1

/

από

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY 0076-1992 English PDF (YY0076-1992)

YY 0076-1992 English PDF (YY0076-1992)

Κανονική τιμή

$200.00 USD

Κανονική τιμή

Τιμή έκπτωσης

$200.00 USD

Τιμή μονάδας

/

ανά

Τα έξοδα αποστολής υπολογίζονται κατά την ολοκλήρωση της αγοράς.

Δεν ήταν δυνατή η φόρτωση της διαθεσιμότητας παραλαβής

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click YY 0076-1992

Historical versions: YY 0076-1992

Preview True-PDF (Reload/Scroll if blank)

YY 0076-1992: Coating classifications for metal product Technical conditions

YY/T 0076-1992 (Renamed from YY 0076-92)

YY

PHARMACEUTICALS INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

C 30

YY 0076-92

Replacing WS 2-1-73

Coating classifications for metal product - Technical

conditions

ISSUED ON: JANUARY 20, 1992

IMPLEMENTED ON: JULY 01, 1992

Issued by: State Pharmaceutical Administration

Table of Contents

1 Scope ... 3

2 Normative references ... 3

3 Classification of plating ... 3

4 Technical requirements for plating ... 4

5 Acceptance rules, inspection methods, marking ... 12

Additional Information: ... 15

Coating classifications for metal product - Technical

conditions

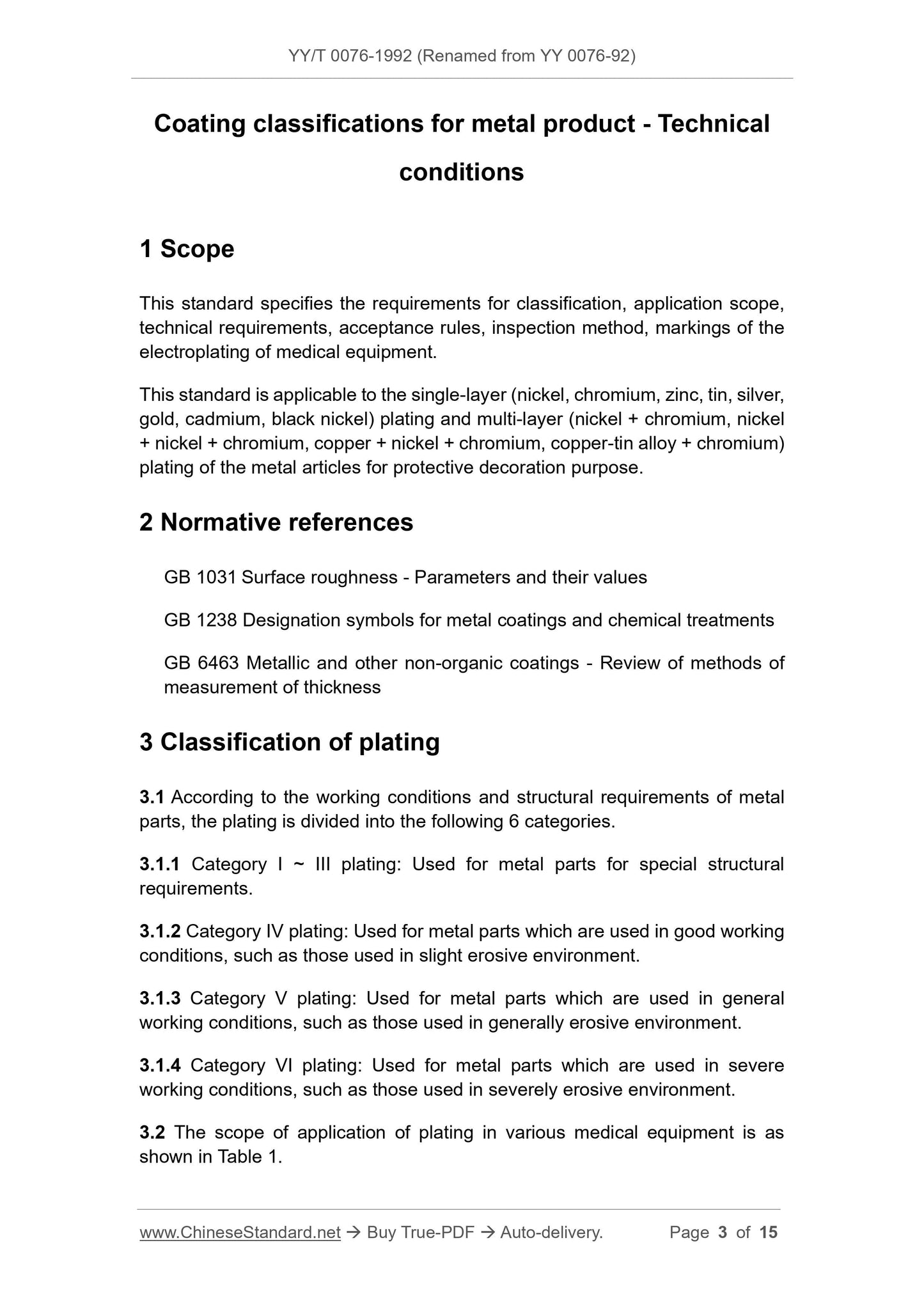

1 Scope

This standard specifies the requirements for classification, application scope,

technical requirements, acceptance rules, inspection method, markings of the

electroplating of medical equipment.

This standard is applicable to the single-layer (nickel, chromium, zinc, tin, silver,

gold, cadmium, black nickel) plating and multi-layer (nickel + chromium, nickel

+ nickel + chromium, copper + nickel + chromium, copper-tin alloy + chromium)

plating of the metal articles for protective decoration purpose.

