1

/

af

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

QC/T 29096-2014 English PDF (QCT29096-2014)

QC/T 29096-2014 English PDF (QCT29096-2014)

Normalpris

$135.00 USD

Normalpris

Udsalgspris

$135.00 USD

Stykpris

/

pr.

Levering beregnes ved betaling.

Tilgængelighed for afhentning kunne ikke indlæses

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click QC/T 29096-2014

Historical versions: QC/T 29096-2014

Preview True-PDF (Reload/Scroll if blank)

QC/T 29096-2014: The bench test methods of automobile steering gear

QC/T 29096-2014

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.040.50

T 23

Replacing QC/T 29096-1992

The bench test methods of automobile steering gear

ISSUED ON: MAY 06, 2014

IMPLEMENTED ON: OCTOBER 01, 2014

Issued by: Ministry of Industry and Information Technology of the

People's Republic of China

Table of Contents

Foreword ... 7

1 Scope ... 9

2 Normative references ... 9

3 Terms and definitions ... 9

4 General requirements ... 9

5 Test methods ... 10

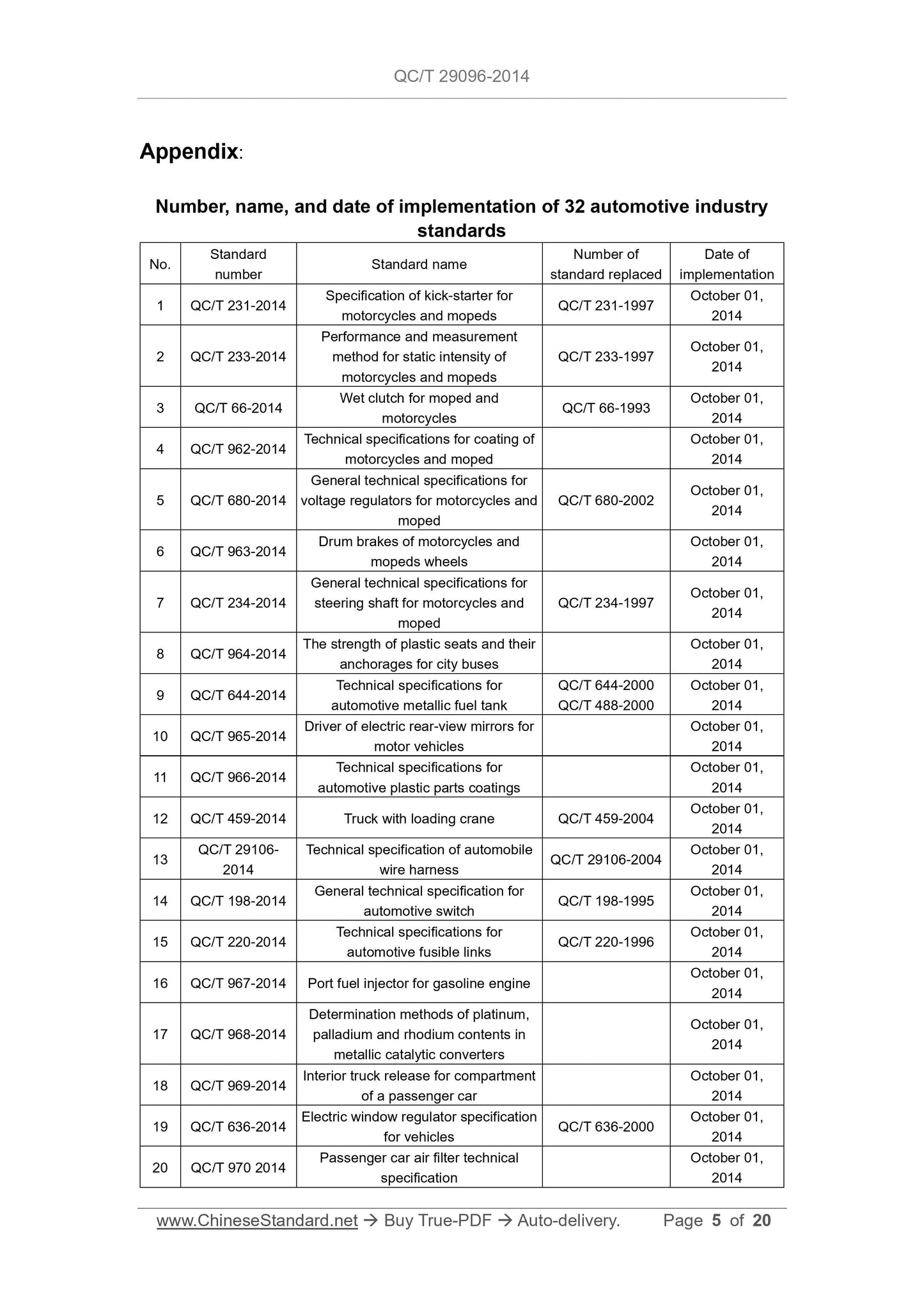

Appendix:

