1

/

von

11

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB 1886.3-2021 English PDF (GB1886.3-2021)

GB 1886.3-2021 English PDF (GB1886.3-2021)

Normaler Preis

$125.00 USD

Normaler Preis

Verkaufspreis

$125.00 USD

Grundpreis

/

pro

Versand wird beim Checkout berechnet

Verfügbarkeit für Abholungen konnte nicht geladen werden

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB 1886.3-2021

Historical versions: GB 1886.3-2021

Preview True-PDF (Reload/Scroll if blank)

GB 1886.3-2021: National food safety standard - Food additives - Calcium hydrogen phosphate

GB 1886.3-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

National food safety standard -

Food additives - Calcium hydrogen phosphate

食品添加剂 磷酸氢钙

ISSUED ON: FEBRUARY 22, 2021

IMPLEMENTED ON: AUGUST 22, 2021

Issued by: National Health Commission of the People's Republic of China;

State Administration for Market Regulation.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Molecular formula and relative molecular mass ... 4

3 Technical requirements ... 4

Annex A Inspection methods ... 6

National food safety standard -

Food additives - Calcium hydrogen phosphate

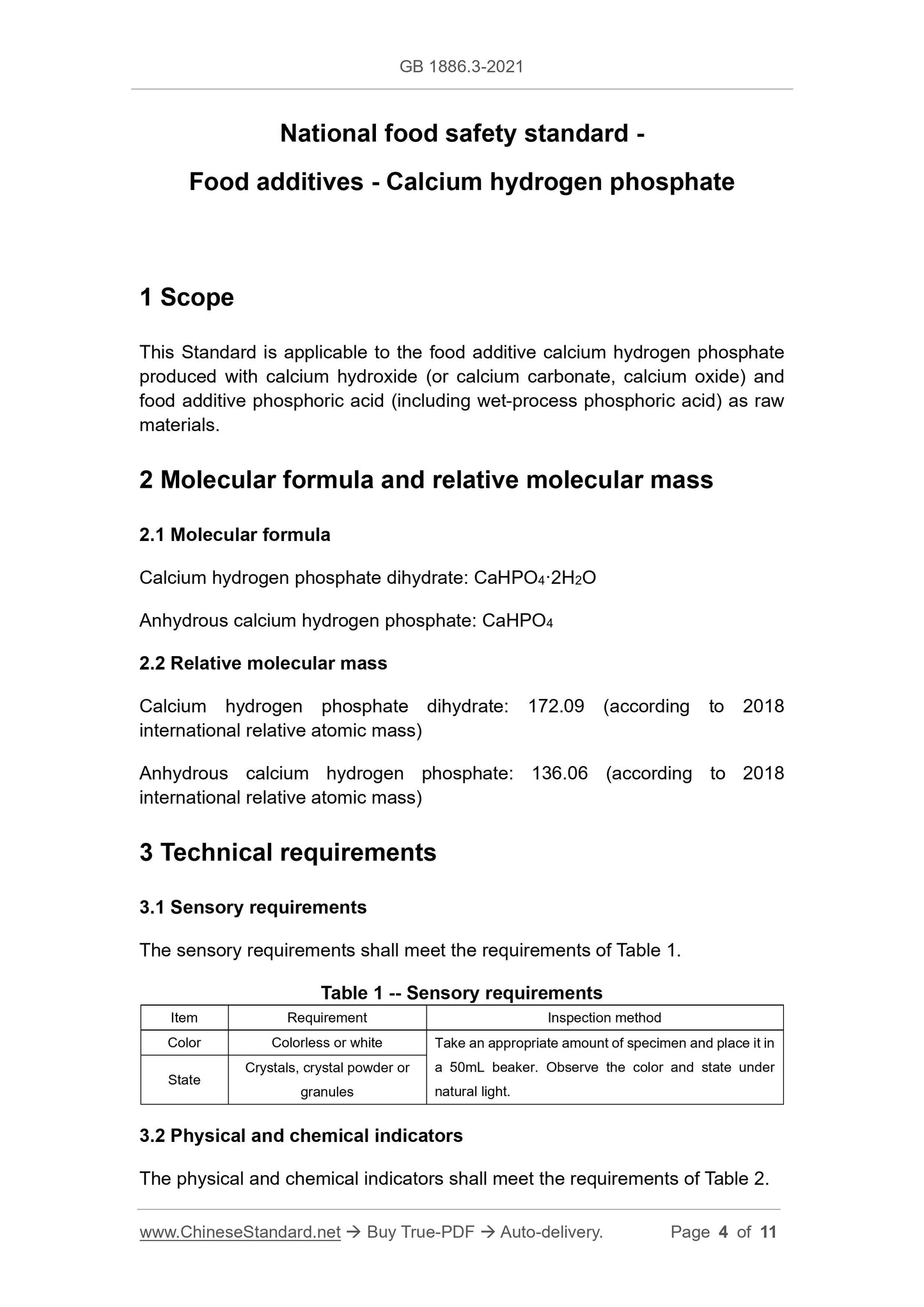

1 Scope

This Standard is applicable to the food additive calcium hydrogen phosphate

produced with calcium hydroxide (or calcium carbonate, calcium oxide) and

food additive phosphoric acid (including wet-process phosphoric acid) as raw

materials.

2 Molecular formula and relative molecular mass

2.1 Molecular formula

Calcium hydrogen phosphate dihydrate: CaHPO4·2H2O

Anhydrous calcium hydrogen phosphate: CaHPO4

2.2 Relative molecular mass

Calcium hydrogen phosphate dihydrate: 172.09 (according to 2018

international relative atomic mass)

Anhydrous calcium hydrogen phosphate: 136.06 (according to 2018

international relative atomic mass)

3 Technical requirements

3.1 Sensory requirements

The sensory requirements shall meet the requirements of Table 1.

