1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

QC/T 740-2017 English PDF (QCT740-2017)

QC/T 740-2017 English PDF (QCT740-2017)

Regular price

$155.00 USD

Regular price

Sale price

$155.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click QC/T 740-2017

Historical versions: QC/T 740-2017

Preview True-PDF (Reload/Scroll if blank)

QC/T 740-2017: Seat assembly of passenger car

QC/T 740-2017

AUTOMOTIVE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.040.60

T 26

Replacing QC/T 740-2005

Seat Assembly of Passenger Car

ISSUED ON: APRIL 12, 2017

IMPLEMENTED ON: OCTOBER 01, 2017

Issued by: Ministry of Industry and Information Technology of PRC

Ministry of Industry and Information Technology of the PRC

April 12, 2017

Attachment:

Number, name and date of implementation of 22 automotive industry

standards

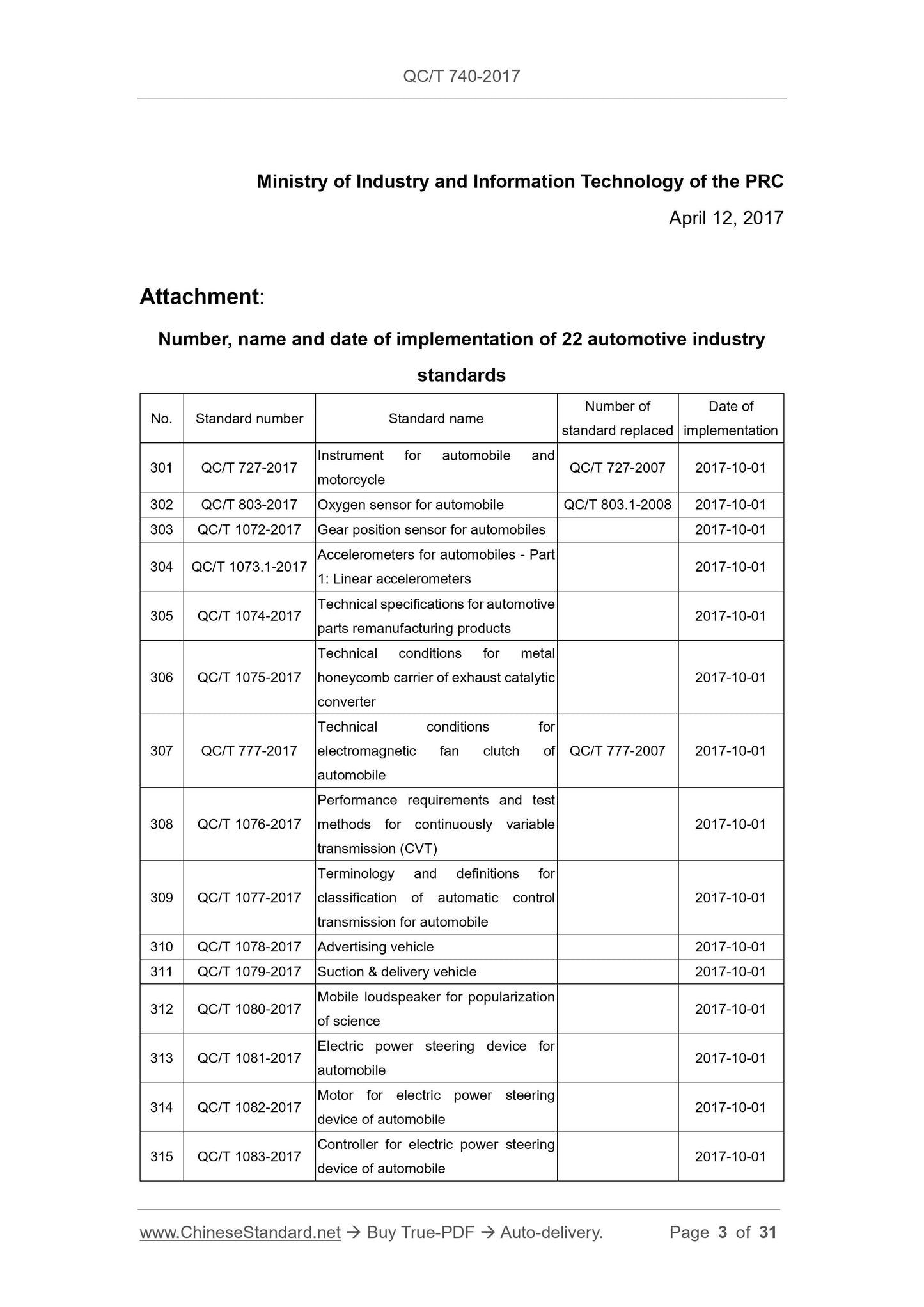

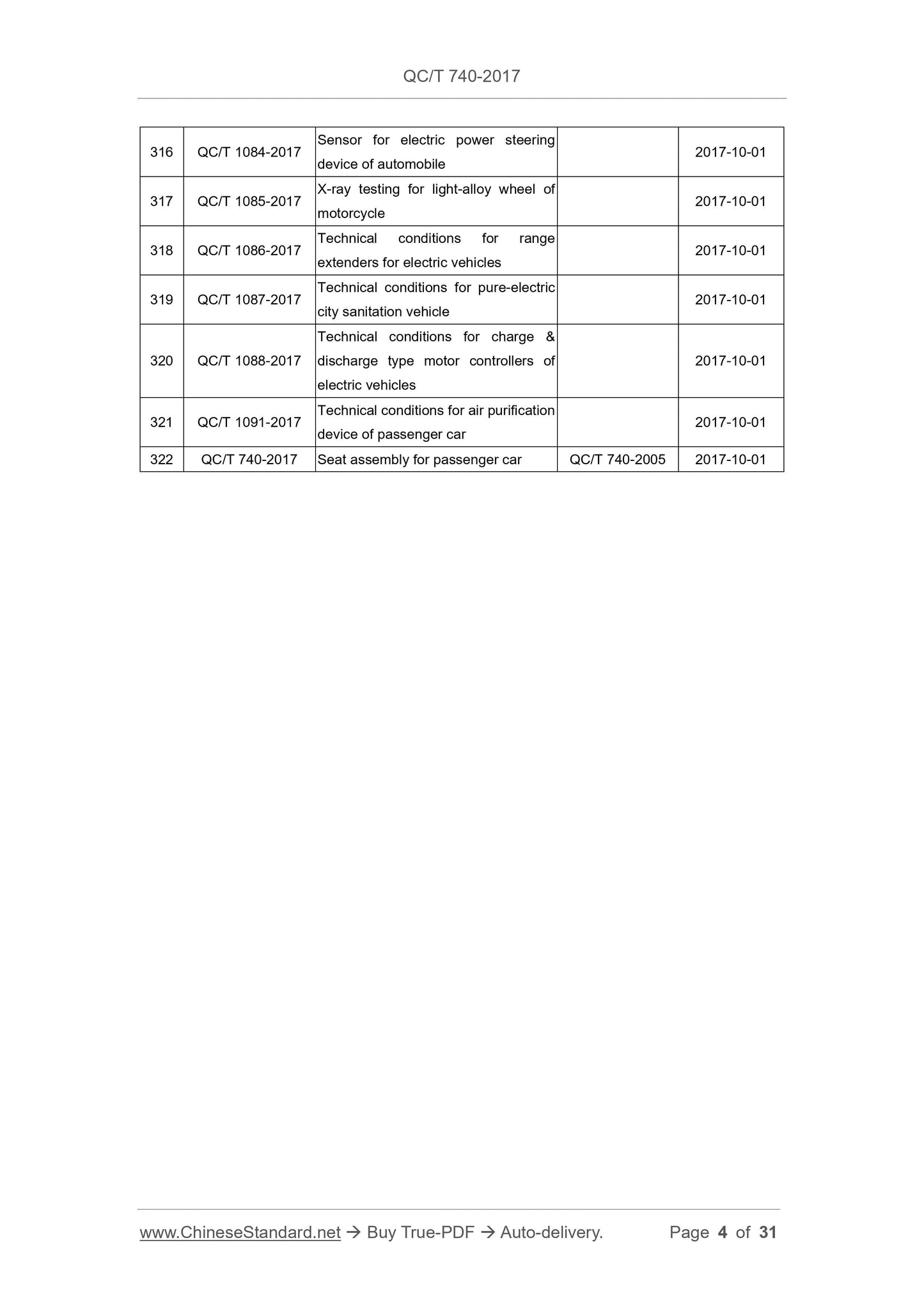

No. Standard number Standard name Number of standard replaced

Date of

implementation

301 QC/T 727-2017 Instrument for automobile and motorcycle QC/T 727-2007 2017-10-01

302 QC/T 803-2017 Oxygen sensor for automobile QC/T 803.1-2008 2017-10-01

303 QC/T 1072-2017 Gear position sensor for automobiles 2017-10-01

304 QC/T 1073.1-2017 Accelerometers for automobiles - Part 1: Linear accelerometers 2017-10-01

305 QC/T 1074-2017 Technical specifications for automotive parts remanufacturing products 2017-10-01

306 QC/T 1075-2017

Technical conditions for metal

honeycomb carrier of exhaust catalytic

converter

2017-10-01

307 QC/T 777-2017

Technical conditions for

electromagnetic fan clutch of

automobile

QC/T 777-2007 2017-10-01

308 QC/T 1076-2017

Performance requirements and test

methods for continuously variable

transmission (CVT)

2017-10-01

309 QC/T 1077-2017

Terminology and definitions for

