1

/

of

12

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

QB 2806-2006 English PDF (QB2806-2006)

QB 2806-2006 English PDF (QB2806-2006)

Regular price

$180.00 USD

Regular price

Sale price

$180.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.Newer version: (Replacing this standard) QB/T 2806-2017

Get QUOTATION in 1-minute: Click QB 2806-2006

Historical versions: QB 2806-2006

Preview True-PDF (Reload/Scroll if blank)

QB 2806-2006: [Replaced by QB/T 2806-2017] Thermostatic faucets

QB 2806-2006

QB

LIGHT INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 91.060

Category No.. Y 71

Record No.. 18919-2006

Thermostatic faucets

温控水嘴

ISSUED ON. SEPTEMBER 14, 2006

IMPLEMENTED ON. MAY 01, 2007

Issued by. National Development and Reform Commission of People’s Republic of China

Table of Contents

Foreword ... 3

Introduction ... 5

1 Scope ... 6

2 Normative references ... 6

3 Terms and definitions ... 7

4 Classification and marking ... 9

5 Service conditions ... 10

6 Requirements ... 10

7 Test methods ... 19

8 Inspection rules ... 21

9 Marking, packaging, transportation and storage ... 23

Annex A ... 25

Annex B ... 31

Annex C ... 37

Annex D ... 38

Annex E ... 42

Annex F ... 43

Annex G ... 44

Annex H ... 45

Foreword

The Articles 6.1.1, 6.1.2, 6.4.1, 6.4.2, 6.4.3, 6.4.4, 6.4.5 and 6.4.6 of this Standard are

compulsory provisions; the rest are recommended.

The development of this Standard has adopted, through modifications, the American Society of

Sanitary Engineering ASSE 1016-2005 “Performance Requirements for Automatic

Compensating Valves for Individual Showers and Tub/ Shower Combinations”, and made

references to the European standards EN 1111.1998 “Thermostatic mixing valves (PN 10) -

General technical specification”, EN 1287.1999 “Low pressure thermostatic mixing valves --

General technical specifications”, ASME A112.18.1-2005/CSA B1125.1-2005 “Plumbing supply

fittings” and other foreign advanced standards. The main technical contents include.

-- All the materials applied by the products in direct touch with drinking water shall comply

with provisions of GB/T 17219;

-- Outlet water temperature stability. the deviation between the outlet water temperature of

mixing water and the set temperature shall be ≤ 2ºC;

-- Safety. Within the first 5s after cold water is stopped, the water yield shall be ≤200mL,

which shall be able to control the maximum outlet water temperature to be 49ºC;

-- After the service-life test of thermostatic faucet, the sealing performance and outlet water

temperature shall be within the changing range as specified.

The Annexes A, C, D, E, F, G and H are normative, while Annex B is informative.

This Standard was proposed by China Light Industry Federation.

This Standard shall be under the jurisdiction by the Subcommittee on Building Hardware of

National Technical Committee on Hardware of Standardization Administration of China.

The drafting organizations of this Standard. Suprema (Zhuhai J/V) Thermostatic Sanitary Ware

Co., Ltd., Zhoushan Pilima Sanitary Utensils Co., Ltd., Guangdong Meijie Plumbing Co., Ltd.,

Guangdong Chaoyang Sanitary Ware Co., Ltd., Wenzhou Hongsheng Group Co., Ltd., Shenluda

Group Co., Ltd., Jomoo Group Co. Ltd., Fujian Huihuang Plumbing Group Co., Ltd., MOEN

Guangzhou Faucet Co., Ltd., Shenzhen Globe Union Industrial Corp., Zoje Holding Group Co.,

Ltd., Ningbo Sino-japan San Sanitary Ware Co., Ltd., Zhuhai Mingshi Ceramics Valve Co. Ltd.,

Ningbo Jiuteng Ceramics Valve Co. Ltd., HENT Science and Technology Development Co., Ltd.,

National Building Material Industry Hardware and Plumbing Equipment Quality Supervision and

Test Center.

