1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

QC/T 1037-2016 English PDF (QCT1037-2016)

QC/T 1037-2016 English PDF (QCT1037-2016)

Regular price

$125.00 USD

Regular price

Sale price

$125.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click QC/T 1037-2016

Historical versions: QC/T 1037-2016

Preview True-PDF (Reload/Scroll if blank)

QC/T 1037-2016: High voltage cables for road vehicle

QC/T 1037-2016

QC

AUTOMOBILE STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 43.040.10

T 36

High voltage cables for road vehicles

ISSUED ON. APRIL 05, 2016

IMPLEMENTED ON. SEPTEMBER 01, 2016

Issued by. Ministry of Industry and Information Technology of the

People's Republic of China

Table of Contents

Announcement ... 3

Foreword ... 8

1 Scope ... 9

2 Normative references ... 9

3 Terms and definitions ... 9

4 Requirements ... 9

5 Test methods ... 15

6 Inspection rules ... 21

7 Packaging and packaging mark ... 23

Annex A (normative) Structural dimensions of cable ... 25

Annex B (informative) Models of major cables ... 31

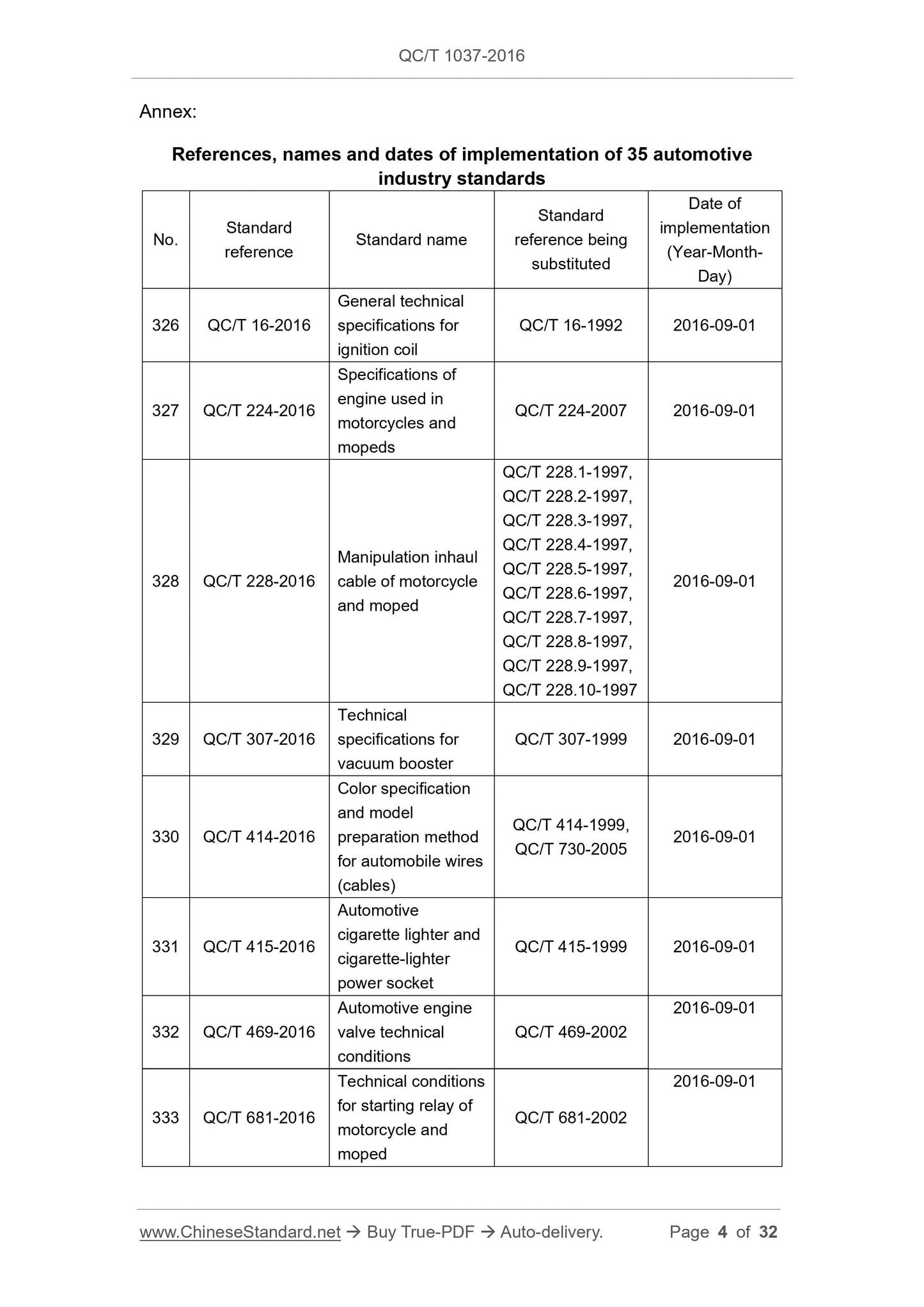

Annex.

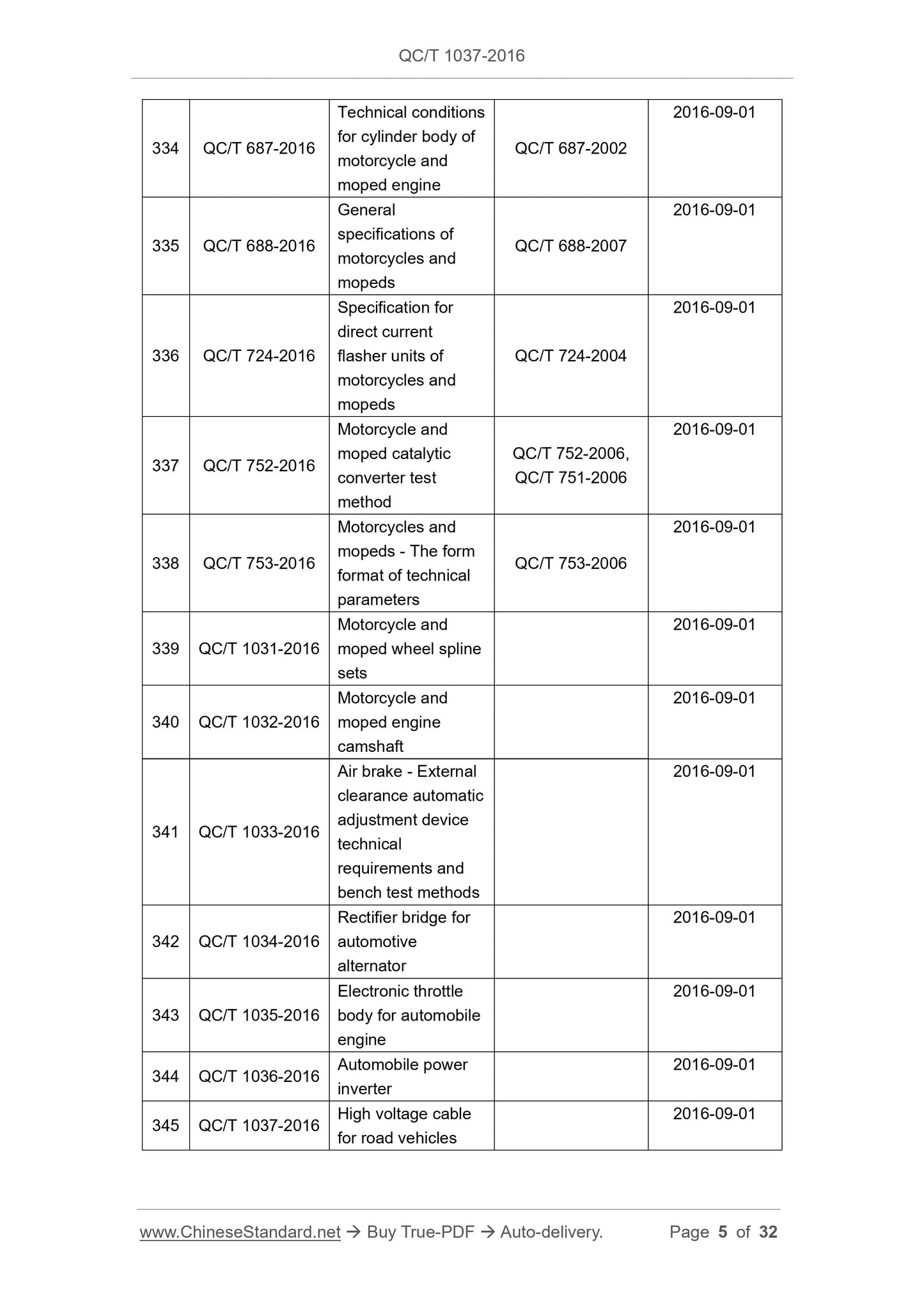

References, names and dates of implementation of 35 automotive

industry standards

No. Standard reference Standard name

Standard

reference being

substituted

Date of

implementation

(Year-Month-

Day)