Table 1 -- Sensory requirements

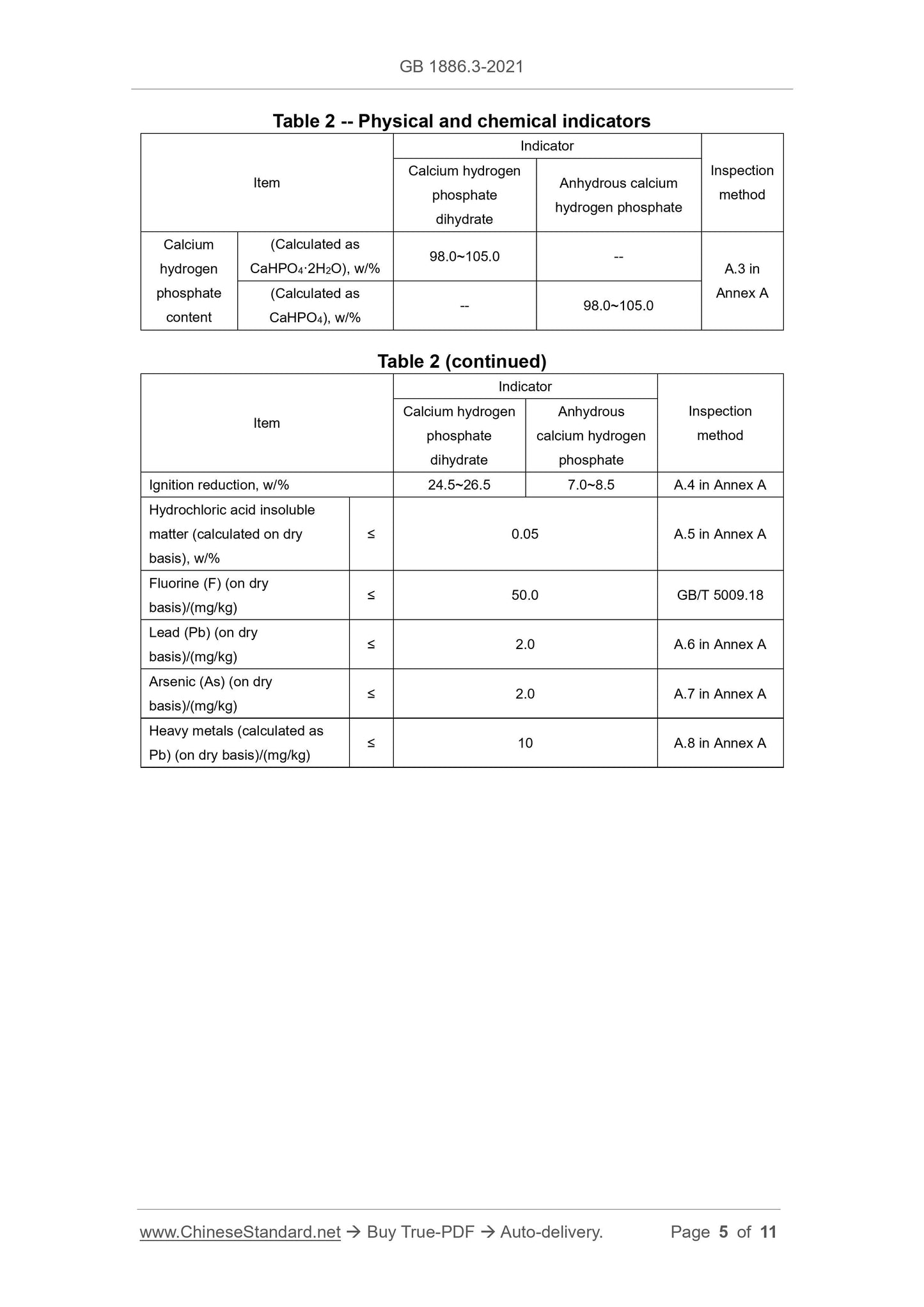

3.2 Physical and chemical indicators

The physical and chemical indicators shall meet the requirements of Table 2.

Annex A

Inspection methods

WARNING: Some reagents used in this test method are toxic or corrosive.

Appropriate safety and protection measures shall be taken during

operation. When necessary, it shall be carried out in a fume hood. If it

splashes on the skin, it shall be rinsed with water immediately. The severe

cases shall be treated immediately.

A.1 General

The reagents and water used in this Standard refer to analytically-pure reagents

and grade three water specified in GB/T 6682 when other requirements are not

indicated. All standard solutions, preparations and products used in the test for

impurity determination shall be prepared in accordance with the provisions of

GB/T 601, GB/T 602, and GB/T 603 when other requirements are not specified.

The solution used refers to an aqueous solution when it is not specified which

solvent is used for preparation.

A.2 Identification test

A.2.1 Reagents and materials

A.2.1.1 Hydrochloric acid solution: 1+3.

A.2.1.2 Ammonia solution: 1+1.

A.2.1.3 Nitric acid solution: 1+1.

A.2.1.4 Ammonium oxalate solution: 35g/L. Weigh 3.5g of ammonium oxalate

[(NH4))2C2O4·H2O] and dissolve it in water. Dilute to 100mL.