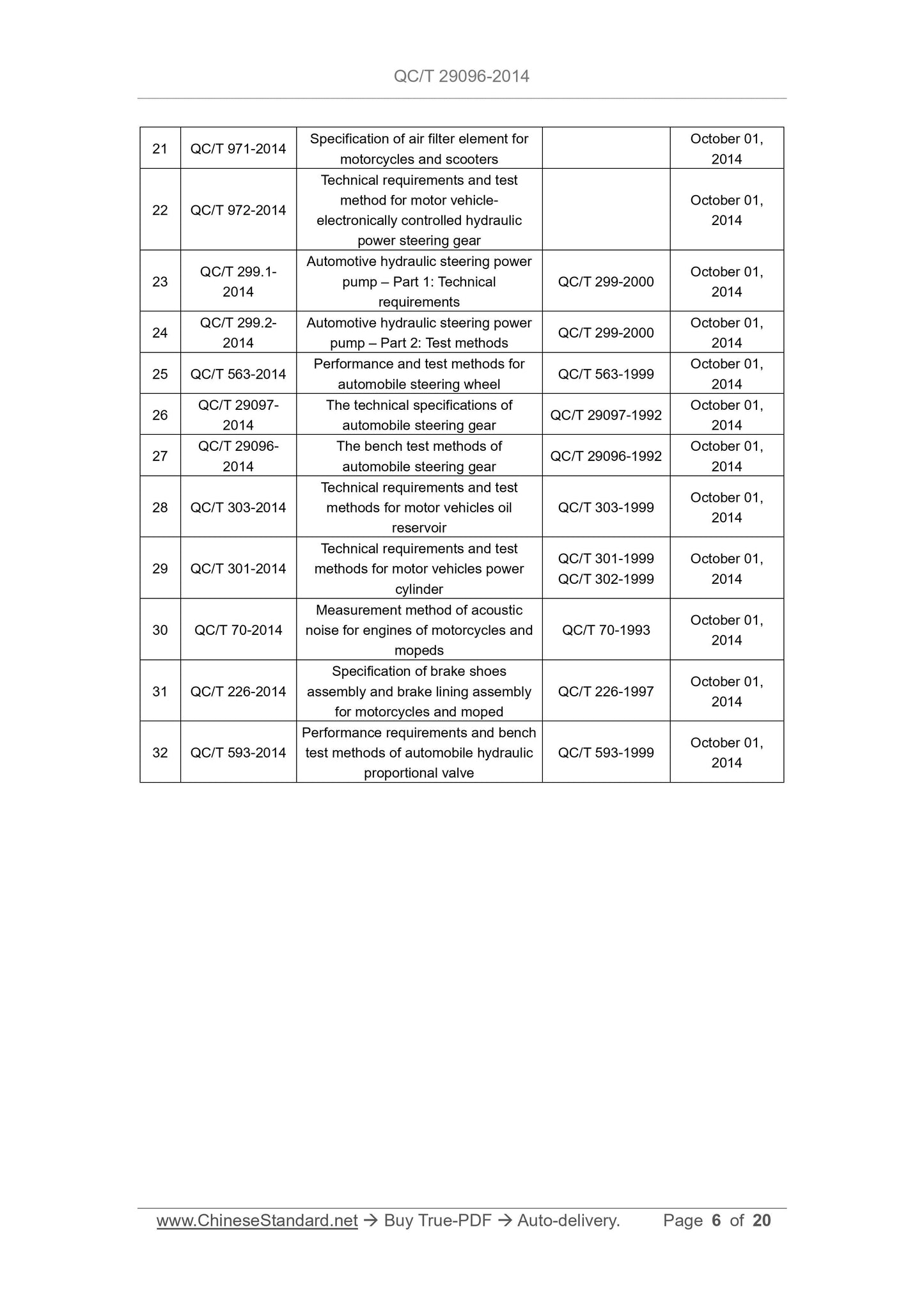

Number, name, and date of implementation of 32 automotive industry

standards

No. Standard number Standard name

Number of

standard replaced

Date of

implementation

1 QC/T 231-2014 Specification of kick-starter for motorcycles and mopeds QC/T 231-1997

October 01,

2014

2 QC/T 233-2014

Performance and measurement

method for static intensity of

motorcycles and mopeds

QC/T 233-1997 October 01, 2014

3 QC/T 66-2014 Wet clutch for moped and motorcycles QC/T 66-1993

October 01,

2014

4 QC/T 962-2014 Technical specifications for coating of motorcycles and moped

October 01,

2014

5 QC/T 680-2014

General technical specifications for

voltage regulators for motorcycles and

moped

QC/T 680-2002 October 01, 2014

6 QC/T 963-2014 Drum brakes of motorcycles and mopeds wheels

October 01,

2014

7 QC/T 234-2014

General technical specifications for

steering shaft for motorcycles and

moped

QC/T 234-1997 October 01, 2014

8 QC/T 964-2014 The strength of plastic seats and their anchorages for city buses

October 01,

2014

9 QC/T 644-2014 Technical specifications for automotive metallic fuel tank

QC/T 644-2000

QC/T 488-2000

October 01,

2014

10 QC/T 965-2014 Driver of electric rear-view mirrors for motor vehicles

October 01,

2014

11 QC/T 966-2014 Technical specifications for automotive plastic parts coatings

October 01,

2014

12 QC/T 459-2014 Truck with loading crane QC/T 459-2004 October 01, 2014

13 QC/T 29106-2014

Technical specification of automobile

wire harness QC/T 29106-2004

October 01,

2014

14 QC/T 198-2014 General technical specification for automotive switch QC/T 198-1995

October 01,

2014

15 QC/T 220-2014 Technical specifications for automotive fusible links QC/T 220-1996

October 01,

2014

16 QC/T 967-2014 Port fuel injector for gasoline engine October 01, 2014

17 QC/T 968-2014

Determination methods of platinum,

palladium and rhodium contents in

metallic catalytic converters

October 01, 2014

18 QC/T 969-2014 Interior truck release for compartment of a passenger car

October 01,

2014