The drafters of this Standard. Xie Qingjun, Lin Yongding, Su Lihua, Ye Guorong, Guan

Hongsheng, Hong Guangming, Lin Shenyan, Wang Jianye, Chen Weikai, Qi Ruiliang, Shen

Zhaorong, Zhang Zhouquan, Chen Zhengbao, Xie Xiangxin, Xin Yaode.

Thermostatic Faucets

1 Scope

This Standard specifies the terms and definitions, classification and marking, requirements, test

methods, inspection rules and marking, packaging, transportation and storage of thermostatic

faucets.

This Standard shall be applicable to the cold-hot water mixing faucets of which the nominal

pressure is not more than 0.5MPa; used under the condition that the hot water temperature is

not more than 85ºC; installed in a lavatory (water closet and bathroom, etc.), kitchen and other

sanitary facilities where the outlet water temperature is automatically controlled by the preset

temperature.

2 Normative references

The provisions contained in the following documents become the provisions of this Standard

when they are quoted. For the dated documents so quoted, the modification lists (excluding the

corrections) or revisions made thereafter shall not be applicable to this Standard, however, all

parties who reach agreements based on this Standard are encouraged to study the possibility to

implement the latest version of these documents. For the undated documents so quoted, the

latest version shall be applicable to this Standard.

GB/T 1176-1987 Specification for cast copper alloys

GB/T 2828.1-2003 Sampling procedures for inspection by attribute – Part 1. Sampling

schemes indexed by acceptance quality limit (AQL) for lot-by-lot inspection

GB/T 2829-2002 Sampling procedures and tables for periodic inspection by attributes (Apply

to inspection of process stability to inspection of process stability)

GB/T 5121.1 ~ 5121.23-1996 Method for chemical analysis of copper

GB/T 5270-2005 Metallic coatings on metallic substrates - Electrodeposited and chemically

deposited coatings - Methods available for testing adhesion

GB/T 7306.1-2000 Pipe threads with 55 degree thread angle where pressure-tight joints are

made on the threads - Part 1. Parallel internal and taper external threads

GB/T 7306.2-2000 Pipe threads with 55 degree thread angle where pressure-tight joints are

made on the threads - Part 2. Taper internal and external threads

GB/T 7307-2001 55 degree non sealing pipe threads

GB/T 9286-1998 Colored paint and varnish - Cross cut test on paint film

GB/T 12600-2005 Metallic coatings - Electroplated coatings of nickel plus chromium on

plastics materials

GB/T 17219-1998 Standard for safety evaluation of equipment and protective materials in

drinking water system

GB/T 18145-2003 Ceramic cartridge faucets

HG/T 3090-1997 General rules of visual quality for molded and extruded rubber products

HG/T 3091-2000 Rubber seals - Joint rings for water supply drainage and sewerage pipelines

- Specification for materials

JC 886-2001 Hose for sanitary fittings

QB/T 3827-1999 Corrosion-resistant testing method of the metal deposits and conversion

coatings for the light industrial products - Acetic salt spraying test (ASS)

QB/T 3832-1999 Evaluation of the corrosion test results of the metal deposits for the light

industrial products

3 Terms and definitions

For the purpose of this standard, the following terms and definitions are applicable to this

Standard.

3.1

Single handle, double handle

They refer to the number of handles (hand wheels) used to control the temperature and flow of

faucets. The single handle means that one handle (hand wheel) is used to control the

temperature and flow of faucets; the double handle means that two handles are used to control

the temperature and flow of faucets.

3.2

Single control, double control

The single control refers to the thermostatic faucet where one control unit can regulate the flow

and temperature. The double control refers to the thermostatic faucet where two separate control

units are used to regulate the flow and temperature.

