1

/

von

7

PayPal, credit cards. Download editable-PDF & invoice In 1 second!

GB/T 33156-2016 English PDF (GBT33156-2016)

GB/T 33156-2016 English PDF (GBT33156-2016)

Normaler Preis

$150.00 USD

Normaler Preis

Verkaufspreis

$150.00 USD

Grundpreis

/

pro

Versand wird beim Checkout berechnet

Verfügbarkeit für Abholungen konnte nicht geladen werden

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 33156-2016

Historical versions: GB/T 33156-2016

Preview True-PDF (Reload/Scroll if blank)

GB/T 33156-2016: Precision welded tubes for gas spring

GB/T 33156-2016

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.75

H 48

Precision Welded Tubes for Gas Spring

ISSUED ON: OCTOBER 13, 2016

IMPLEMENTED ON: SEPTEMBER 01, 2017

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Classification, code ... 6

4 Ordering content ... 7

5 Size, shape, weight and allowable deviation ... 7

6 Technical requirements ... 10

7 Inspection and test methods ... 14

8 Test rules ... 15

9 Packaging, marking and quality certificate ... 15

Foreword

This Standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This Standard was proposed by China Iron and Steel Industry Association.

This Standard shall be under the jurisdiction of National Technical Committee

183 on Iron and Steel of Standardization Administration of China (SAC/TC 183).

The drafting organizations of this Standard: Jiangsu DOM Corporation Limited,

Qingdao Sanhong Precision Instrument Co., Ltd.

The drafters of this Standard: Zhou Feiyao, Pu Chengfu, Bao Yongli, Zhang

Qixu, Yao Zhiqiang, Jiang Xiaojun, Yu Qingwen.

Precision Welded Tubes for Gas Spring

1 Scope

This Standard specifies the classification, code, size, shape, weight and

allowable deviation, technical requirement, inspection and test method,

inspection rule, packaging, marking and quality certificate of precision welded

tubes for gas spring.

This Standard applies to cold-drawn or cold-rolled precision welded tubes for

gas spring (including seat air pressure bars and lifters) in machinery

manufacturing, vehicle manufacturing, and furniture products.

2 Normative references

The following documents are indispensable for the application of this document.

For dated references, only the dated version applies to this document. For

undated references, the latest edition (including all amendments) applies to this

document.

GB/T 222, Permissible tolerances for chemical composition of steel products

GB/T 223.5, Steel and iron. Determination of acid-soluble silicon and total

silicon content. Reduced molybdosilicate spectrophotometric method

GB/T 223.9, Iron, steel and alloy. Determination of aluminium content.

Chrome azurol S photometric method

GB/T 223.11, Iron, steel and alloy. Determination of chromium content. Visual

titration or potentiometric titration method

GB/T 223.12, Methods for chemical analysis of iron, steel and alloy. The

sodium carbonate separation-diphenyl carbazide photometric method for the

determination of chromium content

GB/T 223.14, Methods for chemical analysis of iron, steel and alloy. The N-

benzoy-N-phenylhydroxylamine extraction photometric method for the

determination of vanadium content

GB/T 223.16, Methods for chemical analysis of iron, steel and alloy. The

chromotropic acid photometric method for the determination of titanium

content

GB/T 223.18, Methods for chemical analysis of iron steel and alloy. The

sodium thiosulfate separation iodometric method for the determination of

cupper content

GB/T 223.19, Methods for chemical analysis of iron, steel and alloy. The

neocuproine-chloroform extraction photometric method for the determination

of copper content

GB/T 223.23, Iron, steel and alloy. Determination of nickel content. The

dimethylglyoxime spectrophotometric method

GB/T 223.26, Iron, steel and alloy. Determination of molybdenum content.

The thiocyanate spectrophotometric method

GB/T 223.32, Methods for chemical analysis of iron, steel and alloy. The

hypophosphite reduction-iodometric method for the determination of arsenic

content

GB/T 223.37, Methods for chemical analysis of iron, steel and alloy. The

indophenol blue photometric methods for the determination of nitrogen

content after distillation separation

GB/T 223.40, Iron, steel and alloy. Determination of niobium content by the

sulphochlorophenol S spectrophotometric method

GB/T 223.53, Methods for chemical analysis of iron, steel and alloy. The

flame atomic absorption spectrophotometric method for the determination of

copper content

GB/T 223.58, Methods for chemical analysis of iron, steel and alloy. The

sodium arsenite-sodium nitrite titrimetric method for the determination of

manganese content

GB/T 223.59, Iron, steel and alloy. Determination of phosphorus content.

