1

/

από

12

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

TB/T 3276-2011 English PDF (TBT3276-2011)

TB/T 3276-2011 English PDF (TBT3276-2011)

Κανονική τιμή

$330.00 USD

Κανονική τιμή

Τιμή έκπτωσης

$330.00 USD

Τιμή μονάδας

/

ανά

Τα έξοδα αποστολής υπολογίζονται κατά την ολοκλήρωση της αγοράς.

Δεν ήταν δυνατή η φόρτωση της διαθεσιμότητας παραλαβής

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click TB/T 3276-2011

Historical versions: TB/T 3276-2011

Preview True-PDF (Reload/Scroll if blank)

TB/T 3276-2011: [Including 2017XG1] Rails for high speed railway

TB/T 3276-2011

RAILWAY INDUSTRY STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 45.080

S 11

Rails for high speed railway

ISSUED ON: JULY 15, 2011

IMPLEMENTED ON: AUGUST 01, 2011

Issued by: Ministry of Railways of the PRC

Table of Contents

Foreword ... 5

1 Scope ... 6

2 Normative references ... 6

3 Terms and definitions ... 7

4 Grading and selection ... 8

4.1 Grading ... 8

4.2 Selection ... 8

5 Information required for ordering ... 8

6 Type dimensions, length, weight, and tolerances ... 9

6.1 Type dimensions ... 9

6.2 Length and weight ... 9

6.3 Dimension tolerances ... 9

6.4 Straightness and distortion tolerances ... 10

6.5 Bolt hole ... 11

7 Technical requirements ... 12

7.1 Manufacturing method ... 12

7.2 Designation and chemical composition ... 12

7.3 Tensile properties ... 13

7.4 Hardness ... 13

7.5 Microstructure ... 13

7.6 Decarburization layer ... 13

7.7 Nonmetallic inclusions ... 13

7.8 Macrostructure ... 15

7.9 Drop hammer ... 15

7.10 Surface quality ... 15

7.11 Ultrasonic flaw detection ... 16

7.12 Residual stress of rail flange ... 17

7.13 Fracture toughness ... 17