classification of automatic control

transmission for automobile

2017-10-01

310 QC/T 1078-2017 Advertising vehicle 2017-10-01

311 QC/T 1079-2017 Suction and delivery vehicle 2017-10-01

312 QC/T 1080-2017 Mobile loudspeaker for popularization of science 2017-10-01

313 QC/T 1081-2017 Electric power steering device for automobile 2017-10-01

314 QC/T 1082-2017 Motor for electric power steering device of automobile 2017-10-01

315 QC/T 1083-2017 Controller for electric power steering device of automobile 2017-10-01

Table of Contents

Foreword ... 6

1 Scope ... 8

2 Normative References ... 8

3 Terms and Definitions ... 9

4 Technical Requirements ... 10

5 Test Methods ... 16

6 Inspection Rules ... 28

7 Marking, Package, Transportation and Storage ... 31

Seat Assembly of Passenger Car

1 Scope

This Standard specifies the terms and definitions, technical requirements, test

methods, inspection rules, marking, package, transportation and storage for the seat

assembly of passenger car.

This Standard is applicable to the seat assembly of Type-M1 vehicle.

This Standard is not applicable to the folding seat, side-facing seat, and rearward-

facing seat.

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) are applicable to this document.

GB 7258 Safety Specifications for Power-Driven Vehicles Operating on Roads

GB 8410 Flammability of Automotive Interior Materials

GB 11550 Strength Requirement and Test of Automobile Seats Head Restraints

GB 11551 The Protection of the Occupant in the Event of a Frontal Collision for

Passenger Car

GB 11552 Passenger Car - Internal Protrusions

GB 14167 Safety-Belt Anchorages, ISOFIX Anchorages Systems and ISOFIX Top

Tether Anchorages for Vehicles

GB 15083 Strength Requirement and Test of Automobile Seats their Anchorages

and any Head Restraints