326 QC/T 16-2016

General technical

specifications for

ignition coil

QC/T 16-1992 2016-09-01

327 QC/T 224-2016

Specifications of

engine used in

motorcycles and

mopeds

QC/T 224-2007 2016-09-01

328 QC/T 228-2016

Manipulation inhaul

cable of motorcycle

and moped

QC/T 228.1-1997,

QC/T 228.2-1997,

QC/T 228.3-1997,

QC/T 228.4-1997,

QC/T 228.5-1997,

QC/T 228.6-1997,

QC/T 228.7-1997,

QC/T 228.8-1997,

QC/T 228.9-1997,

QC/T 228.10-1997

2016-09-01

329 QC/T 307-2016

Technical

specifications for

vacuum booster

QC/T 307-1999 2016-09-01

330 QC/T 414-2016

Color specification

and model

preparation method

for automobile wires

(cables)

QC/T 414-1999,

QC/T 730-2005 2016-09-01

331 QC/T 415-2016

Automotive

cigarette lighter and

cigarette-lighter

power socket

QC/T 415-1999 2016-09-01

332 QC/T 469-2016

Automotive engine

valve technical

conditions

QC/T 469-2002

2016-09-01

333 QC/T 681-2016

Technical conditions

for starting relay of

motorcycle and

moped

QC/T 681-2002

2016-09-01

High voltage cables for road vehicles

1 Scope

This Standard specifies the requirements, test methods, inspection rules,

packaging and packaging marks of high voltage cables for road vehicles.

This Standard is applicable to high voltage cables for road vehicles of which the

rated voltages are AC 1000V/DC 1500V and AC 600V/DC 900V.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 1690, Rubber vulcanized or thermoplastic - Determination of the effect

of liquids

GB/T 3953, Round copper wire for electrical purposes

GB/T 4910, Tinned round copper wire

GB/T 25085-2010, Road vehicles - 60 V and 600 V single-core cables

GB/T 25087-2010, Road vehicles - Round, screened and unscreened 60 V

and 600 V multi-core sheathed cables

QC/T 414-2016, Color of low-voltage wire for automobile

3 Terms and definitions

For the purposes of this document, the terms and definitions defined in GB/T

25085 and GB/T 25087 apply.

4 Requirements

4.1 Model

Cable model is compiled according to QC/T 414-2016. See Annex B for major

cable models.

