1

/

of

8

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

JJG 291-2008 English PDF (JJG291-2008)

JJG 291-2008 English PDF (JJG291-2008)

Regular price

$170.00 USD

Regular price

Sale price

$170.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click JJG 291-2008

Historical versions: JJG 291-2008

Preview True-PDF (Reload/Scroll if blank)

JJG 291-2008: Verification regulation of dissolved oxygen meter with covered-membrane-electrode

JJG 291-2008

JJF

National Metrology Technical Specifications

of the People's Republic of China

Dissolved Oxygen Meter with Covered-Membrane-

Electrode

ISSUED ON. DECEMBER 23, 2008

IMPLEMENTED ON. JUNE 23, 2009

Issued by. State Administration for Quality Supervision and Inspection and

Quarantine

Verification Regulation of Dissolved Oxygen

Meter with Covered-Membrane-Electrode

Replacing JJG 291-1999

This regulation was approved by General Administration of Quality Supervision, Inspection

and Quarantine on December 23, 2008 and shall be implemented from June 23, 2009.

Jurisdictional organization.

National Technical Committee on Environmental Stoichiometry

Drafting organization.

Zhejiang Province Institute of Metrology

This regulation is entrusted to and shall be responsibly interpreted by National Technical

Committee on Environmental Stoichiometry.

Drafter of this regulation.

Zhang Yanqun (Zhejiang Province Institute of Metrology)

Table of Contents

1 Scope ... 5

2 Overview ... 5

3 Requirements for metrological performance ... 5

4 General technical requirements ... 5

5 Measuring instrument control ... 6

Annex A Preparation of Water for Verification ... 13

Annex B Structural Drawing of Device for Verification Water Preparation ... 14

Annex C Saturation concentration table of oxygen in water with different temperatures

