1

/

von

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB 4066-2017 English PDF (GB4066-2017)

GB 4066-2017 English PDF (GB4066-2017)

Normaler Preis

$350.00 USD

Normaler Preis

Verkaufspreis

$350.00 USD

Grundpreis

/

pro

Versand wird beim Checkout berechnet

Verfügbarkeit für Abholungen konnte nicht geladen werden

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB 4066-2017

Historical versions: GB 4066-2017

Preview True-PDF (Reload/Scroll if blank)

GB 4066-2017: Powder extinguishing agent

GB 4066-2017

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 13.220.10

C 83

Replacing GB 4066.1-2004, GB 4066.2-2004

Powder extinguishing agent

干粉灭火剂

ISSUED ON: DECEMBER 29, 2017

IMPLEMENTED ON: JULY 01, 2018

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Models ... 6

5 Technical requirements ... 7

6 Test methods ... 7

7 Inspection rules ... 18

8 Marks, packaging, instruction manual, transportation and storage ... 19

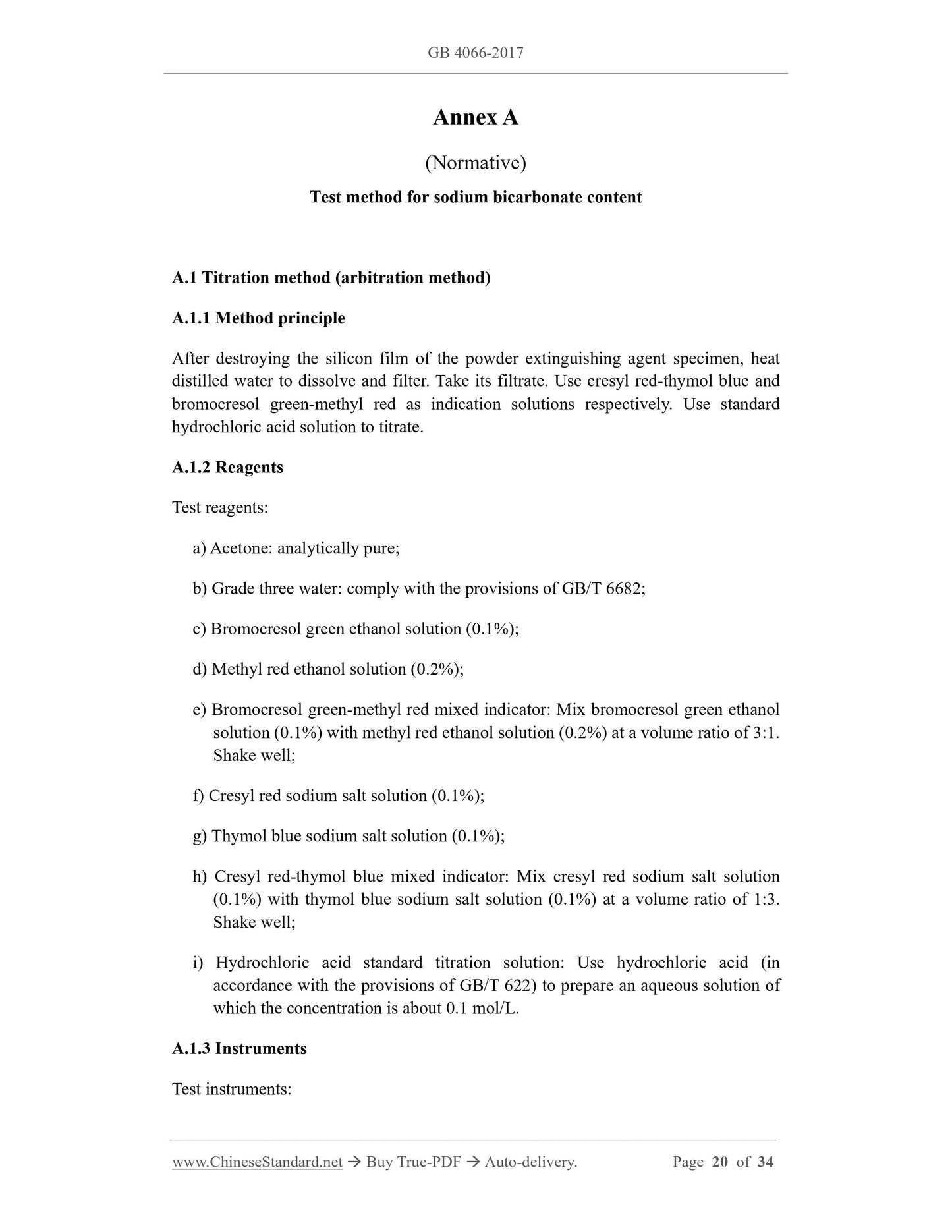

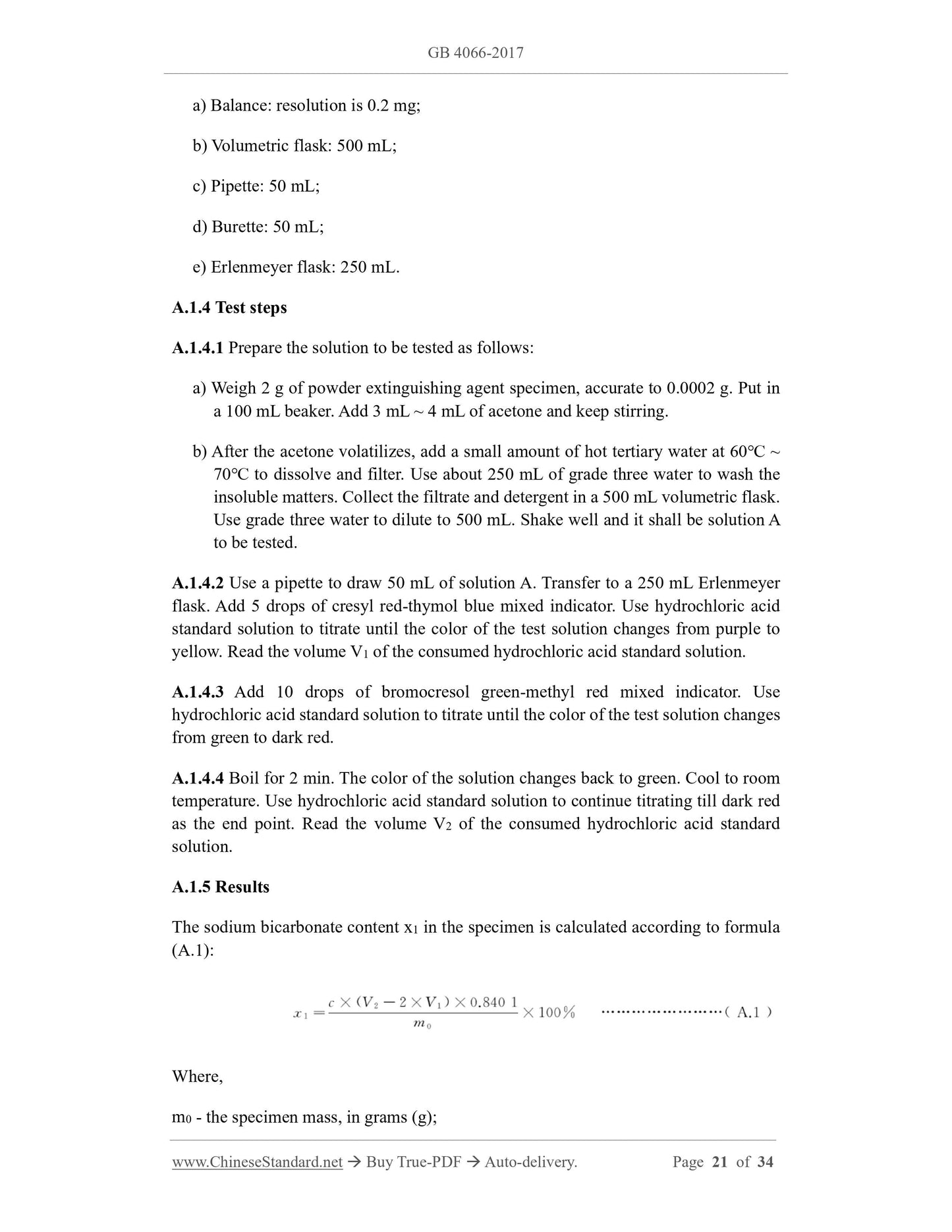

Annex A (Normative) Test method for sodium bicarbonate content ... 20

Annex B (Normative) Test method for ammonium dihydrogen phosphate content ... 24

Annex C (Normative) Test method for class A fire extinguishing performance ... 27

