1

/

von

9

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

LY/T 1580-2010 English PDF (LYT1580-2010)

LY/T 1580-2010 English PDF (LYT1580-2010)

Normaler Preis

$145.00 USD

Normaler Preis

Verkaufspreis

$145.00 USD

Grundpreis

/

pro

Versand wird beim Checkout berechnet

Verfügbarkeit für Abholungen konnte nicht geladen werden

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click LY/T 1580-2010

Historical versions: LY/T 1580-2010

Preview True-PDF (Reload/Scroll if blank)

LY/T 1580-2010: Oriented strand board

LY/T 1580-2010

JC

FORESTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 79.060.20

B 70

Replacing LY/T 1580-2000

Oriented strand board

ISSUED ON. FEBRUARY 09, 2010

IMPLEMENTED ON. JUNE 01, 2010

Issued by. State Forestry Administration

Table of contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Classification ... 6

5 Requirements ... 6

6 Test method ... 9

7 Results calculation and judgment method ... 13

8 Inspection rules ... 14

9 Marking, packaging, transportation and storage ... 17

Foreword

This standard is drafted in accordance with the rules given in GB/T 1.1-2009.

This standard is the revision of the LY/T 1580-2000 “Oriented strand board”. As

compared with LY/T 1580-2000, the main technical changes of this standard

are as follows.

- MODIFY the definition of oriented strand board;

- MODIFY formaldehyde emission test methods and limited value;

- ADD the physical and mechanical property requirements for the two series

products with the loaded OSB thickness > 25 mm, < 32mm and 32 mm ~

40 mm;

- INCLUDE the OSB water resistance under wet conditions into the

necessary measured indicators;

- DELETE the Appendix A and Appendix B from the original standard.

This standard, through modification, adopts ISO/FDIS 16894.2009

“Wood-based panels - Oriented strand board (OSB) - Definitions, classification

and specifications”.

The technical differences between this standard and ISO/FDIS 16894.2009

and the reasons are as follows.

- MODIFY the average density deviation indicator of the board; MAINTAIN

the indicators of the original standard;

- ADD the test methods and inspection rules, in order to be consistent with

the relevant domestic standards.

This standard was proposed by AND shall be under the jurisdiction of the

National Standardization Technical Committee for Wood-based Panel

(SAC/TC 198).

The responsible drafting organization of this standard. Nanjing Forestry

University.

The participating drafting organizations of this standard. Beixin Building

Materials (Group) Co., Ltd., Inner Mongolia Agricultural University, Luli Group

Co., Ltd., Hubei Baoyuan Wood Industry Co., Ltd., Daya Wood-based Panel

Group Co., Ltd.

The main drafters of this standard. Zhou Dingguo, Mei Changtong, Zhou

Xiaoyan, Xu Yonglan, Hua Yukun, Xu Xinwu, Jin Juwan, Deng Yuhe, Zhang

Shiyuan, Wang Xin, Yang Chunyang, Cai Weijin, Hu Zheng

This Standard replaces the standard previously issued as follows.

- LY/T 1580-2000.

Oriented strand board

1 Scope

This standard specifies the classification, requirements, test methods, results

calculation and judgment methods, inspection rules and marking, packaging,

transportation and storage of oriented strand board.

This standard applies to the multi-layer structured oriented strand board made

from the large wood shavings of specified shape and thickness through glue

application, oriented paving, and pressing.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this Standard.

GB/T 17657 Test method of evaluating the properties of wood-based panels

and surface decorated wood-based panels

GB 18580 Indoor decorating and refurbishing materials - Limit of

formaldehyde emission of wood-based panels and finishing products

GB/T 19367 Wood-based panels - Determination of dimensions of panels

3 Terms and definitions

The following terms and definitions apply to this document.

3.1

Oriented strand board, OSB

It refers to the multi-layer structured board made from the large wood

shavings of specified shape and thickness through glue application,

oriented paving, and hot pressing, with its surface shavings arranged in an

oriented manner along the length or width direction of the board.

3.2

Dry condition

It refers to the indoor environment or the outdoor environment with

protective measures. It generally refers to the environment condition of the

temperature of 20 °C AND the relative humidity of not more than 65% or

more than 65% in only a few weeks of a year.

3.3

Humid condition

It refers to the indoor environment or the outdoor environment with

protective measures. It generally refers to the environment condition of the

temperature of 20 °C AND the relative humidity of more than 65% but less

than 85% or otherwise more than 85% in only a few weeks of a year.