2 Normative references

GB 1031 Surface roughness - Parameters and their values

GB 1238 Designation symbols for metal coatings and chemical treatments

GB 6463 Metallic and other non-organic coatings - Review of methods of

measurement of thickness

3 Classification of plating

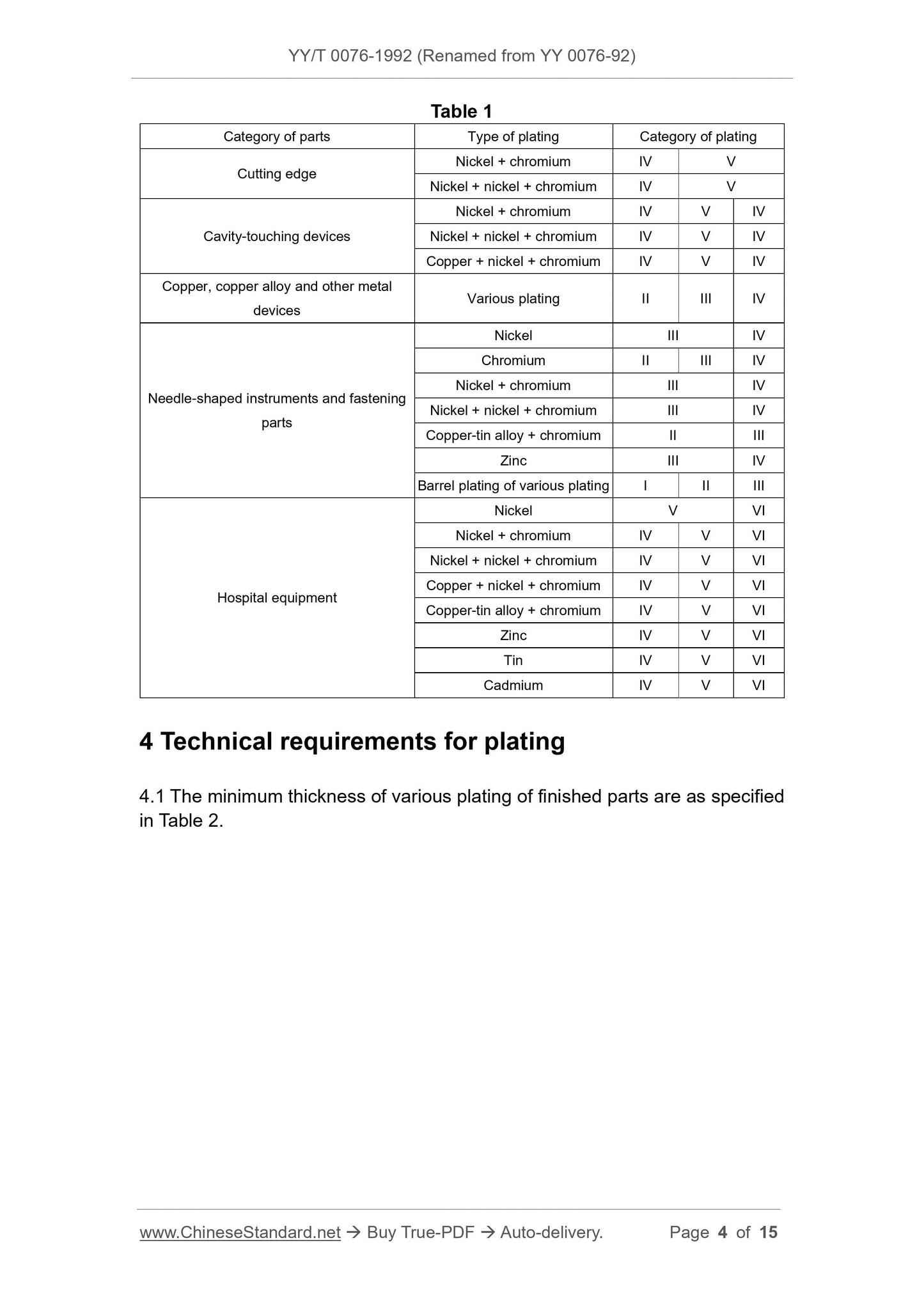

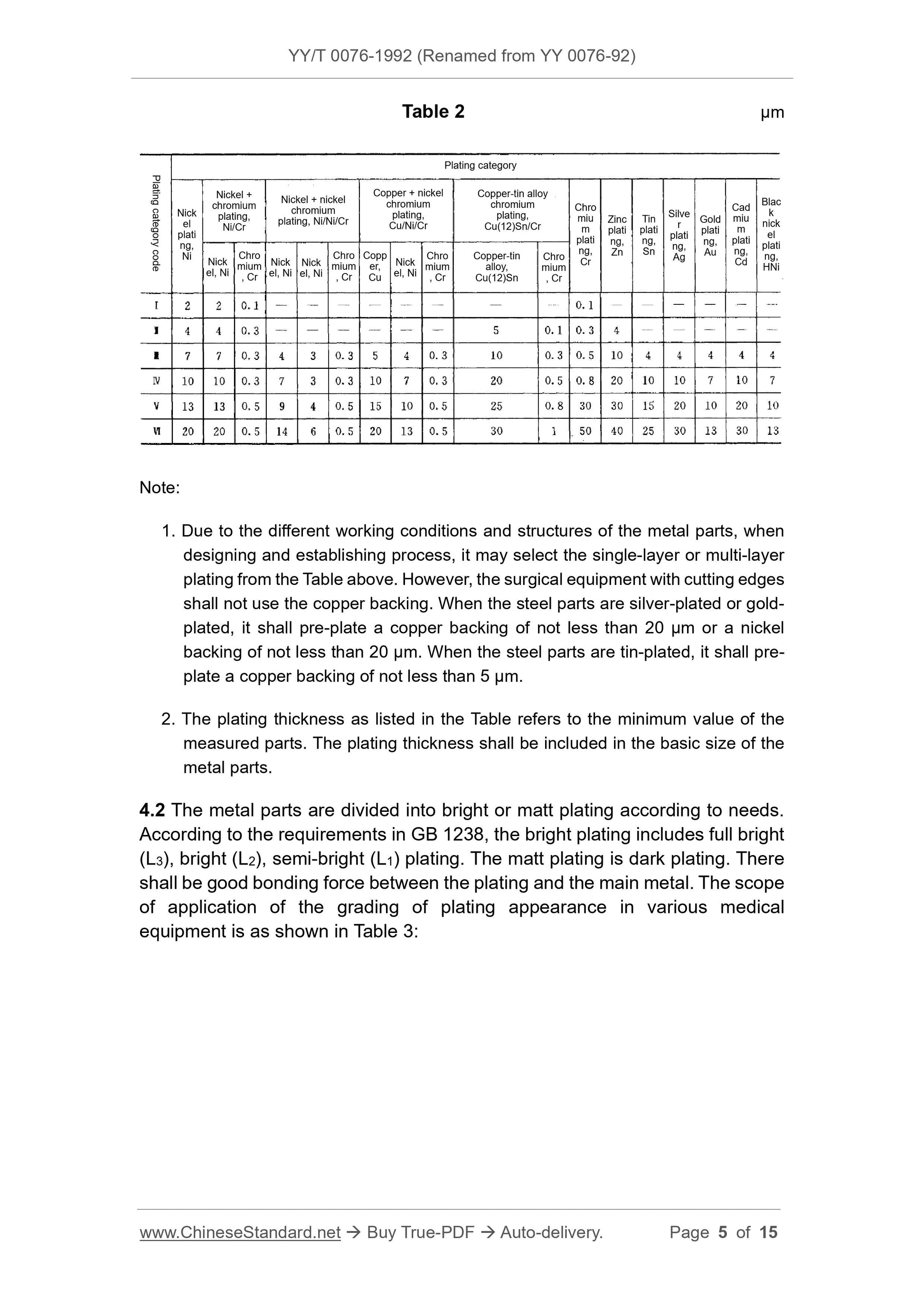

3.1 According to the working conditions and structural requirements of metal

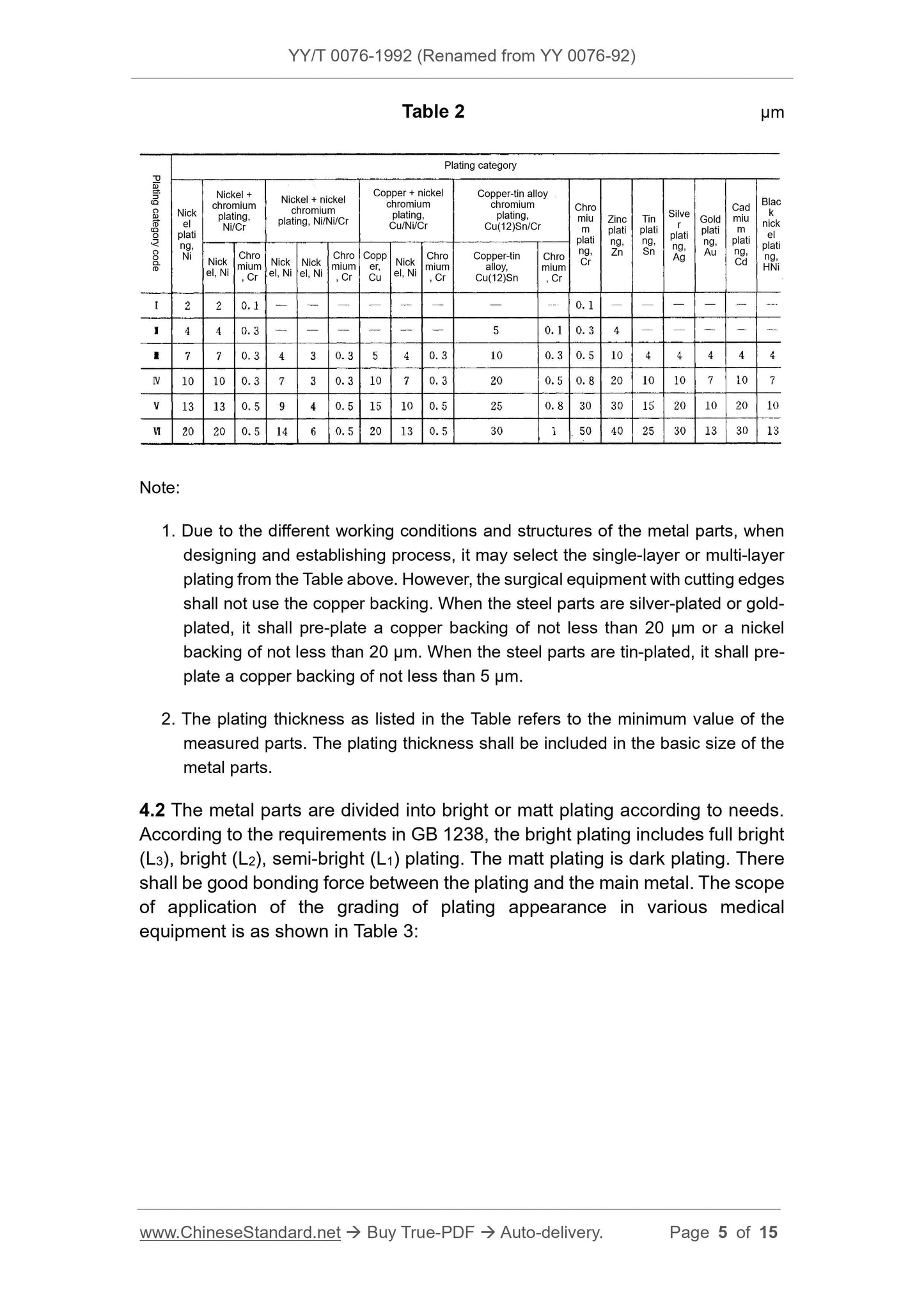

parts, the plating is divided into the following 6 categories.

3.1.1 Category I ~ III plating: Used for metal parts for special structural

requirements.

3.1.2 Category IV plating: Used for metal parts which are used in good working

conditions, such as those used in slight erosive environment.

3.1.3 Category V plating: Used for metal parts which are used in general

working conditions, such as those used in generally erosive environment.

3.1.4 Category VI plating: Used for metal parts which are used in severe

working conditions, such as those used in severely erosive environment.