7.14 Fatigue crack growth rate ... 17

7.15 Fatigue ... 17

8 Test methods ... 17

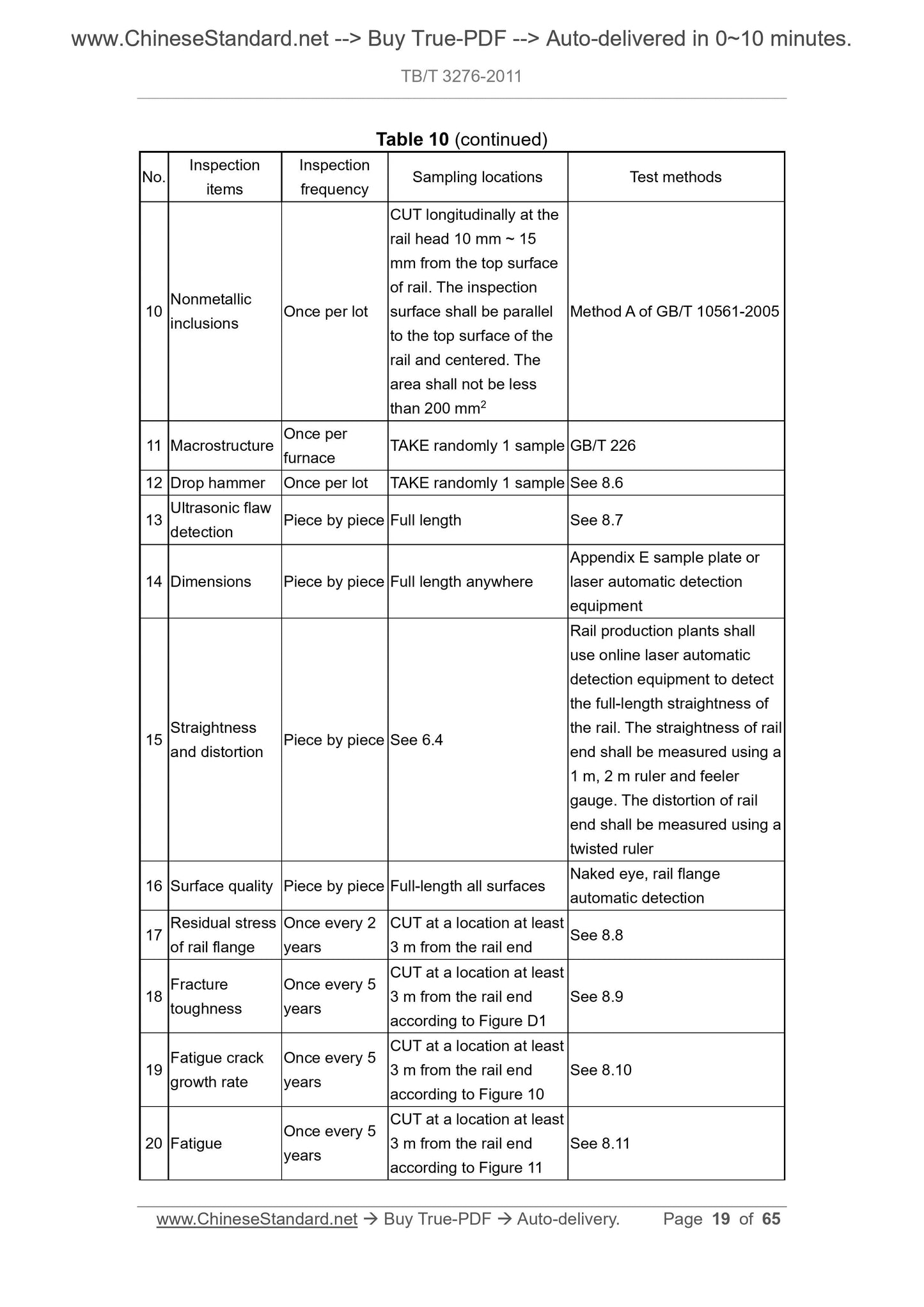

8.1 Inspection items, inspection frequency, sampling locations, and test methods .. 17

8.2 Hydrogen content ... 20

8.3 Total oxygen content and nitrogen content ... 20

8.4 Hardness ... 21

8.5 Microstructure ... 21

8.6 Drop hammer ... 21

8.7 Ultrasonic flaw detection ... 22

8.8 Residual stress of rail flange ... 25

8.9 Fracture toughness ... 25

8.10 Fatigue crack growth rate ... 25

8.11 Fatigue ... 26

9 Inspection rules ... 28

9.1 Supervision ... 28

9.2 Type inspection ... 28

9.3 Exit-factory inspection ... 28

9.4 Re-inspection and judgement ... 29

9.5 Rounding off of numerical values ... 30

10 Marking and quality certificate ... 31

10.1 Marking ... 31

10.2 Quality certificate ... 32

11 Quality assurance ... 32

11.1 Quality assurance system ... 32

11.2 Quality assurance period ... 33

Appendix A (Normative) Type dimensions of 60 kg/m rail ... 34

Appendix B (Normative) Impermissible defects on transverse acid-leached test

piece of rail ... 36

Appendix C (Normative) Method for determining the longitudinal residual stress

of rail flange ... 48

Appendix D (Normative) Test method of rail plane-strain fracture toughness KIC

... 50

Appendix E (Normative) Sample plate diagrams for inspection of geometric

dimensions of rail ... 54

Bibliography ... 64

Amendment No.1 [2017XG1] TB/T 3276-2011 “Rails for high speed railway”65

Rails for high speed railway

1 Scope

This Standard specifies the type dimensions and tolerances, technical

requirements, test methods, inspection rules, marking and quality certificate,

quality assurance, etc. of the rails.