Bismuth phosphomolybdate blue spectrophotometric method and antimony

phosphomolybdate blue spectrophotometric method

GB/T 223.60, Methods for chemical analysis of iron, steel and alloy The

perchloric acid dehydration gravimetric method for the determination of

silicon content

GB/T 223.63, Methods for chemical analysis of iron, steel and alloy. The

sodium (potassium) periodate photometric method for the determination of

manganese content

GB/T 223.64, Iron, steel and alloy. Determination of manganese content.

Flame atomic absorption spectrometric method

GB/T 223.68, Methods for chemical analysis of iron, steel and alloy The

potassium iodate titration method after combustion in the pipe furnace for the

determination of sulfur content

GB/T 223.71, Methods for chemical analysis of iron, steel and alloy The

gravimetric method after combustion in the pipe furnace for the determination

of carbon content

GB/T 223.72, Iron, steel and alloy - Determination of sulfur content.

Gravimetric method

GB/T 228.1, Metallic materials. Tensile testing - Part 1: Method of test at

room temperature

GB/T 242, Metal materials. Tube. Drift-expending test

GB/T 246, Metal materials. Tube. Flattening test

GB/T 700, Carbon structural steels

GB/T 1031, Surface roughness parameters and their values

GB/T 1591, High strength low alloy structural steels

GB/T 2102, Acceptance, packing, marking and quality certification of steel

pipe

GB/T 2975, Steel and steel products. Location and preparation of samples

and test pieces for mechanical testing

GB/T 4336, Carbon and low-alloy steel. Spark discharge atomic emission

spectrometric method (routine method)

GB/T 7735-2004, Steel tubes. The inspection method on eddy current test

GB/T 20066, Steel and iron. Sampling and preparation of samples for the

determination of chemical composition

GB/T 20123, Steel and iron. Determination of total carbon and sulfur content

Infrared absorption method after combustion in an induction furnace (routine

method)

GB/T 20125, Low-alloy steel. Determination of multi-element contents.

Inductively coupled plasma atomic emission spectrometric method

3 Classification, code

Steel pipes are divided into five classifications according to the delivery state,

and their classifications and codes are:

a) cold drawing or cold rolling / hard state: +C;

b) cold drawing or cold rolling / soft state: + LC;

c) stress-relief annealing state: +SR;

d) annealing state: +A;

e) normalizing state: +N.

4 Ordering content

The contract or order form that orders steel pipes according to this Standard

shall include the following:

a) number of this Standard;

b) product name:

c) steel grade (quality grade);

d) dimensions;

e) ordering quantity (total weight or total length);

f) delivery state;

g) manufacturing method;

h) special requirements.