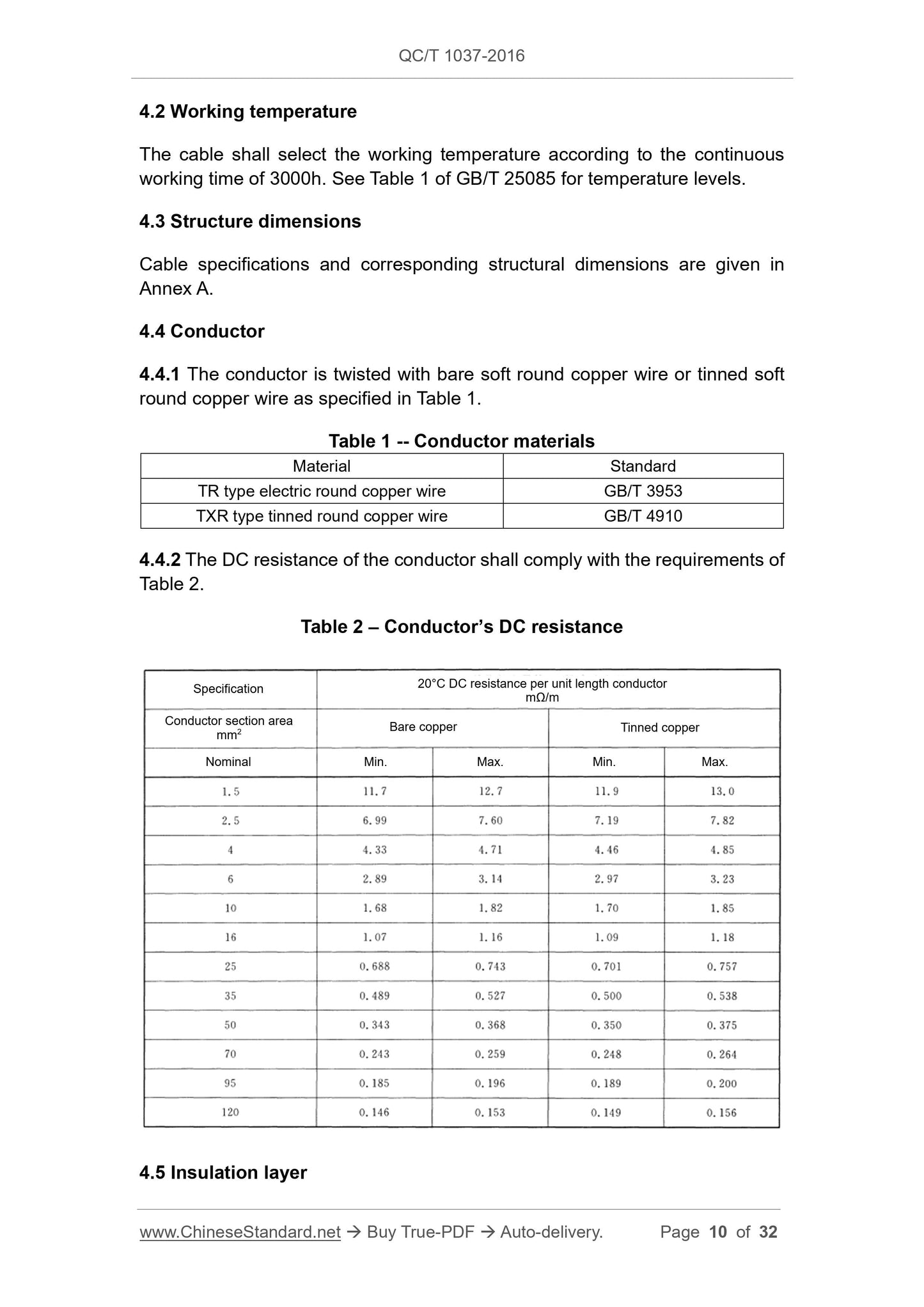

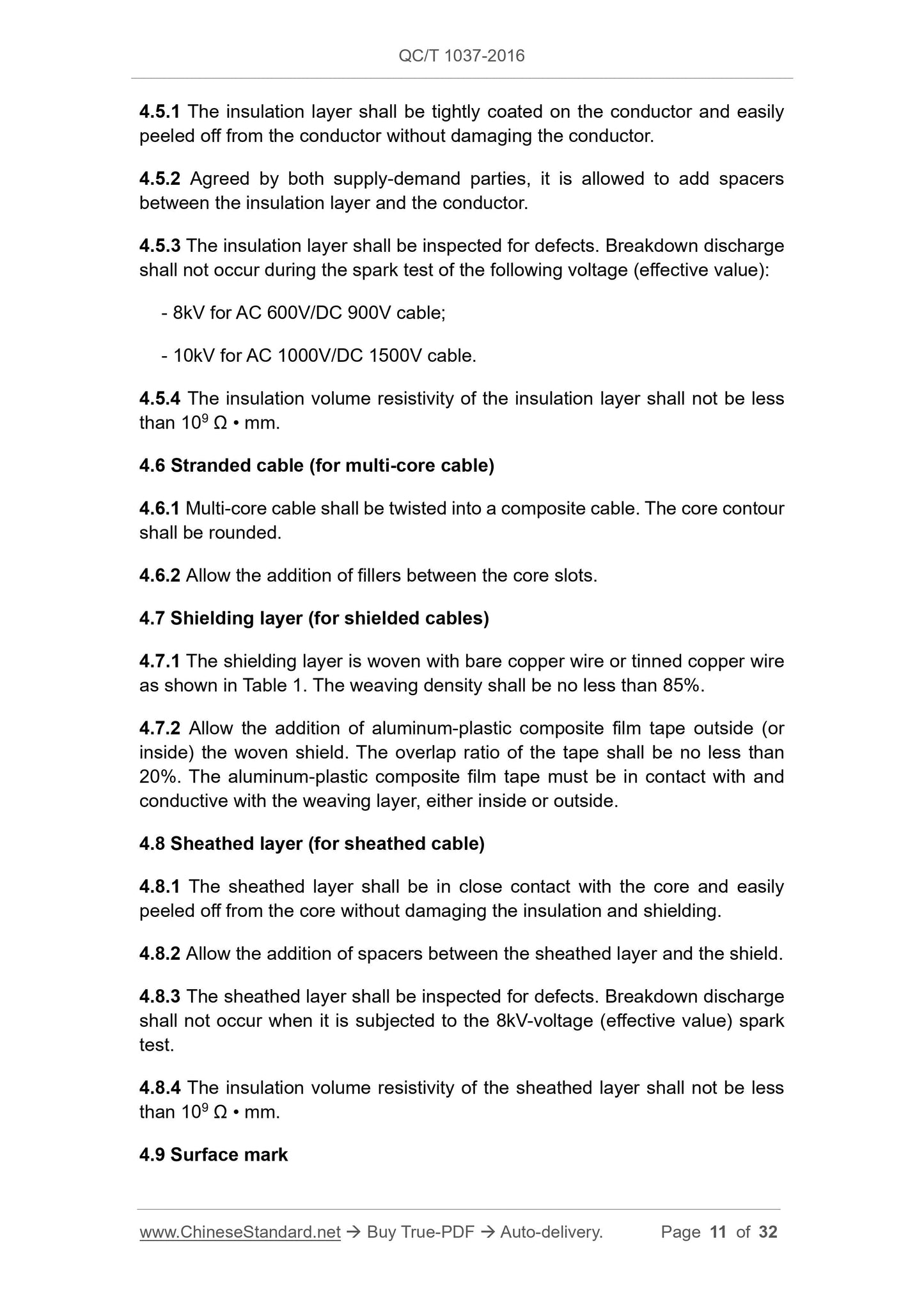

4.5.1 The insulation layer shall be tightly coated on the conductor and easily

peeled off from the conductor without damaging the conductor.

4.5.2 Agreed by both supply-demand parties, it is allowed to add spacers

between the insulation layer and the conductor.

4.5.3 The insulation layer shall be inspected for defects. Breakdown discharge

shall not occur during the spark test of the following voltage (effective value).

- 8kV for AC 600V/DC 900V cable;

- 10kV for AC 1000V/DC 1500V cable.

4.5.4 The insulation volume resistivity of the insulation layer shall not be less

than 109 Ω • mm.

4.6 Stranded cable (for multi-core cable)

4.6.1 Multi-core cable shall be twisted into a composite cable. The core contour

shall be rounded.

4.6.2 Allow the addition of fillers between the core slots.

4.7 Shielding layer (for shielded cables)

4.7.1 The shielding layer is woven with bare copper wire or tinned copper wire

as shown in Table 1. The weaving density shall be no less than 85%.

4.7.2 Allow the addition of aluminum-plastic composite film tape outside (or

inside) the woven shield. The overlap ratio of the tape shall be no less than

20%. The aluminum-plastic composite film tape must be in contact with and

conductive with the weaving layer, either inside or outside.

4.8 Sheathed layer (for sheathed cable)

4.8.1 The sheathed layer shall be in close contact with the core and easily

peeled off from the core without damaging the insulation and shielding.

4.8.2 Allow the addition of spacers between the sheathed layer and the shield.

4.8.3 The sheathed layer shall be inspected for defects. Breakdown discharge

shall not occur when it is subjected to the 8kV-voltage (effective value) spark

test.

4.8.4 The insulation volume resistivity of the sheathed layer shall not be less

than 109 Ω • mm.