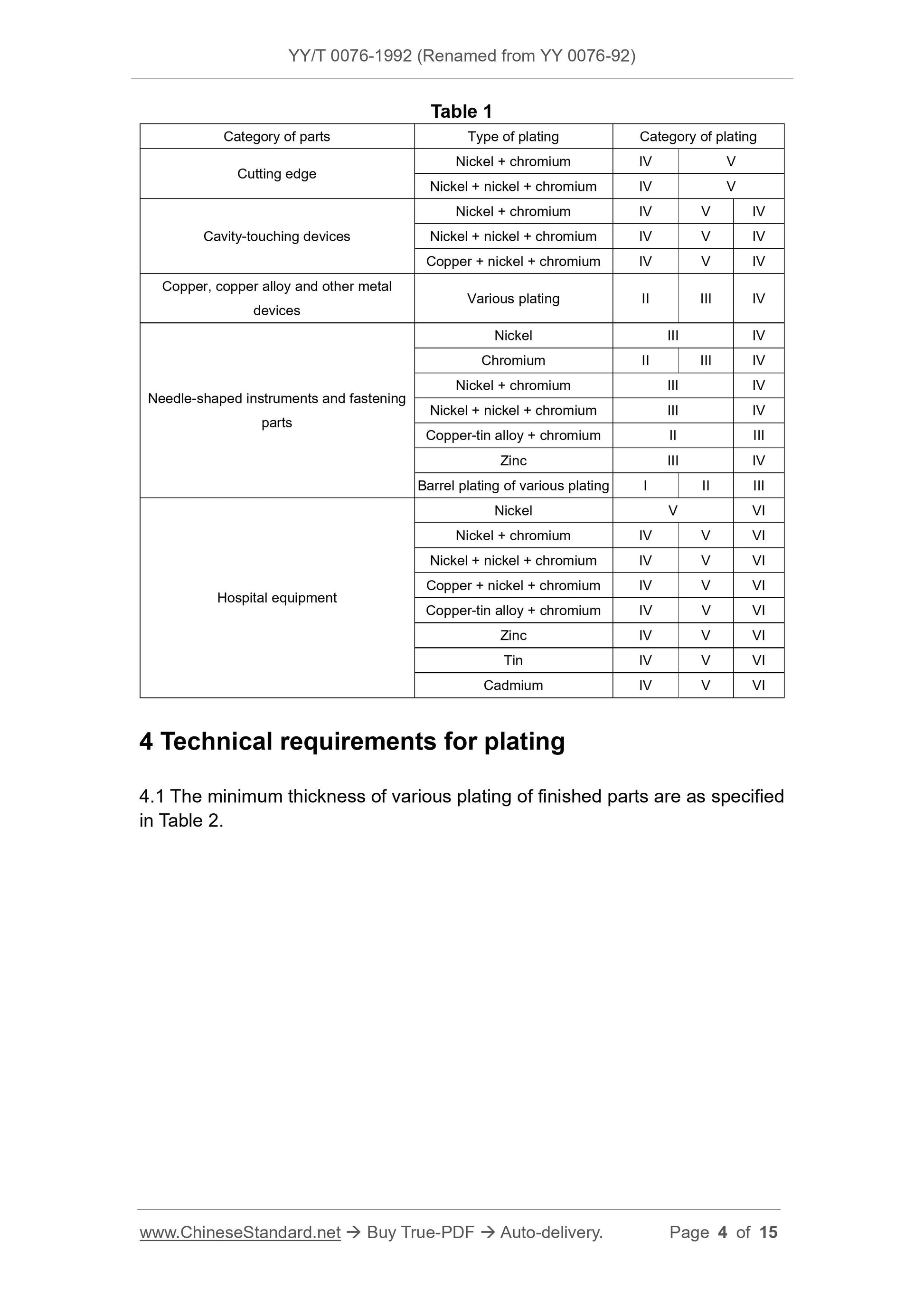

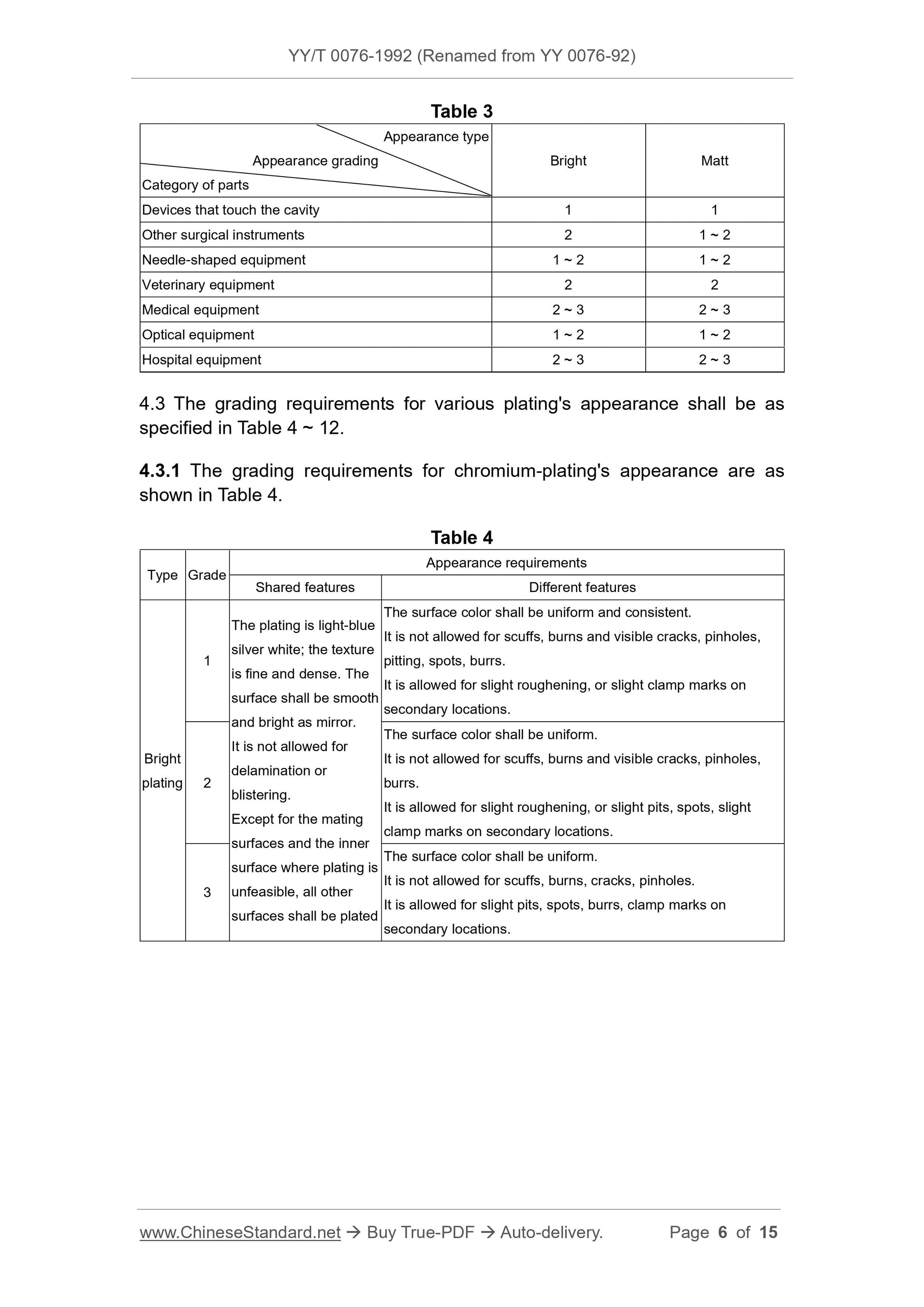

3.2 The scope of application of plating in various medical equipment is as

shown in Table 1.