19 QC/T 636-2014 Electric window regulator specification for vehicles QC/T 636-2000

October 01,

2014

20 QC/T 970 2014 Passenger car air filter technical specification

October 01,

2014

The bench test methods of automobile steering gear

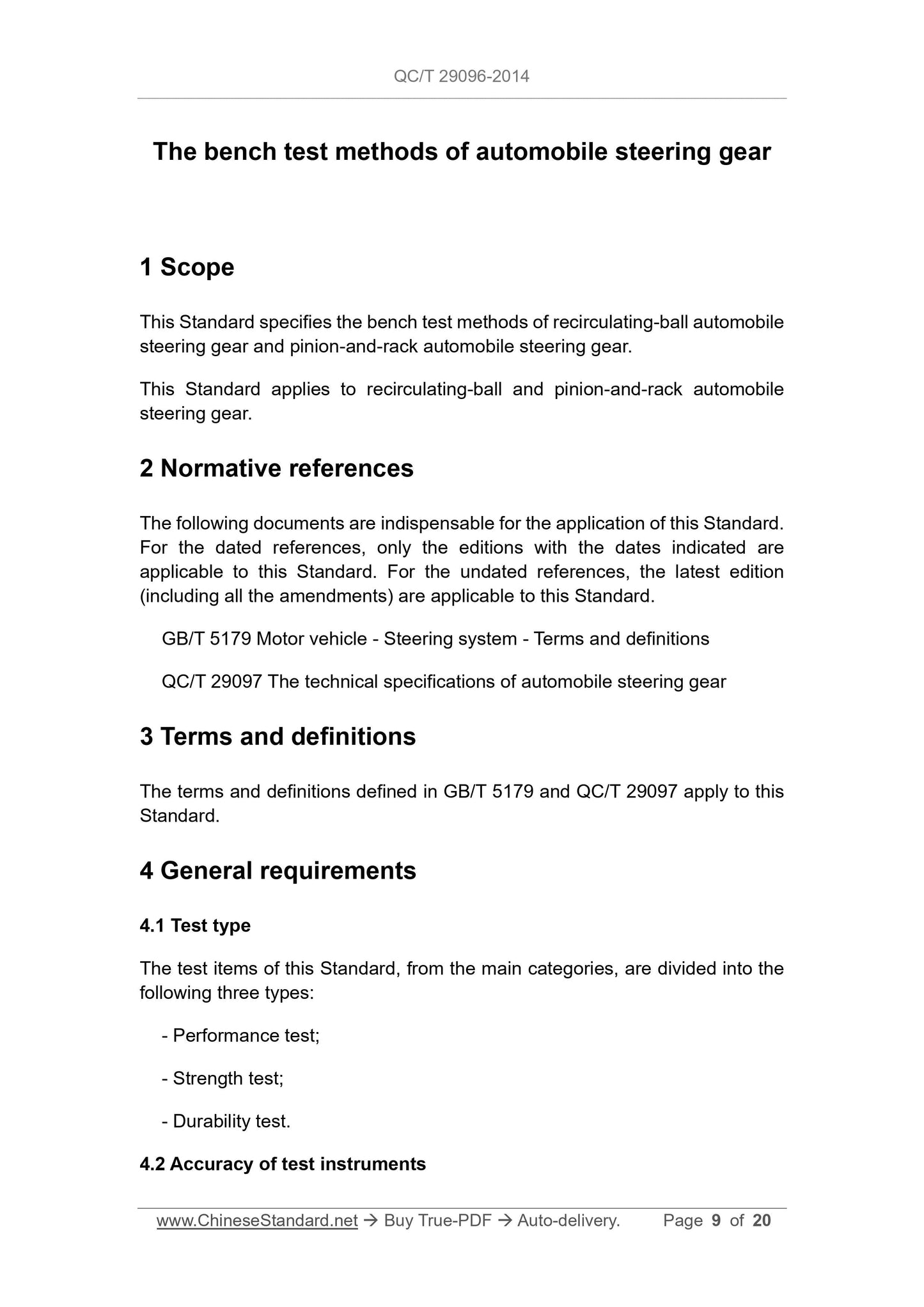

1 Scope

This Standard specifies the bench test methods of recirculating-ball automobile

steering gear and pinion-and-rack automobile steering gear.

This Standard applies to recirculating-ball and pinion-and-rack automobile

steering gear.

2 Normative references

The following documents are indispensable for the application of this Standard.

For the dated references, only the editions with the dates indicated are

applicable to this Standard. For the undated references, the latest edition

(including all the amendments) are applicable to this Standard.

GB/T 5179 Motor vehicle - Steering system - Terms and definitions

QC/T 29097 The technical specifications of automobile steering gear

3 Terms and definitions

The terms and definitions defined in GB/T 5179 and QC/T 29097 apply to this

Standard.

4 General requirements

4.1 Test type

The test items of this Standard, from the main categories, are divided into the

following three types:

- Performance test;

- Strength test;

- Durability test.

4.2 Accuracy of test instruments

The accuracy of the test instruments used in each test item must meet the

following corresponding requirements:

- Accuracy requirement of angle sensor: 0.1°;

- Accuracy of displacement sensor: 0.01 mm;

- Accuracy of torque sensor: 1%;

- Accuracy of force sensor: 1%.

5 Test methods

5.1 Performance

5.1.1 Full rotation angle of input shaft.

FIX the steering gear. There shall be no gap between the sensor and the input

shaft. ROTATE the input shaft from one limit position to another limit position;

MEASURE the total rotation angle.

5.1.2 Rack travel.

FIX the steering gear. There shall be no gap between the sensor and the rack.

Install pull rods or substitutes on both ends of the rack; MEASURE the distance

that the rack moves from one end to the other.

