PayPal, credit cards. Download editable-PDF and invoice in 1 second!

CJ/T 395-2012 English PDF (CJT395-2012)

CJ/T 395-2012 English PDF (CJT395-2012)

Precio habitual

$125.00 USD

Precio habitual

Precio de oferta

$125.00 USD

Precio unitario

/

por

Los gastos de envío se calculan en la pantalla de pago.

No se pudo cargar la disponibilidad de retiro

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click CJ/T 395-2012

Historical versions: CJ/T 395-2012

Preview True-PDF (Reload/Scroll if blank)

CJ/T 395-2012: Gas-fired heating and hot water condensing combi-boilers

CJ/T 395-2012

INDUSTRY STANDARD OF THE

PEOPLE'S REPUBLIC OF CHINA

ICS 91.140

P 46

CJ/T 395-2012

Gas-fired Heating and Hot Water

Condensing Combi-boilers

ISSUED ON: FEBRUARY 29, 2012

IMPLEMENTED ON: AUGUST 01, 2012

Issued by: Ministry of Housing and Urban-Rural Development of the People's

Republic of China

CJ/T 395-2012

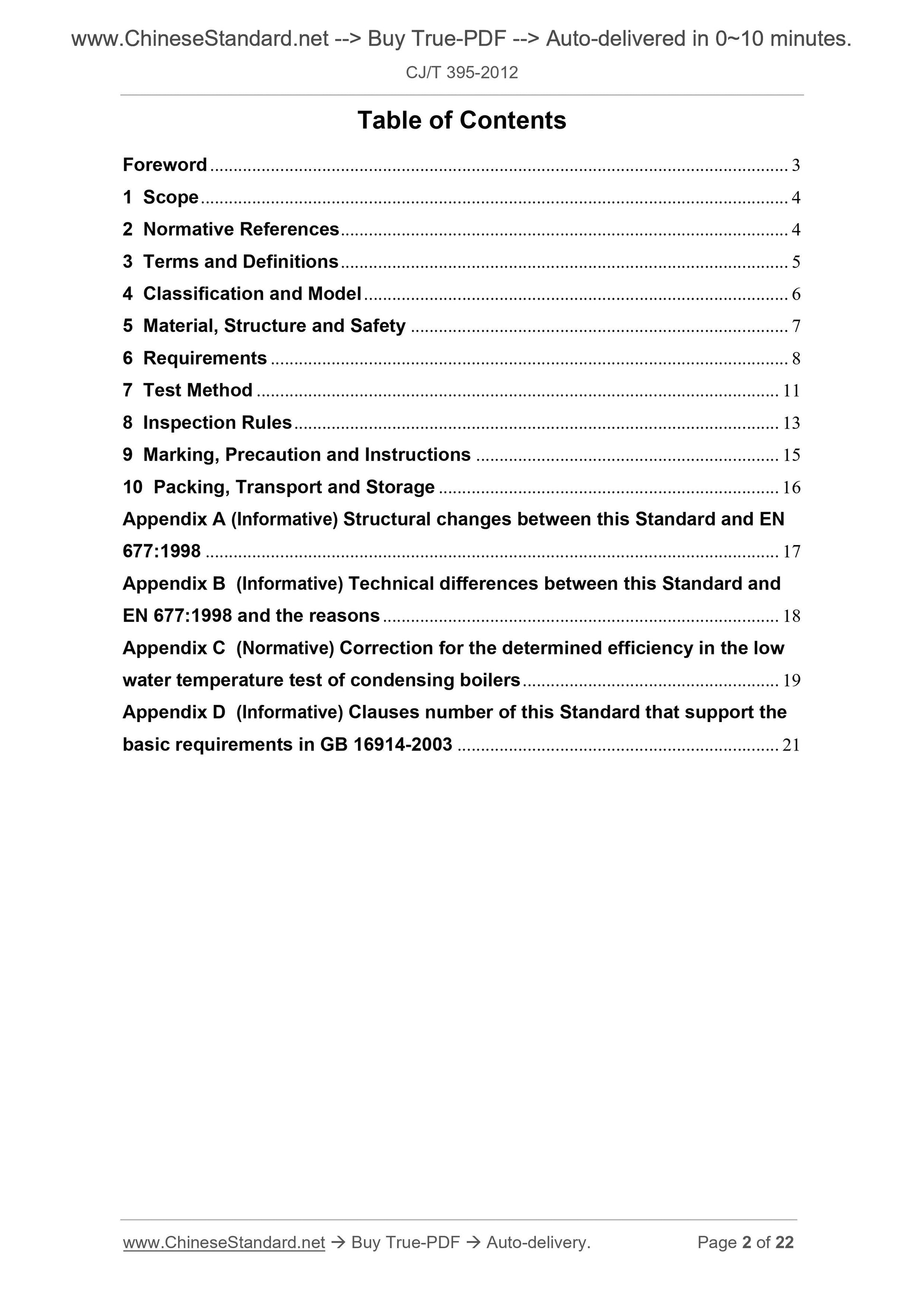

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 5

4 Classification and Model ... 6

5 Material, Structure and Safety ... 7