5 Size, shape, weight and allowable deviation

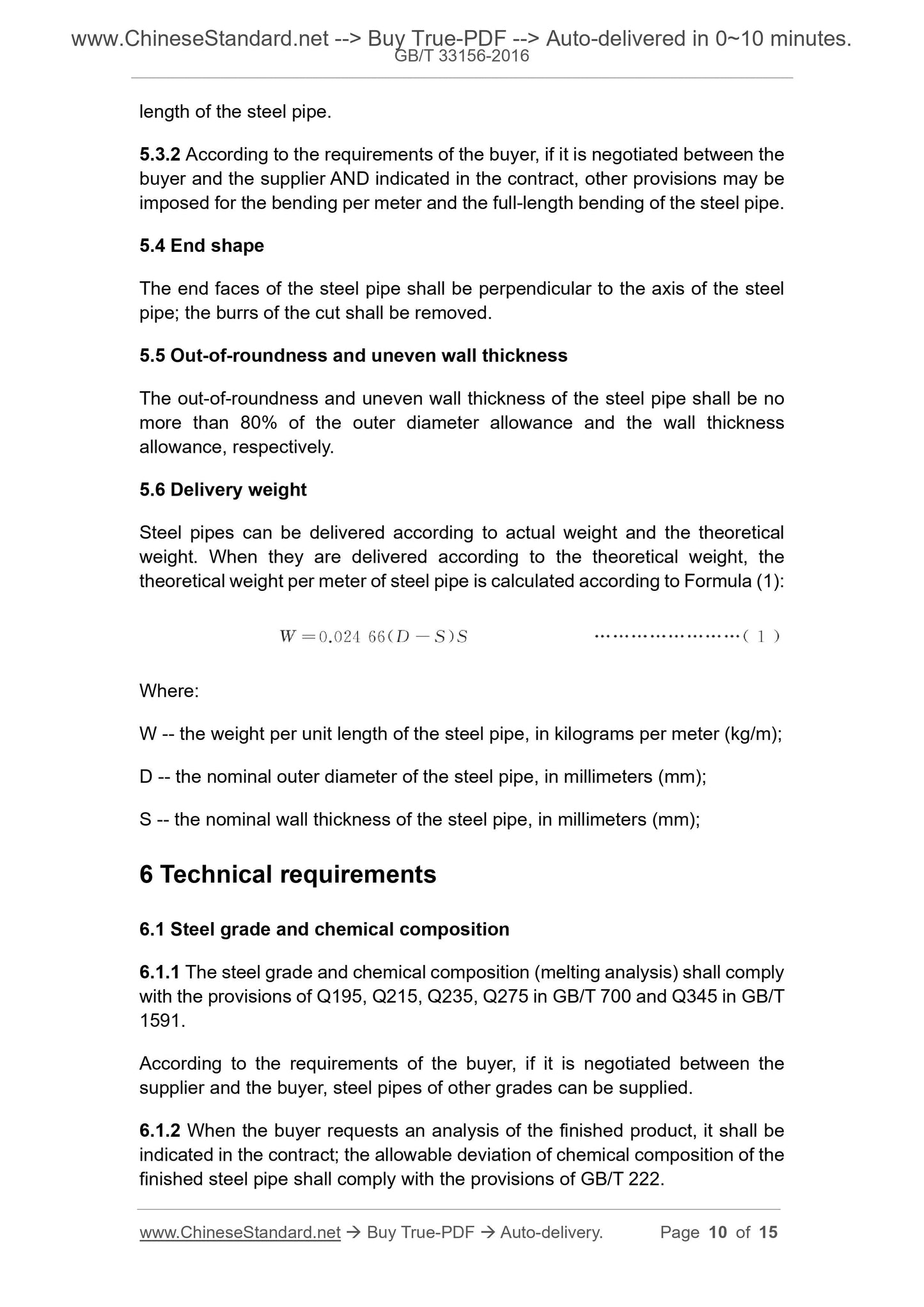

5.1 Outer diameter, inner diameter and w...

Get QUOTATION in 1-minute: Click GB/T 33156-2016

Historical versions: GB/T 33156-2016

Preview True-PDF (Reload/Scroll if blank)

GB/T 33156-2016: Precision welded tubes for gas spring

GB/T 33156-2016

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.140.75

H 48

Precision Welded Tubes for Gas Spring

ISSUED ON: OCTOBER 13, 2016

IMPLEMENTED ON: SEPTEMBER 01, 2017

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Classification, code ... 6

4 Ordering content ... 7

5 Size, shape, weight and allowable deviation ... 7

6 Technical requirements ... 10

7 Inspection and test methods ... 14

8 Test rules ... 15

9 Packaging, marking and quality certificate ... 15

Foreword

This Standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This Standard was proposed by China Iron and Steel Industry Association.

This Standard shall be under the jurisdiction of National Technical Committee

183 on Iron and Steel of Standardization Administration of China (SAC/TC 183).

The drafting organizations of this Standard: Jiangsu DOM Corporation Limited,

Qingdao Sanhong Precision Instrument Co., Ltd.

The drafters of this Standard: Zhou Feiyao, Pu Chengfu, Bao Yongli, Zhang

Qixu, Yao Zhiqiang, Jiang Xiaojun, Yu Qingwen.

Precision Welded Tubes for Gas Spring

1 Scope

This Standard specifies the classification, code, size, shape, weight and

allowable deviation, technical requirement, inspection and test method,

inspection rule, packaging, marking and quality certificate of precision welded

tubes for gas spring.

This Standard applies to cold-drawn or cold-rolled precision welded tubes for

gas spring (including seat air pressure bars and lifters) in machinery

manufacturing, vehicle manufacturing, and furniture products.

2 Normative references

The following documents are indispensable for the application of this document.

For dated references, only the dated version applies to this document. For

undated references, the latest edition (including all amendments) applies to this

document.

GB/T 222, Permissible tolerances for chemical composition of steel products

GB/T 223.5, Steel and iron. Determination of acid-soluble silicon and total

silicon content. Reduced molybdosilicate spectrophotometric method

GB/T 223.9, Iron, steel and alloy. Determination of aluminium content.

