1

/

/

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

SJ/T 11624-2016 English PDF (SJT11624-2016)

SJ/T 11624-2016 English PDF (SJT11624-2016)

Normal fiyat

$280.00 USD

Normal fiyat

İndirimli fiyat

$280.00 USD

Birim fiyat

/

/

Kargo, ödeme sayfasında hesaplanır.

Teslim alım stok durumu yüklenemedi

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click SJ/T 11624-2016

Historical versions: SJ/T 11624-2016

Preview True-PDF (Reload/Scroll if blank)

SJ/T 11624-2016: Specifications of LED devices for LED displays

SJ/T 11624-2016

SJ

ELECTRONIC INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 31.120

L 63

Record No.:

Specifications of LED Devices for LED Displays

ISSUED ON: APRIL 05, 2016

IMPLEMENTED ON: SEPTEMBER 01, 2016

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 5

4 Classification ... 5

5 Requirements ... 6

6 Inspection Methods ... 8

7 Inspection Rules ... 11

8 Additional Instructions ... 16

Appendix A (Normative) Electrical Endurance Test ... 18

Appendix B (Normative) Test on Resistance to Welding Heat – Simulated

Reflow Soldering ... 20

Specifications of LED Devices for LED Displays

1 Scope

This Specification specifies the performance requirements, inspection methods,

inspection rules, etc. of light-emitting diode (hereinafter referred to as "LED") used in

light-emitting diode (LED) displays.

This Specification is applicable to LED used in indoor and outdoor LED displays.

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) is applicable to this document.

GB/T 2423.3 Environmental Testing for Electric and Electronic Products - Part 2:

Testing Method Test Cab: Damp Heat Steady State

GB/T 4589.1-2006 Semiconductor Devices - Part 10: Generic Specification for

Discrete Devices and Integrated Circuits

GB/T 4937-1995 Mechanical and Climatic Test Methods for Semiconductor

Devices

GB/T 11499-2001 Letter Symbols for Discrete Semiconductor Devices

GB/T 12565-1990 Semiconductor Devices Sectional Specification for

Optoelectronic Devices

GB/T 15651 Semiconductor Devices Discrete Devices and Integrated Circuits

Part 5: Optoelectronic Devices

SJ/T 11394-2009 Measure Methods of Semiconductor Light Emitting Diodes

SJ/T 11395-2009 Semiconductor Lighting Terminology

SJ/T 11400-2009 Semiconductor Optoelectronic Devices - Blank Detail

Specification for Lower-Power Light-Emitting Diodes

a) Temperature: 25°C±2°C;

b) Relative humidity: 45%~55%;

c) Air pressure: 86kPa~106kPa

6.1.2 Darkroom conditions

The darkroom conditions shall be ≤1 lx.

6.2 Appearance

Under the conditions of environmental illumination of 300 lx~1000 lx, use a 3× to 10×

magnifier for inspection.

6.3 Overall dimensions

Use measuring tools that meet the accuracy requirements for measurement.

6.4 Measuring methods of photoelectric characteristics

6.4.1 Forward voltage

It shall be carried out according to the Method-1001 in SJ/T 11394-2009.

6.4.2 Average luminous intensity

It shall be carried out according to the Method-2001 in SJ/T 11394-2009.

6.4.3 Half-intensity angle

It shall be carried out according to the Method-2002 in SJ/T 11394-2009.

6.4.4 Reverse current

It shall be carried out according to the Method-1003 in SJ/T 11394-2009.

6.4.5 Dominant wavelength

It shall be carried out according to the Method-4003 in SJ/T 11394-2009.

6.4.6 Chromaticity coordinate

It shall be carried out according to the Method-4001/4002 in SJ/T 11394-2009.

6.5 Electrostatic discharge sensitivity

The human body mode shall be carried out according to the Method-6001 in SJ/T

11394-2009.