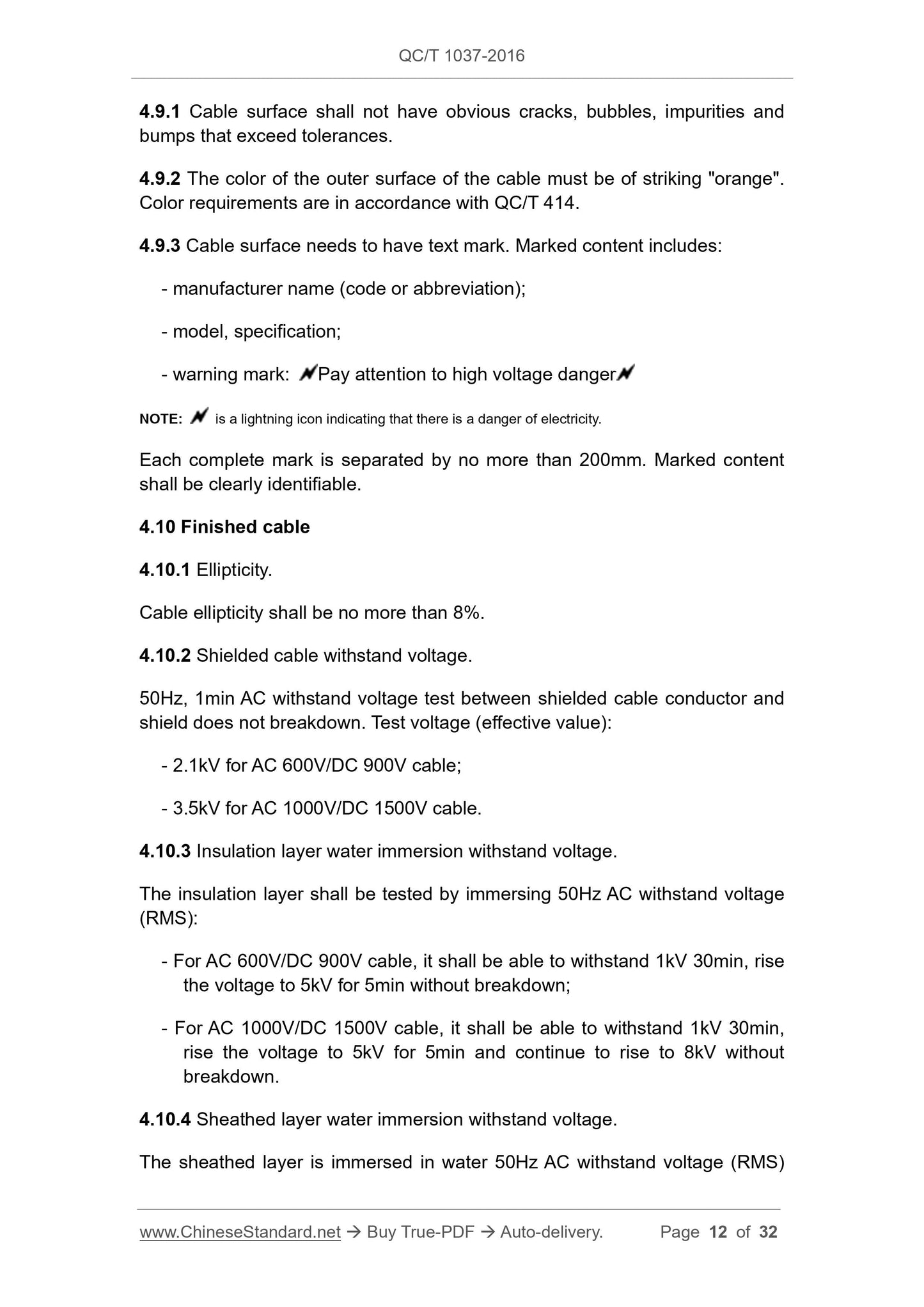

4.9 Surface mark

4.10.16 Chemical resistance reagent.

The cable is tested by chemical resistance reagent, and the insulation/sheath

shall not be exposed/shielded after winding. Carry out the withstand voltage

test without breakdown. The type of medium for chemical resistance reagent is

determined by both supply-demand parties.

4.10.17 Mark durability.

After the cable has been tested for durability, it shall comply with the

requirements of 11.3.4 of GB/T 25085.

4.10.18 Ozone resistance.

After the cable has been tested for ozone resistance.

- For single-core unshielded cables, the requirements of 11.4.5 of GB/T

25085 shall be met;

- For shielded cables, the requirements of 11.3.5 of GB/T 25087 shall be met.

4.10.19 Temperature and humidity alternation.

After the cable has passed the temperature and humidity alternating test.

- For single-core unshielded cables, the requirements of 11.6.5 of GB/T

25085 shall be met;

- For shielded cables, the requirements of 11.4.5 of GB/T 25087 shall be met.

