1

/

af

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY 0174-2019 English PDF (YY0174-2019)

YY 0174-2019 English PDF (YY0174-2019)

Normalpris

$230.00 USD

Normalpris

Udsalgspris

$230.00 USD

Stykpris

/

pr.

Levering beregnes ved betaling.

Tilgængelighed for afhentning kunne ikke indlæses

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click YY 0174-2019

Historical versions: YY 0174-2019

Preview True-PDF (Reload/Scroll if blank)

YY 0174-2019: [YY/T 0174-2019] Scalpel blade

YY 0174-2019

YY

PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.040.30

C 31

Replacing YY 0174-2005

Scalpel blade

ISSUED ON: MAY 31, 2019

IMPLEMENTED ON: JUNE 01, 2020

Issued by: National Medical Products Administration

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Classification and marks ... 6

4 Requirements ... 7

5 Test methods ... 8

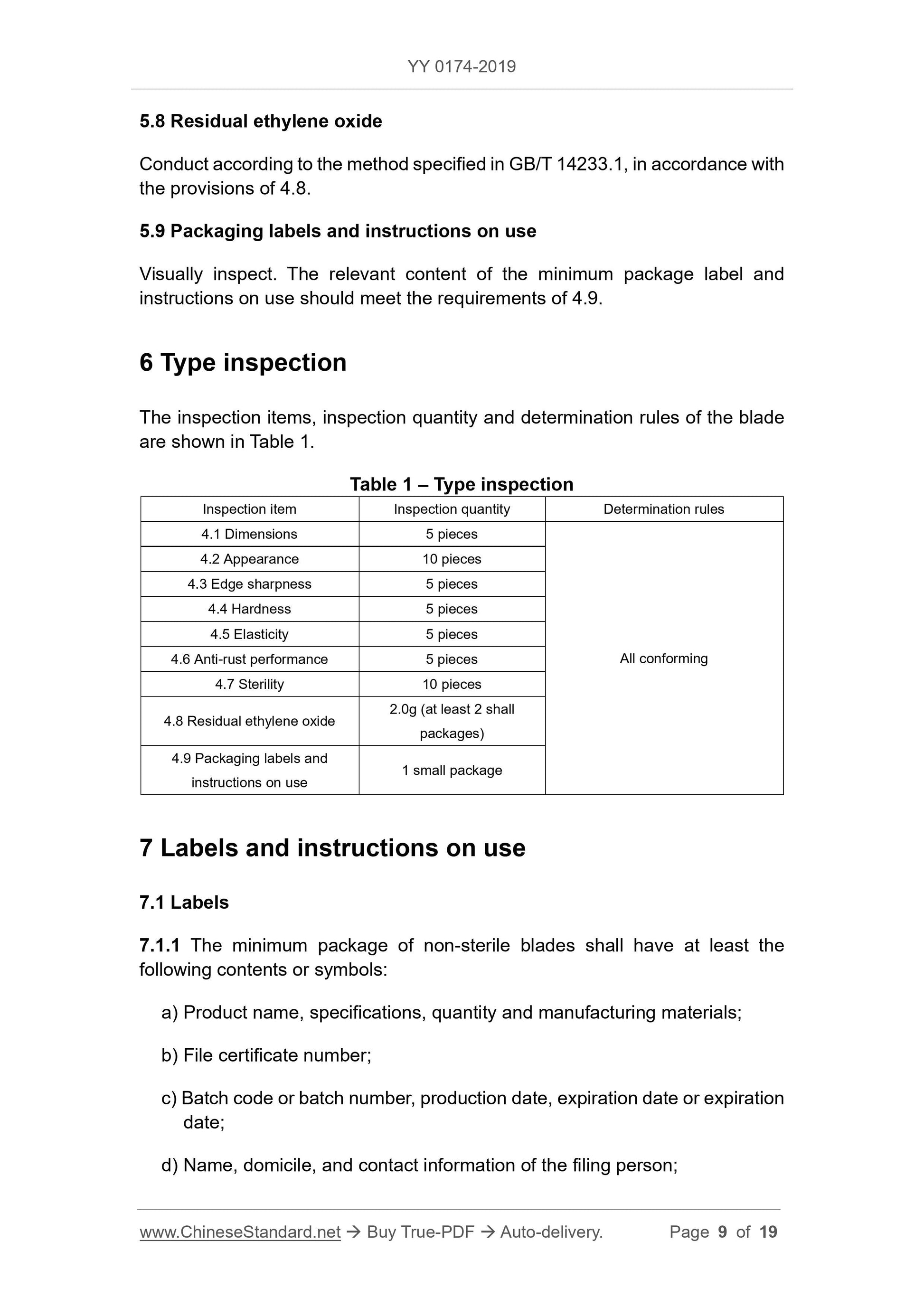

6 Type inspection ... 9

7 Labels and instructions on use ... 9

8 Packaging, transportation, storage and validity period ... 12

Annex A (informative) Blade specifications type... 13

Annex B (normative) Test method for scalpel blade edge sharpness ... 16

Annex C (normative) Test method for elasticity ... 18

Scalpel blade

1 Scope

This Standard specifies the classification and marks, requirements, test

methods, type inspection, labels and instructions on use, packaging,

transportation, storage and valid period of scalpel blade.

This Standard is applicable to the scalpel blade that is installed on the scalpel

handle for cutting soft tissue (hereinafter referred to as the blade).

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 191, Packaging and storage marks