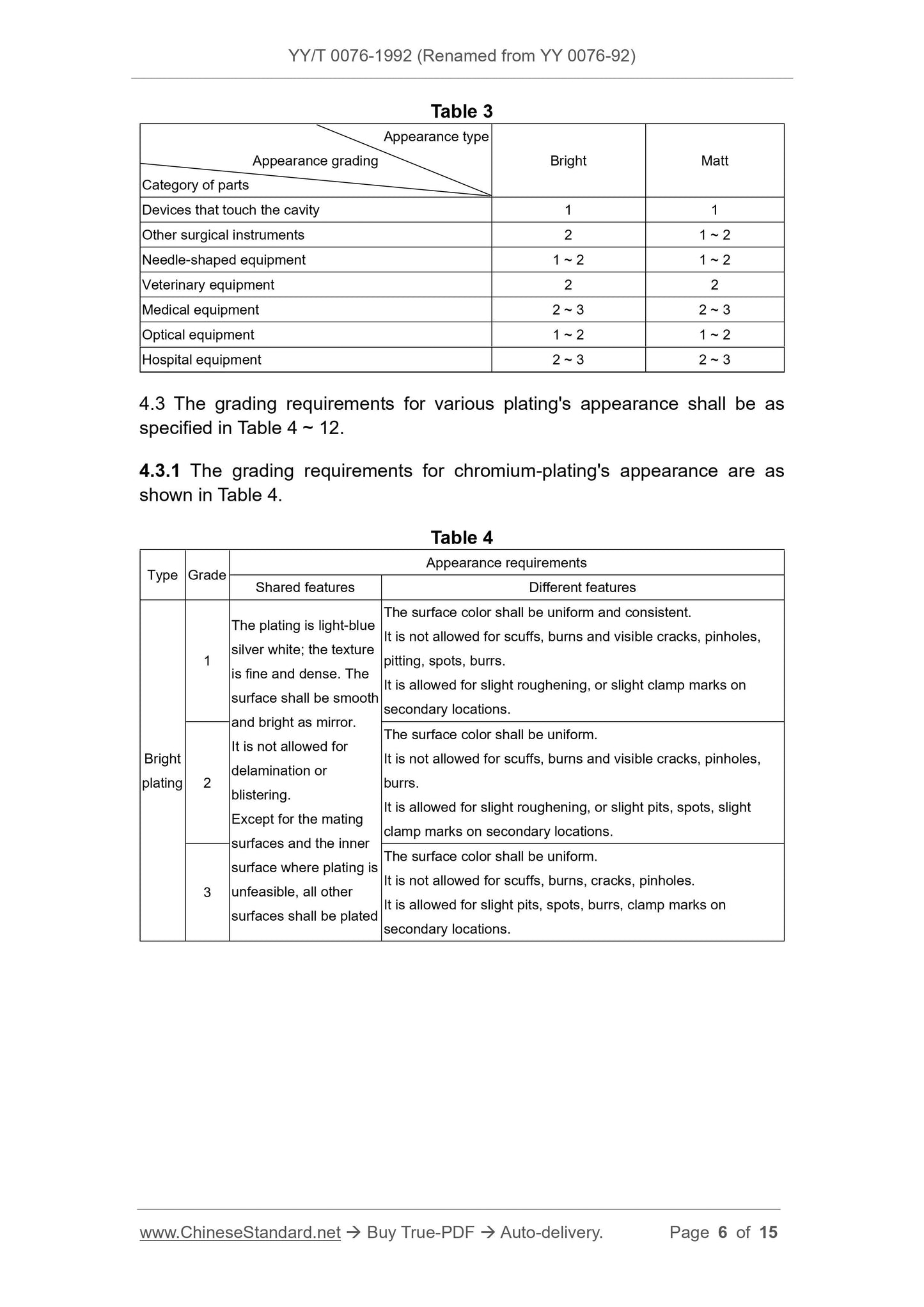

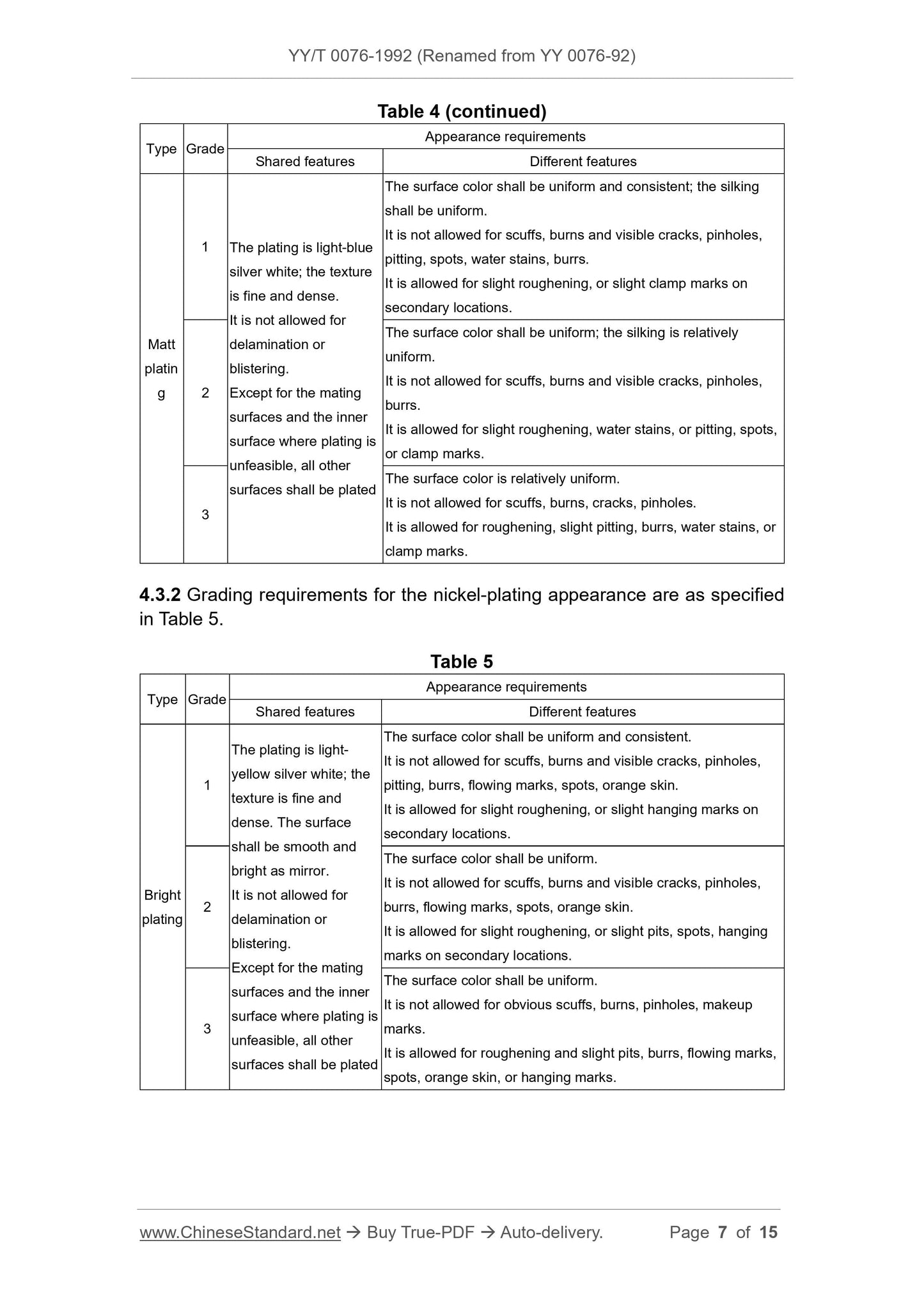

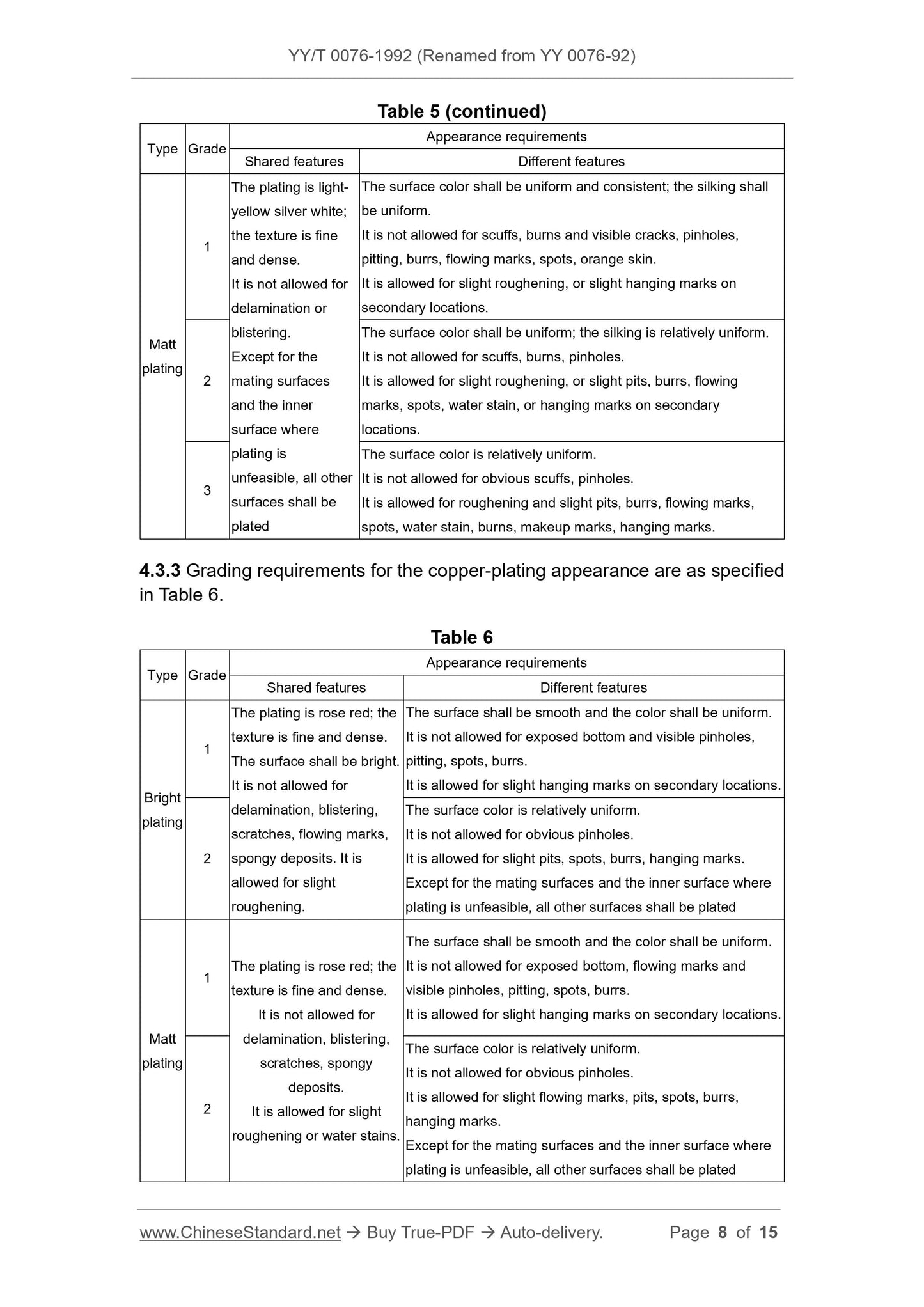

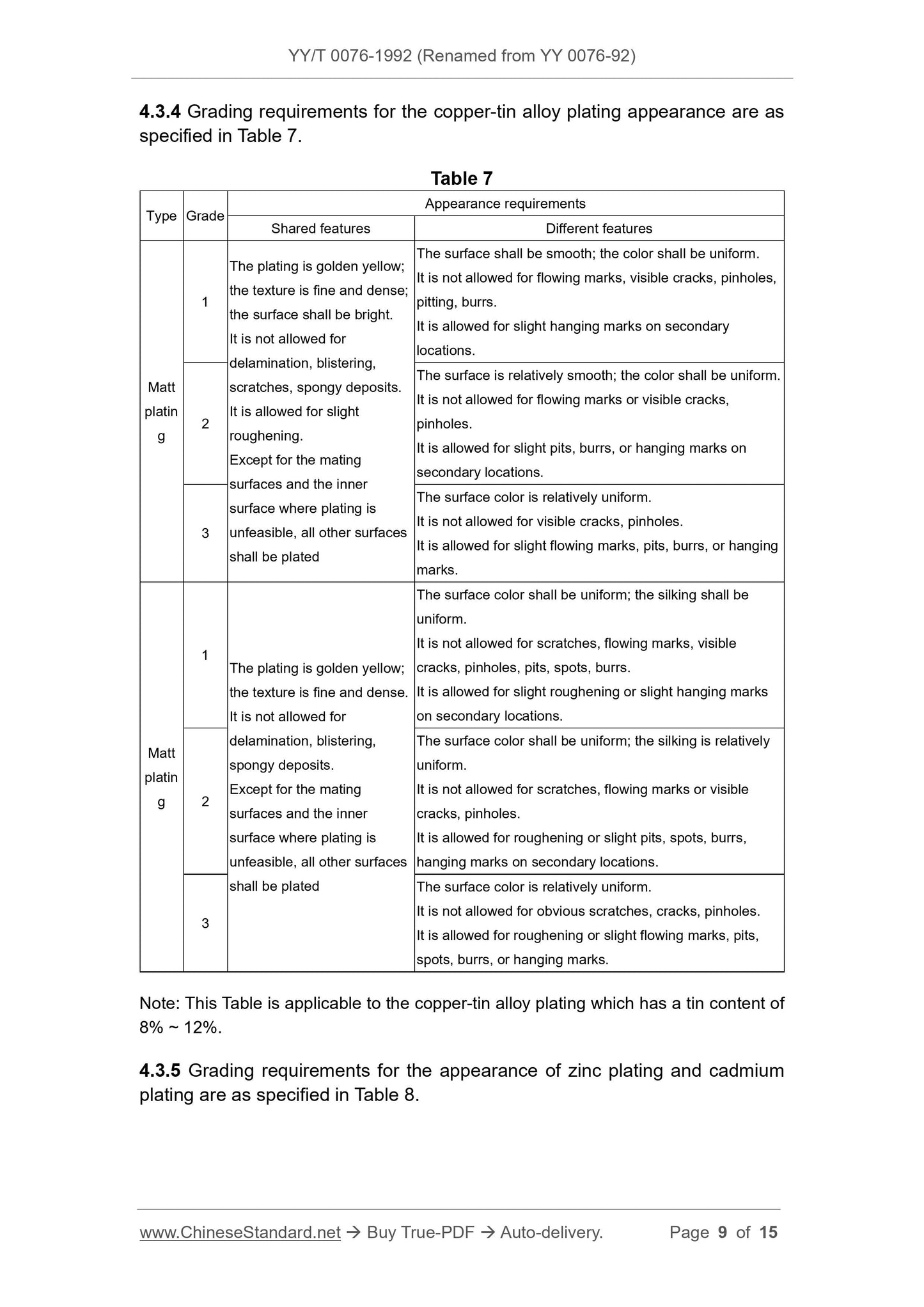

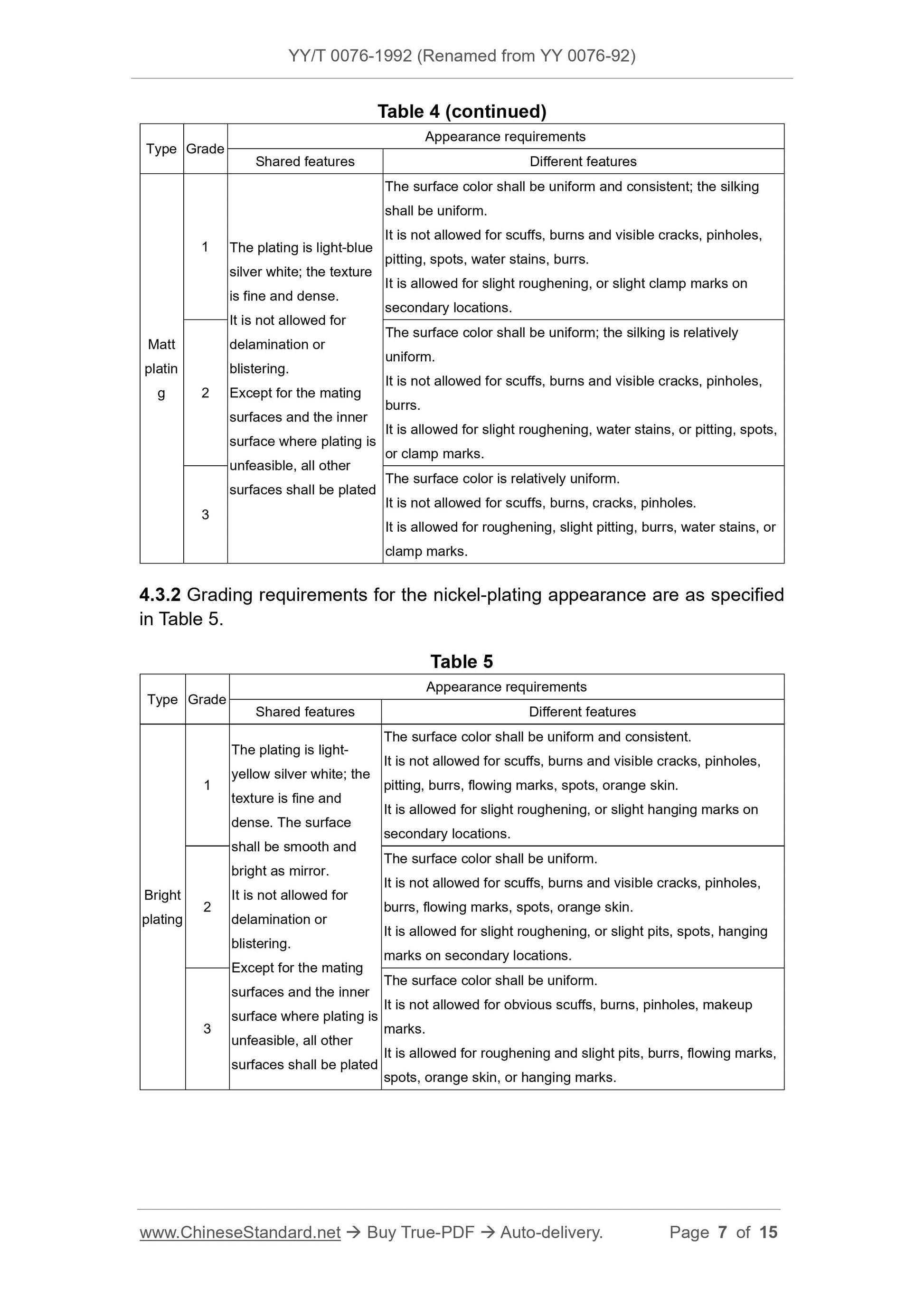

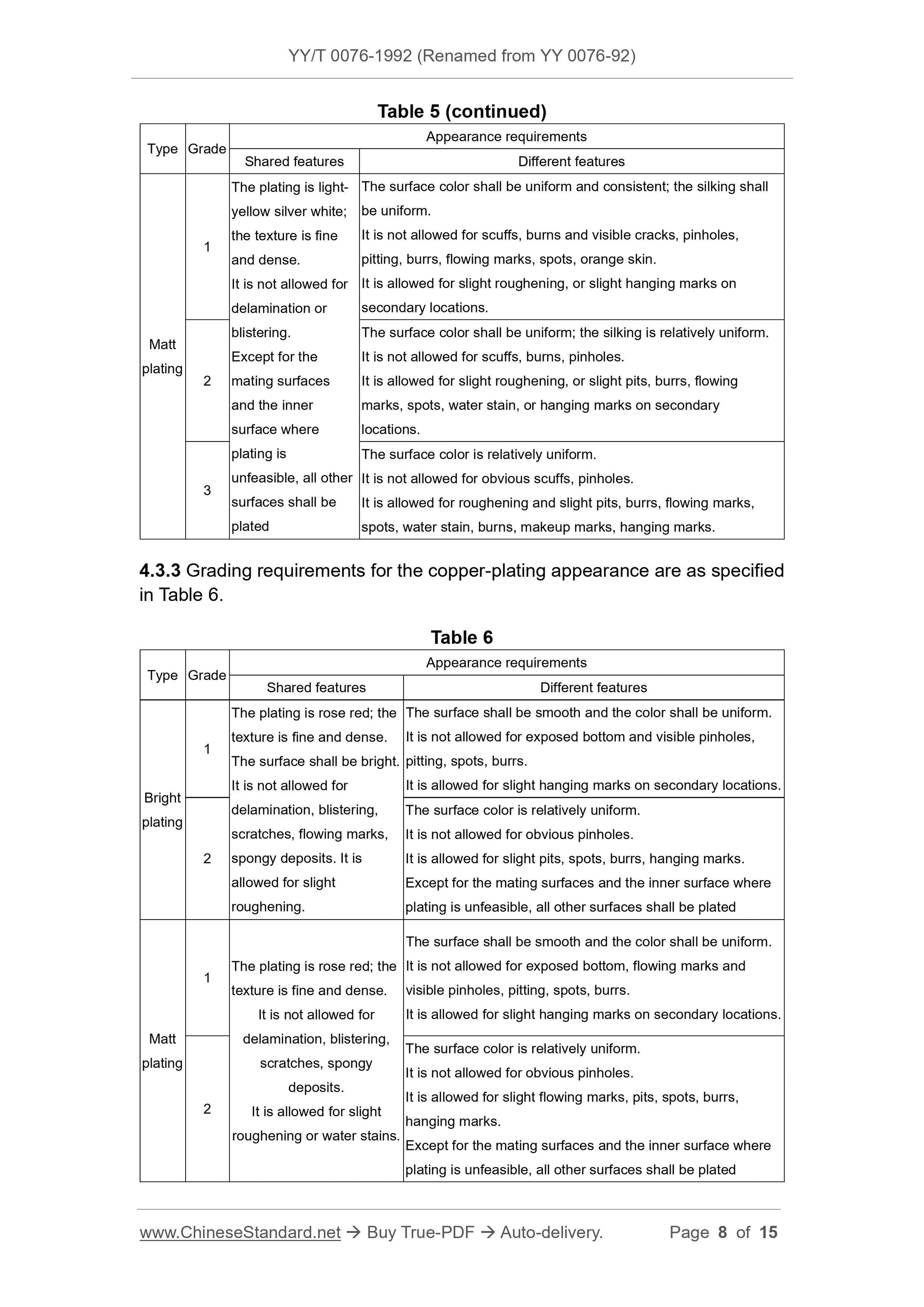

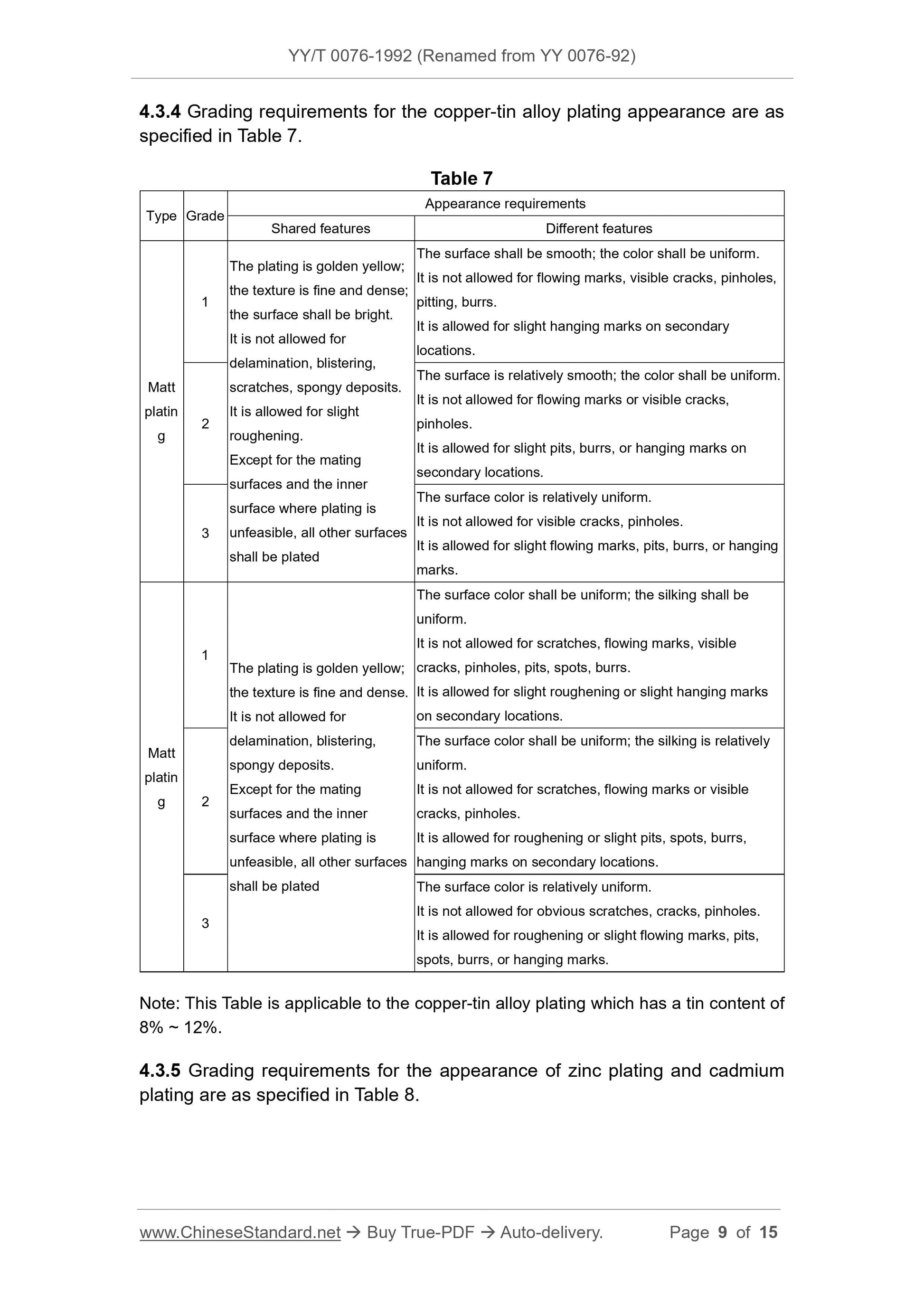

4.3.4 Grading requirements for the copper-tin alloy plating appearance are as

specified in Table 7.

Table 7

Type Grade

Appearance requirements

Shared features Different features

Matt

platin

The plating is golden yellow;

the texture is fine and dense;

the surface shall be bright.

It is not allowed for

delamination, blistering,

scratches, spongy deposits.

It is allowed for slight

roughening.

Except for the mating

surfaces and the inner

surface where plating is

unfeasible, all other surfaces

shall be plated

The surface shall be smooth; the color shall be uniform.

It is not allowed for flowing marks, visible cracks, pinholes,

pitting, burrs.

It is allowed for slight hanging marks on secondary

locations.

The surface is relatively smooth; the color shall be uniform.

It is not allowed for flowing marks or visible cracks,

pinholes.

It is allowed for slight pits, burrs, or hanging marks on

secondary locations.

The surface color is relatively uniform.

It is not allowed for visible cracks, pinholes.

It is allowed for slight flowing marks, pits, burrs, or hanging

marks.

Matt

platin

The plating is golden yellow;

the texture is fine and dense.

It is not allowed for

delamination, blistering,

spongy deposits.

Except for the mating

surfaces and the inner

surface where plating is

unfeasible, all other surfaces

shall be plated

The surface color shall be uniform; the silking shall be

uniform.

It is not allowed for scratches, flowing marks, visible

cracks, pinholes, pits, spots, burrs.

It is allowed for slight roughening or slight hanging marks

on secondary locations.

The surface color shall be uniform; the silking is relatively

uniform.

It is not allowed for scratches, flowing marks or visible

cracks, pinholes.