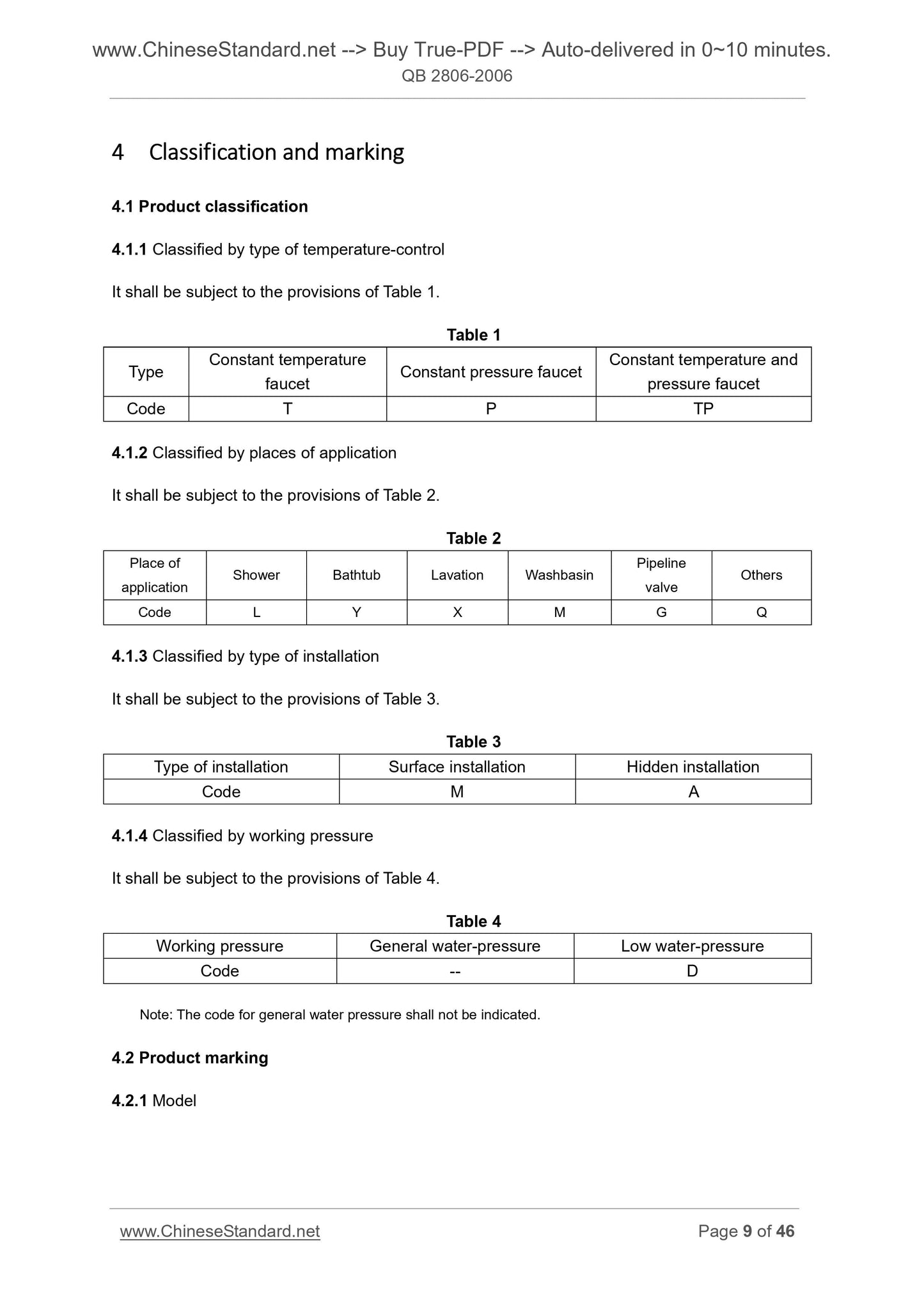

4 Classification and marking

4.1 Product classification

4.1.1 Classified by type of temperature-control

It shall be subject to the provisions of Table 1.