4 Classification

Oriented strand board can be divided into four types based on the conditions of

use.

OSB/1 - General purpose unloaded board, for interior decoration materials

and furniture under dry condition;

OSB/2 - Loaded board, for dry condition;

OSB/3 - Loaded board, for wet condition;

OSB/4 - Heavy loaded board, for wet condition.

5 Requirements

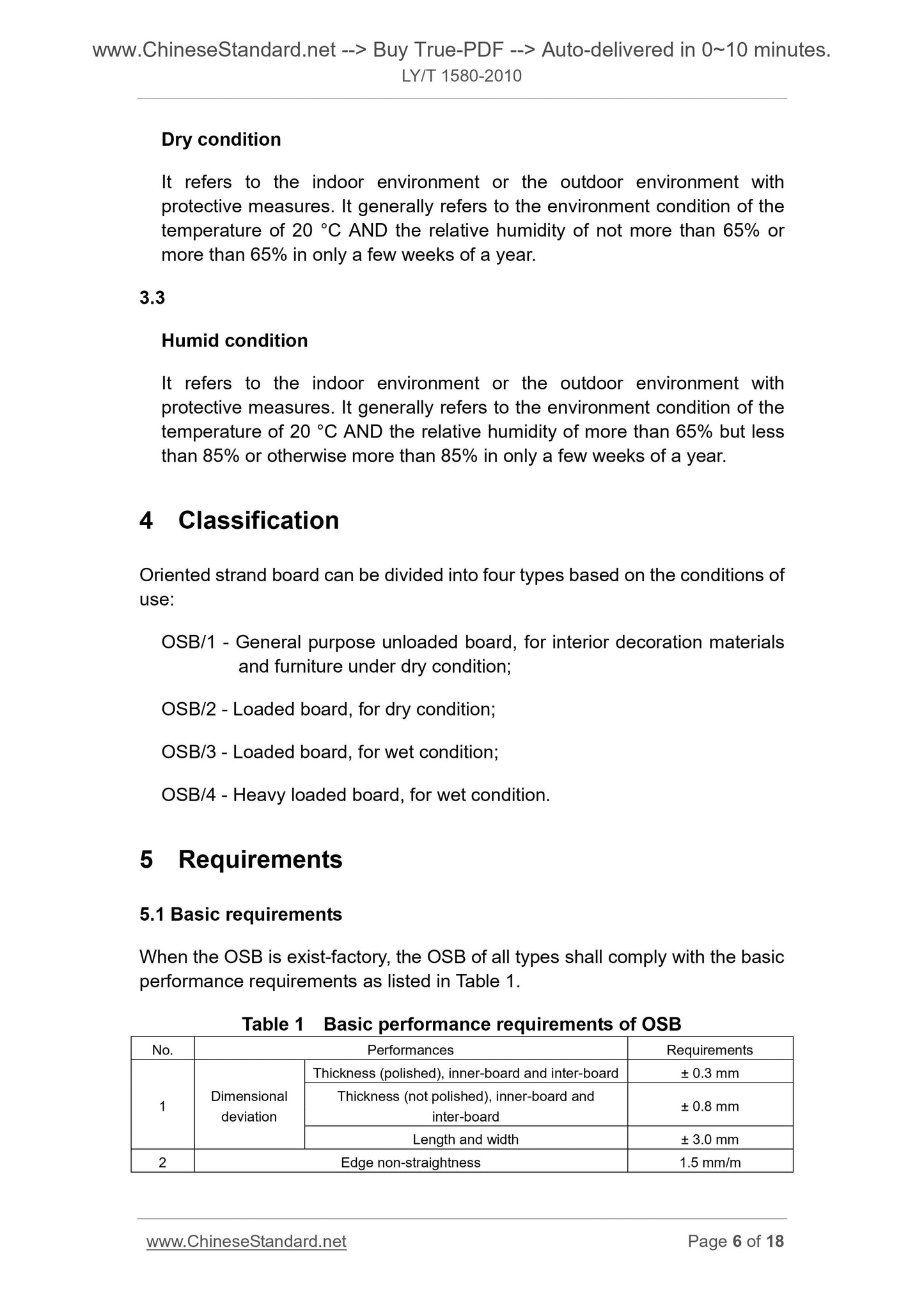

5.1 Basic requirements

When the OSB is exist-factory, the OSB of all types shall comply with the basic

performance requirements as listed in Table 1.