6 Requirements ... 8

7 Test Method ... 11

8 Inspection Rules ... 13

9 Marking, Precaution and Instructions ... 15

10 Packing, Transport and Storage ... 16

Appendix A (Informative) Structural changes between this Standard and EN

677:1998 ... 17

Appendix B (Informative) Technical differences between this Standard and

EN 677:1998 and the reasons ... 18

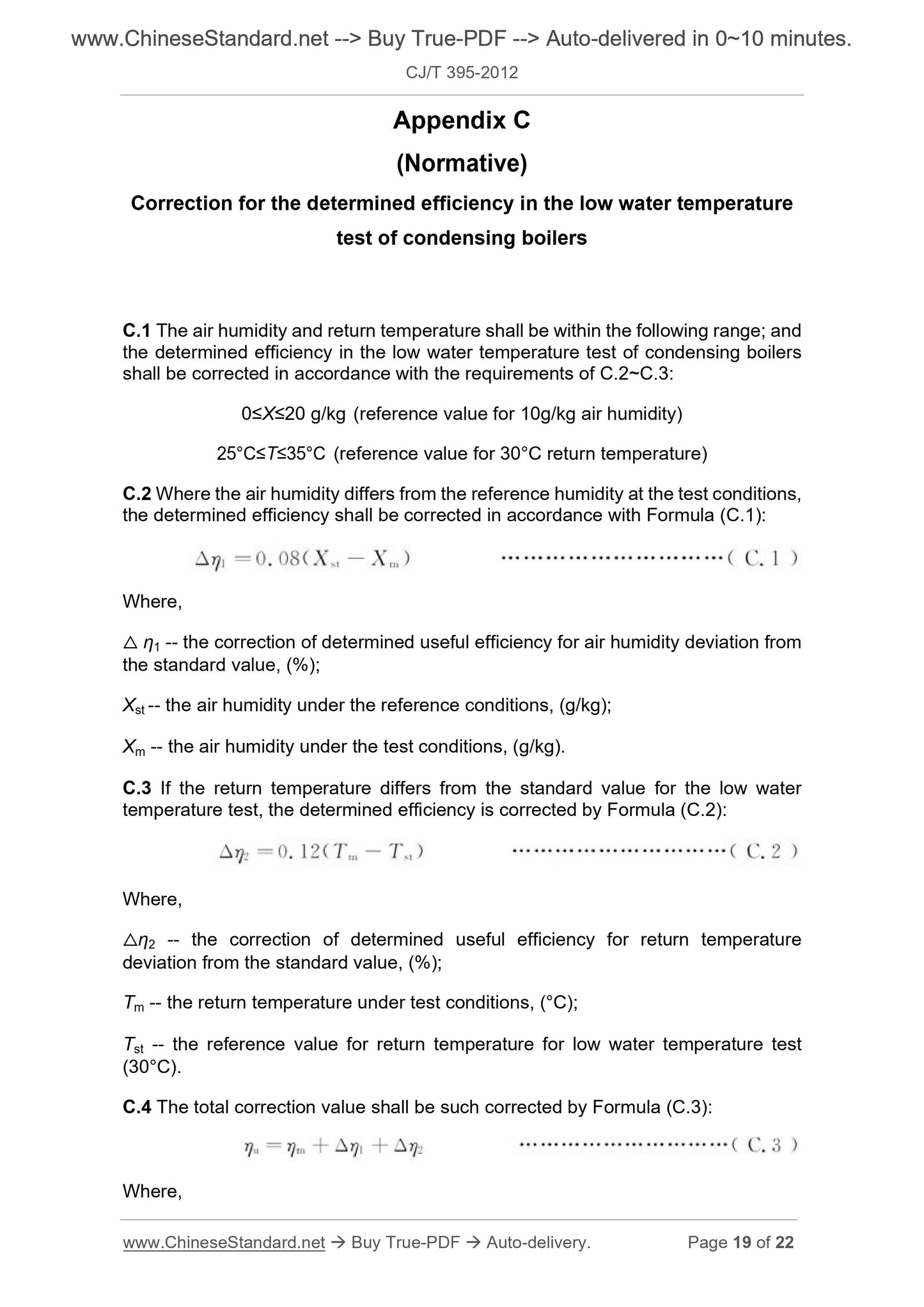

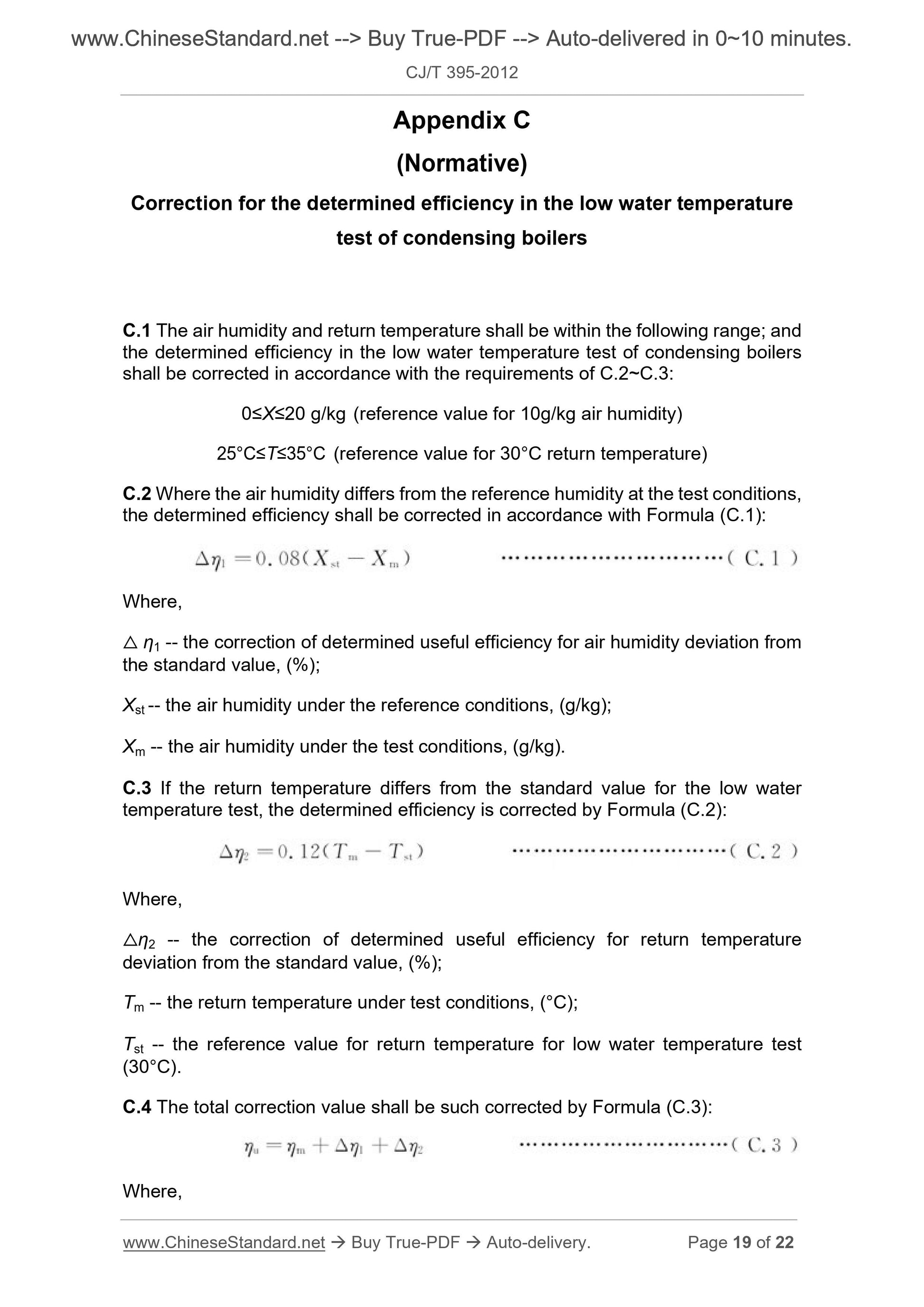

Appendix C (Normative) Correction for the determined efficiency in the low

water temperature test of condensing boilers ... 19

Appendix D (Informative) Clauses number of this Standard that support the

basic requirements in GB 16914-2003 ... 21

CJ/T 395-2012

Gas-fired Heating and Hot Water

Condensing Combi-boilers

1 Scope

This Standard specifies the gas-fired heating and hot water condensing

combi-boilers’ (hereinafter referred to as "condensing boilers") terms and definitions;

classification and model; requirements for material, structure and safety;

performance requirements; test method; inspection rules; marking; precaution and