This Standard applies to 60 kg/m hot-rolled rails for high speed railway

operating at speeds of 200 km/h and above. Rails for railway operating at

speeds greater than 160 km/h and less than 200 km/h may refer to it for

implementation.

2 Normative references

The following documents are indispensable for the application of this document.

For the dated references, only the editions with the dates indicated are

applicable to this document. For the undated references, the latest edition

(including all the amendments) are applicable to this document.

GB/T 223.14 Methods for Chemical Analysis of Iron, Steel and Alloy - The N-

Benzoy-N-Phenylhydroxylamine Extraction Photometric Method for the

Determination of Vanadium Content

GB/T 223.60 Methods for chemical analysis of iron, steel and alloy - The

perchloric acid dehydration gravimetric method for the determination of

silicon content

GB/T 223.62 Methods for chemical analysis of iron, steel and alloy - The

butyl acetate extraction photometric method for the determination of

phosphorus content

GB/T 223.63 Methods for chemical analysis of iron, steel and alloy - The

sodium (potassium) periodate photometric method for the determination of

manganese content

GB/T 223.68 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Potassium Iodate Titration Method after Combustion in the Pipe Furnace for

the Determination of Sulfur Content

GB/T 223.71 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Gravimetric Method after Combustion in the Pipe Furnace for the

Determination of Carbon Content

GB/T 223.82 Steel and iron - Determination of hydrogen content - Thermal

conductivity/infrared method after fusion under inert gas

GB/T 226 Test method for macrostructure and defect of steel by etching

GB/T 228 Metallic materials - Tensile testing at ambient temperature

GB/T 231.1 Metallic materials - Brinell hardness test - Part 1: Test method

GB/T 3075 Metallic materials - Fatigue testing - Axial-force-controlled

method

GB/T 4161 Metallic materials - Determination of plane-strain fracture

toughness

GB/T 4336 Carbon and low-alloy steel - Determination of multi-element

contents - Spark discharge atomic emission spectrometric method (routine

method)

GB/T 6398 Metallic materials - Fatigue testing - Fatigue crack growth method

GB/T 10561-2005 Steel - Determination of Content of Nonmetallic Inclusions

- Micrographic Method Using Standards Diagrams

GB/T 11261 Steel and Iron - Determination of oxygen content - The pulse

heating inert gas fusion-infra-red absorption method

GB/T 13298 Inspection methods of microstructure for metals

GB/T 19001 Quality management systems - Requirements

GB/T 20066 Steel and Iron - Sampling and Preparation of Samples for the

Determination of Chemical Composition

GB/T 20124 Steel and iron - Determination of nitrogen content - Thermal

conductimetric method after fusion in a current of inert gas

YB/T 081 Rule for rounding off of numerical values and judgement of testing

values for technical standards of metallurgy

3 Terms and definitions

The following terms and definitions apply to this document.

3.1 Heat

All slabs cast from a furnace of molten steel; but excluding the first slab cast

from the next furnace of molten steel entering into tundish casting.

3.2 Sequence

Continuous casting of the same designation by molten steel of different heats

in tundish.

3.3 Transition area

The part cast by a mixture of two furnaces of molten steel.

4 Grading and selection

4.1 Grading

The nonmetallic inclusions in the steel are divided into two grades, A and B.

4.2 Selection

This Standard specifies two steel designations of U71MnG and U75VG. High

speed railways above 250 km/h and high speed passenger railways of 200 km/h

~ 250 km/h shall select U71MnG rails. High speed passenger and freight mixed

railways of 200 km/h ~ 250 km/h shall select U75VG rails.

For nonmetallic inclusions of rails for high speed railway above 250 km/h, it

shall adopt Grade A. For nonmetallic inclusions of rails for high speed railway

of 200 km/h ~ 250 km/h, it shall adopt Grade B.

