1

/

of

11

www.ChineseStandard.us -- Field Test Asia Pte. Ltd.

SH/T 0805-2008 English PDF (SH/T0805-2008)

SH/T 0805-2008 English PDF (SH/T0805-2008)

Regular price

$150.00

Regular price

Sale price

$150.00

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

SH/T 0805-2008: Determination of the filterability of lubricating oils

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click SH/T 0805-2008 (Self-service in 1-minute)

Historical versions (Master-website): SH/T 0805-2008

Preview True-PDF (Reload/Scroll-down if blank)

SH/T 0805-2008

SH

INDUSTRY STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 75.100

E34

Determination of the filterability of lubricating oils

(ISO 13357-2.2005, Petroleum products - Determination of the filterability of

lubricating oils - Part 1. Procedure for dry oils; ISO 13357-1.2002, Part 2.

Procedure for oils in the presence of water, MOD)

ISSUED ON. APRIL 23, 2008

IMPLEMENTED ON. OCTOBER 01, 2008

Issued by. National Development and Reform Commission of PRC

Table of Contents

Foreword ... 3

Introduction ... 4

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Method one (dry method) ... 6

5 Method two (wet method) ... 13

6 Test report ... 15

Annex A ... 16

Annex B ... 17

Foreword

This Standard modifies and adopts international standards ISO 13357-2.2005

“Petroleum products – Determination method of the filterability of lubricating oils –

Part 2. Procedure for dry oils” and ISO 13357-1.2002 “Petroleum products –

Determination method of the filterability of lubricating oils – Part 1. Procedure for oils

in the presence of water”.

The method one in this Standard is redrafted according to the standard ISO

13357-2.2005; the method two is redrafted according to the standard ISO13357

-1.2002.

In order to suit to the national condition of China, this Standard is partly modified when