A.2.1.5 Ammonium molybdate solution: 60g/L. Weigh 6g of ammonium

molybdate [(NH4)6Mo7O24·4H2O] and dissolve it in 50mL of water. While stirring,

slowly add the nitric acid solution to about 100mL. Store in a brown reagent

bottle.

A.2.2 Identification method

A.2.2.1 Identification of calcium ion

Weigh about 0.1g of specimen. Add 5mL of water, 5mL of hydrochloric acid

solution to make the specimen dissolved. Add 2.5mL of ammonia solution

dropwise while shaking. Then add 5mL of ammonium oxalate solution to

generate white precipitation.

A.2.2.2 Identification of phosphate ion

Weigh about 0.1g of specimen. Add nitric acid solution dropwise until the

specimen is dissolved and then exceed by 1mL. Heat to 40°C~50°C. Add 10mL

of ammonium molybdate solution to generate yellow precipitation.

A.3 Determination of calcium hydrogen phosphate content

A.3.1 Method summary

In the test solution, use triethanolamine as a masking agent. Under the acidic

conditions, add the standard titration solution of disodium

ethylenediaminetetraacetic acid dropwise to the end point. Use sodium

hydroxide solution to adjust the pH of the test solution within the pH range of

the hydroxynaphthol blue indicator color development. Continue to titrate the

remaining calcium.

A.3.2 Reagents and materials

A.3.2.1 Triethanolamine.