5 Information required for ordering

When the user is ordering, it shall provide the following basic information:

a) Product name;

b) Product standard number;

c) Steel designation;

d) Rail type and applicable speed range (or grade of nonmetallic inclusions);

e) No-hole or hole rail (number of holes, one end drilled or both ends drilled);

f) ...

Get QUOTATION in 1-minute: Click TB/T 3276-2011

Historical versions: TB/T 3276-2011

Preview True-PDF (Reload/Scroll if blank)

TB/T 3276-2011: [Including 2017XG1] Rails for high speed railway

TB/T 3276-2011

RAILWAY INDUSTRY STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 45.080

S 11

Rails for high speed railway

ISSUED ON: JULY 15, 2011

IMPLEMENTED ON: AUGUST 01, 2011

Issued by: Ministry of Railways of the PRC

Table of Contents

Foreword ... 5

1 Scope ... 6

2 Normative references ... 6

3 Terms and definitions ... 7

4 Grading and selection ... 8

4.1 Grading ... 8

4.2 Selection ... 8

5 Information required for ordering ... 8

6 Type dimensions, length, weight, and tolerances ... 9

6.1 Type dimensions ... 9

6.2 Length and weight ... 9

6.3 Dimension tolerances ... 9

6.4 Straightness and distortion tolerances ... 10

6.5 Bolt hole ... 11

7 Technical requirements ... 12

7.1 Manufacturing method ... 12

7.2 Designation and chemical composition ... 12

7.3 Tensile properties ... 13

7.4 Hardness ... 13

7.5 Microstructure ... 13

7.6 Decarburization layer ... 13

7.7 Nonmetallic inclusions ... 13

7.8 Macrostructure ... 15

7.9 Drop hammer ... 15

7.10 Surface quality ... 15

7.11 Ultrasonic flaw detection ... 16

7.12 Residual stress of rail flange ... 17

7.13 Fracture toughness ... 17

7.14 Fatigue crack growth rate ... 17

7.15 Fatigue ... 17

8 Test methods ... 17

8.1 Inspection items, inspection frequency, sampling locations, and test methods .. 17

8.2 Hydrogen content ... 20

8.3 Total oxygen content and nitrogen content ... 20

8.4 Hardness ... 21

8.5 Microstructure ... 21

8.6 Drop hammer ... 21

8.7 Ultrasonic flaw detection ... 22

8.8 Residual stress of rail flange ... 25

8.9 Fracture toughness ... 25

8.10 Fatigue crack growth rate ... 25

8.11 Fatigue ... 26

9 Inspection rules ... 28

9.1 Supervision ... 28

9.2 Type inspection ... 28

9.3 Exit-factory inspection ... 28

9.4 Re-inspection and judgement ... 29

9.5 Rounding off of numerical values ... 30

10 Marking and quality certificate ... 31

10.1 Marking ... 31

10.2 Quality certificate ... 32

11 Quality assurance ... 32

11.1 Quality assurance system ... 32

11.2 Quality assurance period ... 33

Appendix A (Normative) Type dimensions of 60 kg/m rail ... 34

Appendix B (Normative) Impermissible defects on transverse acid-leached test

piece of rail ... 36

Appendix C (Normative) Method for determining the longitudinal residual stress

of rail flange ... 48

Appendix D (Normative) Test method of rail plane-strain fracture toughness KIC

... 50

Appendix E (Normative) Sample plate diagrams for inspection of geometric

dimensions of rail ... 54

Bibliography ... 64

Amendment No.1 [2017XG1] TB/T 3276-2011 “Rails for high speed railway”65

Rails for high speed railway

1 Scope

This Standard specifies the type dimensions and tolerances, technical

requirements, test methods, inspection rules, marking and quality certificate,

quality assurance, etc. of the rails.

This Standard applies to 60 kg/m hot-rolled rails for high speed railway

operating at speeds of 200 km/h and above. Rails for railway operating at

speeds greater than 160 km/h and less than 200 km/h may refer to it for

implementation.

2 Normative references

The following documents are indispensable for the application of this document.