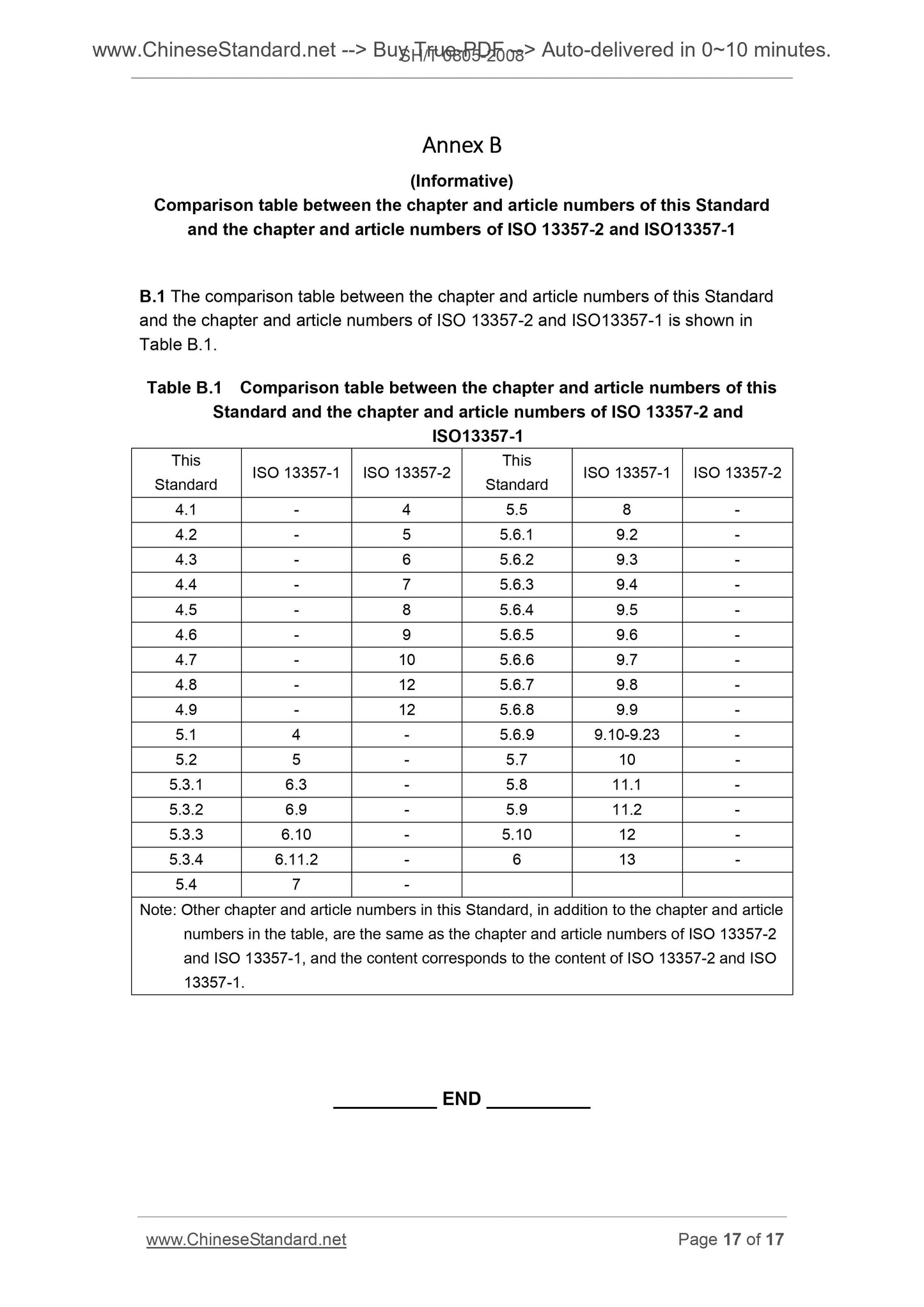

adopting ISO 13357-2.2005 and ISO13357-1.2002. The comparison table between

the chapter and article numbers of this Standard and the chapter and article numbers

of ISO 13357-2.2005 and ISO13357-1.2002 is shown in Annex B. The main technical

differences between this Standard AND ISO 13357-2.2005 and ISO13357-1.2002 are

as follows.

— CHANGE the 70°C ± 10°C of the oven precision in method one in ISO

13357-2.2005 TO 70°C ± 2°C. The change is done to simplify the test device for

the 70°C ± 2°C of the oven precision used in method two.

— CHANGE some of reference standards TO current national standards in China.

— MODIFY the repeatability and reproducibility textual representation according to

the habits in China.

Annex A and Annex B in this Standard are informative.

This Standard was proposed by China Petrochemical Corporation (Sinopec Group).

This Standard shall be under the jurisdiction of Research Institute of Petroleum and

Petrochemicals of China Petrochemical Corporation.

Drafting organizations of this Standard. Dalian Lubricant Research and Development

Center of PetroChina Company Limited, and Lubricant Research and Development

Center (Beijing) of China Petrochemical Corporation.

Main drafters of this Standard. Li Chuncheng, Cui Haiou, and Yanghua.

Introduction

As a lubricant in hydraulic system, the main function of the fluid is to reduce the wear

and tear of mechanical components. Therefore, lowering the concentration of the hard

particle contamination in the system is very important, especially in the sophisticated

systems with small gap. Generally, the particulate contaminants are removed through

filters. The capacity of not being clogged by hydraulic oil when it passes through filters

with certain specification is called filterability. ISO 13357-1 describes the laboratory

determination methods for evaluating the filterability of the mineral oil after being

heated in the presence of water. ISO 13357-2 describes the laboratory determination

method for evaluating the filterability of the mineral oil under dry environment. The

filterability defined here is not the physical property of oil products, but reflects the

performance assessment of oils at work.

Each part of the ISO 13357 method contains two evaluation methods, known as the

"stages". Stage I utilizes the ratio between the mean flow rate of the fluid through the

filtration membrane and the initial flow rate to evaluate the filterability. When the fluid

has good filterability at stage I, while has poor filterability in stage II (see below), the

use of it will not generate performance problems generally, unless the very

sophisticated system filter is used.