Annex D (Normative) Test method for class B, C fire extinguishing performance ... 31

Powder extinguishing agent

1 Scope

This Standard specifies the terms and definitions, models, technical requirements, test

methods, inspection rules, marks, packaging, transportation and storage for powder

extinguishing agent.

This Standard applies to powder extinguishing agent whose major chemical content is

not less than 75%. It is not suitable for ultra-fine powder extinguishing agent specified

in GA 578 and Class D powder extinguishing agent specified in GA 979.

2 Normative references

The following referenced documents are indispensable for the application of this

document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

GB/T 535, Fertilizer grade ammonium sulphate

GB/T 622, Chemical reagent - Hydrochloric acid

GB 4351.1, Portable fire extinguishers - Part 1: Performance and construction

GB/T 4509, Standard test method for penetration of bitumen

GB/T 4968, Classification of fires

GB/T 5907 (all parts), Fire protection vocabulary

GB/T 6003.1, Test sieves - Technical requirements and testing - Part 1: Test sieves

of metal wire cloth

GB/T 6682, Water for analytical laboratory use - Specification and test methods

GB/T 9969, General principles for preparation of instructions for use of industrial

products

GA 578, Super fine powder fire extinguishing agent

GA 634, Adiabatic protective clothing for firefighter

GA 979, Fire extinguishing media. D power

3 Terms and definitions

For the purposes of this document, the terms and definitions defined in GB/T 5907 and

GB/T 4968 as well as the followings apply.

3.1 characterization statement

The data and information on the physical or chemical properties of powder

extinguishing agent provided by the manufacturer or the inspection entrusting party. It

includes the content of chemical content, bulk density, particle size distribution, fire

extinguishing performance, etc.

3.2 chemical content

The basic component of powder extinguishing agent. Additives used to improve

extinguishing agent storage, moisture resistance, fluidity, etc. are not included.

3.3 major chemical content

Among the chemical contents of powder extinguishing agent, the chemical content with

the highest content.

3.4 batch

Uniformed products that are produced according to the same formula and the same

process, one-time feeding and production.

3.5 lot

Multiple batches of products under the same formula, process, and raw materials. The

total amount shall not exceed 25 t.

NOTE: Any major changes in production personnel, manufacturing process, raw materials or

environmental conditions are considered as different lots.

4 Models

The model of powder extinguishing agent is represented by a combination of fire type

codes applicable to firefighting, chemical content and amount, and enterprise-defined

information. The total content of chemical contents shall not be less than 90%.

b) Weighing bottle: ϕ70 mm × 40 mm;

c) Desiccator: ϕ220 mm;

d) Balance: accuracy is 0.2 mg.

6.3.2 Test steps

6.3.2.1 In the weighing bottle with constant weight, weigh 5 g of powder extinguishing

agent specimen, accurate to 0.2 mg.

6.3.2.2 Place the weighing bottle without the cap in the desiccator filled with sulfuric

acid at a temperature of 20°C±2°C for 48 h.

6.3.2.3 Take out the weighing bottle and put it in the desiccator. Weigh after standing

for 15 min, accurate to 0.2 mg.

6.3.3 Results

Moisture content x1 is calculated according to formula (2):

Where,

m1 - the mass of the specimen before drying, in grams (g);

m2 - the mass of the specimen after drying, in grams (g).

Take the average of the two test results with a difference of not more than 0.02% as the

measurement result.