A.3.2.2 Hydrochloric acid solution: 1+1.

A.3.2.3 Sodium hydroxide solution: 450g/L.

A.3.2.4 Standard titration solution of disodium ethylenediaminetetraacetic acid:

c(EDTA)=0.05mol/L.

A.3.2.5 Hydroxynaphthol blue indicator.

A.3.3 Instruments and equipment

Magnetic stirrer.

A.3.4 Analysis steps

A.3.4.1 Preparation of test solution

Weigh 2.5g of specimen, to the nearest of 0.0002g. Place in a 100mL beaker.

Add 20mL of hydrochloric acid solution to dissolve. Transfer completely into a

250mL volumetric flask. Add water to the scale mark. Shake well. This solution

shall be the test solution.

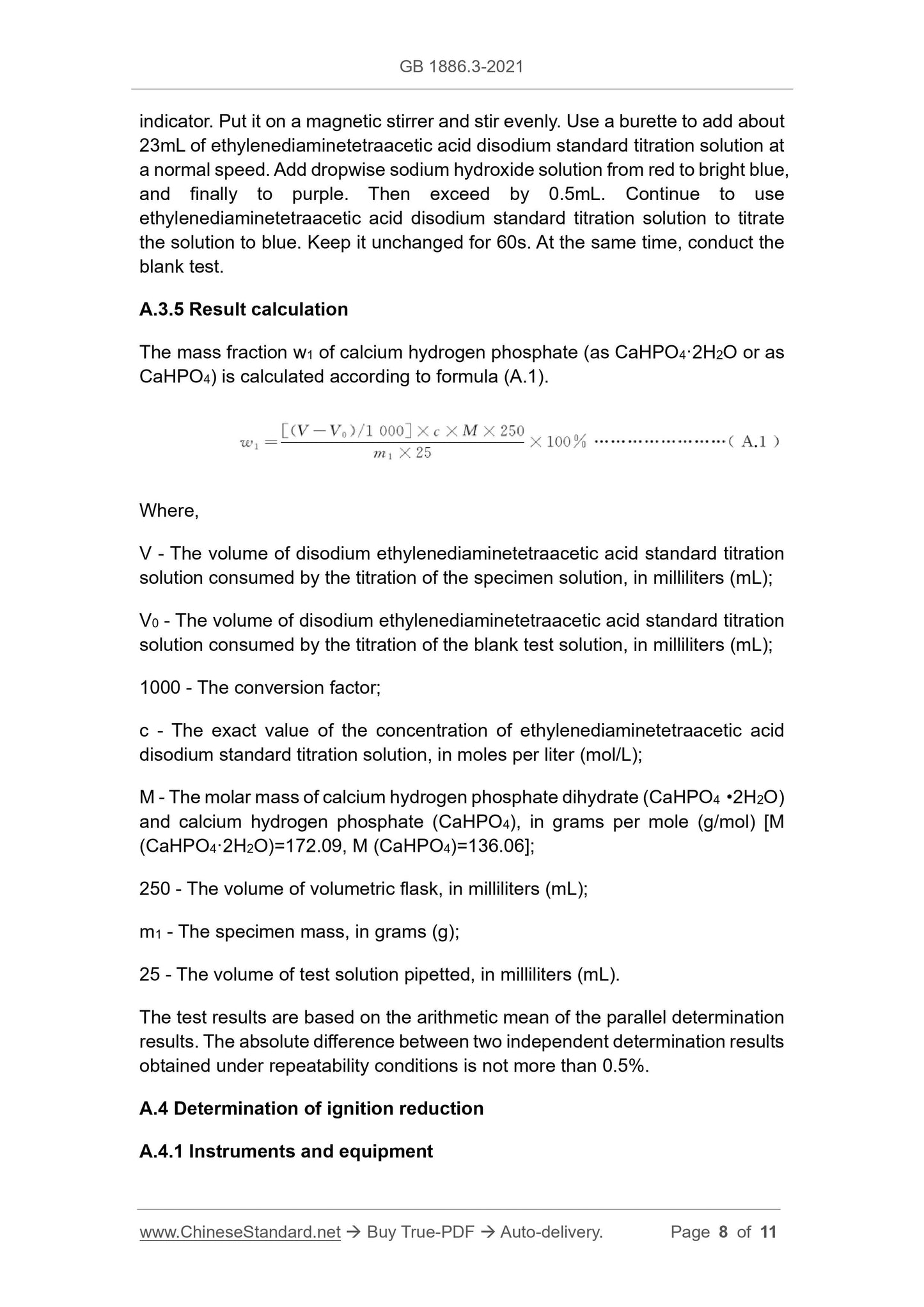

A.3.4.2 Determination

Accurately pipette 25mLof test solution in a 250mL Erlenmeyer flask. Add

100mL of water, 0.5mL of triethanolamine. Add 0.3g of hydroxynaphthol blue

A.4.1.1 High temperature furnace: The temperature control range is

800°C~825°C.

A.4.1.2 Porcelain crucible: 30mL.

A.4.2 Analysis steps

Weigh 3g of specimen, to the nearest of 0.0002g. Place in a porcelain crucible

that has been burnt at 800°C~825°C to a constant mass. Burn at 800°C~825°C

until the mass is constant.