GB/T 1299, Alloy tool steels

GB/T 4340.1, Metallic materials - Vickers hardness test - Part 1: Test method

GB 8662, Fitting dimension between scalpel blades and handles

GB/T 9969, General Principles for Preparation of Instructions for Use of

Industrial Products

GB/T 14233.1, Test methods for infusion transfusion injection equipment for

medical use - Part 1: Chemical analysis methods

YY 0167-2005, Non-absorbable surgical suture

YY/T 0294.1, Surgical instruments - Metallic materials - Part 1: Stainless

steel

YY/T 0466.1, Medical devices - Symbols to be used with medical device

labels, labelling and information to be supplied - Part 1: General

requirements

YY/T 1052, Marking requirements for surgical instruments

Pharmacopoeia of the People's Republic of China (Edition 2015· Fourth

4 Requirements

4.1 dimensions

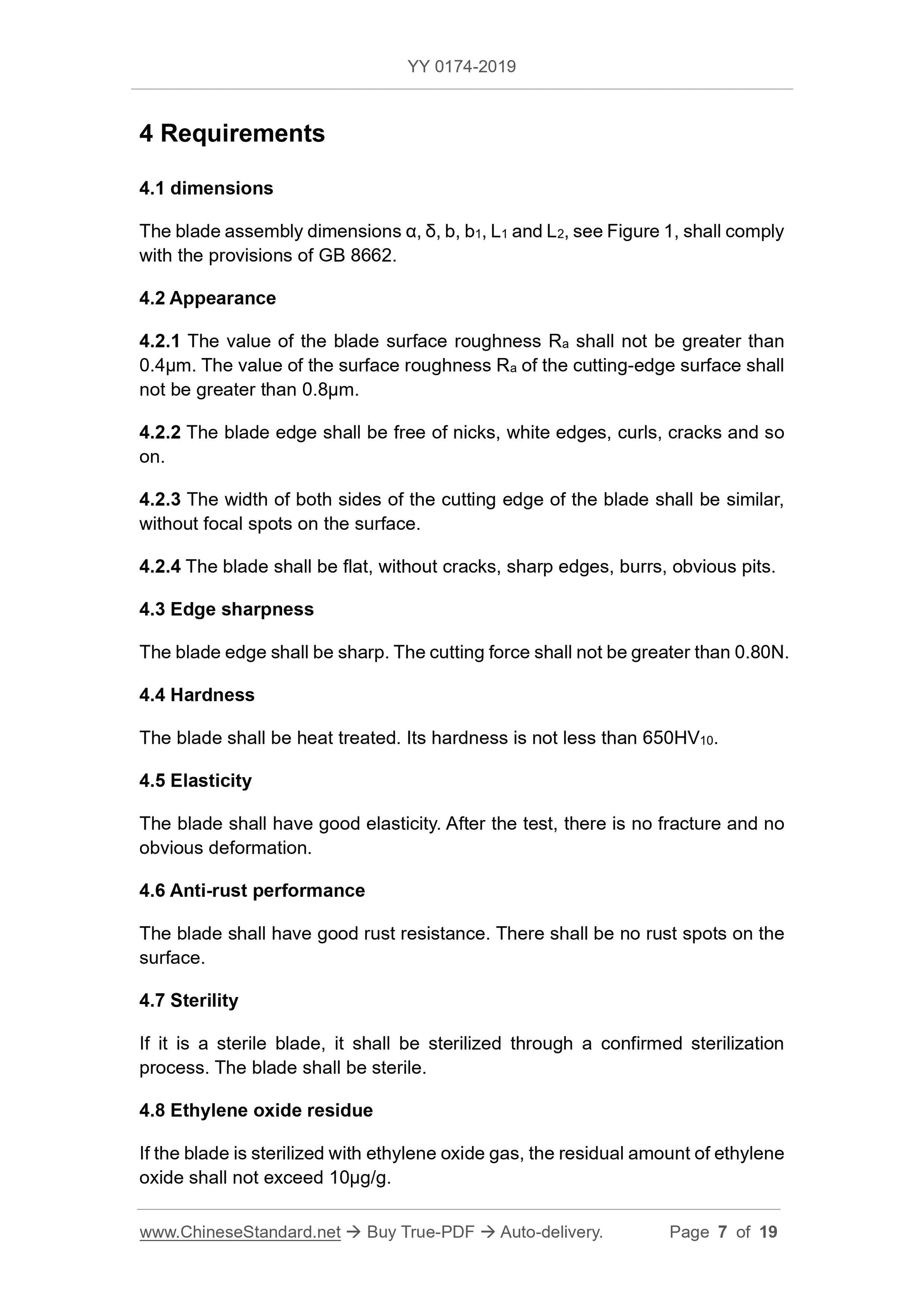

The blade assembly dimensions α, δ, b, b1, L1 and L2, see Figure 1, shall comply

with the provisions of GB 8662.

4.2 Appearance

4.2.1 The value of the blade surface roughness Ra shall not be greater than

0.4μm. The value of the surface roughness Ra of the cutting-edge surface shall

not be greater than 0.8μm.

4.2.2 The blade edge shall be free of nicks, white edges, curls, cracks and so

on.

4.2.3 The width of both sides of the cutting edge of the blade shall be similar,

without focal spots on the surface.

4.2.4 The blade shall be flat, without cracks, sharp edges, burrs, obvious pits.