Table 1

Type Constant temperature faucet Constant pressur...

Get QUOTATION in 1-minute: Click QB 2806-2006

Historical versions: QB 2806-2006

Preview True-PDF (Reload/Scroll if blank)

QB 2806-2006: [Replaced by QB/T 2806-2017] Thermostatic faucets

QB 2806-2006

QB

LIGHT INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 91.060

Category No.. Y 71

Record No.. 18919-2006

Thermostatic faucets

温控水嘴

ISSUED ON. SEPTEMBER 14, 2006

IMPLEMENTED ON. MAY 01, 2007

Issued by. National Development and Reform Commission of People’s Republic of China

Table of Contents

Foreword ... 3

Introduction ... 5

1 Scope ... 6

2 Normative references ... 6

3 Terms and definitions ... 7

4 Classification and marking ... 9

5 Service conditions ... 10

6 Requirements ... 10

7 Test methods ... 19

8 Inspection rules ... 21

9 Marking, packaging, transportation and storage ... 23

Annex A ... 25

Annex B ... 31

Annex C ... 37

Annex D ... 38

Annex E ... 42

Annex F ... 43

Annex G ... 44

Annex H ... 45

Foreword

The Articles 6.1.1, 6.1.2, 6.4.1, 6.4.2, 6.4.3, 6.4.4, 6.4.5 and 6.4.6 of this Standard are

compulsory provisions; the rest are recommended.

The development of this Standard has adopted, through modifications, the American Society of

Sanitary Engineering ASSE 1016-2005 “Performance Requirements for Automatic

Compensating Valves for Individual Showers and Tub/ Shower Combinations”, and made

references to the European standards EN 1111.1998 “Thermostatic mixing valves (PN 10) -

General technical specification”, EN 1287.1999 “Low pressure thermostatic mixing valves --

General technical specifications”, ASME A112.18.1-2005/CSA B1125.1-2005 “Plumbing supply

fittings” and other foreign advanced standards. The main technical contents include.

-- All the materials applied by the products in direct touch with drinking water shall comply

with provisions of GB/T 17219;

-- Outlet water temperature stability. the deviation between the outlet water temperature of

mixing water and the set temperature shall be ≤ 2ºC;

-- Safety. Within the first 5s after cold water is stopped, the water yield shall be ≤200mL,

which shall be able to control the maximum outlet water temperature to be 49ºC;

-- After the service-life test of thermostatic faucet, the sealing performance and outlet water

temperature shall be within the changing range as specified.

The Annexes A, C, D, E, F, G and H are normative, while Annex B is informative.

This Standard was proposed by China Light Industry Federation.

This Standard shall be under the jurisdiction by the Subcommittee on Building Hardware of

National Technical Committee on Hardware of Standardization Administration of China.

The drafting organizations of this Standard. Suprema (Zhuhai J/V) Thermostatic Sanitary Ware

Co., Ltd., Zhoushan Pilima Sanitary Utensils Co., Ltd., Guangdong Meijie Plumbing Co., Ltd.,

Guangdong Chaoyang Sanitary Ware Co., Ltd., Wenzhou Hongsheng Group Co., Ltd., Shenluda

Group Co., Ltd., Jomoo Group Co. Ltd., Fujian Huihuang Plumbing Group Co., Ltd., MOEN

Guangzhou Faucet Co., Ltd., Shenzhen Globe Union Industrial Corp., Zoje Holding Group Co.,

Ltd., Ningbo Sino-japan San Sanitary Ware Co., Ltd., Zhuhai Mingshi Ceramics Valve Co. Ltd.,

Ningbo Jiuteng Ceramics Valve Co. Ltd., HENT Science and Technology Development Co., Ltd.,

National Building Material Industry Hardware and Plumbing Equipment Quality Supervision and

Test Center.

