1

/

von

7

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

FZ/T 73019.1-2017 English PDF (FZT73019.1-2017)

FZ/T 73019.1-2017 English PDF (FZT73019.1-2017)

Normaler Preis

$120.00 USD

Normaler Preis

Verkaufspreis

$120.00 USD

Grundpreis

/

pro

Versand wird beim Checkout berechnet

Verfügbarkeit für Abholungen konnte nicht geladen werden

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click FZ/T 73019.1-2017

Historical versions: FZ/T 73019.1-2017

Preview True-PDF (Reload/Scroll if blank)

FZ/T 73019.1-2017: Knitted shape inner wear. Elastic style

FZ/T 73019.1-2017

TEXTILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 59.080.30

W 63

Replacing FZ/T 73019.1-2010

Knitted shape inner wear - Elastic style

针织塑身内衣 弹力型

ISSUED ON: NOVEMBER 07, 2017

IMPLEMENTED ON: APRIL 01, 2018

Issued by: Ministry of Industry and Information Technology of the PRC

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Size... 6

5 Requirements ... 7

6 Tests ... 11

7 Judgment rules ... 16

8 Product use instructions, packaging, transportation, and storage ... 17

Knitted shape inner wear - Elastic style

1 Scope

This Standard specifies the terms and definitions, size, requirements, tests,

judgment rules, use instructions, packaging, transportation, and storage of

knitted shape inner wear-elastic style products.

This Standard applies to the identification of the quality of elastic-style knitted

shape inner wear and side seam-free knitted shape inner wear products.

This Standard does not apply to the clothing of infants and young children aged

36 months or less.

2 Normative references

The following documents are indispensable for the application of this document.

For the dated references, only the editions with the dates indicated are

applicable to this document. For the undated references, the latest edition

(including all the amendments) are applicable to this document.

GB/T 250 Textiles - Tests for colour fastness - Grey scale for assessing

change in colour

GB/T 2910 (all parts) Textiles - Quantitative chemical analysis

GB/T 2912.1 Textiles - Determination of formaldehyde - Part 1: Free and

hydrolyzed formaldehyde (water extraction method)

GB/T 3920 Textiles - Tests for colour fastness - Colour fastness to rubbing

GB/T 3921-2008 Textiles - Tests for colour fastness - Colour fastness to

washing with soap or soap and soda

GB/T 3922 Textiles - Testing method for colour fastness to perspiration

GB/T 4802.1-2008 Textiles - Determination of fabric propensity to surface

fuzzing and to pilling - Part 1: Circular locus method

GB/T 4856 Package of cotton goods and knitwear

GB/T 5296.4 Instructions for use of products of consumer interest - Part 4:

Textiles and apparel

the net chest (waist) circumference of the human body suitable, for example:

155-165/85-90, or according to the provisions of GB/T 6411.

5 Requirements

5.1 Requirement content

Requirements are divided into two aspects: intrinsic quality and appearance

quality. Intrinsic quality includes indicators such as fiber content, formaldehyde

content, pH value, odor, decomposable carcinogenic aromatic amine dye,

colour fastness to washing with soap or soap and soda, colour fastness to

rubbing, colour fastness to perspiration, colour fastness to water, size stability

to washing, and pilling. Appearance quality includes indicators such as surface

defects, size deviations of major parts of the finished product, size differences

of symmetrical parts, stitch elongation, and sewing regulations.

5.2 Grading regulations

5.2.1 The quality grade of knitted shape inner wear-elastic style products is

divided into superior product, first-class product, and qualified product.

5.2.2 For the quality grading of knitted shape inner wear-elastic style products,

the intrinsic quality is graded by lot (delivery lot); the appearance quality is

graded by piece. The combination of intrinsic quality and appearance quality is

graded at the lowest grade.

5.2.3 The indicators of intrinsic quality take the lowest one of the test results as

the grading basis of this lot of products.

5.2.4 When the appearance quality problems of different grades are found on

the same product, it is graded at the lowest grade. Only two extreme surface

defects of the same grade are allowed on the same product; those exceeding

this limit shall be reduced by one grade.