4.10.20 Anti-flame retardant.

After the finished cable is subjected to the anti-flame retarding test, the

combustion flame shall be extinguished within 30s. The upper end of the

specimen shall have at least 50mm of insulation/sheath unburned.

5 Test methods

5.1 General

Except for the exit-factory test, all test samples shall be stored at (23 ± 5)°C for

at least 16h.

5.2 Inspection of structural dimensions

For single-core unshielded cables, measure according to Clause 5 of GB/T

25085. For shielded cables, measure according to Clause 5 of GB/T 25087.

cable. Conduct the test according to 7.2 in GB/T 25087 for shielded cable.

5.16 Cyclic bending test

Conduct the test according to 7.3 in GB/T 25087.

5.17 Low temperature winding test

Conduct the test according to 8.1 in GB/T 25085 for single core unshielded

cable. Conduct the test according to 8.1 in GB/T 25087 for shielded cable.

5.18 Low temperature impact test

Conduct the test according to 8.2 in GB/T 25085 for single core unshielded

cable. Conduct the test according to 8.2 in GB/T 25087 for shielded cable.

5.19 Abrasion resistance test

Conduct the test according to 9.3 in GB/T 25085. For shielded cables, the shield

shall be gr...

Get QUOTATION in 1-minute: Click QC/T 1037-2016

Historical versions: QC/T 1037-2016

Preview True-PDF (Reload/Scroll if blank)

QC/T 1037-2016: High voltage cables for road vehicle

QC/T 1037-2016

QC

AUTOMOBILE STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 43.040.10

T 36

High voltage cables for road vehicles

ISSUED ON. APRIL 05, 2016

IMPLEMENTED ON. SEPTEMBER 01, 2016

Issued by. Ministry of Industry and Information Technology of the

People's Republic of China

Table of Contents

Announcement ... 3

Foreword ... 8

1 Scope ... 9

2 Normative references ... 9

3 Terms and definitions ... 9

4 Requirements ... 9

5 Test methods ... 15

6 Inspection rules ... 21

7 Packaging and packaging mark ... 23

Annex A (normative) Structural dimensions of cable ... 25

Annex B (informative) Models of major cables ... 31

Annex.

References, names and dates of implementation of 35 automotive

industry standards

No. Standard reference Standard name

Standard

reference being

substituted

Date of

implementation

(Year-Month-

Day)

326 QC/T 16-2016

General technical

specifications for

ignition coil

QC/T 16-1992 2016-09-01

327 QC/T 224-2016

Specifications of

engine used in

motorcycles and

mopeds

QC/T 224-2007 2016-09-01

328 QC/T 228-2016

Manipulation inhaul

cable of motorcycle

and moped

QC/T 228.1-1997,

QC/T 228.2-1997,

QC/T 228.3-1997,

QC/T 228.4-1997,

QC/T 228.5-1997,

QC/T 228.6-1997,

QC/T 228.7-1997,

QC/T 228.8-1997,

QC/T 228.9-1997,

QC/T 228.10-1997

2016-09-01

329 QC/T 307-2016

Technical

specifications for

vacuum booster

QC/T 307-1999 2016-09-01

330 QC/T 414-2016

Color specification

and model

preparation method

for automobile wires

(cables)

QC/T 414-1999,

QC/T 730-2005 2016-09-01

331 QC/T 415-2016

Automotive

cigarette lighter and

cigarette-lighter

power socket

QC/T 415-1999 2016-09-01

332 QC/T 469-2016

Automotive engine

valve technical

conditions

QC/T 469-2002

2016-09-01

333 QC/T 681-2016

Technical conditions

for starting relay of

motorcycle and

moped

QC/T 681-2002

2016-09-01

High voltage cables for road vehicles

1 Scope

This Standard specifies the requirements, test methods, inspection rules,

packaging and packaging marks of high voltage cables for road vehicles.

This Standard is applicable to high voltage cables for road vehicles of which the

rated voltages are AC 1000V/DC 1500V and AC 600V/DC 900V.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 1690, Rubber vulcanized or thermoplastic - Determination of the effect

of liquids

GB/T 3953, Round copper wire for electrical purposes

GB/T 4910, Tinned round copper wire

GB/T 25085-2010, Road vehicles - 60 V and 600 V single-core cables

GB/T 25087-2010, Road vehicles - Round, screened and unscreened 60 V

and 600 V multi-core sheathed cables

QC/T 414-2016, Color of low-voltage wire for automobile

3 Terms and definitions

For the purposes of this document, the terms and definitions defined in GB/T

25085 and GB/T 25087 apply.