It is allowed for roughening or slight pits, spots, burrs,

hanging marks on secondary locations.

The surface color is relatively uniform.

It is not allowed for obvious scratches, cracks, pinholes.

It is allowed for roughening or slight flowing marks, pits,

spots, burrs, or hanging marks.

Note: This Table is applicable to the copper-tin alloy plating which has a tin content of

8% ~ 12%.

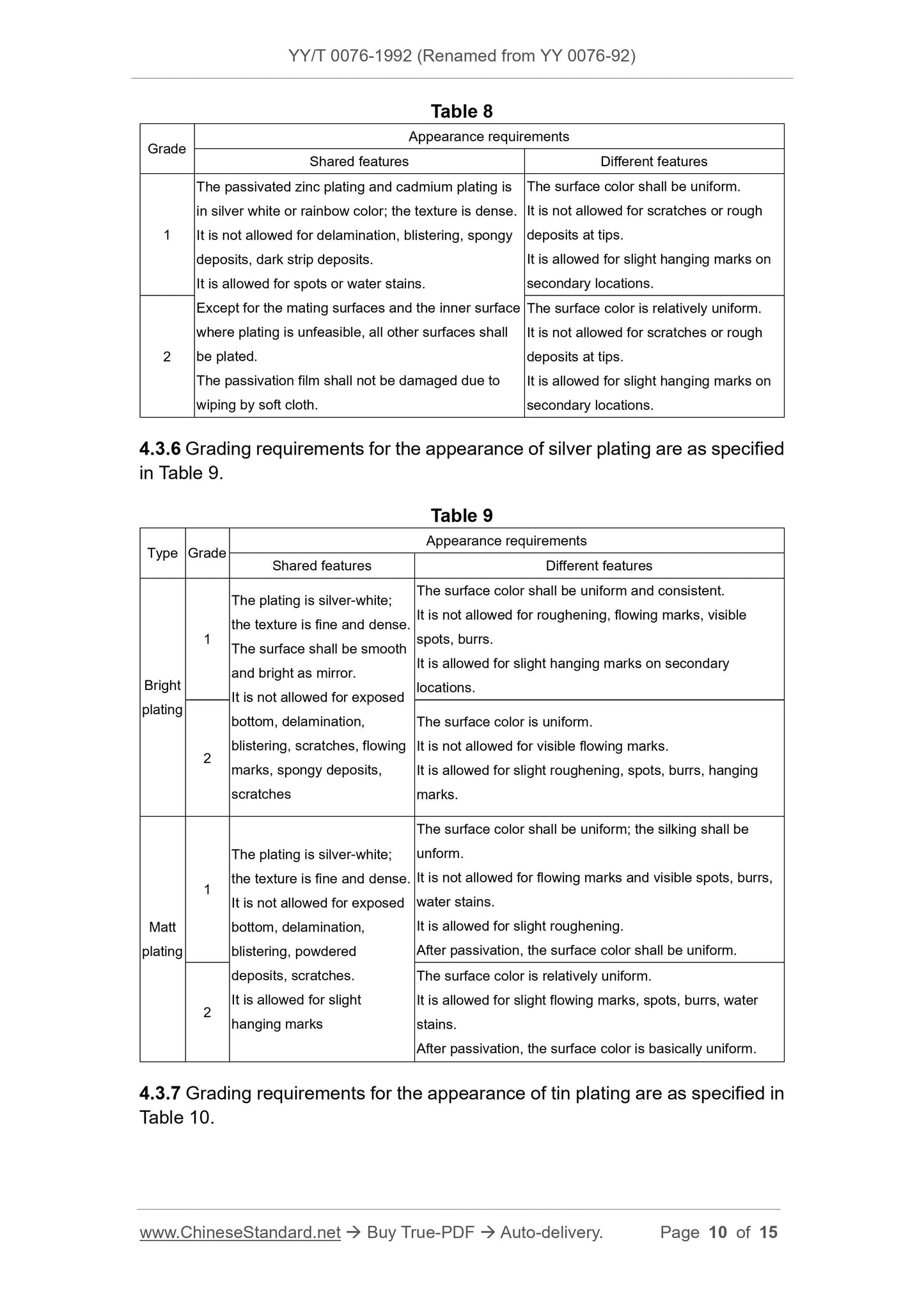

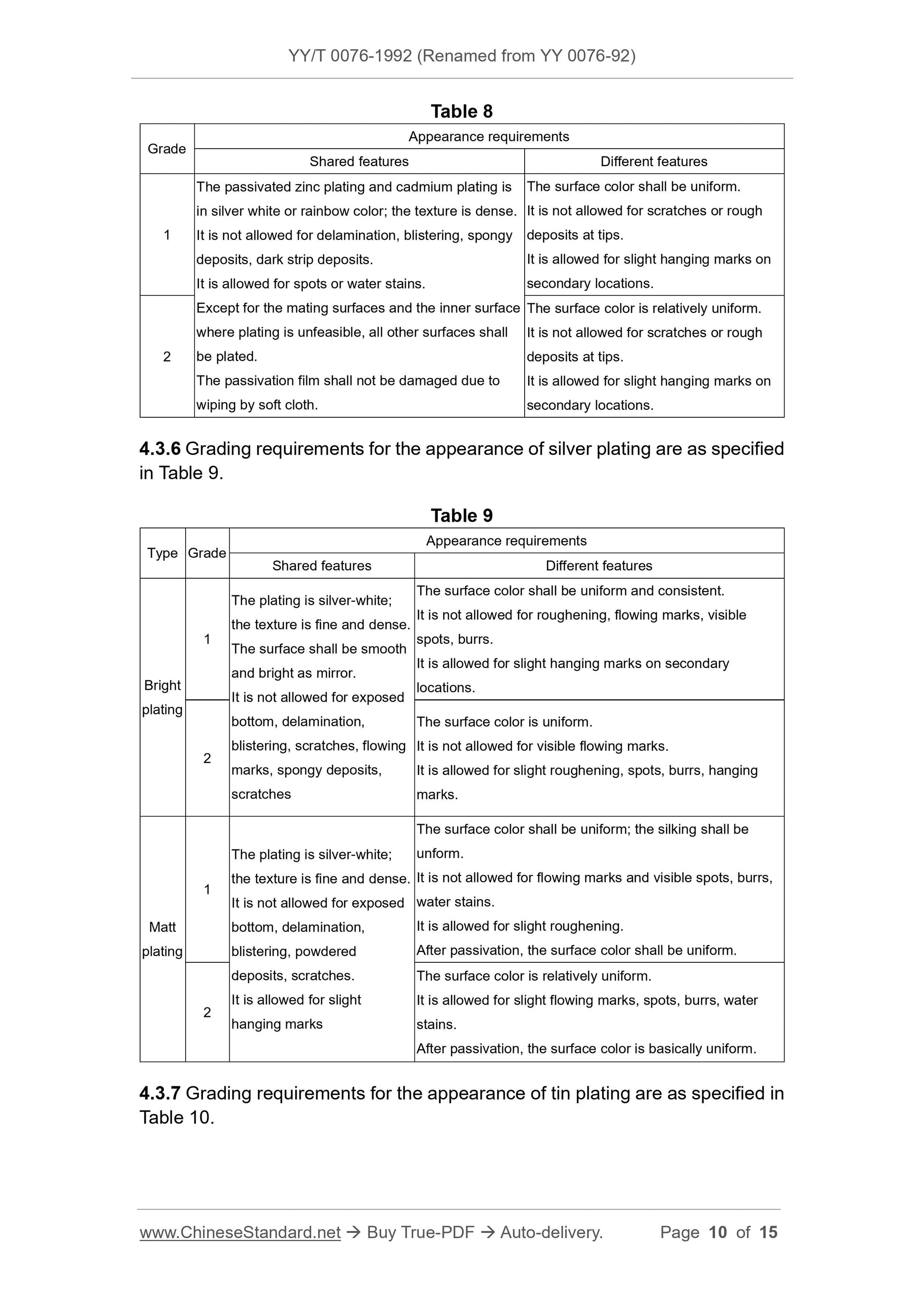

4.3.5 Grading requirements for the appearance of zinc plating and cadmium

plating are as specified in Table 8.

