 For chargers installed before January 1, 2023, if the accuracy level is not marked, it will be

implemented as level 2.

6.2 Testing interface

The technical indicators of the test output and communication interface of the charger

used for verification shall meet the requirements of relevant standards.

6.3 Constant

The charger shall have a pulse output corresponding to the measured DC energy. It shall

be consistent with the constant marked on the nameplate.

6.4 Minimum power variable

The minimum electric energy variable shall be 0.001kW·h.

6.5 Display of charging energy

The charger shall be able to display the charging energy. The number of digits for

electric energy display shall be no less than 6 digits (including at least 3 decimal places).

For chargers with time-sharing charging function, the resolution of clock time display

is not greater than 1s.

7 Measuring instrument control

7.1 First verification, follow-up verification and in-use inspection

The first verification is for a charger that has not been verified. The follow-up

verification is any verification after the first verification. The repaired charger must be

according to the first verification. In-use inspection is an inspection to find out whether

the verification mark or verification certificate of the charger is valid, and whether the

verified charger has been significantly modified.

7.2 Verification conditions

7.2.1 Ambient conditions for verification

When verifying the charger, the following conditions shall be met:

- Verification conditions and their deviations do not exceed those specified in Table

3.

- There shall be no appreciable shock load. The seal of the charger is complete.

b) Verification operate error

Compare the DC power value measured simultaneously by the verification device

and the charger under test, so as to determine the operate error of the charger

under test.

According to the principle, it can be divided into real load test method and virtual

load test method.

1) Real load test method

Connect the charger calibrator and load composition verification device to the

connection point. Use method I or method II at the selected load point.

Compare the DC power values measured simultaneously by the verification

device and the charger under test, so as to determine the operate error of the

charger under test.

Method I:

When both the charging pile calibrator and the inspected charger are working

continuously, the pulse output by the inspected charger is used to control the

counting of the charging pile calibrator to determine the operate error of the

inspected charger. When using this method, use method Ⅱ to check whether

the charger constant is correct.

The operate error γ of the tested charger is calculated according to (1).

Where,

m - the measured pulse number;

m0 - the calculated and determined pulse number, calculated according to

formula (2).

Where,

N - the number of pulses of the tested charger;

C0 - the constant of calibrator, imp/ (kW·h);

CL - the constant of the charger under test, imp/ (kW·h).

NOTE: Select the appropriate pulse number N of the tested charger, so that the

quantization error of the calculated pulse number is not greater than 1/10 of the grade

index of the tested charger.

Method II:

When both the charging pile calibrator and the inspected charger are working

continuously, the operate error of the tested charger is determined by using the

output electric energy indication value of the inspected charger and the electric

energy value measured by the charging pile calibrator.

The operate error γ of the charger under test is calculated according to (3):

Where,

E' - the difference between the indicated value of the output electric energy

when the tested charger stops charging and starts charging, kW·h;

E - the electric energy value measured by the standard meter, kW·h;

γ0 - the established systematic error of the verification device, when no

correction is required, γ0=0.

The charging pile calibrator shall run synchronously with the tested charger.

The ratio (%) of the electric energy value represented by the last word (or the

minimum scale value) of the display of the tested charger to the accumulated

E' shall not be greater than 1/5 of the grade index of the tested charger.

During the verification process, record the error measurement data at least

twice. Take the average value to calculate the operate error.

2) Virtual load test method

Use the verification device. Compare the DC power values measured

simultaneously by the verification device and the tested charger, so as to

determine the operate error of the tested charger. When using the virtual load

test method, the influence of the connection position on the test results shall

be considered.

The standard table method is used to verify the charger according to the

provisions of 1).

Use watt-second method to verify the charger. Use a verifier to measure the

set constant power, or use a standard power source to determine the power.

The quantization error of the number of digits displayed by the verifier or

Where,

T - the reference clock display time, ××h××min××s;

T0 - the display time of the charging pile under inspection, ××h××min××s.

The test results shall meet the requirements of 5.2.

7.4 Processing of verification results

7.4.1 Processing of verification results

7.4.1.1 Judging all data shall be subject to the rounded data.

7.4.1.2 The rounding interval of operate error is 1/10 of the accuracy level of the charger.

7.4.1.3 The rounding interval of the clock time error is 1s.

7.4.2 Rounding off method for measurement data

7.4.2.1 Rounding off method when the rounding off interval is 1: The right side of the

reserved digit is for the reserved digit 1. If it is greater than 0.5, add 1 to the reserved

digit. If it is less than 0.5, the reserved digit remains unchanged. If it is equal to 0.5, the

reserved digit remains unchanged when it is an even number. Add 1 when the reserved

digit is odd.

NOTE: "Reserved digit" refers to the number corresponding to the rounding interval. This value is

called a "reserved digit".

7.4.2.2 Rounding method when the rounding interval is n (n≠1): Divide the measured

data by n. Then round off according to the method of 7.4.2.1. After rounding, multiply

by n, which is the final rounding result.

7.4.3 If all items meet the requirements, it is judged as qualified, otherwise it is judged

as unqualified. Chargers that pass the verification will be issued with a verification

certificate (see Annexes B and C for the format of the verification certificate) and a

verification-pass mark.

7.4.4 A verification-pass charger must be sealed at the position of the electric energy

meter or metrology module used inside it. Splitters that are used separately also need to

be sealed.

NOTE: For chargers installed before January 1, 2023, the implementation of shunt seal

requirements will be suspended until December 31, 2027, under special circumstances.

7.4.5 A test result notification will be issued to the unqualified charger (see Annexes B

and C for the format). Cancel the original verification-pass seal or verification-pass

mark.

JJF 1149-2022

JJF

NATIONAL METROLOGICAL VERIFICATION REGULATIONS

OF THE PEOPLE’S REPUBLIC OF CHINA

JJG 1149-2022

Off-board Chargers for Electric Vehicles (for Trial

Implementation)

ISSUED ON: JUNE 28, 2022

IMPLEMENTED ON: DECEMBER 28, 2022

Issued by: State Administration for Market Regulation

Table of Contents

Introduction ... 5

1 Scope ... 6

2 Normative references ... 6

3 Terms ... 6

4 Overview ... 7

5 Metrology performance requirements ... 8

5.1 Operate error ... 8

5.2 Clock time error ... 9

6 General technical requirements ... 9

6.1 Identification ... 9

6.2 Testing interface ... 10

6.3 Constant ... 10

6.4 Minimum power variable ... 10

6.5 Display of charging energy ... 10

7 Measuring instrument control ... 10

7.1 First verification, follow-up verification and in-use inspection ... 10

7.2 Verification conditions ... 10

7.3 Verification items and verification methods ... 11

7.4 Processing of verification results ... 16

7.5 Verification period ... 17

Annex A Format for original record of verification ... 18

Annex B Format for inner page of verification certificate/ verification result notification

(Page 2) ... 21

Annex C Format for inner page of verification certificate/ verification result notification

(Page 3) ... 22

Verification Regulation of Off-board Chargers for Electric

Vehicles (for Trial Implementation)

1 Scope

This Regulation applies to the first verification, follow-up verification and in-use

inspection for off-board chargers for electric vehicles.

The verification of off-board chargers for electric vehicles based on statistical sampling

methods can be carried out in accordance with this Regulation.

2 Normative references

This Regulation refers to the following documents:

JJG 842-2017, Electronic Meters for Measuring Direct-current Electrical Energy

JJF 1139, Principle and method for determination verification period of measuring

instruments

NB/T 33001-2018, Spec...

Share