4.3 Edge sharpness

The blade edge shall be sharp. The cutting force shall not be greater than 0.80N.

4.4 Hardness

The blade shall be heat treated. Its hardness is not less than 650HV10.

4.5 Elasticity

The blade shall have good elasticity. After the test, there is no fracture and no

obvious deformation.

4.6 Anti-rust performance

The blade shall have good rust resistance. There shall be no rust spots on the

surface.

4.7 Sterility

If it is a sterile blade, it shall be sterilized through a confirmed sterilization

process. The blade shall be sterile.

4.8 Ethylene oxide residue

If the blade is sterilized with ethylene oxide gas, the residual amount of ethylene

oxide shall not exceed 10μg/g.

e) Manufacturer’s name, domicile, production address, contact information

and production file certificate number;

f) Words or symbols of "Other contents are detailed in the instructions on

use".

7.1.2 The minimum package of sterile blades shall have at least the following

contents or symbols:

a) Product name and specifications;

b) Sterilization method, sterility, single-use mark;

c) Product registration certificate number;

d) Words or symbols of "Do not use if the package is damaged";

e) Batch code or batch number, production date, expiration date or expiration

date;

f) Name and domicile of the registrant or manufacturer;

g) Words or symbols of "Other contents are detailed in the instructions on

use".