5.3 Intrinsic quality requirements

5.3.1 The intrinsic quality requirements are shown in Table 1.

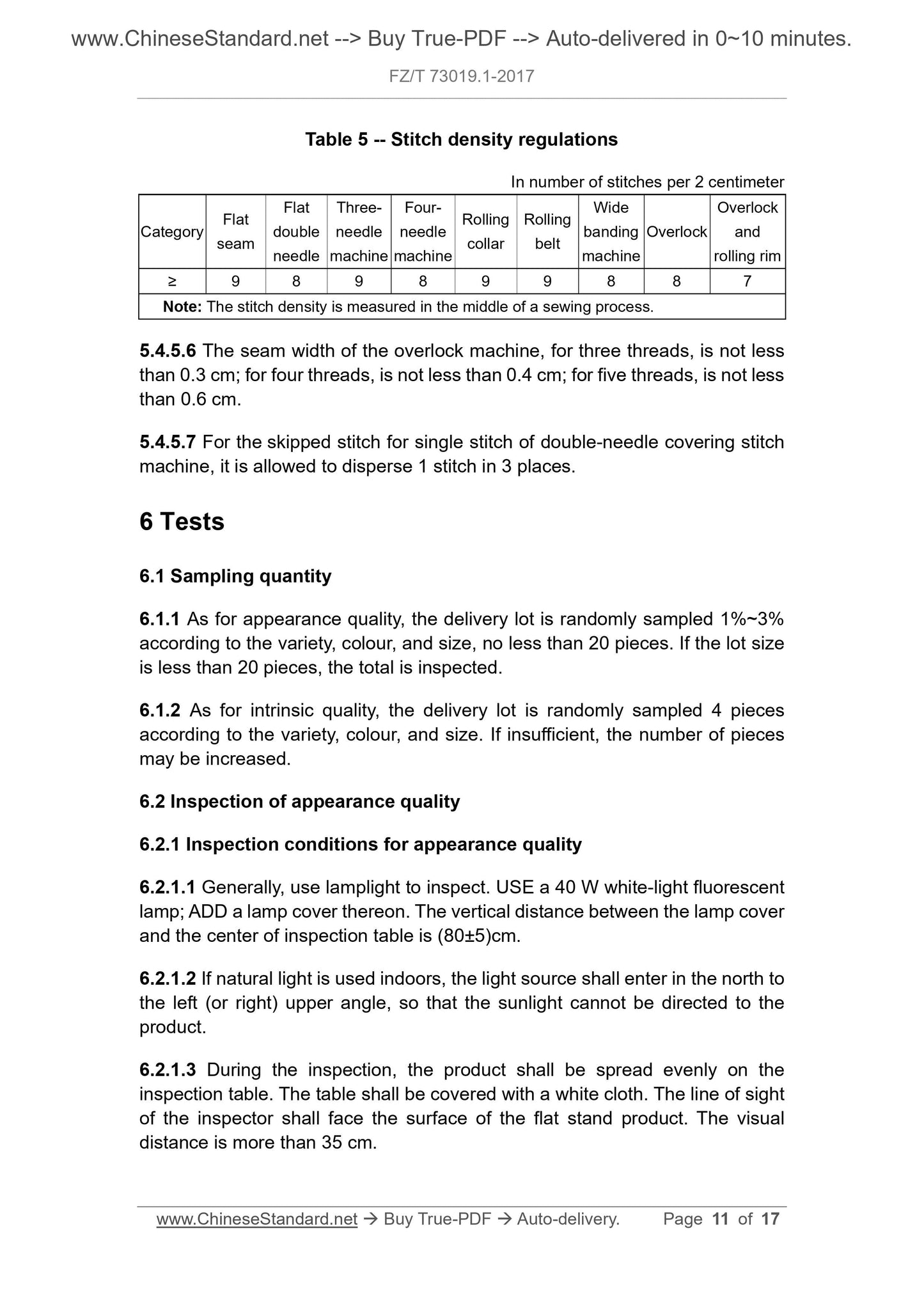

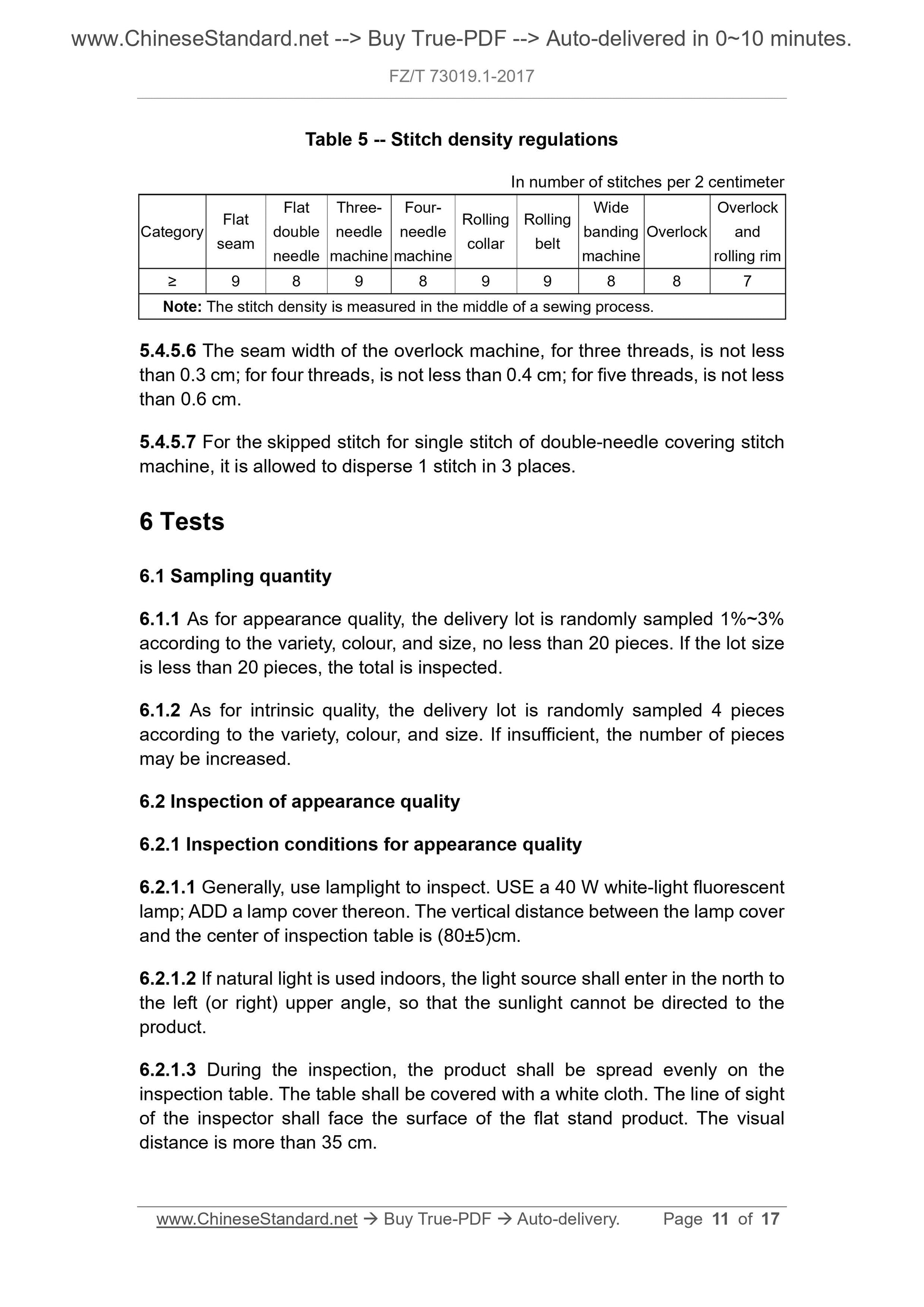

Table 5 -- Stitch density regulations

In number of stitches per 2 centimeter

Category Flat seam

Flat

double

needle

Three-

needle

machine

Four-

needle

machine

Rolling

collar

Rolling

belt

Wide

banding

machine

Overlock

Overlock

and

rolling rim

≥ 9 8 9 8 9 9 8 8 7

Note: The stitch density is measured in the middle of a sewing process.

5.4.5.6 The seam width of the overlock machine, for three threads, is not less

than 0.3 cm; for four threads, is not less than 0.4 cm; for five threads, is not less

than 0.6 cm.

5.4.5.7 For the skipped stitch for single stitch of double-needle covering stitch

machine, it is allowed to disperse 1 stitch in 3 places.

6 Tests

6.1 Sampling quantity

6.1.1 As for appearance quality, the delivery lot is randomly sampled 1%~3%

according to the variety, colour, and size, no less than 20 pieces. If the lot size

is less than 20 pieces, the total is inspected.