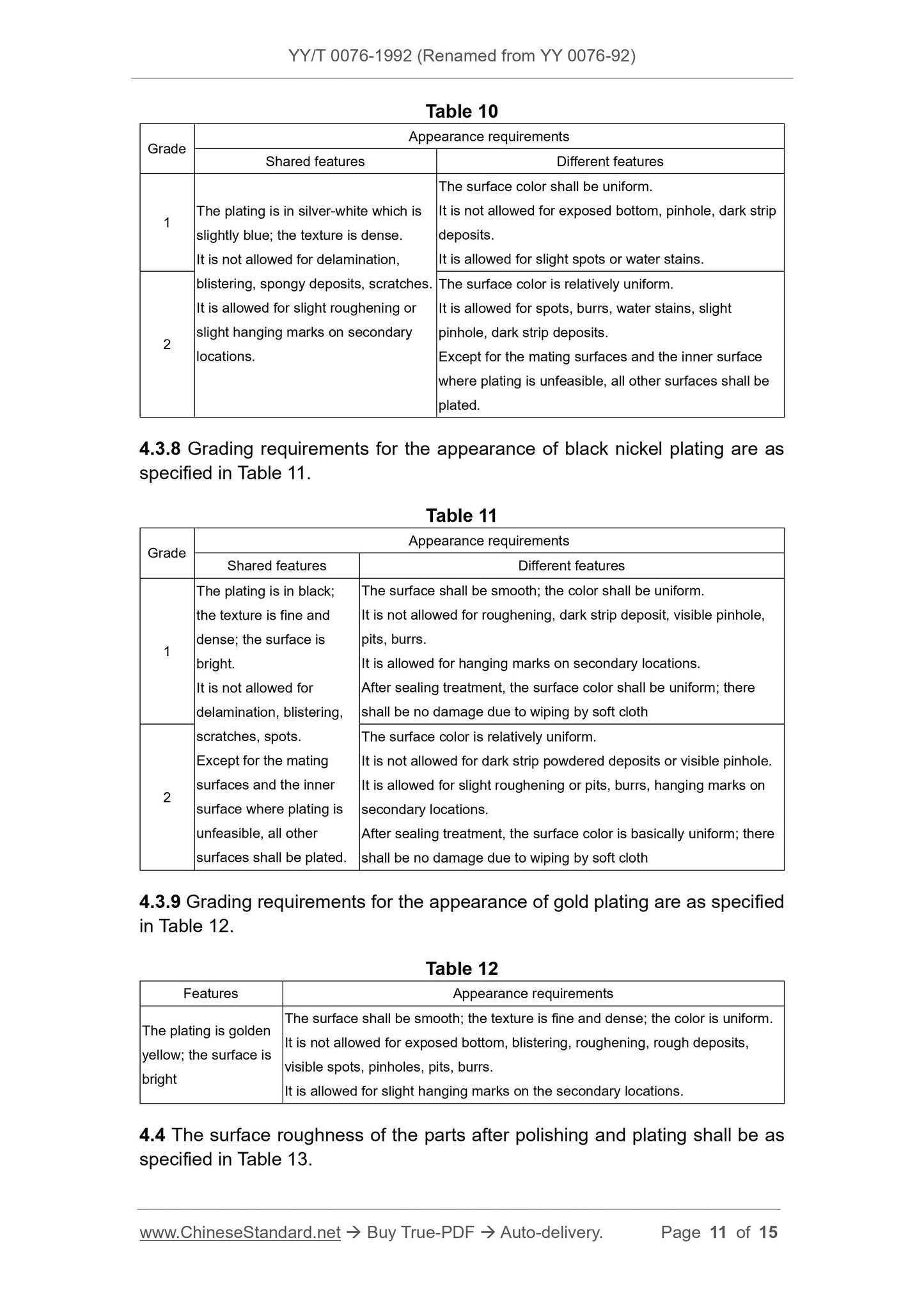

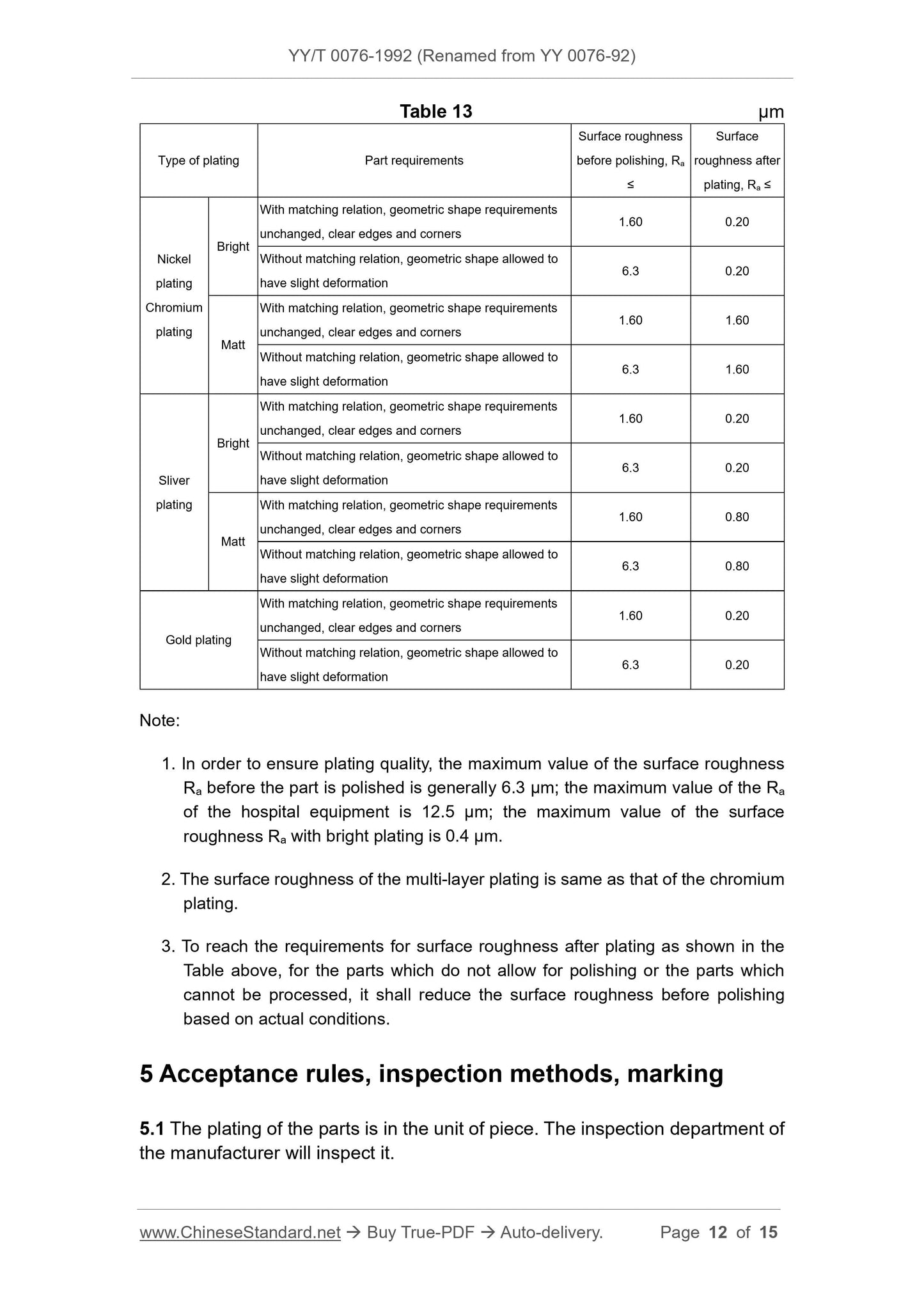

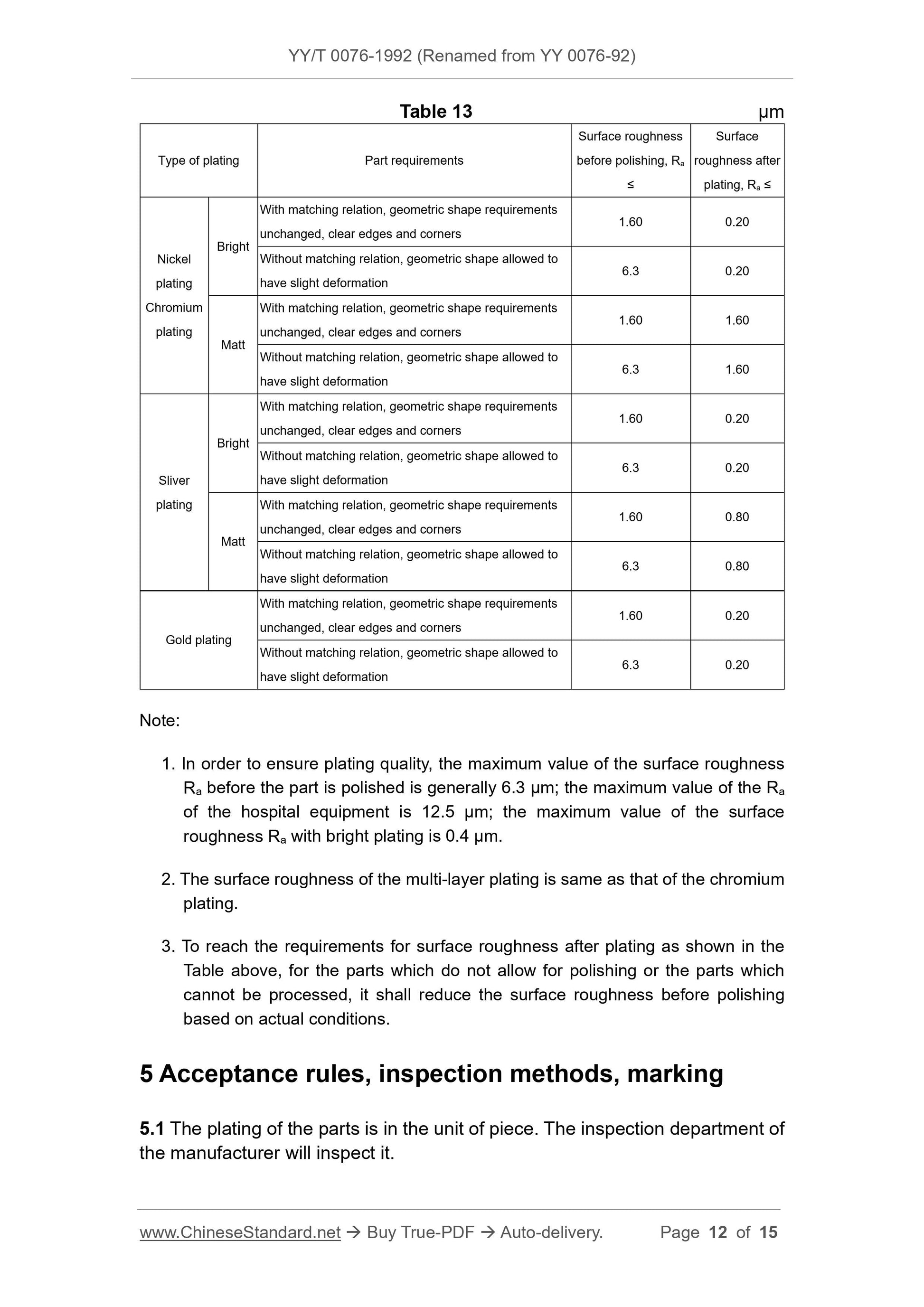

Table 13 µm

Type of plating Part requirements

Surface roughness

before polishing, Ra

Surface

roughness after

plating, Ra ≤

Nickel

plating

Chromium

plating

Bright

With matching relation, geometric shape requirements

unchanged, clear edges and corners

1.60 0.20

Without matching relation, geometric shape allowed to

have slight deformation

6.3 0.20

Matt

With matching relation, geometric shape requirements

unchanged, clear edges and corners

1.60 1.60

Without matching relation, geometric shape allowed to

have slight deformation

6.3 1.60

Sliver

plating

Bright

With matching relation, geometric shape requirements

unchanged, clear edges and corners

1.60 0.20

Without matching relation, geometric shape allowed to

have slight deformation

6.3 0.20

Matt

With matching relation, geometric shape requirements

unchanged, clear edges and corners

1.60 0.80

Without matching relation, geometric shape allowed to

have slight deformation

6.3 0.80

Gold plating

With matching relation, geometric shape requirements

unchanged, clear edges and corners

1.60 0.20

Without matching relation, geometric shape allowed to

have slight deformation

6.3 0.20

Note:

1. In order to ensure plating quality, the maximum value of the surface roughness

Ra before the part is polished is generally 6.3 µm; the maximum value of the Ra

of the hospital equipment is 12.5 µm; the maximum value of the surface

roughness Ra with bright plating is 0.4 µm.

2. The surface roughness of the multi-layer plating is same as that of the chromium

plating.

3. To reach the requirements for surface roughness after plating as shown in the

Table above, for the parts which do not allow for polishing or the parts which

cannot be processed, it shall reduce the surface roughness before polishing

based on actual conditions.