7.1.3 The minimum sales unit packaging shall have at least the following

contents or symbols:

a) Product name;

b) Specifications, quantity;

c) Sterilization method (for sterile blades), single-use mark;

d) Batch code or batch number, production date, expiration date or expiration

date;

e) Product registration certificate number or record certificate number,

production license number or production record certificate number;

f) Name of the registrant or filing person, the name of the manufacturer, the

address, and the contact information.

7.1.4 There shall be an inspection certificate in each minimum sales unit. At

least the following content shall be included on the certificate:

a) Name of the registrant or filing person or manufacturer;

b) Number of product technical requirements;

c) Batch code or batch number;

d) Inspection date and inspector code.

7.1.5 The packaging, storage and transportation marks on the package shall

comply with the relevant regulations of GB/T 191 and YY/T 0466.1.

7.2 Instructions on use

There shall be instructions on use in each minimum sales unit. The preparation

of the instructions on use shall comply with the requirements of GB/T 9969, at

least containing the followings:

a) Product name, specifications;

b) Name, address, contact information and after-sales service information of

the registrant or filing person or manufacturer; If it is entrusted production,

it shall also indicate the name, address and production license number of

the entrusted production enterprise or production record document

number;

c) Product registration certificate number or record certificate number,

production license number or production record certificate number;

d) Number of product technical requirements;

e) Product performance, manufacturing materials, scope of application;

f) Installation and use instructions or icons;

g) Storage conditions and methods;

h) Description on one-time use, detailed sterilization or disinfection method,

production date, use period or expiration date;

i) Explanation of the graphics, symbols, abbreviations used in the label;

j) Preparation of instructions on use or revision date;

k) Contraindications, precautions, warnings and reminders:

1) Requirements to ensure the correct and safe use of the blade, and post-

processing requirements for safe use;

2) Precautions when the blade is used in conjunction with other

instruments;

3) The sterile blade shall indicate the treatment method when the

minimum single package is damaged.

Get QUOTATION in 1-minute: Click YY 0174-2019

Historical versions: YY 0174-2019

Preview True-PDF (Reload/Scroll if blank)

YY 0174-2019: [YY/T 0174-2019] Scalpel blade

YY 0174-2019

YY

PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.040.30

C 31

Replacing YY 0174-2005

Scalpel blade

ISSUED ON: MAY 31, 2019

IMPLEMENTED ON: JUNE 01, 2020

Issued by: National Medical Products Administration

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Classification and marks ... 6

4 Requirements ... 7

5 Test methods ... 8

6 Type inspection ... 9

7 Labels and instructions on use ... 9

8 Packaging, transportation, storage and validity period ... 12

Annex A (informative) Blade specifications type... 13

Annex B (normative) Test method for scalpel blade edge sharpness ... 16

Annex C (normative) Test method for elasticity ... 18

Scalpel blade

1 Scope

This Standard specifies the classification and marks, requirements, test

methods, type inspection, labels and instructions on use, packaging,

transportation, storage and valid period of scalpel blade.

This Standard is applicable to the scalpel blade that is installed on the scalpel

handle for cutting soft tissue (hereinafter referred to as the blade).

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 191, Packaging and storage marks

GB/T 1299, Alloy tool steels

GB/T 4340.1, Metallic materials - Vickers hardness test - Part 1: Test method

GB 8662, Fitting dimension between scalpel blades and handles

GB/T 9969, General Principles for Preparation of Instructions for Use of

Industrial Products

GB/T 14233.1, Test methods for infusion transfusion injection equipment for

medical use - Part 1: Chemical analysis methods

YY 0167-2005, Non-absorbable surgical suture

YY/T 0294.1, Surgical instruments - Metallic materials - Part 1: Stainless

steel

YY/T 0466.1, Medical devices - Symbols to be used with medical device

labels, labelling and information to be supplied - Part 1: General

requirements

YY/T 1052, Marking requirements for surgical instruments

Pharmacopoeia of the People's Republic of China (Edition 2015· Fourth

4 Requirements

4.1 dimensions

The blade assembly dimensions α, δ, b, b1, L1 and L2, see Figure 1, shall comply

with the provisions of GB 8662.