GB/T 15089 Classification of Power-Driven Vehicles and Trailer

GB/T 29120 Procedure for H-Point and R-Point Determination

GB/T 30512 Requirements for Prohibited Substances on Automobiles

3.7 Side-facing seat

The seat used in the running of the vehicle, arranged to the side of the vehicle. The

angle between the symmetrical vertical plane of the seat and the symmetrical vertical

plane of the vehicle is 90°±10°.

3.8 Rearward-facing seat

The seat used in the running of the vehicle, arranged to the rear part of the vehicle.

The angle between the symmetrical vertical plane of the seat and the symmetrical

vertical plane of the vehicle is 0°±10°.

3.9 Seat trim cover assy.

The seat covering that is the outermost layer of the seat made of fabric, leather and

other materials for protection and decoration.

3.10 Seat covering

The outer surface of the seat trim cover.

3.11 Map pocket/insert

The pocket for inserting books, newspapers, etc. on the back or side of the seat.

4 Technical Requirements

4.1 General requirements

4.1.1 The seat shall meet the requirements of this Standard, and be manufactured in

accordance with the product drawings and technical documents approved by the

prescribed procedures.

4.1.2 If the seat and headrest surfaces are covered by a material with a Shore

hardness (A) of less than 50; its rigid parts shall meet the requirements of GB 11552

or GB 15083.

4.1.3 All trim covers shall meet the requirements for sewing and appearance according

to corresponding drawings and technical documents.

4.1.4 The trim covers of the seat shall be free of pollution, damage, crack, and crack

of the seam.

4.1.5 The seat covering shall be free of unacceptable wrinkles, bulging, stitch bending,

unevenness and the like defects as agreed between the supplier and the purchaser.