5.1.3 Transmission ratio.

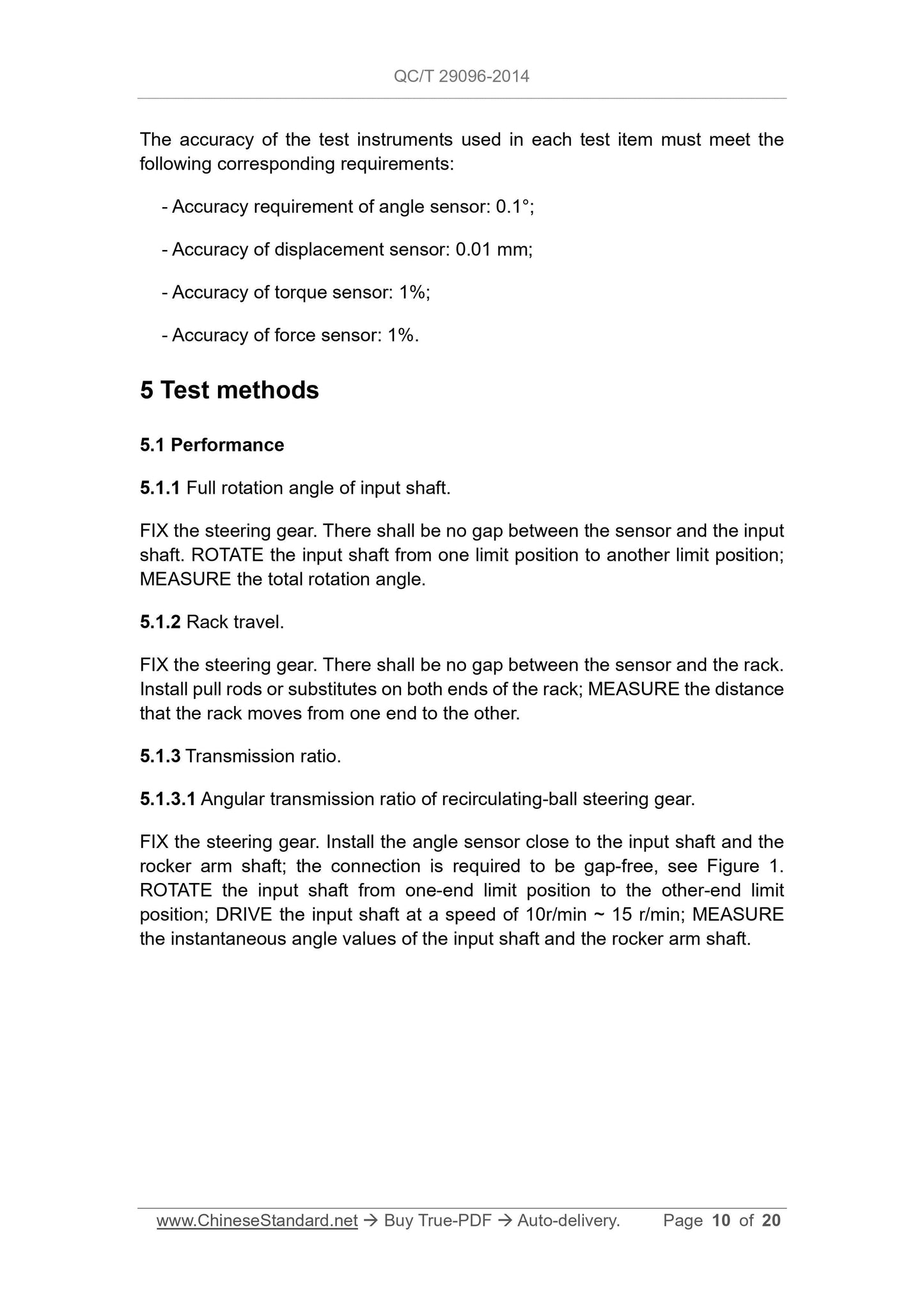

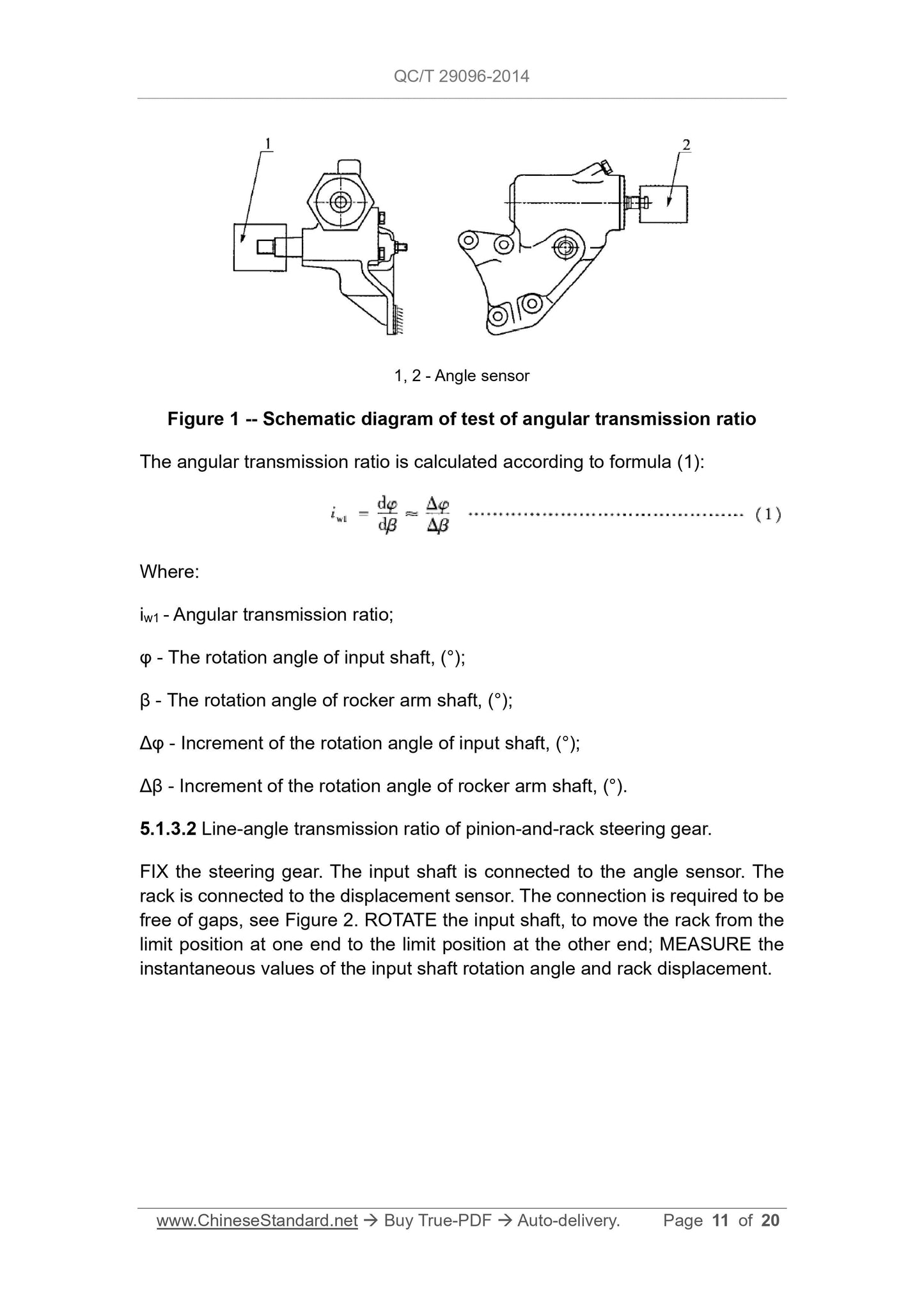