instruction; packing; transport and storage.

This Standard is applicable to condensing boilers such as -- rated heat input is not

greater than 70kW; maximum heating operating water pressure is not greater than

0.3MPa; the water temperature is not greater than 95°C in the operation; it adopts

the blower atmospheric burner or full premix burner. For the condensing boilers of

which the rated heat input in greater than 70 kW, it may refer to this Standard.

This Standard is applicable to combi-condensing boilers of heating and hot water,

or condensing boilers of heating-only.

This Standard is applicable to the condensing boilers of natural gas, liquefied

petroleum gas, and manufactured gas that comply with those specified in GB/T

13611.

This Standard is not applicable to condensing boilers of the following types:

-- Natural draught flue type, and natural draught balance type;

-- Outdoor type;

-- Volume type;

-- Condensing boilers that adopt two sets of independent combustion systems

respectively for heating and hot water within the same enclosure, including

the boilers with common flue.

2 Normative References

The following referenced documents are indispensable for the application of this

document. For dated references, only the edition cited applies. For undated

references, the latest edition of the normative document (including any

amendments) applies.

GB/T 13611 Classification and Essential Property of City Gas

GB 25034-2010 Gas-fired Heating and Hot Water Combi-boilers

GB/T 2828.1-2003 Sampling Procedures for Inspection by Attributes - Part 1:

CJ/T 395-2012

Sampling Schemes Indexed by Acceptance Quality Limit (AQL) for Lot-by-lot

Inspection

3 Terms and Definitions

For the purposes of this document, the terms and definitions defined in GB

25034-2010 AND the following terms and definitions apply.

3.1

Condensing gas-fired heating and hot water combi-boilers

The heating and hot water combi-device or heating-only device, in which the water

vapor in the combustion flue gas is partially condensated, and the latent heat that is

released during the condensation process is effectively utilized.