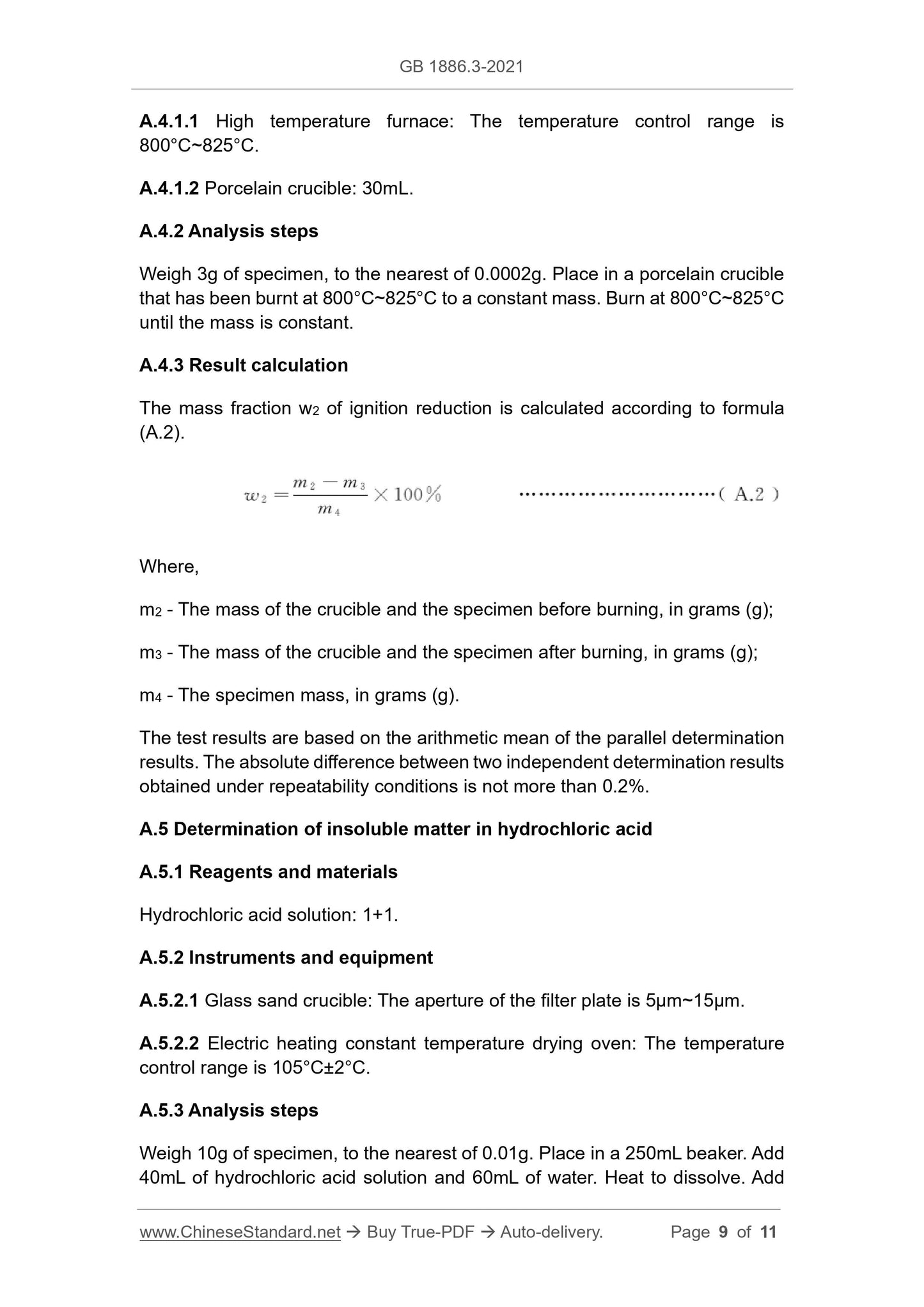

A.4.3 Result calculation

The mass fraction w2 of ignition reduction is calculated according to formula

(A.2).

Where,

m2 - The mass of the crucible and the specimen before burning, in grams (g);

m3 - The mass of the crucible and the specimen after burning, in grams (g);

m4 - The specimen mass, in grams (g).

The test results are based on the arithmetic mean of the parallel determination

results. The absolute difference between two independent determination results

obtained under repeatability conditions is not more than 0.2%.

A.5 Determination of insoluble matter in hydrochloric acid

A.5.1 Reagents and materials

Hydrochloric acid solution: 1+1.

A.5.2 Instruments and equipment

A.5.2.1 Glass sand crucible: The aperture of the filter plate is 5μm~15μm.

A.5.2.2 Electric heating constant temperature drying oven: The temperature

control range is 105°C±2°C.