Table 1 Basic performance requirements of OSB

No. Performances Requirements

1 Dimensional deviation

Thickness (polished), inner-board and inter-board ± 0.3 mm

Thickness (not polished), inner-board and

inter-board ± 0.8 mm

Length and width ± 3.0 mm

2 Edge non-straightness 1.5 mm/m

CONDUCT it in accordance with the provisions on internal bonding strength of

GB/T 17657.

6.3.9 Determination of grip screw force

CONDUCT it in accordance with the provisions on grip screw force of GB/T

17657.

6.3.10 Determination of 24 h water absorption thickness expansion rate

CONDUCT it in accordance with the provisions on 24 h water absorption

thickness expansion rate of GB/T 17657.

6.3.11 Determination of static bending strength after cyclic test

After the test specimen is taken out from the constant temperature and

humidity box, immediately PLACE it vertically into the water of temperature

20 °C ± 2 °C for 72 h ± 1 h; FREEZE the test specimen in the refrigerator of

-12 °C ~ -20 °C for 24 h ± 0.25 h. After freezing, PLACE it into the drying box of

70 °C ± 1 °C to dry it for 72 h ± 1 h; after three cycles, CONDUCT the static

bending strength determination.

6.3.12 Determination of internal bonding strength after cyclic test

Cyclic treatment conditions are same as those in 6.3.11; and CONDUCT the

internal bonding strength determination after cyclic treatment.

6.3.13 Determination of internal bonding strength after boiling test

After the test specimen is subjected to mass constant treatment, PLACE it

vertically in the boiling water for 2 h; TAKE it out and IMMERSE it in the water

of 20 °C ± 5 °C for 1 h; PLACE it into the drying box of 70 °C ± 2 °C to dry it for

16 h; TAKE it out and DETERMINE its internal bonding strength.