The drafters of this Standard. Xie Qingjun, Lin Yongding, Su Lihua, Ye Guorong, Guan

Hongsheng, Hong Guangming, Lin Shenyan, Wang Jianye, Chen Weikai, Qi Ruiliang, Shen

Zhaorong, Zhang Zhouquan, Chen Zhengbao, Xie Xiangxin, Xin Yaode.

Thermostatic Faucets

1 Scope

This Standard specifies the terms and definitions, classification and marking, requirements, test

methods, inspection rules and marking, packaging, transportation and storage of thermostatic

faucets.

This Standard shall be applicable to the cold-hot water mixing faucets of which the nominal

pressure is not more than 0.5MPa; used under the condition that the hot water temperature is

not more than 85ºC; installed in a lavatory (water closet and bathroom, etc.), kitchen and other

sanitary facilities where the outlet water temperature is automatically controlled by the preset

temperature.

2 Normative references

The provisions contained in the following documents become the provisions of this Standard

when they are quoted. For the dated documents so quoted, the modification lists (excluding the

corrections) or revisions made thereafter shall not be applicable to this Standard, however, all

parties who reach agreements based on this Standard are encouraged to study the possibility to

implement the latest version of these documents. For the undated documents so quoted, the

latest version shall be applicable to this Standard.

GB/T 1176-1987 Specification for cast copper alloys

GB/T 2828.1-2003 Sampling procedures for inspection by attribute – Part 1. Sampling

schemes indexed by acceptance quality limit (AQL) for lot-by-lot inspection

GB/T 2829-2002 Sampling procedures and tables for periodic inspection by attributes (Apply

to inspection of process stability to inspection of process stability)

GB/T 5121.1 ~ 5121.23-1996 Method for chemical analysis of copper

GB/T 5270-2005 Metallic coatings on metallic substrates - Electrodeposited and chemically

deposited coatings - Methods available for testing adhesion

GB/T 7306.1-2000 Pipe threads with 55 degree thread angle where pressure-tight joints are

made on the threads - Part 1. Parallel internal and taper external threads

GB/T 7306.2-2000 Pipe threads with 55 degree thread angle where pressure-tight joints are

made on the threads - Part 2. Taper internal and external threads

GB/T 7307-2001 55 degree non sealing pipe threads

GB/T 9286-1998 Colored paint and varnish - Cross cut test on paint film

GB/T 12600-2005 Metallic coatings - Electroplated coatings of nickel plus chromium on

plastics materials

GB/T 17219-1998 Standard for safety evaluation of equipment and protective materials in

drinking water system

GB/T 18145-2003 Ceramic cartridge faucets

HG/T 3090-1997 General rules of visual quality for molded and extruded rubber products

HG/T 3091-2000 Rubber seals - Joint rings for water supply drainage and sewerage pipelines

- Specification for materials

JC 886-2001 Hose for sanitary fittings

QB/T 3827-1999 Corrosion-resistant testing method of the metal deposits and conversion

coatings for the light industrial products - Acetic salt spraying test (ASS)

QB/T 3832-1999 Evaluation of the corrosion test results of the metal deposits for the light

industrial products

3 Terms and definitions

For the purpose of this standard, the following terms and definitions are applicable to this

Standard.

3.1

Single handle, double handle

They refer to the number of handles (hand wheels) used to control the temperature and flow of

faucets. The single handle means that one handle (hand wheel) is used to control the

temperature and flow of faucets; the double handle means that two handles are used to control

the temperature and flow of faucets.

3.2

Single control, double control

The single control refers to the thermostatic faucet where one control unit can regulate the flow

and temperature. The double control refers to the thermostatic faucet where two separate control

units are used to regulate the flow and temperature.

4 Classification and marking

4.1 Product classification

4.1.1 Classified by type of temperature-control

It shall be subject to the provisions of Table 1.

Table 1

Type Constant temperature faucet Constant pressur...

Share