... 15

Annex D Saturated Vapor Pressure of Pure Water at Different Temperatures... 16

Annex E Verification Record ... 17

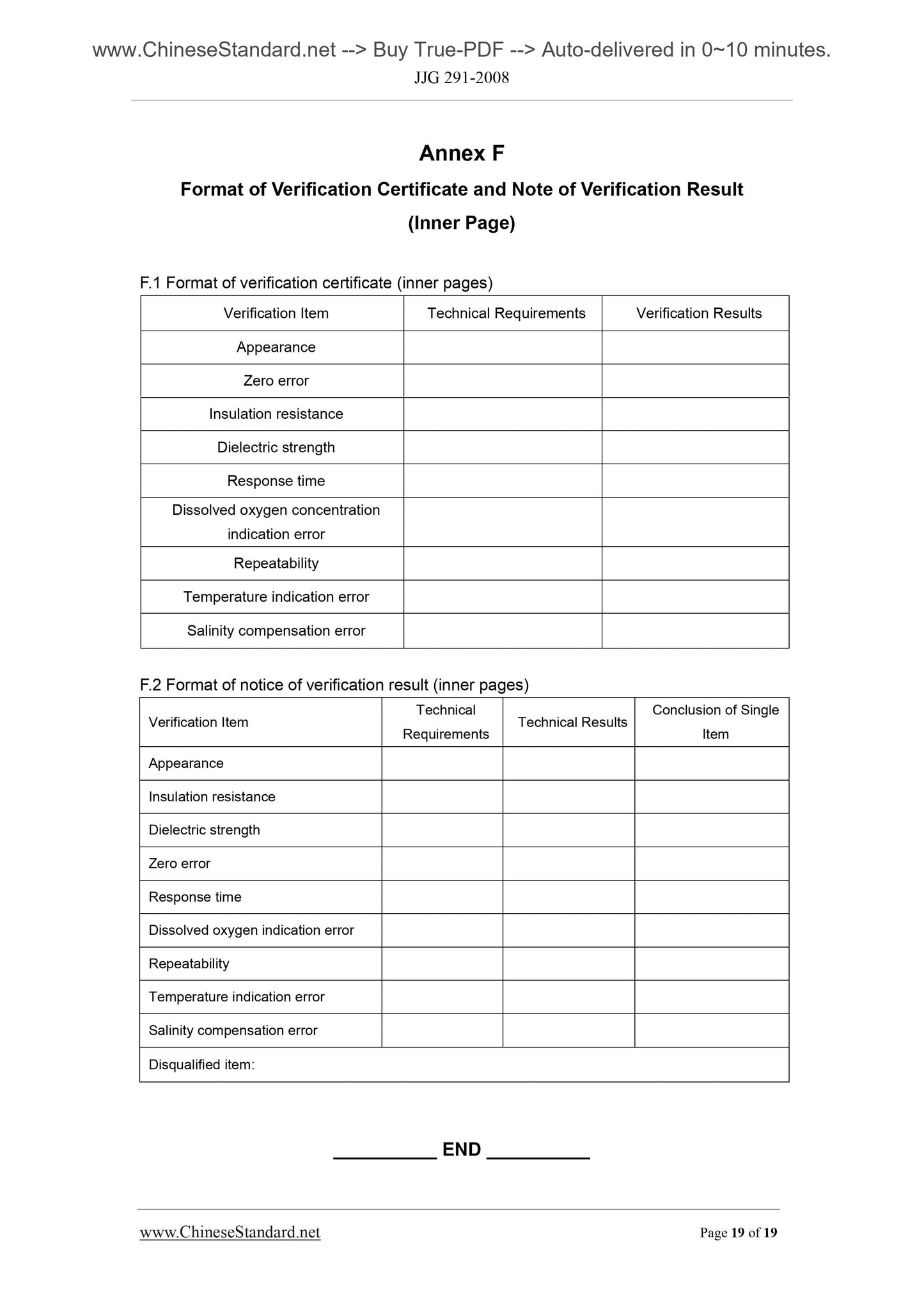

Annex F Format of Verification Certificate and Note of Verification Result ... 19

(Inner Page) ... 19

Dissolved Oxygen Meter with Covered-Membrane-Electrode

1 Scope

This regulation applies to initial verification, subsequent verification and in-use verification of

laboratory-service and portable dissolved oxygen meters with covered-membrane-electrode

(hereinafter referred to as the instrument) that have a measuring range of (0 ~ 20)mg/L.

2 Overview

The instrument is used to measure concentration of constant dissolved oxygen meter (DO) in

water.

The instrument is composed of covered-membrane-oxygen electrode, electronic unit and

displayer.

3 Requirements for metrological performance

3.1 Zero error

Zero error of instrument shall not exceed 0.10 mg/L.

3.2 Response time

Response time of instrument shall not exceed 60 s.

3.3 Dissolved oxygen concentration indication error

Dissolved oxygen concentration indication error of instrument for initial verification shall not

exceed ±0. 30 mg/L; indication error for subsequent verification shall not exceed ±0. 50 mg/L.

3.4 Repeatability

Standard deviation of instrument for initial verification shall not exceed 0.15 mg/L; standard

deviation for subsequent verification shall not exceed 0.20 mg/L.

3.5 Temperature indication error

Temperature indication error of instrument shall not exceed ± 0. 5°C.

3.6 Salinity compensation error

Salinity compensation error of instrument shall not exceed ± 2 %.

4 General technical requirements

4.1 Appearance

4.1.1 The instrument shall indicate the name of manufacturing company, model and

manufacturing number; domestic instrument shall be marked with metering equipment

referring to Annex D, in Pa. Take △c with maximum absolute value as dissolved oxygen

concentration indication error.

5.3.7 Verification of repeatability

5.3.7.1 Verification of repeatability of instrument shall be carried out in saturated dissolved

oxygen water that thermostatic water batch is close to the room temperature.

5.3.7.2 Measure table saturated dissolved oxygen water for continuous 6 times; record 5.3

Verification method

5.3.1 Appearance

Check through vision or hand feeling according to requirements of 4.1.

5.3.2 Verification of insulation resistance

The instrument is not connected to power source. Turn on the power switch. Connect one end

of insulation resistance meter to the phase of instrument input terminal and neutral conjunction

line, while connect the other end to protective earth terminal (or shell) of the instrument. Apply

test voltage of 500 V and continue for 5 s; measure insulation resistance.

5.3.3 Verification of dielectric strength

The instrument is not connected to power source. Turn on the power switch. Connect two

measuring lines of dielectric strength tester to phase of power input terminal, central

conjunction line and ground terminal (or shell). Apply test voltage of 1 500 V; set leak current

to be 5 mA and lifting time to be (5s to 20)s; keep for 1 min, and then lower the voltage to 0

V stably. There shall be no breakdown and arcing phenomena during the test process.

5.3.4 Verification zero error

5.3.4.1 Calibrate normally according to the requirements of operation instruction of instrument.

5.3.4.2 Immerse electrode into freshly prepared oxygen-free solution at a temperature of

(20±5)°C from air; see A.1 in Annex A for preparation of anaerobic water.

5.3.4.3 Instrument indication after 5 min is just the zero error caused by zero bit current.

5.3.5 Verification of response time

5.3.5.1 Control thermostatic water bath temperature to (20±1)°C; prepare saturated dissolved

oxygen water according to requirements in A.2 of Annex A.

5.3.5.2 Take electrode out of thermostatic water bath and immerse into oxygen-free water

quickly; meanwhile start timing.

5.3.5.3 Stop timing when the instrument displays 90% stable value; the reading of stopwatch

is just the response time.