4.2 Appearance

4.2.1 The value of the blade surface roughness Ra shall not be greater than

0.4μm. The value of the surface roughness Ra of the cutting-edge surface shall

not be greater than 0.8μm.

4.2.2 The blade edge shall be free of nicks, white edges, curls, cracks and so

on.

4.2.3 The width of both sides of the cutting edge of the blade shall be similar,

without focal spots on the surface.

4.2.4 The blade shall be flat, without cracks, sharp edges, burrs, obvious pits.

4.3 Edge sharpness

The blade edge shall be sharp. The cutting force shall not be greater than 0.80N.

4.4 Hardness

The blade shall be heat treated. Its hardness is not less than 650HV10.

4.5 Elasticity

The blade shall have good elasticity. After the test, there is no fracture and no

obvious deformation.

4.6 Anti-rust performance

The blade shall have good rust resistance. There shall be no rust spots on the

surface.

4.7 Sterility

If it is a sterile blade, it shall be sterilized through a confirmed sterilization

process. The blade shall be sterile.

4.8 Ethylene oxide residue

If the blade is sterilized with ethylene oxide gas, the residual amount of ethylene

oxide shall not exceed 10μg/g.

e) Manufacturer’s name, domicile, production address, contact information

and production file certificate number;

f) Words or symbols of "Other contents are detailed in the instructions on

use".

7.1.2 The minimum package of sterile blades shall have at least the following

contents or symbols:

a) Product name and specifications;

b) Sterilization method, sterility, single-use mark;

c) Product registration certificate number;

d) Words or symbols of "Do not use if the package is damaged";

e) Batch code or batch number, production date, expiration date or expiration

date;

f) Name and domicile of the registrant or manufacturer;

g) Words or symbols of "Other contents are detailed in the instructions on

use".

7.1.3 The minimum sales unit packaging shall have at least the following

contents or symbols:

a) Product name;

b) Specifications, quantity;

c) Sterilization method (for sterile blades), single-use mark;

d) Batch code or batch number, production date, expiration date or expiration

date;

e) Product registration certificate number or record certificate number,

production license number or production record certificate number;

f) Name of the registrant or filing person, the name of the manufacturer, the

address, and the contact information.

7.1.4 There shall be an inspection certificate in each minimum sales unit. At

least the following content shall be included on the certificate:

a) Name of the registrant or filing person or manufacturer;

b) Number of product technical requirements;

c) Batch code or batch number;

d) Inspection date and inspector code.

7.1.5 The packaging, storage and transportation marks on the package shall

comply with the relevant regulations of GB/T 191 and YY/T 0466.1.

7.2 Instructions on use

There shall be instructions on use in each minimum sales unit. The preparation

of the instructions on use shall comply with the requirements of GB/T 9969, at

least containing the followings:

a) Product name, specifications;

b) Name, address, contact information and after-sales service information of

the registrant or filing person or manufacturer; If it is entrusted production,

it shall also indicate the name, address and production license number of

the entrusted production enterprise or production record document

number;

c) Product registration certificate number or record certificate number,

production license number or production record certificate number;

d) Number of product technical requirements;

e) Product performance, manufacturing materials, scope of application;

f) Installation and use instructions or icons;

g) Storage conditions and methods;

h) Description on one-time use, detailed sterilization or disinfection method,

production date, use period or expiration date;

i) Explanation of the graphics, symbols, abbreviations used in the label;

j) Preparation of instructions on use or revision date;

k) Contraindications, precautions, warnings and reminders:

1) Requirements to ensure the correct and safe use of the blade, and post-

processing requirements for safe use;

2) Precautions when the blade is used in conjunction with other

instruments;

3) The sterile blade shall indicate the treatment method when the

minimum single package is damaged.

Share