For the dated references, only the editions with the dates indicated are

applicable to this document. For the undated references, the latest edition

(including all the amendments) are applicable to this document.

GB/T 223.14 Methods for Chemical Analysis of Iron, Steel and Alloy - The N-

Benzoy-N-Phenylhydroxylamine Extraction Photometric Method for the

Determination of Vanadium Content

GB/T 223.60 Methods for chemical analysis of iron, steel and alloy - The

perchloric acid dehydration gravimetric method for the determination of

silicon content

GB/T 223.62 Methods for chemical analysis of iron, steel and alloy - The

butyl acetate extraction photometric method for the determination of

phosphorus content

GB/T 223.63 Methods for chemical analysis of iron, steel and alloy - The

sodium (potassium) periodate photometric method for the determination of

manganese content

GB/T 223.68 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Potassium Iodate Titration Method after Combustion in the Pipe Furnace for

the Determination of Sulfur Content

GB/T 223.71 Methods for Chemical Analysis of Iron, Steel and Alloy - The

Gravimetric Method after Combustion in the Pipe Furnace for the

Determination of Carbon Content

GB/T 223.82 Steel and iron - Determination of hydrogen content - Thermal

conductivity/infrared method after fusion under inert gas

GB/T 226 Test method for macrostructure and defect of steel by etching

GB/T 228 Metallic materials - Tensile testing at ambient temperature

GB/T 231.1 Metallic materials - Brinell hardness test - Part 1: Test method

GB/T 3075 Metallic materials - Fatigue testing - Axial-force-controlled

method

GB/T 4161 Metallic materials - Determination of plane-strain fracture

toughness

GB/T 4336 Carbon and low-alloy steel - Determination of multi-element

contents - Spark discharge atomic emission spectrometric method (routine

method)

GB/T 6398 Metallic materials - Fatigue testing - Fatigue crack growth method

GB/T 10561-2005 Steel - Determination of Content of Nonmetallic Inclusions

- Micrographic Method Using Standards Diagrams

GB/T 11261 Steel and Iron - Determination of oxygen content - The pulse

heating inert gas fusion-infra-red absorption method

GB/T 13298 Inspection methods of microstructure for metals

GB/T 19001 Quality management systems - Requirements

GB/T 20066 Steel and Iron - Sampling and Preparation of Samples for the

Determination of Chemical Composition

GB/T 20124 Steel and iron - Determination of nitrogen content - Thermal

conductimetric method after fusion in a current of inert gas

YB/T 081 Rule for rounding off of numerical values and judgement of testing

values for technical standards of metallurgy

3 Terms and definitions

The following terms and definitions apply to this document.

3.1 Heat

All slabs cast from a furnace of molten steel; but excluding the first slab cast

from the next furnace of molten steel entering into tundish casting.

3.2 Sequence

Continuous casting of the same designation by molten steel of different heats

in tundish.

3.3 Transition area

The part cast by a mixture of two furnaces of molten steel.

4 Grading and selection

4.1 Grading

The nonmetallic inclusions in the steel are divided into two grades, A and B.

4.2 Selection

This Standard specifies two steel designations of U71MnG and U75VG. High

speed railways above 250 km/h and high speed passenger railways of 200 km/h

~ 250 km/h shall select U71MnG rails. High speed passenger and freight mixed

railways of 200 km/h ~ 250 km/h shall select U75VG rails.

For nonmetallic inclusions of rails for high speed railway above 250 km/h, it

shall adopt Grade A. For nonmetallic inclusions of rails for high speed railway

of 200 km/h ~ 250 km/h, it shall adopt Grade B.

5 Information required for ordering

When the user is ordering, it shall provide the following basic information:

a) Product name;

b) Product standard number;

c) Steel designation;

d) Rail type and applicable speed range (or grade of nonmetallic inclusions);

e) No-hole or hole rail (number of holes, one end drilled or both ends drilled);

f) ...

Share