5.3.6 Verification of dissolved oxygen concentration indication error

5.3.6.1 Re-calibrate the instrument.

instrument according to Formula (4).

)4...(...si

Where,

Ti - Instrument indication temperature value, in °C;

Ts - Reading of precision thermometer, in °C.

Take △T with maximum absolute value as instrument temperature indication error of

instrument.

5.3.9 Verification of salinity compensation error

5.3.9.1 Pour 1 L of distilled water into the beaker; place it into thermostatic water bath at a

temperature of (15±0.2)°C; stop bubbling 1 h after the start; still for 10 min and measure

concentration N0 of dissolved oxygen concentration with zero salt. Standard value of water

dissolved oxygen concentration that salt content is n(g/L) is obtained according to Formula (5).

)5...(...9055.0-0sn nNN

Where,

n - Salt (NaCl) in grams, n may be 10g, 20g and 30g.

Note. 0.055 9 refers to the variation of solubility when water temperature is 15°C and salt content is 1 g/L

(△Cs). See Annex A of GB/T 11913- 1989.

5.3.9.2 Maintain pure water temperature 15°C; add salt of 10 g and stir uniformly; prepare it to

be saturated dissolved oxygen water that salt content is 10 g/L and measure to get N10

(measure for 2 times and take the average value). Use the same method to prepare water into

saturated dissolved oxygen water that salt content is 20, 30 g/L and measure to get N20 and

N30 respectively. Calculate salinity compensation error according to Formula (6).

߂ܰ ൌ ܰିܰ௦ܰୱ ൈ 100% ... (6)

Where,

Nn - Concentration of saline dissolved oxygen, which may be N10, N20, N30, in mg/L.

Take the △N with the maximum absolute value as salinity compensation error of instrument.

5.4 Verification results handling

5.4.1 In case of poor electrode performance discovered during verification process, it is

allowed to replace electrode electrolyte and membrane; re-verification is required after the

replacement.

5.4.2 Issue verification qualification certificate for instruments tha...

Get QUOTATION in 1-minute: Click JJG 291-2008

Historical versions: JJG 291-2008

Preview True-PDF (Reload/Scroll if blank)

JJG 291-2008: Verification regulation of dissolved oxygen meter with covered-membrane-electrode

JJG 291-2008

JJF

National Metrology Technical Specifications

of the People's Republic of China

Dissolved Oxygen Meter with Covered-Membrane-

Electrode

ISSUED ON. DECEMBER 23, 2008

IMPLEMENTED ON. JUNE 23, 2009

Issued by. State Administration for Quality Supervision and Inspection and

Quarantine

Verification Regulation of Dissolved Oxygen

Meter with Covered-Membrane-Electrode

Replacing JJG 291-1999

This regulation was approved by General Administration of Quality Supervision, Inspection

and Quarantine on December 23, 2008 and shall be implemented from June 23, 2009.

Jurisdictional organization.

National Technical Committee on Environmental Stoichiometry

Drafting organization.

Zhejiang Province Institute of Metrology

This regulation is entrusted to and shall be responsibly interpreted by National Technical

Committee on Environmental Stoichiometry.

Drafter of this regulation.

Zhang Yanqun (Zhejiang Province Institute of Metrology)

Table of Contents

1 Scope ... 5

2 Overview ... 5

3 Requirements for metrological performance ... 5

4 General technical requirements ... 5

5 Measuring instrument control ... 6

Annex A Preparation of Water for Verification ... 13

Annex B Structural Drawing of Device for Verification Water Preparation ... 14

Annex C Saturation concentration table of oxygen in water with different temperatures

... 15

Annex D Saturated Vapor Pressure of Pure Water at Different Temperatures... 16

Annex E Verification Record ... 17

Annex F Format of Verification Certificate and Note of Verification Result ... 19

(Inner Page) ... 19

Dissolved Oxygen Meter with Covered-Membrane-Electrode

1 Scope

This regulation applies to initial verification, subsequent verification and in-use verification of

laboratory-service and portable dissolved oxygen meters with covered-membrane-electrode

(hereinafter referred to as the instrument) that have a measuring range of (0 ~ 20)mg/L.

2 Overview

The instrument is used to measure concentration of constant dissolved oxygen meter (DO) in

water.

The instrument is composed of covered-membrane-oxygen electrode, electronic unit and

displayer.

3 Requirements for metrological performance

3.1 Zero error

Zero error of instrument shall not exceed 0.10 mg/L.

3.2 Response time

Response time of instrument shall not exceed 60 s.

3.3 Dissolved oxygen concentration indication error

Dissolved oxygen concentration indication error of instrument for initial verification shall not

exceed ±0. 30 mg/L; indication error for subsequent verification shall not exceed ±0. 50 mg/L.