Stage II uses the ratio between the mean flow rate of the fluid through the filtration

membrane and the initial flow rate to evaluate the filterability. It is generally believed

that the test conditions at stage II are more demanding, and more sensitive to the gel

and fine debris in the oil products. Especially in the aging of oil or the heating at high

temperatures, the debris and gel are easier to generate. If oils at stage II has good

filterability, it will not arise filtration problem even under extreme conditions or under

the condition where the precision filter (pore diameter is less than 5μm) is used.

Therefore, this kind of oil product is applicable to more demanding hydraulic and

lubrication systems.

This test method can be used to evaluate mineral oil with ISO viscosity grade being

not higher than 100, and does not apply to oil products with higher viscosity grade. At

present, the actual reason has not been found (the highest viscosity of oil products

used in reality is 220). Similarly, the applicable scope of this method can also be

expanded to fluids other than mineral oils. However, some fluids, such as fire

resistance fluid, are not compatible with the filtration membrane specified in this

method. For these fluids, even the filtration membrane with the same pore size and

same pore density are used, the obtained test data can only be used for comparison.

Determination of the Filterability of Lubricating Oils

Warning. this Standard may involves certain hazardous materials, equipment, and

operations. However, the recommendations about relevant safety problem of

equipment are not ALL been proposed. Therefore, the user has the responsibility to

establish appropriate safety and protective measures before using this Standard, and

determine the corresponding management system.

1 Scope

1.1 This Standard specifies the determination of filterability of lubricating oil taking

mineral oil as base oil, especially the method for evaluating the filterability of hydraulic

oil in hydraulic system. This Standard applies to oils with viscosity grade being not

higher than 100 according to the viscosity classification provisions of GB/T 3141. This

Standard does not apply to liquids taking other materials as base material, such as

fire resistant fluid, because there may be compatibility problems between it and the

filtration membrane used in this Standard. This Standard does not apply to hydraulic

oil with special properties, because it may contain insolvable additives or partially

dissolved additives or special macromolecular substances.

1.2 Method one. dry method; it is suitable for evaluating the filterability of lubricating

oils under dry conditions.

1.3 Method two. wet method; it is suitable for evaluating the filterability of lubricating

oils in the presence of water.

2 Normative references

The provisions in following documents become the provisions of this Standard through

reference in this Standard. For dated references, the subsequent amendments

(excluding corrections) or revisions do not apply to this Standard, however, parties

who reach an agreement based on this Standard are encouraged to study if the latest

versions of these documents are applicable. For undated references, the latest edition

of the referenced document applies.

GB/T 3141 Industrial liquid lubricants - ISO viscosity classification (GB/T

3141-1994, eqv ISO 3448.1992)

GB/T 4756 Petroleum liquids - Manual sampling (GB/T 4756-1998, eqv ISO 3170.

1988)

GB/T 6682 Water for analytical laboratory use - Specification and test methods

(GB/T 6682-1992, neq ISO 3696.1987)

GB/T 7305 Standard test method for water separability of petroleum oils and

synthetic fluids

3 Terms and definitions

Following terms and definitions apply to this Standard.

3.1

Filterability

The specific volume ratio of the filtration sample (stage I) or the filtration rate ratio of

the sample (stage II), expressed by percentage.

3.2

Stage I filterability

The ratio between the volume of filtration sample and 240mL, under the ideal

condition where there is no membrane clogging it, expressed by percentage.

3.3

Stage II filterability

The ratio BETWEEN the flow rate closing to the start of the sample AND the flow rate

when filtering 200mL~300mL, expressed by percentage.

4 Method one (dry method)

4.1 Method outline

Under specified conditions, MAKE the sample to pass through the filtration membrane

with average pore size of 0.8μm; RECORD the time that is used to filter specified

volume of sample. CALCULATE the filterability through the ratio between the initial

filtration rate and the filtration rate of the last 100mL; TAKE the average value of three

determined values as the test result.

Note. The filtration rate is constant under ideal condition.

4.2 Reagents and ...

SH/T 0805-2008

SH

INDUSTRY STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 75.100

E34

Determination of the filterability of lubricating oils

(ISO 13357-2.2005, Petroleum products - Determination of the filterability of

lubricating oils - Part 1. Procedure for dry oils; ISO 13357-1.2002, Part 2.