6.4 Moisture absorption rate

6.4.1 Reagents, instruments and equipment

The requirements for reagents, instruments, and equipment for the moisture absorption

rate test are as follows:

a) Ammonium chloride: chemically pure;

b) Balance: accuracy is 0.2 mg;

c) Weighing bottle: ϕ50 mm × 30 mm;

d) Desiccator: ϕ220 mm;

e) Constant temperature and humidity system: saturated ammonium chloride

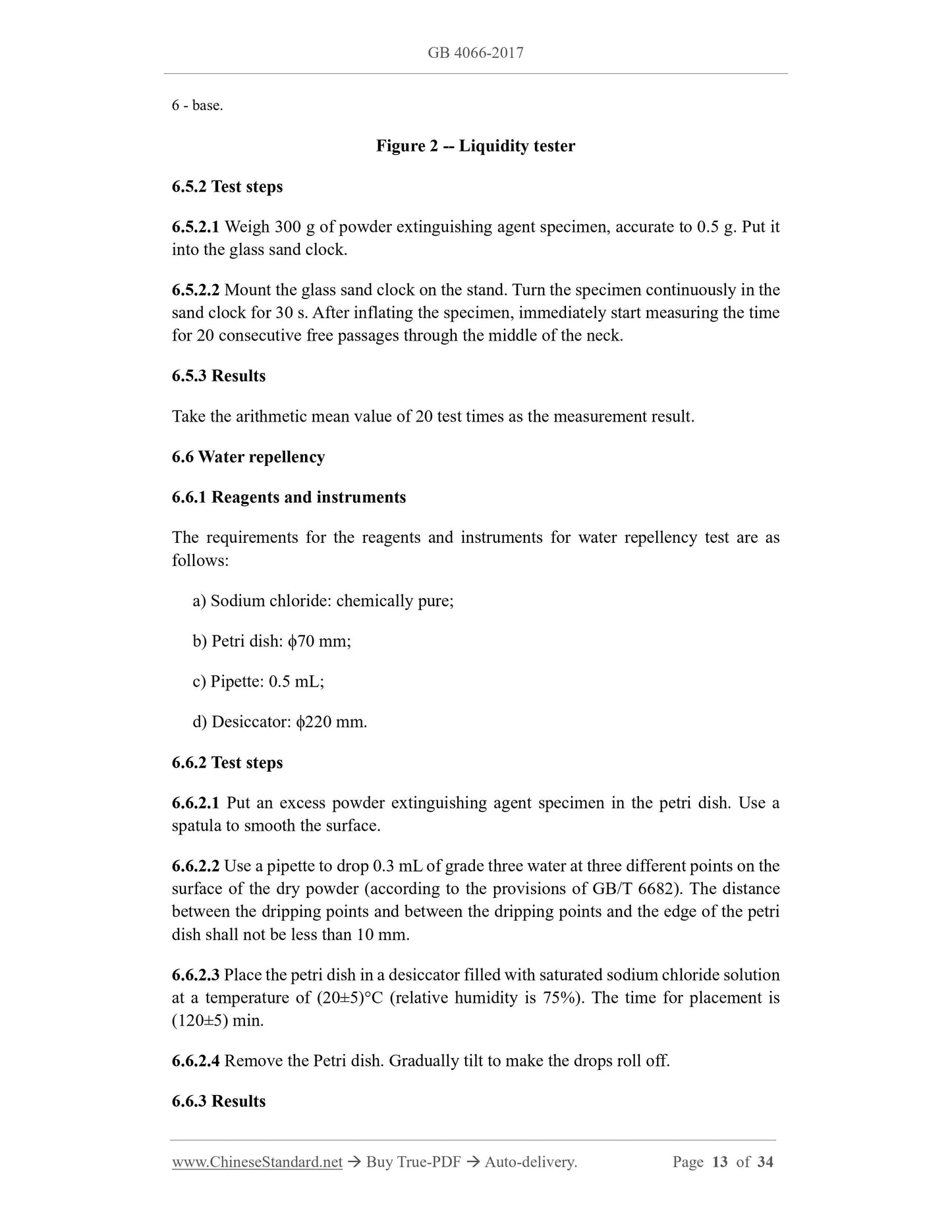

6 - base.

Figure 2 -- Liquidity tester

6.5.2 Test steps

6.5.2.1 Weigh 300 g of powder extinguishing agent specimen, accurate to 0.5 g. Put it

into the glass sand clock.

6.5.2.2 Mount the glass sand clock on the stand. Turn the specimen continuously in the

sand clock for 30 s. After inflating the specimen, immediately start measuring the time

for 20 consecutive free passages through the middle of the neck.