3.4 Repeatability

Standard deviation of instrument for initial verification shall not exceed 0.15 mg/L; standard

deviation for subsequent verification shall not exceed 0.20 mg/L.

3.5 Temperature indication error

Temperature indication error of instrument shall not exceed ± 0. 5°C.

3.6 Salinity compensation error

Salinity compensation error of instrument shall not exceed ± 2 %.

4 General technical requirements

4.1 Appearance

4.1.1 The instrument shall indicate the name of manufacturing company, model and

manufacturing number; domestic instrument shall be marked with metering equipment

referring to Annex D, in Pa. Take △c with maximum absolute value as dissolved oxygen

concentration indication error.

5.3.7 Verification of repeatability

5.3.7.1 Verification of repeatability of instrument shall be carried out in saturated dissolved

oxygen water that thermostatic water batch is close to the room temperature.

5.3.7.2 Measure table saturated dissolved oxygen water for continuous 6 times; record 5.3

Verification method

5.3.1 Appearance

Check through vision or hand feeling according to requirements of 4.1.

5.3.2 Verification of insulation resistance

The instrument is not connected to power source. Turn on the power switch. Connect one end

of insulation resistance meter to the phase of instrument input terminal and neutral conjunction

line, while connect the other end to protective earth terminal (or shell) of the instrument. Apply

test voltage of 500 V and continue for 5 s; measure insulation resistance.

5.3.3 Verification of dielectric strength

The instrument is not connected to power source. Turn on the power switch. Connect two

measuring lines of dielectric strength tester to phase of power input terminal, central

conjunction line and ground terminal (or shell). Apply test voltage of 1 500 V; set leak current

to be 5 mA and lifting time to be (5s to 20)s; keep for 1 min, and then lower the voltage to 0

V stably. There shall be no breakdown and arcing phenomena during the test process.

5.3.4 Verification zero error

5.3.4.1 Calibrate normally according to the requirements of operation instruction of instrument.

5.3.4.2 Immerse electrode into freshly prepared oxygen-free solution at a temperature of

(20±5)°C from air; see A.1 in Annex A for preparation of anaerobic water.

5.3.4.3 Instrument indication after 5 min is just the zero error caused by zero bit current.

5.3.5 Verification of response time

5.3.5.1 Control thermostatic water bath temperature to (20±1)°C; prepare saturated dissolved

oxygen water according to requirements in A.2 of Annex A.

5.3.5.2 Take electrode out of thermostatic water bath and immerse into oxygen-free water

quickly; meanwhile start timing.

5.3.5.3 Stop timing when the instrument displays 90% stable value; the reading of stopwatch

is just the response time.

5.3.6 Verification of dissolved oxygen concentration indication error

5.3.6.1 Re-calibrate the instrument.

instrument according to Formula (4).

)4...(...si

Where,

Ti - Instrument indication temperature value, in °C;

Ts - Reading of precision thermometer, in °C.

Take △T with maximum absolute value as instrument temperature indication error of

instrument.

5.3.9 Verification of salinity compensation error

5.3.9.1 Pour 1 L of distilled water into the beaker; place it into thermostatic water bath at a

temperature of (15±0.2)°C; stop bubbling 1 h after the start; still for 10 min and measure

concentration N0 of dissolved oxygen concentration with zero salt. Standard value of water

dissolved oxygen concentration that salt content is n(g/L) is obtained according to Formula (5).

)5...(...9055.0-0sn nNN

Where,

n - Salt (NaCl) in grams, n may be 10g, 20g and 30g.

Note. 0.055 9 refers to the variation of solubility when water temperature is 15°C and salt content is 1 g/L

(△Cs). See Annex A of GB/T 11913- 1989.

5.3.9.2 Maintain pure water temperature 15°C; add salt of 10 g and stir uniformly; prepare it to

be saturated dissolved oxygen water that salt content is 10 g/L and measure to get N10

(measure for 2 times and take the average value). Use the same method to prepare water into

saturated dissolved oxygen water that salt content is 20, 30 g/L and measure to get N20 and

N30 respectively. Calculate salinity compensation error according to Formula (6).

߂ܰ ൌ ܰିܰ௦ܰୱ ൈ 100% ... (6)

Where,

Nn - Concentration of saline dissolved oxygen, which may be N10, N20, N30, in mg/L.

Take the △N with the maximum absolute value as salinity compensation error of instrument.

5.4 Verification results handling

5.4.1 In case of poor electrode performance discovered during verification process, it is

allowed to replace electrode electrolyte and membrane; re-verification is required after the

replacement.

5.4.2 Issue verification qualification certificate for instruments tha...

Share