Procedure for oils in the presence of water, MOD)

ISSUED ON. APRIL 23, 2008

IMPLEMENTED ON. OCTOBER 01, 2008

Issued by. National Development and Reform Commission of PRC

Table of Contents

Foreword ... 3

Introduction ... 4

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Method one (dry method) ... 6

5 Method two (wet method) ... 13

6 Test report ... 15

Annex A ... 16

Annex B ... 17

Foreword

This Standard modifies and adopts international standards ISO 13357-2.2005

“Petroleum products – Determination method of the filterability of lubricating oils –

Part 2. Procedure for dry oils” and ISO 13357-1.2002 “Petroleum products –

Determination method of the filterability of lubricating oils – Part 1. Procedure for oils

in the presence of water”.

The method one in this Standard is redrafted according to the standard ISO

13357-2.2005; the method two is redrafted according to the standard ISO13357

-1.2002.

In order to suit to the national condition of China, this Standard is partly modified when

adopting ISO 13357-2.2005 and ISO13357-1.2002. The comparison table between

the chapter and article numbers of this Standard and the chapter and article numbers

of ISO 13357-2.2005 and ISO13357-1.2002 is shown in Annex B. The main technical

differences between this Standard AND ISO 13357-2.2005 and ISO13357-1.2002 are

as follows.

— CHANGE the 70°C ± 10°C of the oven precision in method one in ISO

13357-2.2005 TO 70°C ± 2°C. The change is done to simplify the test device for

the 70°C ± 2°C of the oven precision used in method two.

— CHANGE some of reference standards TO current national standards in China.

— MODIFY the repeatability and reproducibility textual representation according to

the habits in China.

Annex A and Annex B in this Standard are informative.

This Standard was proposed by China Petrochemical Corporation (Sinopec Group).

This Standard shall be under the jurisdiction of Research Institute of Petroleum and

Petrochemicals of China Petrochemical Corporation.

Drafting organizations of this Standard. Dalian Lubricant Research and Development

Center of PetroChina Company Limited, and Lubricant Research and Development

Center (Beijing) of China Petrochemical Corporation.

Main drafters of this Standard. Li Chuncheng, Cui Haiou, and Yanghua.

Introduction

As a lubricant in hydraulic system, the main function of the fluid is to reduce the wear

and tear of mechanical components. Therefore, lowering the concentration of the hard

particle contamination in the system is very important, especially in the sophisticated

systems with small gap. Generally, the particulate contaminants are removed through

filters. The capacity of not being clogged by hydraulic oil when it passes through filters

with certain specification is called filterability. ISO 13357-1 describes the laboratory

determination methods for evaluating the filterability of the mineral oil after being

heated in the presence of water. ISO 13357-2 describes the laboratory determination

method for evaluating the filterability of the mineral oil under dry environment. The

filterability defined here is not the physical property of oil products, but reflects the

performance assessment of oils at work.

Each part of the ISO 13357 method contains two evaluation methods, known as the

"stages". Stage I utilizes the ratio between the mean flow rate of the fluid through the

filtration membrane and the initial flow rate to evaluate the filterability. When the fluid

has good filterability at stage I, while has poor filterability in stage II (see below), the

use of it will not generate performance problems generally, unless the very

sophisticated system filter is used.

Stage II uses the ratio between the mean flow rate of the fluid through the filtration

membrane and the initial flow rate to evaluate the filterability. It is generally believed

that the test conditions at stage II are more demanding, and more sensitive to the gel

and fine debris in the oil products. Especially in the aging of oil or the heating at high

temperatures, the debris and gel are easier to generate. If oils at stage II has good

filterability, it will not arise filtration problem even under extreme conditions or under

the condition where the precision filter (pore diameter is less than 5μm) is used.

Therefore, this kind of oil product is applicable to more demanding hydraulic and

lubrication systems.

This test method can be used to evaluate mineral oil with ISO viscosity grade being

not higher than 100, and does not apply to oil products with higher viscosity grade. At

present, the actual reason has not been found (the highest viscosity of oil products

used in reality is 220). Similarly, the applicable scope of this method can also be

expanded to fluids ot...