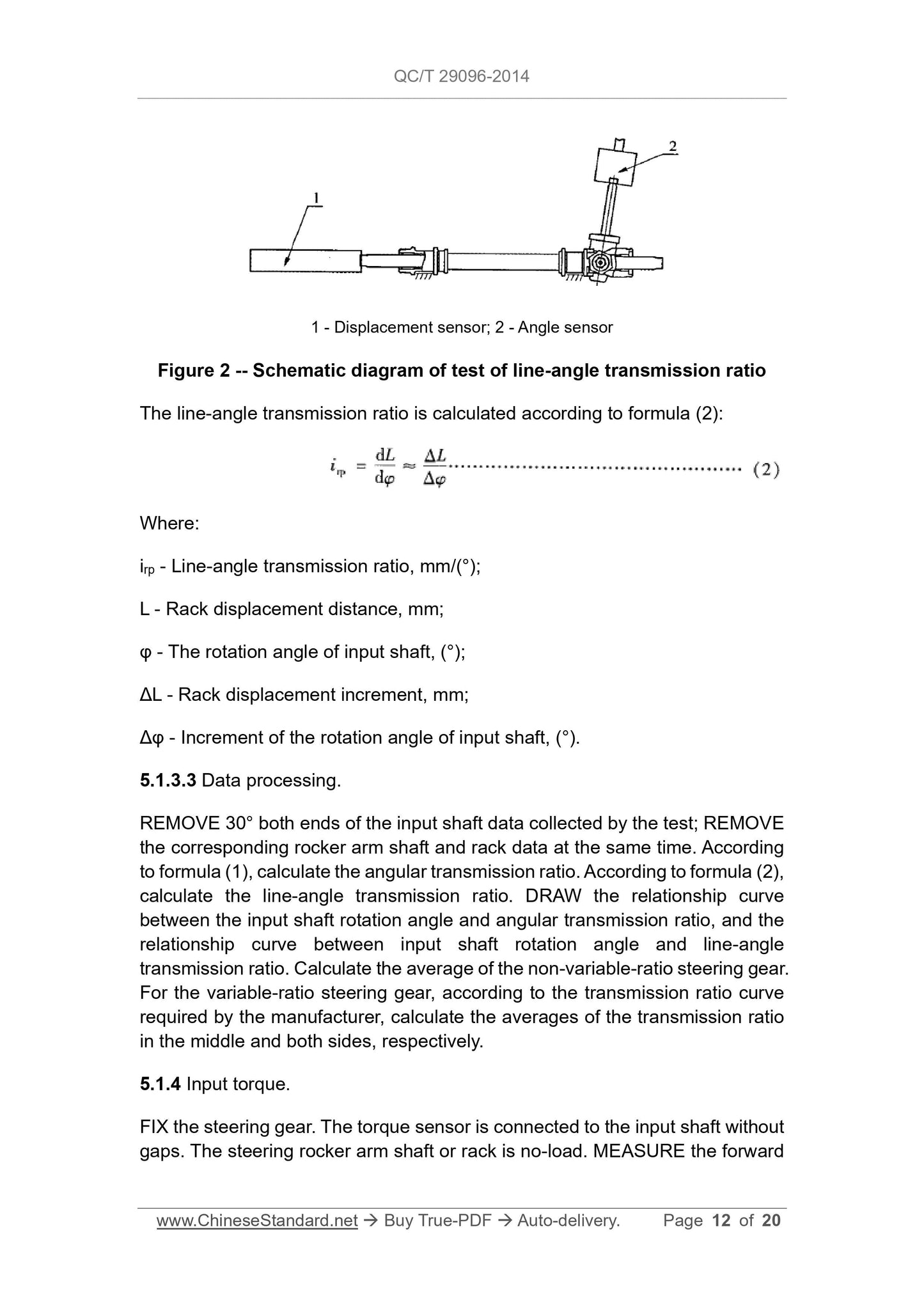

5.1.3.1 Angular transmission ratio of recirculating-ball steering gear.

FIX the steering gear. Install the angle sensor close to the input shaft and the

rocker arm shaft; the connection is required to be gap-free, see Figure 1.