6.1.2 As for intrinsic quality, the delivery lot is randomly sampled 4 pieces

according to the variety, colour, and size. If insufficient, the number of pieces

may be increased.

6.2 Inspection of appearance quality

6.2.1 Inspection conditions for appearance quality

6.2.1.1 Generally, use lamplight to inspect. USE a 40 W white-light fluorescent

lamp; ADD a lamp cover thereon. The vertical distance between the lamp cover

and the center of inspection table is (80±5)cm.

6.2.1.2 If natural light is used indoors, the light source shall enter in the north to

the left (or right) upper angle, so that the sunlight cannot be directed to the

product.

6.2.1.3 During the inspection, the product shall be spread evenly on the

inspection table. The table shall be covered with a white cloth. The line of sight

of the inspector shall face the surface of the flat stand product. The visual

distance is more than 35 cm.

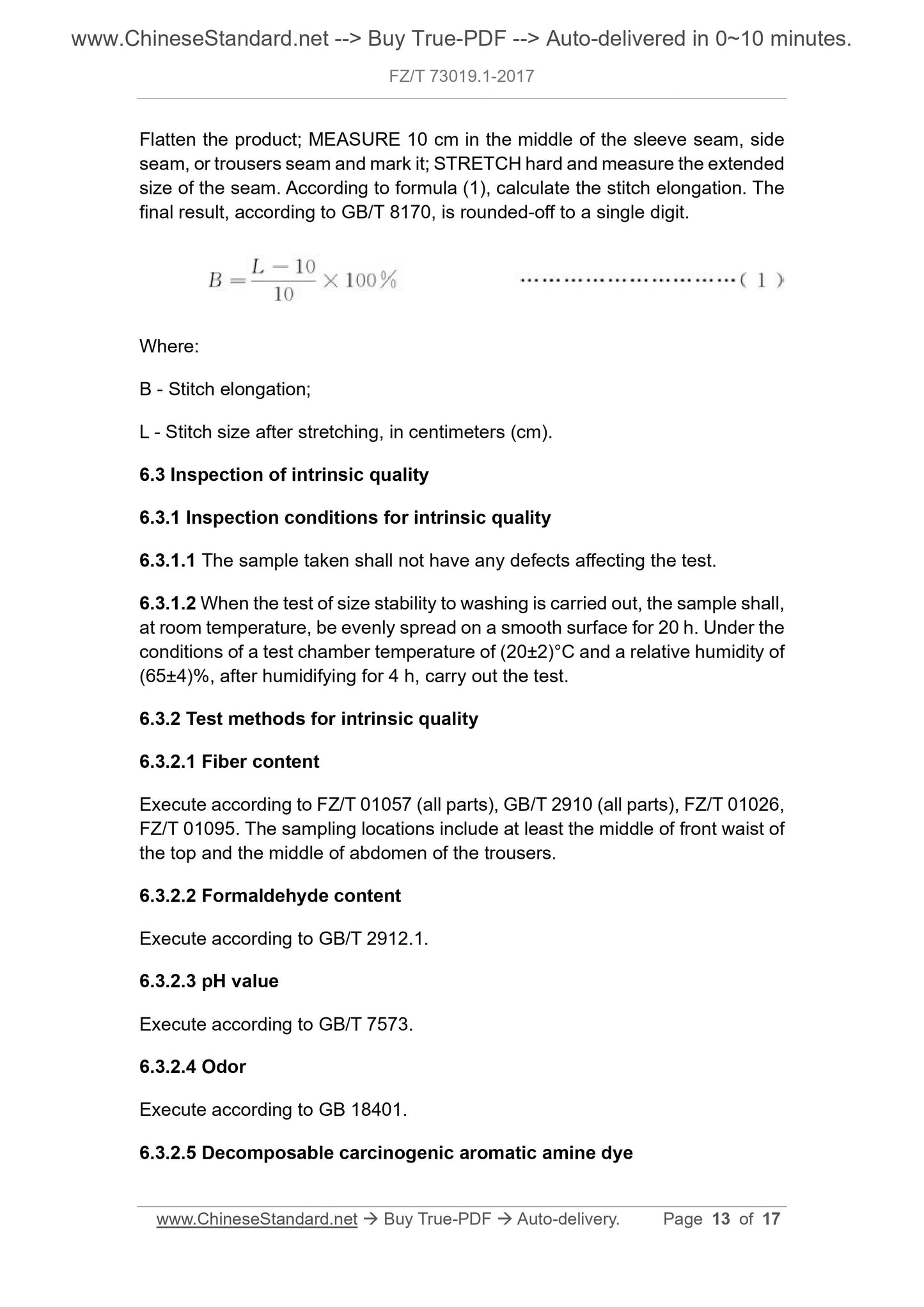

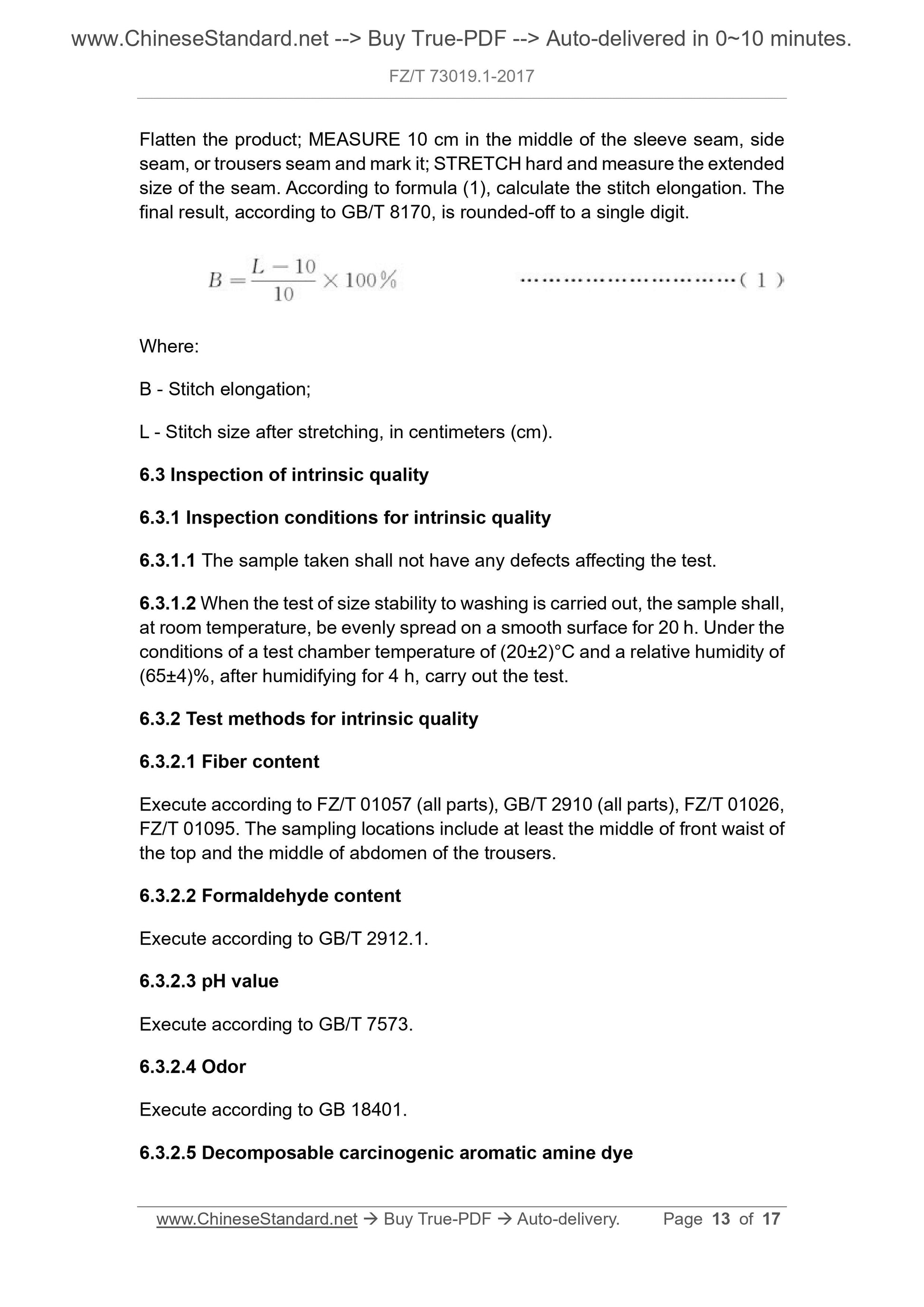

Flatten the product; MEASURE 10 cm in the middle of the sleeve seam, side

seam, or trousers seam and mark it; STRETCH hard and measure the extended

size of the seam. According to formula (1), calculate the stitch elongation. The

final result, according to GB/T 8170, is rounded-off to a single digit.