Delivery: 9 seconds. Download (& Email) true-PDF + Invoice.

Get Quotation: Click SH/T 0805-2008 (Self-service in 1-minute)

Historical versions (Master-website): SH/T 0805-2008

Preview True-PDF (Reload/Scroll-down if blank)

SH/T 0805-2008

SH

INDUSTRY STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 75.100

E34

Determination of the filterability of lubricating oils

(ISO 13357-2.2005, Petroleum products - Determination of the filterability of

lubricating oils - Part 1. Procedure for dry oils; ISO 13357-1.2002, Part 2.

Procedure for oils in the presence of water, MOD)

ISSUED ON. APRIL 23, 2008

IMPLEMENTED ON. OCTOBER 01, 2008

Issued by. National Development and Reform Commission of PRC

Table of Contents

Foreword ... 3

Introduction ... 4

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Method one (dry method) ... 6

5 Method two (wet method) ... 13

6 Test report ... 15

Annex A ... 16

Annex B ... 17

Foreword

This Standard modifies and adopts international standards ISO 13357-2.2005

“Petroleum products – Determination method of the filterability of lubricating oils –

Part 2. Procedure for dry oils” and ISO 13357-1.2002 “Petroleum products –

Determination method of the filterability of lubricating oils – Part 1. Procedure for oils

in the presence of water”.

The method one in this Standard is redrafted according to the standard ISO

13357-2.2005; the method two is redrafted according to the standard ISO13357

-1.2002.

In order to suit to the national condition of China, this Standard is partly modified when

adopting ISO 13357-2.2005 and ISO13357-1.2002. The comparison table between

the chapter and article numbers of this Standard and the chapter and article numbers

of ISO 13357-2.2005 and ISO13357-1.2002 is shown in Annex B. The main technical

differences between this Standard AND ISO 13357-2.2005 and ISO13357-1.2002 are

as follows.

— CHANGE the 70°C ± 10°C of the oven precision in method one in ISO

13357-2.2005 TO 70°C ± 2°C. The change is done to simplify the test device for

the 70°C ± 2°C of the oven precision used in method two.

— CHANGE some of reference standards TO current national standards in China.

— MODIFY the repeatability and reproducibility textual representation according to

the habits in China.

Annex A and Annex B in this Standard are informative.

This Standard was proposed by China Petrochemical Corporation (Sinopec Group).

This Standard shall be under the jurisdiction of Research Institute of Petroleum and

Petrochemicals of China Petrochemical Corporation.

Drafting organizations of this Standard. Dalian Lubricant Research and Development

Center of PetroChina Company Limited, and Lubricant Research and Development

Center (Beijing) of China Petrochemical Corporation.

Main drafters of this Standard. Li Chuncheng, Cui Haiou, and Yanghua.

Introduction

As a lubricant in hydraulic system, the main function of the fluid is to reduce the wear

and tear of mechanical components. Therefore, lowering the concentration of the hard

particle contamination in the system is very important, especially in the sophisticated

systems with small gap. Generally, the particulate contaminants are removed through

filters. The capacity of not being clogged by hydraulic oil when it passes through filters

with certain specification is called filterability. ISO 13357-1 describes the laboratory

determination methods for evaluating the filterability of the mineral oil after being

heated in the presence of water. ISO 13357-2 describes the laboratory determination

method for evaluating the filterability of the mineral oil under dry environment. The

filterability defined here is not the physical property of oil products, but reflects the

performance assessment of oils at work.

Each part of the ISO 13357 method contains two evaluation methods, known as the

"stages". Stage I utilizes the ratio between the mean flow rate of the fluid through the

filtration membrane and the initial flow rate to evaluate the filterability. When the fluid

has good filterability at stage I, while has poor filterability in stage II (see below), the

use of it will not generate performance problems generally, unless the very

sophisticated system filter is used.