ROTATE the input shaft from one-end limit position to the other-end limit

position; DRIVE the input shaft at a speed of 10r/min ~ 15 r/min; MEASURE

the instantaneous angle values of the input shaft and the rocker arm shaft.

and reverse torque of the input shaft in the whole process. The input shaft

speed is 15r/min.

REMOVE about 30° at both ends of the relationship curve, obtained by the test,

between the rotation angle and the torque. Calculate the average torque of ±

180° in the middle and the average torque of the remaining rotation angles on

both sides.

5.1.5 Rack moving force.

FIX the steering gear housing. Connect the force sensor and displacement

sensor to the rack. The connection is required to be free of gaps. PUSH (PULL)

the rack; MEASURE the moving force of the rack. The rack moving speed is

0.5m/min.

REMOVE the 3mm data at both ends of the displacement and force relationship

curve obtained by the test; DRAW the displacement and force relationship

curve.

5.1.6 Transmission clearance.

5.1.6.1 Transmission clearance of recirculating-ball steering gear.

Method 1: FIX the rocker arm shaft and the housing; LOAD a torque of ± 2N •

m on the input shaft end; MEASURE the difference of the input shaft rotation

angle, which is the clearance of this point (used for exit-factory test).

Method 2: Connect angle sensors to the input shaft and rocker arm shaft,

respectively. The connection is required to be free of gaps. ADD a load of 10N

• m to the rocker arm shaft; at a speed of 10r/min ~ 15r/min, drive the input shaft

forward. MEASURE the instantaneous corresponding angle values of the input

shaft and the rocker arm shaft. Then at the same speed, reversely drive the

input shaft, to measure the same data (see Figure 3).

1 - Torque sensor; 2, 3 - Angle sensor; A - Fixed or add ± 10N • m torque

Figure 3 -- Schematic diagram of test of recirculating-ball transmission

clearance

M1, M2 - Input and output torque of rocker arm shaft, N • m;

W1, W2 - Input and output torque of input shaft, N • m.

5.1.7.2 Transmission efficiency of pinion-and-rack steering gear.

FIX the steering gear. Connect the torque sensor and angle sensor to the input

shaft. Connect the force sensor and displacement sensor to the rack. The

connection is required to be free of gaps. At a speed of 15r/min, drive the input

shaft; MEASURE the torque and rotation angle, ...

Get QUOTATION in 1-minute: Click QC/T 29096-2014

Historical versions: QC/T 29096-2014

Preview True-PDF (Reload/Scroll if blank)

QC/T 29096-2014: The bench test methods of automobile steering gear

QC/T 29096-2014

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.040.50

T 23

Replacing QC/T 29096-1992

The bench test methods of automobile steering gear

ISSUED ON: MAY 06, 2014

IMPLEMENTED ON: OCTOBER 01, 2014

Issued by: Ministry of Industry and Information Technology of the

People's Republic of China

Table of Contents

Foreword ... 7

1 Scope ... 9

2 Normative references ... 9

3 Terms and definitions ... 9

4 General requirements ... 9

5 Test methods ... 10

Appendix:

Number, name, and date of implementation of 32 automotive industry

standards

No. Standard number Standard name

Number of

standard replaced

Date of

implementation

1 QC/T 231-2014 Specification of kick-starter for motorcycles and mopeds QC/T 231-1997

October 01,

2014

2 QC/T 233-2014

Performance and measurement

method for static intensity of

motorcycles and mopeds

QC/T 233-1997 October 01, 2014

3 QC/T 66-2014 Wet clutch for moped and motorcycles QC/T 66-1993

October 01,

2014

4 QC/T 962-2014 Technical specifications for coating of motorcycles and moped

October 01,

2014

5 QC/T 680-2014

General technical specifications for

voltage regulators for motorcycles and

moped

QC/T 680-2002 October 01, 2014

6 QC/T 963-2014 Drum brakes of motorcycles and mopeds wheels

October 01,

2014

7 QC/T 234-2014

General technical specifications for

steering shaft for motorcycles and

moped

QC/T 234-1997 October 01, 2014

8 QC/T 964-2014 The strength of plastic seats and their anchorages for city buses

October 01,

2014

9 QC/T 644-2014 Technical specifications for automotive metallic fuel tank

QC/T 644-2000

QC/T 488-2000

October 01,

2014

10 QC/T 965-2014 Driver of electric rear-view mirrors for motor vehicles

October 01,

2014

11 QC/T 966-2014 Technical specifications for automotive plastic parts coatings

October 01,

2014

12 QC/T 459-2014 Truck with loading crane QC/T 459-2004 October 01, 2014

13 QC/T 29106-2014

Technical specification of automobile

wire harness QC/T 29106-2004

October 01,

2014

14 QC/T 198-2014 General technical specification for automotive switch QC/T 198-1995

October 01,

2014

15 QC/T 220-2014 Technical specifications for automotive fusible links QC/T 220-1996

October 01,

2014

16 QC/T 967-2014 Port fuel injector for gasoline engine October 01, 2014

17 QC/T 968-2014

Determination methods of platinum,

palladium and rhodium contents in

metallic catalytic converters

October 01, 2014

18 QC/T 969-2014 Interior truck release for compartment of a passenger car

October 01,

2014

19 QC/T 636-2014 Electric window regulator specification for vehicles QC/T 636-2000

October 01,

2014

20 QC/T 970 2014 Passenger car air filter technical specification

October 01,

2014

The bench test methods of automobile steering gear

1 Scope

This Standard specifies the bench test methods of recirculating-ball automobile

steering gear and pinion-and-rack automobile steering gear.

This Standard applies to recirculating-ball and pinion-and-rack automobile

steering gear.

2 Normative references

The following documents are indispensable for the application of this Standard.

For the dated references, only the editions with the dates indicated are

applicable to this Standard. For the undated references, the latest edition

(including all the amendments) are applicable to this Standard.

GB/T 5179 Motor vehicle - Steering system - Terms and definitions

QC/T 29097 The technical specifications of automobile steering gear

3 Terms and definitions

The terms and definitions defined in GB/T 5179 and QC/T 29097 apply to this

Standard.

4 General requirements

4.1 Test type

The test items of this Standard, from the main categories, are divided into the

following three types:

- Performance test;

- Strength test;

- Durability test.

4.2 Accuracy of test instruments

The accuracy of the test instruments used in each test item must meet the

following corresponding requirements:

- Accuracy requirement of angle sensor: 0.1°;

- Accuracy of displacement sensor: 0.01 mm;

- Accuracy of torque sensor: 1%;

- Accuracy of force sensor: 1%.

5 Test methods

5.1 Performance

5.1.1 Full rotation angle of input shaft.

FIX the steering gear. There shall be no gap between the sensor and the input

shaft. ROTATE the input shaft from one limit position to another limit position;

MEASURE the total rotation angle.

5.1.2 Rack travel.

FIX the steering gear. There shall be no gap between the sensor and the rack.

Install pull rods or substitutes on both ends of the rack; MEASURE the distance

that the rack moves from one end to the other.

5.1.3 Transmission ratio.

5.1.3.1 Angular transmission ratio of recirculating-ball steering gear.

FIX the steering gear. Install the angle sensor close to the input shaft and the

rocker arm shaft; the connection is required to be gap-free, see Figure 1.

ROTATE the input shaft from one-end limit position to the other-end limit

position; DRIVE the input shaft at a speed of 10r/min ~ 15 r/min; MEASURE

the instantaneous angle values of the input shaft and the rocker arm shaft.

and reverse torque of the input shaft in the whole process. The input shaft

speed is 15r/min.

REMOVE about 30° at both ends of the relationship curve, obtained by the test,

between the rotation angle and the torque. Calculate the average torque of ±

180° in the middle and the average torque of the remaining rotation angles on

both sides.

5.1.5 Rack moving force.

FIX the steering gear housing. Connect the force sensor and displacement

sensor to the rack. The connection is required to be free of gaps. PUSH (PULL)

the rack; MEASURE the moving force of the rack. The rack moving speed is

0.5m/min.

REMOVE the 3mm data at both ends of the displacement and force relationship

curve obtained by the test; DRAW the displacement and force relationship

curve.

5.1.6 Transmission clearance.

5.1.6.1 Transmission clearance of recirculating-ball steering gear.

Method 1: FIX the rocker arm shaft and the housing; LOAD a torque of ± 2N •

m on the input shaft end; MEASURE the difference of the input shaft rotation

angle, which is the clearance of this point (used for exit-factory test).

Method 2: Connect angle sensors to the input shaft and rocker arm shaft,

respectively. The connection is required to be free of gaps. ADD a load of 10N

• m to the rocker arm shaft; at a speed of 10r/min ~ 15r/min, drive the input shaft

forward. MEASURE the instantaneous corresponding angle values of the input

shaft and the rocker arm shaft. Then at the same speed, reversely drive the

input shaft, to measure the same data (see Figure 3).

1 - Torque sensor; 2, 3 - Angle sensor; A - Fixed or add ± 10N • m torque

Figure 3 -- Schematic diagram of test of recirculating-ball transmission

clearance

M1, M2 - Input and output torque of rocker arm shaft, N • m;

W1, W2 - Input and output torque of input shaft, N • m.

5.1.7.2 Transmission efficiency of pinion-and-rack steering gear.

FIX the steering gear. Connect the torque sensor and angle sensor to the input

shaft. Connect the force sensor and displacement sensor to the rack. The

connection is required to be free of gaps. At a speed of 15r/min, drive the input

shaft; MEASURE the torque and rotation angle, ...

Share