4.2.5 Seat system strength

The seat system strength shall meet the requirements of GB 15083.

4.2.6 Frontal collision

During and after the sled accelerated or decelerated test, the dummy can be restrained

by the seat belt assembly, and he fixing device between the seat and the floor is not

allowed to be completely separated; the seat parts are not allowed to be loose or break,

the locking device is not allowed to fail; the permanent deformation is allowed to occur

during the collision without increasing the degree of damage; no sharp corners are

allowed to generated to additionally injure the occupants in the vehicles; the

displacement device that allows or facilitates the passage of the occupant shall be in

operation and at least guaranteed to be unlocked once, and the seat and the portion

of the seat can be moved as needed; the headrest remains in the original locked

position. For test method, see 5.1.

4.2.7 Rear collision

During and after the sled accelerated or decelerated test, the dummy can be restrained

by the seat belt assembly, and he fixing device between the seat and the floor is not

allowed to be completely separated. The seat parts are not allowed to be loose or

break. The backrest can be tilted with the maximum tilt angle of backrest meeting the

requirements of drawings and technical documents. The locking device of the seat is

not allowed to be loose, and maintain its function intact; the permanent deformation is

allowed to occur during the collision without increasing the degree of damage; no sharp

corners are allowed to generated to additionally injure the occupants in the vehicles;

the displacement device that allows or facilitates the passage of the occupant shall be

in operation and at least guaranteed to be unlocked once, and the seat and the portion

of the seat can be moved as needed; the locking device of the backrest shall still

maintain functions intact; the headrest remains in the original locked position. For test

method, see 5.2.

4.2.8 Low-speed rear collision neck protection (whiplash test)

The low-speed rear collision neck protection (whiplash test) can refer to ISO

17373:2005; the evalua...

Get QUOTATION in 1-minute: Click QC/T 740-2017

Historical versions: QC/T 740-2017

Preview True-PDF (Reload/Scroll if blank)

QC/T 740-2017: Seat assembly of passenger car

QC/T 740-2017

AUTOMOTIVE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.040.60

T 26

Replacing QC/T 740-2005

Seat Assembly of Passenger Car

ISSUED ON: APRIL 12, 2017

IMPLEMENTED ON: OCTOBER 01, 2017

Issued by: Ministry of Industry and Information Technology of PRC

Ministry of Industry and Information Technology of the PRC

April 12, 2017

Attachment:

Number, name and date of implementation of 22 automotive industry

standards

No. Standard number Standard name Number of standard replaced

Date of

implementation

301 QC/T 727-2017 Instrument for automobile and motorcycle QC/T 727-2007 2017-10-01

302 QC/T 803-2017 Oxygen sensor for automobile QC/T 803.1-2008 2017-10-01

303 QC/T 1072-2017 Gear position sensor for automobiles 2017-10-01

304 QC/T 1073.1-2017 Accelerometers for automobiles - Part 1: Linear accelerometers 2017-10-01

305 QC/T 1074-2017 Technical specifications for automotive parts remanufacturing products 2017-10-01

306 QC/T 1075-2017

Technical conditions for metal

honeycomb carrier of exhaust catalytic

converter

2017-10-01

307 QC/T 777-2017

Technical conditions for

electromagnetic fan clutch of

automobile

QC/T 777-2007 2017-10-01

308 QC/T 1076-2017

Performance requirements and test

methods for continuously variable

transmission (CVT)

2017-10-01

309 QC/T 1077-2017

Terminology and definitions for

classification of automatic control

transmission for automobile

2017-10-01

310 QC/T 1078-2017 Advertising vehicle 2017-10-01

311 QC/T 1079-2017 Suction and delivery vehicle 2017-10-01

312 QC/T 1080-2017 Mobile loudspeaker for popularization of science 2017-10-01

313 QC/T 1081-2017 Electric power steering device for automobile 2017-10-01

314 QC/T 1082-2017 Motor for electric power steering device of automobile 2017-10-01

315 QC/T 1083-2017 Controller for electric power steering device of automobile 2017-10-01

Table of Contents

Foreword ... 6

1 Scope ... 8

2 Normative References ... 8

3 Terms and Definitions ... 9

4 Technical Requirements ... 10

5 Test Methods ... 16

6 Inspection Rules ... 28

7 Marking, Package, Transportation and Storage ... 31

Seat Assembly of Passenger Car

1 Scope

This Standard specifies the terms and definitions, technical requirements, test

methods, inspection rules, marking, package, transportation and storage for the seat

assembly of passenger car.