Where:

B - Stitch elongation;

L - Stitch size after stretching, in centimeters (cm).

6.3 Inspection of intrinsic quality

6.3.1 Inspection conditions for intrinsic quality

6.3.1.1 The sample taken shall not have any defects affecting the test.

6.3.1.2 When the test of size stability to washing is carried out, the sample shall,

at room temperature, be evenly spread on a smooth surface for 20 h. Under the

conditions of a test chamber temperature of (20±2)°C and a relative humidity of

(65±4)%, after humidifying for 4 h, carry out the test.

6.3.2 Test methods for intrinsic quality

6.3.2.1 Fiber content

Execute according to FZ/T 01057 (all parts), GB/T 2910 (all parts), FZ/T 01026,

FZ/T 01095. The sampling locations include at least the middle of front waist of

the top and the middle of abdomen of the trousers.

6.3.2.2 Formaldehyde content

Execute according to GB/T 2912.1.

6.3.2.3 pH value

Execute according to GB/T 7573.

6.3.2.4 Odor

Execute according to GB 18401.

6.3.2.5 Decomposable carcinogenic aromatic amine dye

6.3.2.11 Pilling

Execute according to Method E in GB/T 4802.1-2008. The grade is evaluated

based on the fabric style and the pilling shape according to GSB 16-1523.