6.5.3 Results

Take the arithmetic mean value of 20 test times as the measurement result.

6.6 Water repellency

6.6.1 Reagents and instruments

The requirements for the reagents and instruments for water repellency test are as

follows:

a) Sodium chloride: chemically pure;

b) Petri dish: ϕ70 mm;

c) Pipette: 0.5 mL;

d) Desiccator: ϕ220 mm.

6.6.2 Test steps

6.6.2.1 Put an excess powder extinguishing agent specimen in the petri dish. Use a

spatula to smooth the surface.

6.6.2.2 Use a pipette to drop 0.3 mL of grade three water at three different points on the

surface of the dry powder (according to the provisions of GB/T 6682). The distance

between the dripping points and between the dripping points and the edge of the petri

dish shall not be less than 10 mm.

6.6.2.3 Place the petri dish in a desiccator filled with saturated sodium chloride solution

at a temperature of (20±5)°C (relative humidity is 75%). The time for placement is

(120±5) min.

6.6.2.4 Remove the Petri dish. Gradually tilt to make the drops roll off.

6.6.3 Results

Observe whether the specimen has obvious water absorption and agglomeration.

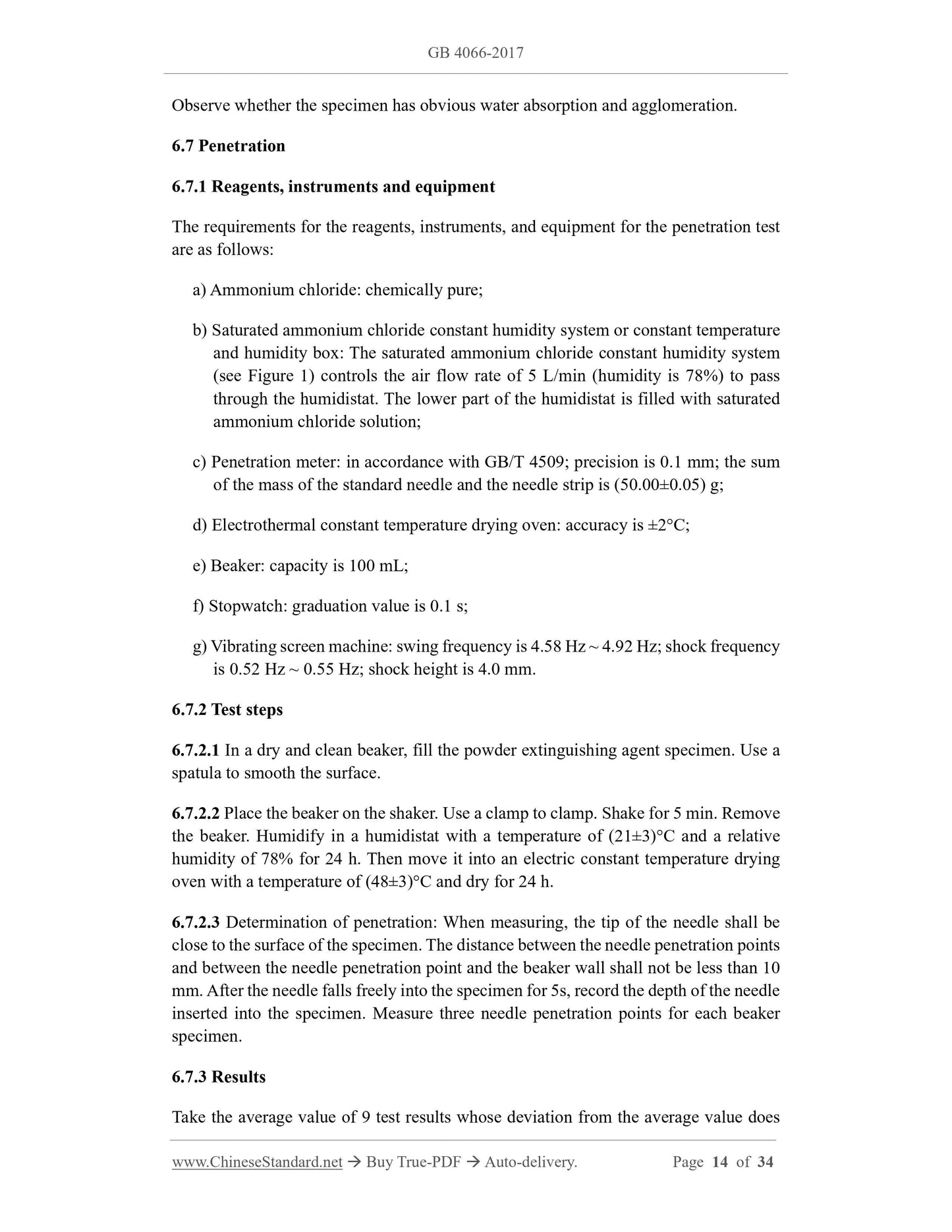

6.7 Penetration

6.7.1 Reagents, instruments and equipment

The requirements for the reagents, instruments, and equipment for the penetration test

are as follows:

a) Ammonium chloride: chemically pure;

b) Saturated ammonium chloride constant humidity system or constant temperature

and humidity box: The saturated ammonium chloride constant humidity system

(see Figure 1) controls the air flow rate of 5 L/min (humidity is 78%) to pass

through the humidistat. The lower part of the humidistat is filled with saturated

ammonium chloride solution;

c) Penetration meter: in accordance with GB/T 4509; precision is 0.1 mm; the sum

of...

Get QUOTATION in 1-minute: Click GB 4066-2017

Historical versions: GB 4066-2017

Preview True-PDF (Reload/Scroll if blank)

GB 4066-2017: Powder extinguishing agent

GB 4066-2017

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 13.220.10

C 83

Replacing GB 4066.1-2004, GB 4066.2-2004

Powder extinguishing agent

干粉灭火剂

ISSUED ON: DECEMBER 29, 2017

IMPLEMENTED ON: JULY 01, 2018

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Models ... 6

5 Technical requirements ... 7

6 Test methods ... 7

7 Inspection rules ... 18

8 Marks, packaging, instruction manual, transportation and storage ... 19