Stage II uses the ratio between the mean flow rate of the fluid through the filtration

membrane and the initial flow rate to evaluate the filterability. It is generally believed

that the test conditions at stage II are more demanding, and more sensitive to the gel

and fine debris in the oil products. Especially in the aging of oil or the heating at high

temperatures, the debris and gel are easier to generate. If oils at stage II has good

filterability, it will not arise filtration problem even under extreme conditions or under

the condition where the precision filter (pore diameter is less than 5μm) is used.

Therefore, this kind of oil product is applicable to more demanding hydraulic and

lubrication systems.

This test method can be used to evaluate mineral oil with ISO viscosity grade being

not higher than 100, and does not apply to oil products with higher viscosity grade. At

present, the actual reason has not been found (the highest viscosity of oil products

used in reality is 220). Similarly, the applicable scope of this method can also be

expanded to fluids other than mineral oils. However, some fluids, such as fire

resistance fluid, are not compatible with the filtration membrane specified in this

method. For these fluids, even the filtration membrane with the same pore size and

same pore density are used, the obtained test data can only be used for comparison.

Determination of the Filterability of Lubricating Oils

Warning. this Standard may involves certain hazardous materials, equipment, and

operations. However, the recommendations about relevant safety problem of

equipment are not ALL been proposed. Therefore, the user has the responsibility to

establish appropriate safety and protective measures before using this Standard, and

determine the corresponding management system.

1 Scope

1.1 This Standard specifies the determination of filterability of lubricating oil taking

mineral oil as base oil, especially the method for evaluating the filterability of hydraulic

oil in hydraulic system. This Standard applies to oils with viscosity grade being not

higher than 100 according to the viscosity classification provisions of GB/T 3141. This

Standard does not apply to liquids taking other materials as base material, such as

fire resistant fluid, because there may be compatibility problems between it and the

filtration membrane used in this Standard. This Standard does not apply to hydraulic

oil with special properties, because it may contain insolvable additives or partially

dissolved additives or special macromolecular substances.

1.2 Method one. dry method; it is suitable for evaluating the filterability of lubricating

oils under dry conditions.

1.3 Method two. wet method; it is suitable for evaluating the filterability of lubricating

oils in the presence of water.

2 Normative references

The provisions in following documents become the provisions of this Standard through

reference in this Standard. For dated references, the subsequent amendments

(excluding corrections) or revisions do not apply to this Standard, however, parties

who reach an agreement based on this Standard are encouraged to study if the latest

versions of these documents are applicable. For undated references, the latest edition

of the referenced document applies.

GB/T 3141 Industrial liquid lubricants - ISO viscosity classification (GB/T

3141-1994, eqv ISO 3448.1992)

GB/T 4756 Petroleum liquids - Manual sampling (GB/T 4756-1998, eqv ISO 3170.

1988)

GB/T 6682 Water for analytical laboratory use - Specification and test methods

(GB/T 6682-1992, neq ISO 3696.1987)

GB/T 7305 Standard test method for water separability of petroleum oils and

synthetic fluids

3 Terms and definitions

Following terms and definitions apply to this Standard.

3.1

Filterability

The specific volume ratio of the filtration sample (stage I) or the filtration rate ratio of

the sample (stage II), expressed by percentage.

3.2

Stage I filterability

The ratio between the volume of filtration sample and 240mL, under the ideal

condition where there is no membrane clogging it, expressed by percentage.

3.3

Stage II filterability

The ratio BETWEEN the flow rate closing to the start of the sample AND the flow rate

when filtering 200mL~300mL, expressed by percentage.

4 Method one (dry method)

4.1 Method outline

Under specified conditions, MAKE the sample to pass through the filtration membrane

with average pore size of 0.8μm; RECORD the time that is used to filter specified

volume of sample. CALCULATE the filterability through the ratio between the initial

filtration rate and the filtration rate of the last 100mL; TAKE the average value of three

determined values as the test result.

Note. The filtration rate is constant under ideal condition.

4.2 Reagents and ...

SH/T 0805-2008

SH

INDUSTRY STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 75.100

E34

Determination of the filterability of lubricating oils

(ISO 13357-2.2005, Petroleum products - Determination of the filterability of

lubricating oils - Part 1. Procedure for dry oils; ISO 13357-1.2002, Part 2.