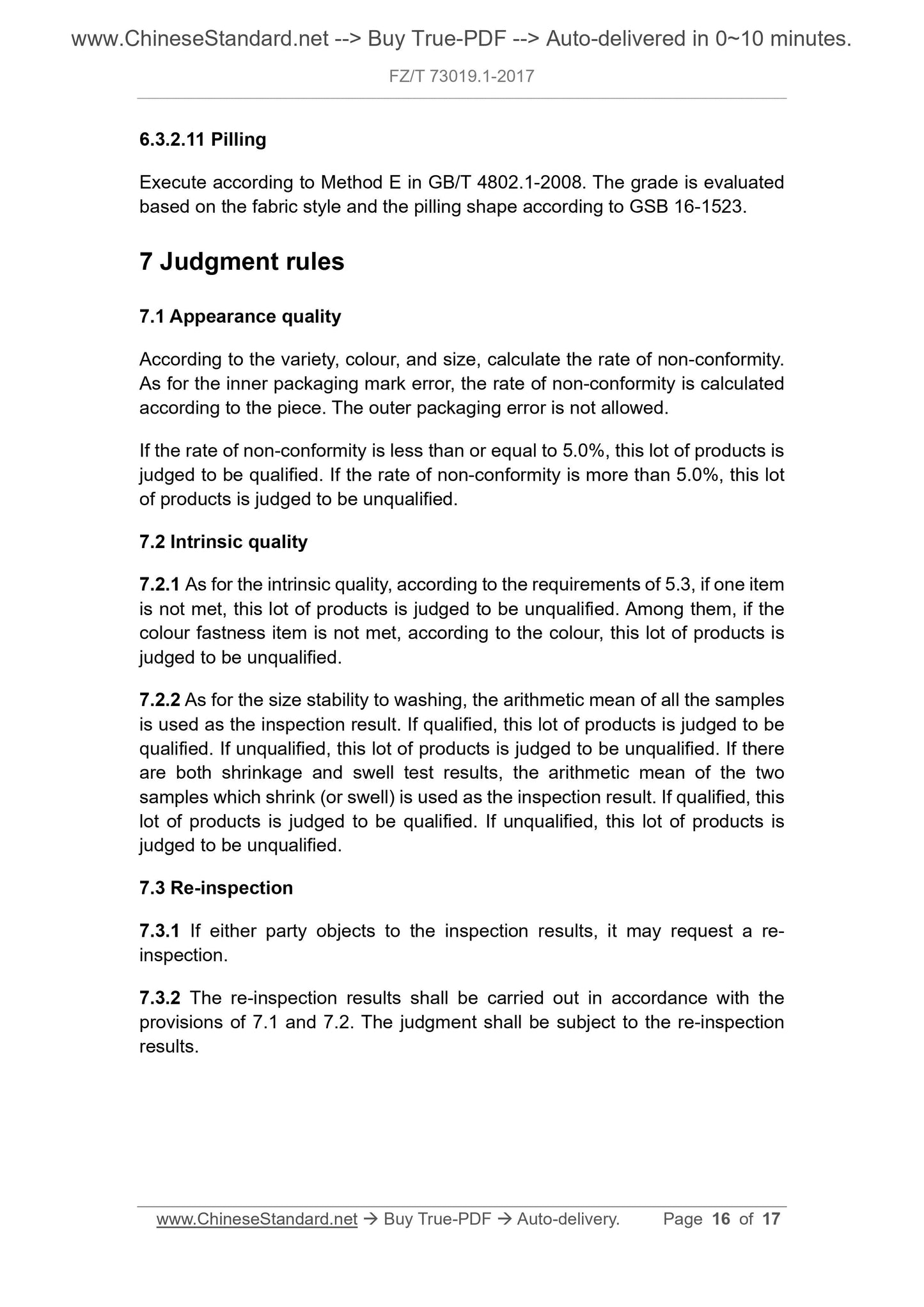

7 Judg...

Get QUOTATION in 1-minute: Click FZ/T 73019.1-2017

Historical versions: FZ/T 73019.1-2017

Preview True-PDF (Reload/Scroll if blank)

FZ/T 73019.1-2017: Knitted shape inner wear. Elastic style

FZ/T 73019.1-2017

TEXTILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 59.080.30

W 63

Replacing FZ/T 73019.1-2010

Knitted shape inner wear - Elastic style

针织塑身内衣 弹力型

ISSUED ON: NOVEMBER 07, 2017

IMPLEMENTED ON: APRIL 01, 2018

Issued by: Ministry of Industry and Information Technology of the PRC

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Size... 6

5 Requirements ... 7

6 Tests ... 11

7 Judgment rules ... 16

8 Product use instructions, packaging, transportation, and storage ... 17

Knitted shape inner wear - Elastic style

1 Scope

This Standard specifies the terms and definitions, size, requirements, tests,

judgment rules, use instructions, packaging, transportation, and storage of

knitted shape inner wear-elastic style products.

This Standard applies to the identification of the quality of elastic-style knitted

shape inner wear and side seam-free knitted shape inner wear products.

This Standard does not apply to the clothing of infants and young children aged

36 months or less.

2 Normative references

The following documents are indispensable for the application of this document.

For the dated references, only the editions with the dates indicated are

applicable to this document. For the undated references, the latest edition

(including all the amendments) are applicable to this document.

GB/T 250 Textiles - Tests for colour fastness - Grey scale for assessing

change in colour

GB/T 2910 (all parts) Textiles - Quantitative chemical analysis

GB/T 2912.1 Textiles - Determination of formaldehyde - Part 1: Free and

hydrolyzed formaldehyde (water extraction method)

GB/T 3920 Textiles - Tests for colour fastness - Colour fastness to rubbing

GB/T 3921-2008 Textiles - Tests for colour fastness - Colour fastness to

washing with soap or soap and soda

GB/T 3922 Textiles - Testing method for colour fastness to perspiration

GB/T 4802.1-2008 Textiles - Determination of fabric propensity to surface

fuzzing and to pilling - Part 1: Circular locus method

GB/T 4856 Package of cotton goods and knitwear

GB/T 5296.4 Instructions for use of products of consumer interest - Part 4:

Textiles and apparel

the net chest (waist) circumference of the human body suitable, for example:

155-165/85-90, or according to the provisions of GB/T 6411.

5 Requirements

5.1 Requirement content

Requirements are divided into two aspects: intrinsic quality and appearance

quality. Intrinsic quality includes indicators such as fiber content, formaldehyde

content, pH value, odor, decomposable carcinogenic aromatic amine dye,

colour fastness to washing with soap or soap and soda, colour fastness to

rubbing, colour fastness to perspiration, colour fastness to water, size stability

to washing, and pilling. Appearance quality includes indicators such as surface

defects, size deviations of major parts of the finished product, size differences

of symmetrical parts, stitch elongation, and sewing regulations.