7 Results calculation and judgment method

7.1 Result calculation

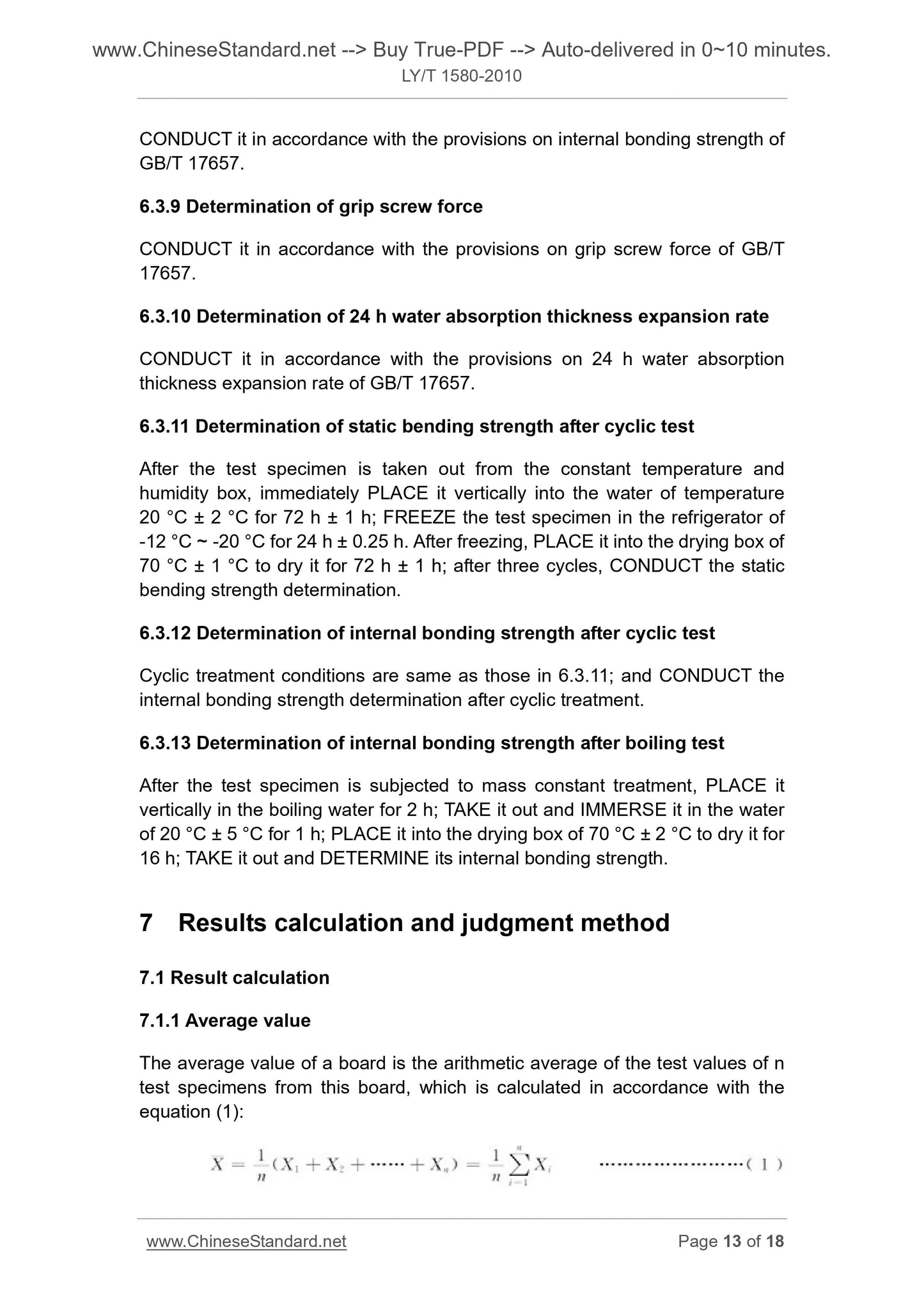

7.1.1 Average value

The average value of a board is the arithmetic average of the test values of n

test specimens from this board, which is calculated in accordance with the

equation (1).

b) Specification;

c) Physical and chemical properties. density, moisture content, water

absorption thickness expansion rate, internal bonding strength, static

bending strength, and free formaldehyde emission.

8.1.2 Type inspection includes all i...

Get QUOTATION in 1-minute: Click LY/T 1580-2010

Historical versions: LY/T 1580-2010

Preview True-PDF (Reload/Scroll if blank)

LY/T 1580-2010: Oriented strand board

LY/T 1580-2010

JC

FORESTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 79.060.20

B 70

Replacing LY/T 1580-2000

Oriented strand board

ISSUED ON. FEBRUARY 09, 2010

IMPLEMENTED ON. JUNE 01, 2010

Issued by. State Forestry Administration

Table of contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Classification ... 6

5 Requirements ... 6

6 Test method ... 9

7 Results calculation and judgment method ... 13

8 Inspection rules ... 14

9 Marking, packaging, transportation and storage ... 17

Foreword

This standard is drafted in accordance with the rules given in GB/T 1.1-2009.

This standard is the revision of the LY/T 1580-2000 “Oriented strand board”. As

compared with LY/T 1580-2000, the main technical changes of this standard

are as follows.

- MODIFY the definition of oriented strand board;

- MODIFY formaldehyde emission test methods and limited value;

- ADD the physical and mechanical property requirements for the two series

products with the loaded OSB thickness > 25 mm, < 32mm and 32 mm ~

40 mm;

- INCLUDE the OSB water resistance under wet conditions into the

necessary measured indicators;

- DELETE the Appendix A and Appendix B from the original standard.

This standard, through modification, adopts ISO/FDIS 16894.2009

“Wood-based panels - Oriented strand board (OSB) - Definitions, classification

and specifications”.

The technical differences between this standard and ISO/FDIS 16894.2009

and the reasons are as follows.

- MODIFY the average density deviation indicator of the board; MAINTAIN

the indicators of the original standard;

- ADD the test methods and inspection rules, in order to be consistent with

the relevant domestic standards.

This standard was proposed by AND shall be under the jurisdiction of the

National Standardization Technical Committee for Wood-based Panel

(SAC/TC 198).

The responsible drafting organization of this standard. Nanjing Forestry

University.

The participating drafting organizations of this standard. Beixin Building

Materials (Group) Co., Ltd., Inner Mongolia Agricultural University, Luli Group

Co., Ltd., Hubei Baoyuan Wood Industry Co., Ltd., Daya Wood-based Panel

Group Co., Ltd.