This Standard is applicable to the seat assembly of Type-M1 vehicle.

This Standard is not applicable to the folding seat, side-facing seat, and rearward-

facing seat.

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) are applicable to this document.

GB 7258 Safety Specifications for Power-Driven Vehicles Operating on Roads

GB 8410 Flammability of Automotive Interior Materials

GB 11550 Strength Requirement and Test of Automobile Seats Head Restraints

GB 11551 The Protection of the Occupant in the Event of a Frontal Collision for

Passenger Car

GB 11552 Passenger Car - Internal Protrusions

GB 14167 Safety-Belt Anchorages, ISOFIX Anchorages Systems and ISOFIX Top

Tether Anchorages for Vehicles

GB 15083 Strength Requirement and Test of Automobile Seats their Anchorages

and any Head Restraints

GB/T 15089 Classification of Power-Driven Vehicles and Trailer

GB/T 29120 Procedure for H-Point and R-Point Determination

GB/T 30512 Requirements for Prohibited Substances on Automobiles

3.7 Side-facing seat

The seat used in the running of the vehicle, arranged to the side of the vehicle. The

angle between the symmetrical vertical plane of the seat and the symmetrical vertical

plane of the vehicle is 90°±10°.

3.8 Rearward-facing seat

The seat used in the running of the vehicle, arranged to the rear part of the vehicle.

The angle between the symmetrical vertical plane of the seat and the symmetrical

vertical plane of the vehicle is 0°±10°.

3.9 Seat trim cover assy.

The seat covering that is the outermost layer of the seat made of fabric, leather and

other materials for protection and decoration.

3.10 Seat covering

The outer surface of the seat trim cover.

3.11 Map pocket/insert

The pocket for inserting books, newspapers, etc. on the back or side of the seat.

4 Technical Requirements

4.1 General requirements

4.1.1 The seat shall meet the requirements of this Standard, and be manufactured in

accordance with the product drawings and technical documents approved by the

prescribed procedures.

4.1.2 If the seat and headrest surfaces are covered by a material with a Shore

hardness (A) of less than 50; its rigid parts shall meet the requirements of GB 11552

or GB 15083.

4.1.3 All trim covers shall meet the requirements for sewing and appearance according

to corresponding drawings and technical documents.

4.1.4 The trim covers of the seat shall be free of pollution, damage, crack, and crack

of the seam.

4.1.5 The seat covering shall be free of unacceptable wrinkles, bulging, stitch bending,

unevenness and the like defects as agreed between the supplier and the purchaser.

4.2.5 Seat system strength

The seat system strength shall meet the requirements of GB 15083.

4.2.6 Frontal collision

During and after the sled accelerated or decelerated test, the dummy can be restrained

by the seat belt assembly, and he fixing device between the seat and the floor is not

allowed to be completely separated; the seat parts are not allowed to be loose or break,

the locking device is not allowed to fail; the permanent deformation is allowed to occur

during the collision without increasing the degree of damage; no sharp corners are

allowed to generated to additionally injure the occupants in the vehicles; the

displacement device that allows or facilitates the passage of the occupant shall be in

operation and at least guaranteed to be unlocked once, and the seat and the portion

of the seat can be moved as needed; the headrest remains in the original locked

position. For test method, see 5.1.

4.2.7 Rear collision

During and after the sled accelerated or decelerated test, the dummy can be restrained

by the seat belt assembly, and he fixing device between the seat and the floor is not

allowed to be completely separated. The seat parts are not allowed to be loose or

break. The backrest can be tilted with the maximum tilt angle of backrest meeting the

requirements of drawings and technical documents. The locking device of the seat is

not allowed to be loose, and maintain its function intact; the permanent deformation is

allowed to occur during the collision without increasing the degree of damage; no sharp

corners are allowed to generated to additionally injure the occupants in the vehicles;

the displacement device that allows or facilitates the passage of the occupant shall be

in operation and at least guaranteed to be unlocked once, and the seat and the portion

of the seat can be moved as needed; the locking device of the backrest shall still

maintain functions intact; the headrest remains in the original locked position. For test

method, see 5.2.

4.2.8 Low-speed rear collision neck protection (whiplash test)

The low-speed rear collision neck protection (whiplash test) can refer to ISO

17373:2005; the evalua...

Share