4 Requirements

4.1 Model

Cable model is compiled according to QC/T 414-2016. See Annex B for major

cable models.

4.5.1 The insulation layer shall be tightly coated on the conductor and easily

peeled off from the conductor without damaging the conductor.

4.5.2 Agreed by both supply-demand parties, it is allowed to add spacers

between the insulation layer and the conductor.

4.5.3 The insulation layer shall be inspected for defects. Breakdown discharge

shall not occur during the spark test of the following voltage (effective value).

- 8kV for AC 600V/DC 900V cable;

- 10kV for AC 1000V/DC 1500V cable.

4.5.4 The insulation volume resistivity of the insulation layer shall not be less

than 109 Ω • mm.

4.6 Stranded cable (for multi-core cable)

4.6.1 Multi-core cable shall be twisted into a composite cable. The core contour

shall be rounded.

4.6.2 Allow the addition of fillers between the core slots.

4.7 Shielding layer (for shielded cables)

4.7.1 The shielding layer is woven with bare copper wire or tinned copper wire

as shown in Table 1. The weaving density shall be no less than 85%.

4.7.2 Allow the addition of aluminum-plastic composite film tape outside (or

inside) the woven shield. The overlap ratio of the tape shall be no less than

20%. The aluminum-plastic composite film tape must be in contact with and

conductive with the weaving layer, either inside or outside.

4.8 Sheathed layer (for sheathed cable)

4.8.1 The sheathed layer shall be in close contact with the core and easily

peeled off from the core without damaging the insulation and shielding.

4.8.2 Allow the addition of spacers between the sheathed layer and the shield.

4.8.3 The sheathed layer shall be inspected for defects. Breakdown discharge

shall not occur when it is subjected to the 8kV-voltage (effective value) spark

test.

4.8.4 The insulation volume resistivity of the sheathed layer shall not be less

than 109 Ω • mm.

4.9 Surface mark

4.10.16 Chemical resistance reagent.

The cable is tested by chemical resistance reagent, and the insulation/sheath

shall not be exposed/shielded after winding. Carry out the withstand voltage

test without breakdown. The type of medium for chemical resistance reagent is

determined by both supply-demand parties.

4.10.17 Mark durability.

After the cable has been tested for durability, it shall comply with the

requirements of 11.3.4 of GB/T 25085.

4.10.18 Ozone resistance.

After the cable has been tested for ozone resistance.

- For single-core unshielded cables, the requirements of 11.4.5 of GB/T

25085 shall be met;

- For shielded cables, the requirements of 11.3.5 of GB/T 25087 shall be met.

4.10.19 Temperature and humidity alternation.

After the cable has passed the temperature and humidity alternating test.

- For single-core unshielded cables, the requirements of 11.6.5 of GB/T

25085 shall be met;

- For shielded cables, the requirements of 11.4.5 of GB/T 25087 shall be met.

4.10.20 Anti-flame retardant.

After the finished cable is subjected to the anti-flame retarding test, the

combustion flame shall be extinguished within 30s. The upper end of the

specimen shall have at least 50mm of insulation/sheath unburned.

5 Test methods

5.1 General

Except for the exit-factory test, all test samples shall be stored at (23 ± 5)°C for

at least 16h.

5.2 Inspection of structural dimensions

For single-core unshielded cables, measure according to Clause 5 of GB/T

25085. For shielded cables, measure according to Clause 5 of GB/T 25087.

cable. Conduct the test according to 7.2 in GB/T 25087 for shielded cable.

5.16 Cyclic bending test

Conduct the test according to 7.3 in GB/T 25087.

5.17 Low temperature winding test

Conduct the test according to 8.1 in GB/T 25085 for single core unshielded

cable. Conduct the test according to 8.1 in GB/T 25087 for shielded cable.

5.18 Low temperature impact test

Conduct the test according to 8.2 in GB/T 25085 for single core unshielded

cable. Conduct the test according to 8.2 in GB/T 25087 for shielded cable.

5.19 Abrasion resistance test

Conduct the test according to 9.3 in GB/T 25085. For shielded cables, the shield

shall be gr...

Share