Annex A (Normative) Test method for sodium bicarbonate content ... 20

Annex B (Normative) Test method for ammonium dihydrogen phosphate content ... 24

Annex C (Normative) Test method for class A fire extinguishing performance ... 27

Annex D (Normative) Test method for class B, C fire extinguishing performance ... 31

Powder extinguishing agent

1 Scope

This Standard specifies the terms and definitions, models, technical requirements, test

methods, inspection rules, marks, packaging, transportation and storage for powder

extinguishing agent.

This Standard applies to powder extinguishing agent whose major chemical content is

not less than 75%. It is not suitable for ultra-fine powder extinguishing agent specified

in GA 578 and Class D powder extinguishing agent specified in GA 979.

2 Normative references

The following referenced documents are indispensable for the application of this

document. For dated references, only the edition cited applies. For undated references,

the latest edition of the referenced document (including any amendments) applies.

GB/T 535, Fertilizer grade ammonium sulphate

GB/T 622, Chemical reagent - Hydrochloric acid

GB 4351.1, Portable fire extinguishers - Part 1: Performance and construction

GB/T 4509, Standard test method for penetration of bitumen

GB/T 4968, Classification of fires

GB/T 5907 (all parts), Fire protection vocabulary

GB/T 6003.1, Test sieves - Technical requirements and testing - Part 1: Test sieves

of metal wire cloth

GB/T 6682, Water for analytical laboratory use - Specification and test methods

GB/T 9969, General principles for preparation of instructions for use of industrial

products

GA 578, Super fine powder fire extinguishing agent

GA 634, Adiabatic protective clothing for firefighter

GA 979, Fire extinguishing media. D power

3 Terms and definitions

For the purposes of this document, the terms and definitions defined in GB/T 5907 and

GB/T 4968 as well as the followings apply.

3.1 characterization statement

The data and information on the physical or chemical properties of powder

extinguishing agent provided by the manufacturer or the inspection entrusting party. It

includes the content of chemical content, bulk density, particle size distribution, fire

extinguishing performance, etc.

3.2 chemical content

The basic component of powder extinguishing agent. Additives used to improve

extinguishing agent storage, moisture resistance, fluidity, etc. are not included.