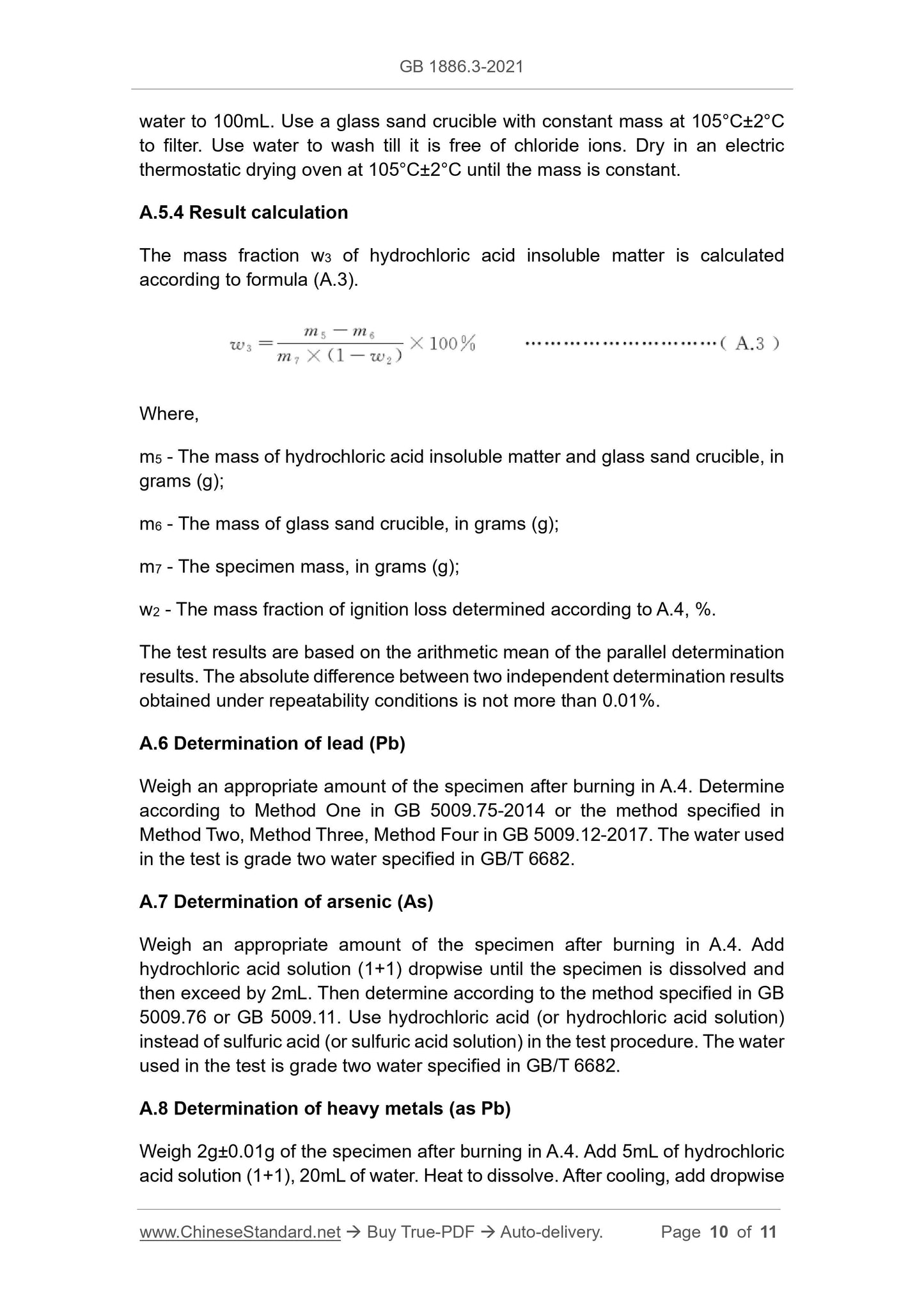

A.5.3 Analysis steps

Weigh 10g of specimen, to the nearest of 0.01g. Place in a 250mL beaker. Add

40mL of hydrochloric acid solution and 60mL of water. Heat to dissolve. Add

Get QUOTATION in 1-minute: Click GB 1886.3-2021

Historical versions: GB 1886.3-2021

Preview True-PDF (Reload/Scroll if blank)

GB 1886.3-2021: National food safety standard - Food additives - Calcium hydrogen phosphate

GB 1886.3-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

National food safety standard -

Food additives - Calcium hydrogen phosphate

食品添加剂 磷酸氢钙

ISSUED ON: FEBRUARY 22, 2021

IMPLEMENTED ON: AUGUST 22, 2021

Issued by: National Health Commission of the People's Republic of China;

State Administration for Market Regulation.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Molecular formula and relative molecular mass ... 4

3 Technical requirements ... 4

Annex A Inspection methods ... 6

National food safety standard -

Food additives - Calcium hydrogen phosphate

1 Scope

This Standard is applicable to the food additive calcium hydrogen phosphate

produced with calcium hydroxide (or calcium carbonate, calcium oxide) and

food additive phosphoric acid (including wet-process phosphoric acid) as raw

materials.

2 Molecular formula and relative molecular mass

2.1 Molecular formula

Calcium hydrogen phosphate dihydrate: CaHPO4·2H2O

Anhydrous calcium hydrogen phosphate: CaHPO4

2.2 Relative molecular mass