The main drafters of this standard. Zhou Dingguo, Mei Changtong, Zhou

Xiaoyan, Xu Yonglan, Hua Yukun, Xu Xinwu, Jin Juwan, Deng Yuhe, Zhang

Shiyuan, Wang Xin, Yang Chunyang, Cai Weijin, Hu Zheng

This Standard replaces the standard previously issued as follows.

- LY/T 1580-2000.

Oriented strand board

1 Scope

This standard specifies the classification, requirements, test methods, results

calculation and judgment methods, inspection rules and marking, packaging,

transportation and storage of oriented strand board.

This standard applies to the multi-layer structured oriented strand board made

from the large wood shavings of specified shape and thickness through glue

application, oriented paving, and pressing.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this Standard.

GB/T 17657 Test method of evaluating the properties of wood-based panels

and surface decorated wood-based panels

GB 18580 Indoor decorating and refurbishing materials - Limit of

formaldehyde emission of wood-based panels and finishing products

GB/T 19367 Wood-based panels - Determination of dimensions of panels

3 Terms and definitions

The following terms and definitions apply to this document.

3.1

Oriented strand board, OSB

It refers to the multi-layer structured board made from the large wood

shavings of specified shape and thickness through glue application,

oriented paving, and hot pressing, with its surface shavings arranged in an

oriented manner along the length or width direction of the board.

3.2

Dry condition

It refers to the indoor environment or the outdoor environment with

protective measures. It generally refers to the environment condition of the

temperature of 20 °C AND the relative humidity of not more than 65% or

more than 65% in only a few weeks of a year.

3.3

Humid condition

It refers to the indoor environment or the outdoor environment with

protective measures. It generally refers to the environment condition of the

temperature of 20 °C AND the relative humidity of more than 65% but less

than 85% or otherwise more than 85% in only a few weeks of a year.

4 Classification

Oriented strand board can be divided into four types based on the conditions of

use.

OSB/1 - General purpose unloaded board, for interior decoration materials

and furniture under dry condition;

OSB/2 - Loaded board, for dry condition;

OSB/3 - Loaded board, for wet condition;

OSB/4 - Heavy loaded board, for wet condition.

5 Requirements

5.1 Basic requirements

When the OSB is exist-factory, the OSB of all types shall comply with the basic

performance requirements as listed in Table 1.

Table 1 Basic performance requirements of OSB

No. Performances Requirements

1 Dimensional deviation

Thickness (polished), inner-board and inter-board ± 0.3 mm

Thickness (not polished), inner-board and

inter-board ± 0.8 mm

Length and width ± 3.0 mm

2 Edge non-straightness 1.5 mm/m

CONDUCT it in accordance with the provisions on internal bonding strength of

GB/T 17657.

6.3.9 Determination of grip screw force

CONDUCT it in accordance with the provisions on grip screw force of GB/T

17657.

6.3.10 Determination of 24 h water absorption thickness expansion rate

CONDUCT it in accordance with the provisions on 24 h water absorption

thickness expansion rate of GB/T 17657.

6.3.11 Determination of static bending strength after cyclic test

After the test specimen is taken out from the constant temperature and

humidity box, immediately PLACE it vertically into the water of temperature

20 °C ± 2 °C for 72 h ± 1 h; FREEZE the test specimen in the refrigerator of

-12 °C ~ -20 °C for 24 h ± 0.25 h. After freezing, PLACE it into the drying box of

70 °C ± 1 °C to dry it for 72 h ± 1 h; after three cycles, CONDUCT the static

bending strength determination.

6.3.12 Determination of internal bonding strength after cyclic test

Cyclic treatment conditions are same as those in 6.3.11; and CONDUCT the

internal bonding strength determination after cyclic treatment.

6.3.13 Determination of internal bonding strength after boiling test

After the test specimen is subjected to mass constant treatment, PLACE it

vertically in the boiling water for 2 h; TAKE it out and IMMERSE it in the water

of 20 °C ± 5 °C for 1 h; PLACE it into the drying box of 70 °C ± 2 °C to dry it for

16 h; TAKE it out and DETERMINE its internal bonding strength.

7 Results calculation and judgment method

7.1 Result calculation

7.1.1 Average value

The average value of a board is the arithmetic average of the test values of n

test specimens from this board, which is calculated in accordance with the

equation (1).

b) Specification;

c) Physical and chemical properties. density, moisture content, water

absorption thickness expansion rate, internal bonding strength, static

bending strength, and free formaldehyde emission.

8.1.2 Type inspection includes all i...

Share