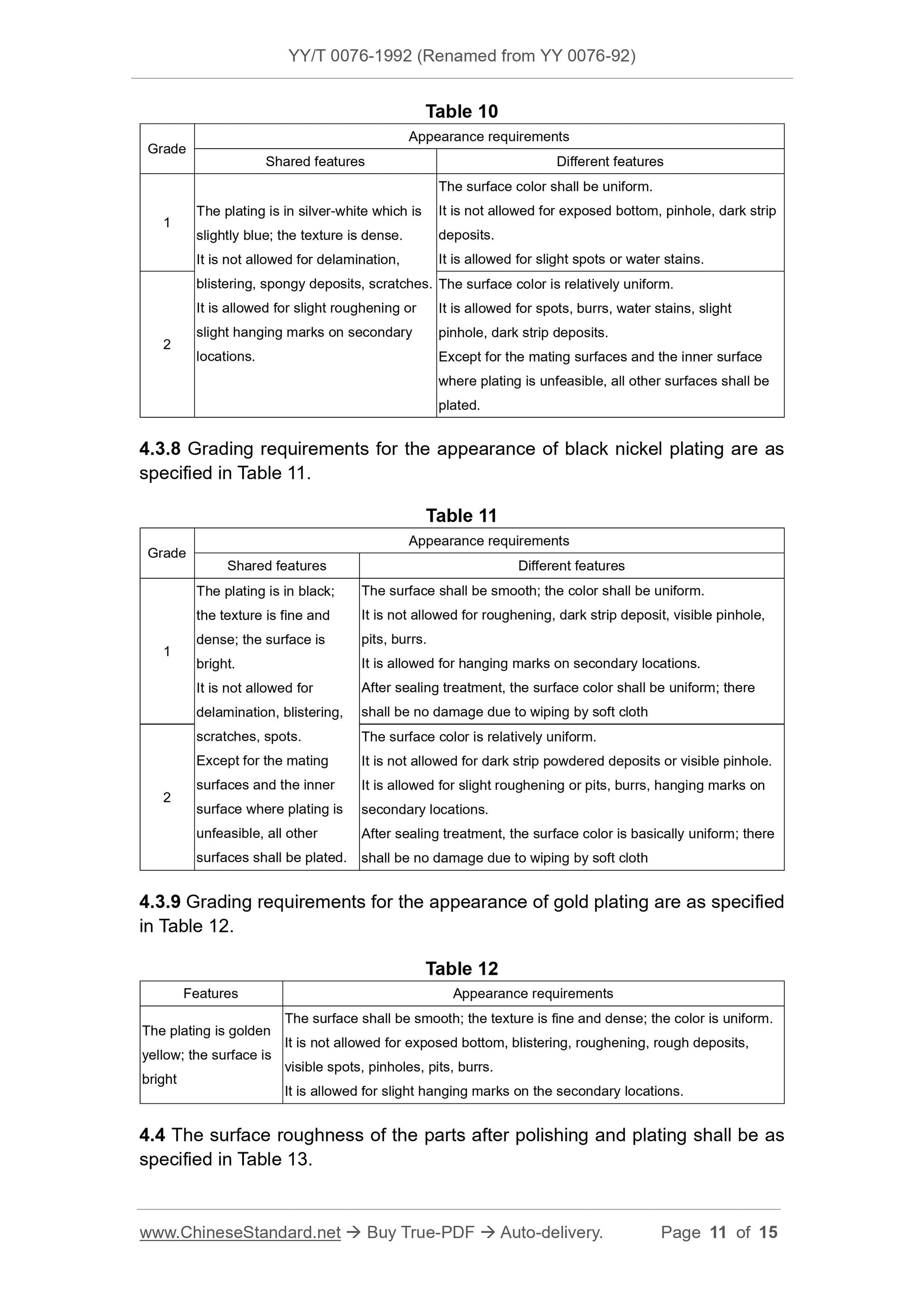

5 Acceptance rules, inspection methods, marking

5.1 The plating of the parts is in the unit of piece. The inspection department of

the manufacturer will inspect it.

5.4.3 The references for the grades of brightness:

Table 14

Grade of brightness Full-bright Bright Semi-bright Matt

Symbols L3 L2 L1 -

Example of

technology

Substrate surface Polished Polished Non-polished Non-polished

Plating surface Polished Non-polished Non-polished Non-polished

Electrolyte Without brightener With brightener With brightener

Without

brightener

Note:

1. When there is no instrument for the measurement of brightness, the technologies

as listed in the Table above are used to represent the brightness concept. These

technologies are not unique methods.

2. The surface roughness before the substrate is plated is specified by each

organization.

5.4.4 The appearance grades after plating are represented by ...

Get QUOTATION in 1-minute: Click YY 0076-1992

Historical versions: YY 0076-1992

Preview True-PDF (Reload/Scroll if blank)

YY 0076-1992: Coating classifications for metal product Technical conditions

YY/T 0076-1992 (Renamed from YY 0076-92)

YY

PHARMACEUTICALS INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

C 30

YY 0076-92

Replacing WS 2-1-73

Coating classifications for metal product - Technical

conditions

ISSUED ON: JANUARY 20, 1992

IMPLEMENTED ON: JULY 01, 1992

Issued by: State Pharmaceutical Administration

Table of Contents

1 Scope ... 3

2 Normative references ... 3

3 Classification of plating ... 3

4 Technical requirements for plating ... 4

5 Acceptance rules, inspection methods, marking ... 12

Additional Information: ... 15

Coating classifications for metal product - Technical

conditions

1 Scope

This standard specifies the requirements for classification, application scope,

technical requirements, acceptance rules, inspection method, markings of the

electroplating of medical equipment.

This standard is applicable to the single-layer (nickel, chromium, zinc, tin, silver,

gold, cadmium, black nickel) plating and multi-layer (nickel + chromium, nickel

+ nickel + chromium, copper + nickel + chromium, copper-tin alloy + chromium)

plating of the metal articles for protective decoration purpose.

2 Normative references

GB 1031 Surface roughness - Parameters and their values

GB 1238 Designation symbols for metal coatings and chemical treatments

GB 6463 Metallic and other non-organic coatings - Review of methods of

measurement of thickness

3 Classification of plating

3.1 According to the working conditions and structural requirements of metal

parts, the plating is divided into the following 6 categories.

3.1.1 Category I ~ III plating: Used for metal parts for special structural

requirements.

3.1.2 Category IV plating: Used for metal parts which are used in good working

conditions, such as those used in slight erosive environment.

3.1.3 Category V plating: Used for metal parts which are used in general

working conditions, such as those used in generally erosive environment.

3.1.4 Category VI plating: Used for metal parts which are used in severe

working conditions, such as those used in severely erosive environment.

3.2 The scope of application of plating in various medical equipment is as

shown in Table 1.

4.3.4 Grading requirements for the copper-tin alloy plating appearance are as

specified in Table 7.

Table 7

Type Grade

Appearance requirements

Shared features Different features

Matt

platin

The plating is golden yellow;

the texture is fine and dense;

the surface shall be bright.

It is not allowed for

delamination, blistering,

scratches, spongy deposits.

It is allowed for slight

roughening.

Except for the mating

surfaces and the inner

surface where plating is

unfeasible, all other surfaces

shall be plated

The surface shall be smooth; the color shall be uniform.

It is not allowed for flowing marks, visible cracks, pinholes,

pitting, burrs.

It is allowed for slight hanging marks on secondary

locations.

The surface is relatively smooth; the color shall be uniform.

It is not allowed for flowing marks or visible cracks,

pinholes.

It is allowed for slight pits, burrs, or hanging marks on

secondary locations.

The surface color is relatively uniform.

It is not allowed for visible cracks, pinholes.

It is allowed for slight flowing marks, pits, burrs, or hanging

marks.

Matt

platin

The plating is golden yellow;

the texture is fine and dense.

It is not allowed for

delamination, blistering,

spongy deposits.

Except for the mating

surfaces and the inner

surface where plating is

unfeasible, all other surfaces

shall be plated

The surface color shall be uniform; the silking shall be

uniform.

It is not allowed for scratches, flowing marks, visible

cracks, pinholes, pits, spots, burrs.

It is allowed for slight roughening or slight hanging marks

on secondary locations.

The surface color shall be uniform; the silking is relatively

uniform.

It is not allowed for scratches, flowing marks or visible

cracks, pinholes.

It is allowed for roughening or slight pits, spots, burrs,

hanging marks on secondary locations.

The surface color is relatively uniform.

It is not allowed for obvious scratches, cracks, pinholes.

It is allowed for roughening or slight flowing marks, pits,

spots, burrs, or hanging marks.

Note: This Table is applicable to the copper-tin alloy plating which has a tin content of

8% ~ 12%.

4.3.5 Grading requirements for the appearance of zinc plating and cadmium

plating are as specified in Table 8.

Table 13 µm

Type of plating Part requirements

Surface roughness

before polishing, Ra

Surface

roughness after

plating, Ra ≤

Nickel

plating

Chromium

plating

Bright

With matching relation, geometric shape requirements

unchanged, clear edges and corners

1.60 0.20

Without matching relation, geometric shape allowed to

have slight deformation

6.3 0.20

Matt

With matching relation, geometric shape requirements

unchanged, clear edges and corners

1.60 1.60

Without matching relation, geometric shape allowed to

have slight deformation

6.3 1.60

Sliver

plating

Bright

With matching relation, geometric shape requirements

unchanged, clear edges and corners

1.60 0.20

Without matching relation, geometric shape allowed to

have slight deformation

6.3 0.20

Matt

With matching relation, geometric shape requirements

unchanged, clear edges and corners

1.60 0.80

Without matching relation, geometric shape allowed to

have slight deformation

6.3 0.80

Gold plating

With matching relation, geometric shape requirements

unchanged, clear edges and corners

1.60 0.20

Without matching relation, geometric shape allowed to

have slight deformation

6.3 0.20

Note:

1. In order to ensure plating quality, the maximum value of the surface roughness

Ra before the part is polished is generally 6.3 µm; the maximum value of the Ra

of the hospital equipment is 12.5 µm; the maximum value of the surface

roughness Ra with bright plating is 0.4 µm.

2. The surface roughness of the multi-layer plating is same as that of the chromium

plating.

3. To reach the requirements for surface roughness after plating as shown in the

Table above, for the parts which do not allow for polishing or the parts which

cannot be processed, it shall reduce the surface roughness before polishing

based on actual conditions.

5 Acceptance rules, inspection methods, marking

5.1 The plating of the parts is in the unit of piece. The inspection department of

the manufacturer will inspect it.

5.4.3 The references for the grades of brightness:

Table 14

Grade of brightness Full-bright Bright Semi-bright Matt

Symbols L3 L2 L1 -

Example of

technology

Substrate surface Polished Polished Non-polished Non-polished

Plating surface Polished Non-polished Non-polished Non-polished

Electrolyte Without brightener With brightener With brightener

Without

brightener

Note:

1. When there is no instrument for the measurement of brightness, the technologies

as listed in the Table above are used to represent the brightness concept. These

technologies are not unique methods.

2. The surface roughness before the substrate is plated is specified by each

organization.

5.4.4 The appearance grades after plating are represented by ...

Share