Procedure for oils in the presence of water, MOD)

ISSUED ON. APRIL 23, 2008

IMPLEMENTED ON. OCTOBER 01, 2008

Issued by. National Development and Reform Commission of PRC

Table of Contents

Foreword ... 3

Introduction ... 4

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Method one (dry method) ... 6

5 Method two (wet method) ... 13

6 Test report ... 15

Annex A ... 16

Annex B ... 17

Foreword

This Standard modifies and adopts international standards ISO 13357-2.2005

“Petroleum products – Determination method of the filterability of lubricating oils –

Part 2. Procedure for dry oils” and ISO 13357-1.2002 “Petroleum products –

Determination method of the filterability of lubricating oils – Part 1. Procedure for oils

in the presence of water”.

The method one in this Standard is redrafted according to the standard ISO

13357-2.2005; the method two is redrafted according to the standard ISO13357

-1.2002.

In order to suit to the national condition of China, this Standard is partly modified when

adopting ISO 13357-2.2005 and ISO13357-1.2002. The comparison table between

the chapter and article numbers of this Standard and the chapter and article numbers

of ISO 13357-2.2005 and ISO13357-1.2002 is shown in Annex B. The main technical

differences between this Standard AND ISO 13357-2.2005 and ISO13357-1.2002 are

as follows.

— CHANGE the 70°C ± 10°C of the oven precision in method one in ISO

13357-2.2005 TO 70°C ± 2°C. The change is done to simplify the test device for

the 70°C ± 2°C of the oven precision used in method two.

— CHANGE some of reference standards TO current national standards in China.

— MODIFY the repeatability and reproducibility textual representation according to

the habits in China.

Annex A and Annex B in this Standard are informative.

This Standard was proposed by China Petrochemical Corporation (Sinopec Group).

This Standard shall be under the jurisdiction of Research Institute of Petroleum and

Petrochemicals of China Petrochemical Corporation.

Drafting organizations of this Standard. Dalian Lubricant Research and Development

Center of PetroChina Company Limited, and Lubricant Research and Development

Center (Beijing) of China Petrochemical Corporation.

Main drafters of this Standard. Li Chuncheng, Cui Haiou, and Yanghua.

Introduction

As a lubricant in hydraulic system, the main function of the fluid is to reduce the wear

and tear of mechanical components. Therefore, lowering the concentration of the hard

particle contamination in the system is very important, especially in the sophisticated

systems with small gap. Generally, the particulate contaminants are removed through

filters. The capacity of not being clogged by hydraulic oil when it passes through filters

with certain specification is called filterability. ISO 13357-1 describes the laboratory

determination methods for evaluating the filterability of the mineral oil after being

heated in the presence of water. ISO 13357-2 describes the laboratory determination

method for evaluating the filterability of the mineral oil under dry environment. The

filterability defined here is not the physical property of oil products, but reflects the

performance assessment of oils at work.

Each part of the ISO 13357 method contains two evaluation methods, known as the

"stages". Stage I utilizes the ratio between the mean flow rate of the fluid through the

filtration membrane and the initial flow rate to evaluate the filterability. When the fluid

has good filterability at stage I, while has poor filterability in stage II (see below), the

use of it will not generate performance problems generally, unless the very

sophisticated system filter is used.

Stage II uses the ratio between the mean flow rate of the fluid through the filtration

membrane and the initial flow rate to evaluate the filterability. It is generally believed

that the test conditions at stage II are more demanding, and more sensitive to the gel

and fine debris in the oil products. Especially in the aging of oil or the heating at high

temperatures, the debris and gel are easier to generate. If oils at stage II has good

filterability, it will not arise filtration problem even under extreme conditions or under

the condition where the precision filter (pore diameter is less than 5μm) is used.

Therefore, this kind of oil product is applicable to more demanding hydraulic and

lubrication systems.

This test method can be used to evaluate mineral oil with ISO viscosity grade being

not higher than 100, and does not apply to oil products with higher viscosity grade. At

present, the actual reason has not been found (the highest viscosity of oil products

used in reality is 220). Similarly, the applicable scope of this method can also be

expanded to fluids ot...

Share