Chrome azurol S photometric method

GB/T 223.11, Iron, steel and alloy. Determination of chromium content. Visual

titration or potentiometric titration method

GB/T 223.12, Methods for chemical analysis of iron, steel and alloy. The

sodium carbonate separation-diphenyl carbazide photometric method for the

determination of chromium content

GB/T 223.14, Methods for chemical analysis of iron, steel and alloy. The N-

benzoy-N-phenylhydroxylamine extraction photometric method for the

determination of vanadium content

GB/T 223.16, Methods for chemical analysis of iron, steel and alloy. The

chromotropic acid photometric method for the determination of titanium

content

GB/T 223.18, Methods for chemical analysis of iron steel and alloy. The

sodium thiosulfate separation iodometric method for the determination of

cupper content

GB/T 223.19, Methods for chemical analysis of iron, steel and alloy. The

neocuproine-chloroform extraction photometric method for the determination

of copper content

GB/T 223.23, Iron, steel and alloy. Determination of nickel content. The

dimethylglyoxime spectrophotometric method

GB/T 223.26, Iron, steel and alloy. Determination of molybdenum content.

The thiocyanate spectrophotometric method

GB/T 223.32, Methods for chemical analysis of iron, steel and alloy. The

hypophosphite reduction-iodometric method for the determination of arsenic

content

GB/T 223.37, Methods for chemical analysis of iron, steel and alloy. The

indophenol blue photometric methods for the determination of nitrogen

content after distillation separation

GB/T 223.40, Iron, steel and alloy. Determination of niobium content by the

sulphochlorophenol S spectrophotometric method

GB/T 223.53, Methods for chemical analysis of iron, steel and alloy. The

flame atomic absorption spectrophotometric method for the determination of

copper content

GB/T 223.58, Methods for chemical analysis of iron, steel and alloy. The

sodium arsenite-sodium nitrite titrimetric method for the determination of

manganese content

GB/T 223.59, Iron, steel and alloy. Determination of phosphorus content.

Bismuth phosphomolybdate blue spectrophotometric method and antimony

phosphomolybdate blue spectrophotometric method

GB/T 223.60, Methods for chemical analysis of iron, steel and alloy The

perchloric acid dehydration gravimetric method for the determination of

silicon content

GB/T 223.63, Methods for chemical analysis of iron, steel and alloy. The

sodium (potassium) periodate photometric method for the determination of

manganese content

GB/T 223.64, Iron, steel and alloy. Determination of manganese content.

Flame atomic absorption spectrometric method

GB/T 223.68, Methods for chemical analysis of iron, steel and alloy The

potassium iodate titration method after combustion in the pipe furnace for the

determination of sulfur content

GB/T 223.71, Methods for chemical analysis of iron, steel and alloy The

gravimetric method after combustion in the pipe furnace for the determination

of carbon content

GB/T 223.72, Iron, steel and alloy - Determination of sulfur content.

Gravimetric method

GB/T 228.1, Metallic materials. Tensile testing - Part 1: Method of test at

room temperature

GB/T 242, Metal materials. Tube. Drift-expending test

GB/T 246, Metal materials. Tube. Flattening test

GB/T 700, Carbon structural steels

GB/T 1031, Surface roughness parameters and their values

GB/T 1591, High strength low alloy structural steels

GB/T 2102, Acceptance, packing, marking and quality certification of steel

pipe

GB/T 2975, Steel and steel products. Location and preparation of samples

and test pieces for mechanical testing

GB/T 4336, Carbon and low-alloy steel. Spark discharge atomic emission

spectrometric method (routine method)

GB/T 7735-2004, Steel tubes. The inspection method on eddy current test

GB/T 20066, Steel and iron. Sampling and preparation of samples for the

determination of chemical composition

GB/T 20123, Steel and iron. Determination of total carbon and sulfur content

Infrared absorption method after combustion in an induction furnace (routine

method)

GB/T 20125, Low-alloy steel. Determination of multi-element contents.

Inductively coupled plasma atomic emission spectrometric method

3 Classification, code

Steel pipes are divided into five classifications according to the delivery state,

and their classifications and codes are:

a) cold drawing or cold rolling / hard state: +C;

b) cold drawing or cold rolling / soft state: + LC;

c) stress-relief annealing state: +SR;

d) annealing state: +A;

e) normalizing state: +N.

4 Ordering content

The contract or order form that orders steel pipes according to this Standard

shall include the following:

a) number of this Standard;

b) product name:

c) steel grade (quality grade);

d) dimensions;

e) ordering quantity (total weight or total length);

f) delivery state;

g) manufacturing method;

h) special requirements.

5 Size, shape, weight and allowable deviation

5.1 Outer diameter, inner diameter and w...

Share