3.3 major chemical content

Among the chemical contents of powder extinguishing agent, the chemical content with

the highest content.

3.4 batch

Uniformed products that are produced according to the same formula and the same

process, one-time feeding and production.

3.5 lot

Multiple batches of products under the same formula, process, and raw materials. The

total amount shall not exceed 25 t.

NOTE: Any major changes in production personnel, manufacturing process, raw materials or

environmental conditions are considered as different lots.

4 Models

The model of powder extinguishing agent is represented by a combination of fire type

codes applicable to firefighting, chemical content and amount, and enterprise-defined

information. The total content of chemical contents shall not be less than 90%.

b) Weighing bottle: ϕ70 mm × 40 mm;

c) Desiccator: ϕ220 mm;

d) Balance: accuracy is 0.2 mg.

6.3.2 Test steps

6.3.2.1 In the weighing bottle with constant weight, weigh 5 g of powder extinguishing

agent specimen, accurate to 0.2 mg.

6.3.2.2 Place the weighing bottle without the cap in the desiccator filled with sulfuric

acid at a temperature of 20°C±2°C for 48 h.

6.3.2.3 Take out the weighing bottle and put it in the desiccator. Weigh after standing

for 15 min, accurate to 0.2 mg.

6.3.3 Results

Moisture content x1 is calculated according to formula (2):

Where,

m1 - the mass of the specimen before drying, in grams (g);

m2 - the mass of the specimen after drying, in grams (g).

Take the average of the two test results with a difference of not more than 0.02% as the

measurement result.

6.4 Moisture absorption rate

6.4.1 Reagents, instruments and equipment

The requirements for reagents, instruments, and equipment for the moisture absorption

rate test are as follows:

a) Ammonium chloride: chemically pure;

b) Balance: accuracy is 0.2 mg;

c) Weighing bottle: ϕ50 mm × 30 mm;

d) Desiccator: ϕ220 mm;

e) Constant temperature and humidity system: saturated ammonium chloride

6 - base.

Figure 2 -- Liquidity tester

6.5.2 Test steps

6.5.2.1 Weigh 300 g of powder extinguishing agent specimen, accurate to 0.5 g. Put it

into the glass sand clock.

6.5.2.2 Mount the glass sand clock on the stand. Turn the specimen continuously in the

sand clock for 30 s. After inflating the specimen, immediately start measuring the time

for 20 consecutive free passages through the middle of the neck.

6.5.3 Results

Take the arithmetic mean value of 20 test times as the measurement result.

6.6 Water repellency

6.6.1 Reagents and instruments

The requirements for the reagents and instruments for water repellency test are as

follows:

a) Sodium chloride: chemically pure;

b) Petri dish: ϕ70 mm;

c) Pipette: 0.5 mL;

d) Desiccator: ϕ220 mm.

6.6.2 Test steps

6.6.2.1 Put an excess powder extinguishing agent specimen in the petri dish. Use a

spatula to smooth the surface.

6.6.2.2 Use a pipette to drop 0.3 mL of grade three water at three different points on the

surface of the dry powder (according to the provisions of GB/T 6682). The distance

between the dripping points and between the dripping points and the edge of the petri

dish shall not be less than 10 mm.

6.6.2.3 Place the petri dish in a desiccator filled with saturated sodium chloride solution

at a temperature of (20±5)°C (relative humidity is 75%). The time for placement is

(120±5) min.

6.6.2.4 Remove the Petri dish. Gradually tilt to make the drops roll off.

6.6.3 Results

Observe whether the specimen has obvious water absorption and agglomeration.

6.7 Penetration

6.7.1 Reagents, instruments and equipment

The requirements for the reagents, instruments, and equipment for the penetration test

are as follows:

a) Ammonium chloride: chemically pure;

b) Saturated ammonium chloride constant humidity system or constant temperature

and humidity box: The saturated ammonium chloride constant humidity system

(see Figure 1) controls the air flow rate of 5 L/min (humidity is 78%) to pass

through the humidistat. The lower part of the humidistat is filled with saturated

ammonium chloride solution;

c) Penetration meter: in accordance with GB/T 4509; precision is 0.1 mm; the sum

of...

Share