Calcium hydrogen phosphate dihydrate: 172.09 (according to 2018

international relative atomic mass)

Anhydrous calcium hydrogen phosphate: 136.06 (according to 2018

international relative atomic mass)

3 Technical requirements

3.1 Sensory requirements

The sensory requirements shall meet the requirements of Table 1.

Table 1 -- Sensory requirements

3.2 Physical and chemical indicators

The physical and chemical indicators shall meet the requirements of Table 2.

Annex A

Inspection methods

WARNING: Some reagents used in this test method are toxic or corrosive.

Appropriate safety and protection measures shall be taken during

operation. When necessary, it shall be carried out in a fume hood. If it

splashes on the skin, it shall be rinsed with water immediately. The severe

cases shall be treated immediately.

A.1 General

The reagents and water used in this Standard refer to analytically-pure reagents

and grade three water specified in GB/T 6682 when other requirements are not

indicated. All standard solutions, preparations and products used in the test for

impurity determination shall be prepared in accordance with the provisions of

GB/T 601, GB/T 602, and GB/T 603 when other requirements are not specified.

The solution used refers to an aqueous solution when it is not specified which

solvent is used for preparation.

A.2 Identification test

A.2.1 Reagents and materials

A.2.1.1 Hydrochloric acid solution: 1+3.