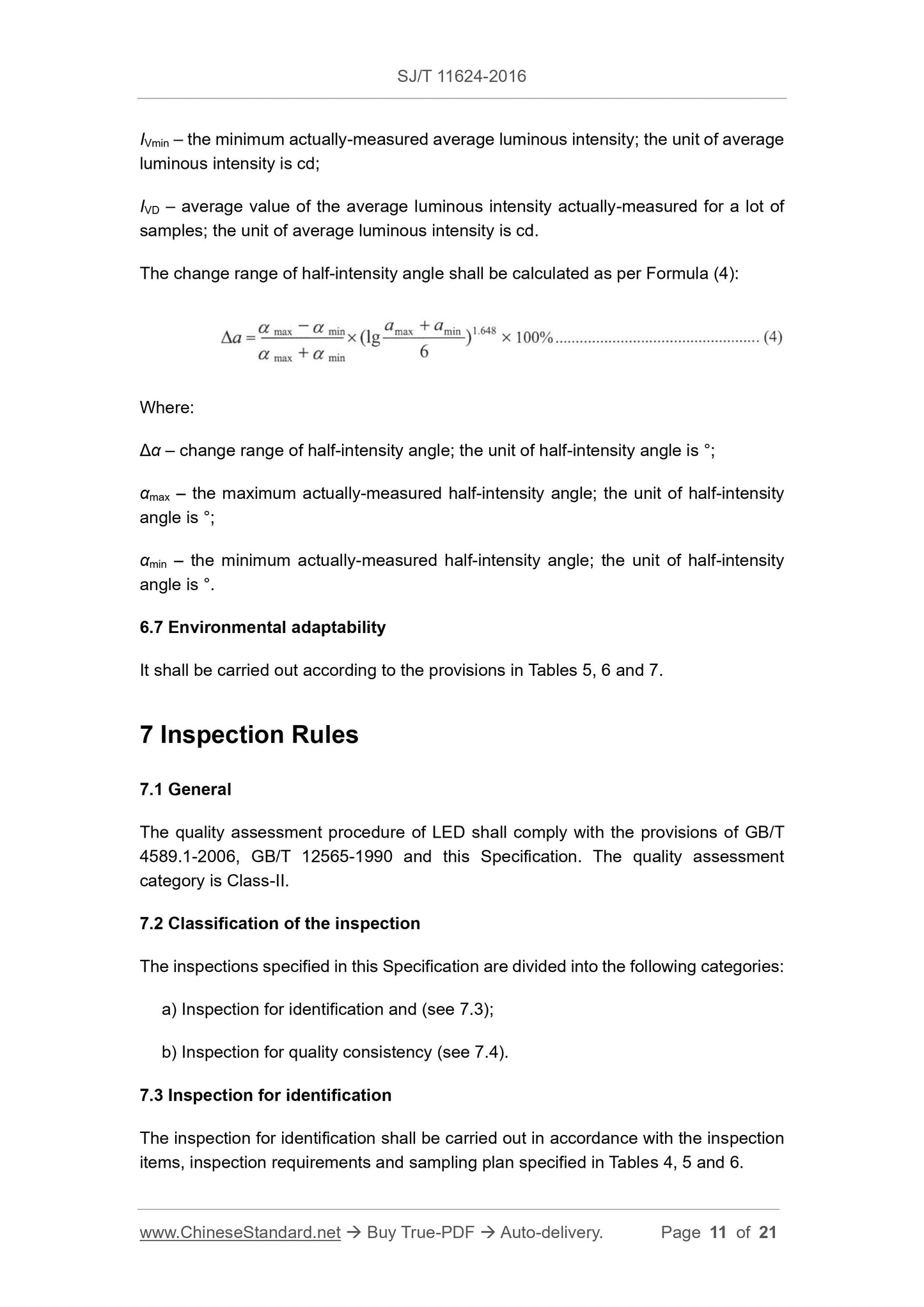

IVmin – the minimum actually-measured average luminous intensity; the unit of average

luminous intensity is cd;

IVD – average value of the average luminous intensity actually-measured for a lot of

samples; the unit of average luminous intensity is cd.