5.2 Grading regulations

5.2.1 The quality grade of knitted shape inner wear-elastic style products is

divided into superior product, first-class product, and qualified product.

5.2.2 For the quality grading of knitted shape inner wear-elastic style products,

the intrinsic quality is graded by lot (delivery lot); the appearance quality is

graded by piece. The combination of intrinsic quality and appearance quality is

graded at the lowest grade.

5.2.3 The indicators of intrinsic quality take the lowest one of the test results as

the grading basis of this lot of products.

5.2.4 When the appearance quality problems of different grades are found on

the same product, it is graded at the lowest grade. Only two extreme surface

defects of the same grade are allowed on the same product; those exceeding

this limit shall be reduced by one grade.

5.3 Intrinsic quality requirements

5.3.1 The intrinsic quality requirements are shown in Table 1.

Table 5 -- Stitch density regulations

In number of stitches per 2 centimeter

Category Flat seam

Flat

double

needle

Three-

needle

machine

Four-

needle

machine

Rolling

collar

Rolling

belt

Wide

banding

machine

Overlock

Overlock

and

rolling rim

≥ 9 8 9 8 9 9 8 8 7

Note: The stitch density is measured in the middle of a sewing process.

5.4.5.6 The seam width of the overlock machine, for three threads, is not less

than 0.3 cm; for four threads, is not less than 0.4 cm; for five threads, is not less

than 0.6 cm.

5.4.5.7 For the skipped stitch for single stitch of double-needle covering stitch

machine, it is allowed to disperse 1 stitch in 3 places.

6 Tests

6.1 Sampling quantity

6.1.1 As for appearance quality, the delivery lot is randomly sampled 1%~3%

according to the variety, colour, and size, no less than 20 pieces. If the lot size

is less than 20 pieces, the total is inspected.

6.1.2 As for intrinsic quality, the delivery lot is randomly sampled 4 pieces

according to the variety, colour, and size. If insufficient, the number of pieces

may be increased.

6.2 Inspection of appearance quality

6.2.1 Inspection conditions for appearance quality

6.2.1.1 Generally, use lamplight to inspect. USE a 40 W white-light fluorescent

lamp; ADD a lamp cover thereon. The vertical distance between the lamp cover

and the center of inspection table is (80±5)cm.

6.2.1.2 If natural light is used indoors, the light source shall enter in the north to

the left (or right) upper angle, so that the sunlight cannot be directed to the

product.

6.2.1.3 During the inspection, the product shall be spread evenly on the

inspection table. The table shall be covered with a white cloth. The line of sight

of the inspector shall face the surface of the flat stand product. The visual

distance is more than 35 cm.

Flatten the product; MEASURE 10 cm in the middle of the sleeve seam, side

seam, or trousers seam and mark it; STRETCH hard and measure the extended

size of the seam. According to formula (1), calculate the stitch elongation. The

final result, according to GB/T 8170, is rounded-off to a single digit.

Where:

B - Stitch elongation;

L - Stitch size after stretching, in centimeters (cm).

6.3 Inspection of intrinsic quality

6.3.1 Inspection conditions for intrinsic quality

6.3.1.1 The sample taken shall not have any defects affecting the test.

6.3.1.2 When the test of size stability to washing is carried out, the sample shall,

at room temperature, be evenly spread on a smooth surface for 20 h. Under the

conditions of a test chamber temperature of (20±2)°C and a relative humidity of

(65±4)%, after humidifying for 4 h, carry out the test.

6.3.2 Test methods for intrinsic quality

6.3.2.1 Fiber content

Execute according to FZ/T 01057 (all parts), GB/T 2910 (all parts), FZ/T 01026,

FZ/T 01095. The sampling locations include at least the middle of front waist of

the top and the middle of abdomen of the trousers.

6.3.2.2 Formaldehyde content

Execute according to GB/T 2912.1.

6.3.2.3 pH value

Execute according to GB/T 7573.

6.3.2.4 Odor

Execute according to GB 18401.

6.3.2.5 Decomposable carcinogenic aromatic amine dye

6.3.2.11 Pilling

Execute according to Method E in GB/T 4802.1-2008. The grade is evaluated

based on the fabric style and the pilling shape according to GSB 16-1523.

7 Judg...

Share