A.2.1.2 Ammonia solution: 1+1.

A.2.1.3 Nitric acid solution: 1+1.

A.2.1.4 Ammonium oxalate solution: 35g/L. Weigh 3.5g of ammonium oxalate

[(NH4))2C2O4·H2O] and dissolve it in water. Dilute to 100mL.

A.2.1.5 Ammonium molybdate solution: 60g/L. Weigh 6g of ammonium

molybdate [(NH4)6Mo7O24·4H2O] and dissolve it in 50mL of water. While stirring,

slowly add the nitric acid solution to about 100mL. Store in a brown reagent

bottle.

A.2.2 Identification method

A.2.2.1 Identification of calcium ion

Weigh about 0.1g of specimen. Add 5mL of water, 5mL of hydrochloric acid

solution to make the specimen dissolved. Add 2.5mL of ammonia solution

dropwise while shaking. Then add 5mL of ammonium oxalate solution to

generate white precipitation.

A.2.2.2 Identification of phosphate ion

Weigh about 0.1g of specimen. Add nitric acid solution dropwise until the

specimen is dissolved and then exceed by 1mL. Heat to 40°C~50°C. Add 10mL

of ammonium molybdate solution to generate yellow precipitation.

A.3 Determination of calcium hydrogen phosphate content

A.3.1 Method summary

In the test solution, use triethanolamine as a masking agent. Under the acidic

conditions, add the standard titration solution of disodium

ethylenediaminetetraacetic acid dropwise to the end point. Use sodium

hydroxide solution to adjust the pH of the test solution within the pH range of

the hydroxynaphthol blue indicator color development. Continue to titrate the

remaining calcium.

A.3.2 Reagents and materials

A.3.2.1 Triethanolamine.

A.3.2.2 Hydrochloric acid solution: 1+1.

A.3.2.3 Sodium hydroxide solution: 450g/L.

A.3.2.4 Standard titration solution of disodium ethylenediaminetetraacetic acid:

c(EDTA)=0.05mol/L.

A.3.2.5 Hydroxynaphthol blue indicator.

A.3.3 Instruments and equipment

Magnetic stirrer.

A.3.4 Analysis steps

A.3.4.1 Preparation of test solution

Weigh 2.5g of specimen, to the nearest of 0.0002g. Place in a 100mL beaker.

Add 20mL of hydrochloric acid solution to dissolve. Transfer completely into a

250mL volumetric flask. Add water to the scale mark. Shake well. This solution

shall be the test solution.

A.3.4.2 Determination

Accurately pipette 25mLof test solution in a 250mL Erlenmeyer flask. Add

100mL of water, 0.5mL of triethanolamine. Add 0.3g of hydroxynaphthol blue

A.4.1.1 High temperature furnace: The temperature control range is

800°C~825°C.

A.4.1.2 Porcelain crucible: 30mL.

A.4.2 Analysis steps

Weigh 3g of specimen, to the nearest of 0.0002g. Place in a porcelain crucible

that has been burnt at 800°C~825°C to a constant mass. Burn at 800°C~825°C

until the mass is constant.

A.4.3 Result calculation

The mass fraction w2 of ignition reduction is calculated according to formula

(A.2).

Where,

m2 - The mass of the crucible and the specimen before burning, in grams (g);

m3 - The mass of the crucible and the specimen after burning, in grams (g);

m4 - The specimen mass, in grams (g).

The test results are based on the arithmetic mean of the parallel determination

results. The absolute difference between two independent determination results

obtained under repeatability conditions is not more than 0.2%.

A.5 Determination of insoluble matter in hydrochloric acid

A.5.1 Reagents and materials

Hydrochloric acid solution: 1+1.

A.5.2 Instruments and equipment

A.5.2.1 Glass sand crucible: The aperture of the filter plate is 5μm~15μm.

A.5.2.2 Electric heating constant temperature drying oven: The temperature

control range is 105°C±2°C.

A.5.3 Analysis steps

Weigh 10g of specimen, to the nearest of 0.01g. Place in a 250mL beaker. Add

40mL of hydrochloric acid solution and 60mL of water. Heat to dissolve. Add

Share