The change range of half-intensity angle shall be calculated as per Formula (4):

Where:

Δα – change range of half-intensity angle; the unit of half-intensity angle is °;

αmax – the maximum actually-measured half-intensity angle; the unit of half-intensity

angle is °;

αmin – the minimum actually-measured half-intensity angle; the unit of half-intensity

angle is °.

6.7 Environmental adaptability

It shall be carried out according to the provisions in Tables 5, 6 and 7.

7 Inspection Rules

7.1 General

The quality assessment procedure of LED shall comply with the provisions of GB/T

4589.1-2006, GB/T 12565-1990 and this Specification. The quality assessment

category is Class-II.

7.2 Classification of the inspection

The inspections specified in this Specification are divided into the following categories:

a) Inspection for identification and (see 7.3);

b) Inspection for quality consistency (see 7.4).

7.3 Inspection for identification

The inspection for identification shall be carried out in accordance with the inspection

items, inspection requirements and sampling plan specified in Tables 4, 5 and 6.

Appendix B

(Normative)

Test on Resistance to Welding Heat – Simulated

Reflow Soldering

B.1 Purpose

In order to evaluate the ability of surface-mounted LED devices to withstand welding

heat within the specified temperature and time conditions, this test is exempted from

pre-treatment, does not use flux or solder for soldering; and only simulates the reflow

soldering test procedures.

B.2 Test conditions

The conditions of the test on resistance to welding heat are as follows:

a) Maximum temperature

Class A: temperature 240°C ± 2°C;

Class B: temperature 250°C ± 2°C;

Class C: temperature 260°C ± 2°C;

b) Maximum temperature duration: 10s ± 1s;

c) Cycle: 3 times at intervals of 5 min ~ 8 min each.

B.3 Test procedures

Follow the procedures below:

a) The sample to be tested is placed on a printed circuit board, and the printed

circuit board shall have vias;

b) Test according to the reflow soldering temperature time curve and disc size given

in the LED product specification. The maximum temperature and duration shall

be in accordance with the provisions of B.2.

c) Repeat the test for three times according to the above steps, each test interval is

5 min~8 min.

Get QUOTATION in 1-minute: Click SJ/T 11624-2016

Historical versions: SJ/T 11624-2016

Preview True-PDF (Reload/Scroll if blank)

SJ/T 11624-2016: Specifications of LED devices for LED displays

SJ/T 11624-2016

SJ

ELECTRONIC INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 31.120

L 63

Record No.:

Specifications of LED Devices for LED Displays

ISSUED ON: APRIL 05, 2016

IMPLEMENTED ON: SEPTEMBER 01, 2016

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 5

4 Classification ... 5

5 Requirements ... 6

6 Inspection Methods ... 8

7 Inspection Rules ... 11

8 Additional Instructions ... 16

Appendix A (Normative) Electrical Endurance Test ... 18

Appendix B (Normative) Test on Resistance to Welding Heat – Simulated

Reflow Soldering ... 20

Specifications of LED Devices for LED Displays

1 Scope

This Specification specifies the performance requirements, inspection methods,

inspection rules, etc. of light-emitting diode (hereinafter referred to as "LED") used in

light-emitting diode (LED) displays.

This Specification is applicable to LED used in indoor and outdoor LED displays.

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) is applicable to this document.

GB/T 2423.3 Environmental Testing for Electric and Electronic Products - Part 2:

Testing Method Test Cab: Damp Heat Steady State

GB/T 4589.1-2006 Semiconductor Devices - Part 10: Generic Specification for

Discrete Devices and Integrated Circuits

GB/T 4937-1995 Mechanical and Climatic Test Methods for Semiconductor

Devices

GB/T 11499-2001 Letter Symbols for Discrete Semiconductor Devices

GB/T 12565-1990 Semiconductor Devices Sectional Specification for

Optoelectronic Devices

GB/T 15651 Semiconductor Devices Discrete Devices and Integrated Circuits

Part 5: Optoelectronic Devices

SJ/T 11394-2009 Measure Methods of Semiconductor Light Emitting Diodes

SJ/T 11395-2009 Semiconductor Lighting Terminology

SJ/T 11400-2009 Semiconductor Optoelectronic Devices - Blank Detail

Specification for Lower-Power Light-Emitting Diodes

a) Temperature: 25°C±2°C;

b) Relative humidity: 45%~55%;

c) Air pressure: 86kPa~106kPa

6.1.2 Darkroom conditions

The darkroom conditions shall be ≤1 lx.

6.2 Appearance

Under the conditions of environmental illumination of 300 lx~1000 lx, use a 3× to 10×

magnifier for inspection.

6.3 Overall dimensions

Use measuring tools that meet the accuracy requirements for measurement.

6.4 Measuring methods of photoelectric characteristics

6.4.1 Forward voltage

It shall be carried out according to the Method-1001 in SJ/T 11394-2009.

6.4.2 Average luminous intensity

It shall be carried out according to the Method-2001 in SJ/T 11394-2009.

6.4.3 Half-intensity angle

It shall be carried out according to the Method-2002 in SJ/T 11394-2009.

6.4.4 Reverse current

It shall be carried out according to the Method-1003 in SJ/T 11394-2009.

6.4.5 Dominant wavelength

It shall be carried out according to the Method-4003 in SJ/T 11394-2009.

6.4.6 Chromaticity coordinate

It shall be carried out according to the Method-4001/4002 in SJ/T 11394-2009.

6.5 Electrostatic discharge sensitivity

The human body mode shall be carried out according to the Method-6001 in SJ/T

11394-2009.

IVmin – the minimum actually-measured average luminous intensity; the unit of average

luminous intensity is cd;

IVD – average value of the average luminous intensity actually-measured for a lot of

samples; the unit of average luminous intensity is cd.

The change range of half-intensity angle shall be calculated as per Formula (4):

Where:

Δα – change range of half-intensity angle; the unit of half-intensity angle is °;

αmax – the maximum actually-measured half-intensity angle; the unit of half-intensity

angle is °;

αmin – the minimum actually-measured half-intensity angle; the unit of half-intensity

angle is °.

6.7 Environmental adaptability

It shall be carried out according to the provisions in Tables 5, 6 and 7.

7 Inspection Rules

7.1 General

The quality assessment procedure of LED shall comply with the provisions of GB/T

4589.1-2006, GB/T 12565-1990 and this Specification. The quality assessment

category is Class-II.

7.2 Classification of the inspection

The inspections specified in this Specification are divided into the following categories:

a) Inspection for identification and (see 7.3);

b) Inspection for quality consistency (see 7.4).

7.3 Inspection for identification

The inspection for identification shall be carried out in accordance with the inspection

items, inspection requirements and sampling plan specified in Tables 4, 5 and 6.

Appendix B

(Normative)

Test on Resistance to Welding Heat – Simulated

Reflow Soldering

B.1 Purpose

In order to evaluate the ability of surface-mounted LED devices to withstand welding

heat within the specified temperature and time conditions, this test is exempted from

pre-treatment, does not use flux or solder for soldering; and only simulates the reflow

soldering test procedures.

B.2 Test conditions

The conditions of the test on resistance to welding heat are as follows:

a) Maximum temperature

Class A: temperature 240°C ± 2°C;

Class B: temperature 250°C ± 2°C;

Class C: temperature 260°C ± 2°C;

b) Maximum temperature duration: 10s ± 1s;

c) Cycle: 3 times at intervals of 5 min ~ 8 min each.

B.3 Test procedures

Follow the procedures below:

a) The sample to be tested is placed on a printed circuit board, and the printed

circuit board shall have vias;

b) Test according to the reflow soldering temperature time curve and disc size given

in the LED product specification. The maximum temperature and duration shall

be in accordance with the provisions of B.2.

c) Repeat the test for three times according to the above steps, each test interval is

5 min~8 min.

Share