3.2

Reference conditions

The dry gas of which the reference conditions are: temperature is 15°C; absolute

pressure is 101.325 kPa.

The laboratory environment conditions are: temperature is 20°C; air humidity is

70%; absolute pressure is 101.325 kPa.

3.3

Condensate

The liquid that is formed by condensation of flue gas in the heat exchange.

3.4

Rated condensing output

The design heat output, in kW, when the supply- and return-water-temperature of

the condensing boilers are being operated at 50°C/30°C respectively, under the

reference conditions specified in this Standard.

3.5

Max-allowable working temperature

The temperature the materials can withstand over a long period of time, under

working conditions.

3.6

Running for condensing condition

The condition when the condensing boilers are operated such that the supply- and

return-water-temperature is 50°C/30°C respectively, under the reference conditions

CJ/T 395-2012

The condensate produced during the operation of the condensing boilers shall be

discharged after being collected or treated by the neutralizing treatment device. The

condensate after being treated by the neutralizing treatment device shall keep the

pH value between 6.5 and 8.5.

5.3.3 Collection and discharge of condensate

The structure to collect and discharge the condensate shall comply with the

following provisions:

a) It shall be easily installed, disassembled, inspected and cleaned, and difficult

to block;

b) The internal diameter of the condensate discharge system shall be at least

13mm;

c) For the water-sealed condensate collecting device, the water trap has a seal of

at least 25mm at the maximum flue duct length specified by the manufacturer;

d) The condensate collecting device shall be sealed well to avoid the leakage on

the surface;

e) The condensate collecting device shall be able to prevent the leakage of flue

gas during the operation of the condensing boilers;

f) The surfaces in contact with condensates (except provided drains, water traps,

neutralization system and siphons) shall be designed to prevent the

condensate retention.

g) The device to monitor the blocking of the condensate should be arranged;

h) The condensate discharge pipe shall be the standard accessories of the

condensing boilers.

5.4 Device for limiting flue gas system temperature

The temperature limitation of flue gas system of condensing boilers shall comply

with the following provisions:

a) For plastic flue duct, it shall adopt the device to limit the temperature in the flue

gas system; the condensing boilers shall be closed safely before the flue gas

temperature reaches that given by the temperature limiting device;

b) The temperature limiting device shall not be adjustable.

6 Requirements

6.1 General

The performance requirement for the condensing boilers shall comply with all the

requirements in Chapter 6 of GB 25034-2010, except 6.7. And it shall comply with

the following requirements in this Chapter.

CJ/T 395-2012

Under test conditions in 7.6.2:

a) For the boilers without range-rating device, the heating efficiency,

corresponding to rated heat input, shall not be less than (97+lgPn)%.

b) For the boilers with range-rating device, the heat efficiency, corresponding to

maximum heat input, shall not be less than (97+lgPmax)% and that,

corresponding to the arithmetic mean of maximum rated heat input and

minimum rated heat input, shall not be less than (97+lgPa)%.

Note 1: Pn is rated heat output, in kW.

Note 2: Pmax is maximum heat output, in kW.

Note 3: Pa is the arithmetic mean of the maximum rated heat output and the

minimum heat output for the boilers with range-rating device...

Get QUOTATION in 1-minute: Click CJ/T 395-2012

Historical versions: CJ/T 395-2012

Preview True-PDF (Reload/Scroll if blank)

CJ/T 395-2012: Gas-fired heating and hot water condensing combi-boilers

CJ/T 395-2012

INDUSTRY STANDARD OF THE

PEOPLE'S REPUBLIC OF CHINA

ICS 91.140

P 46

CJ/T 395-2012

Gas-fired Heating and Hot Water

Condensing Combi-boilers

ISSUED ON: FEBRUARY 29, 2012

IMPLEMENTED ON: AUGUST 01, 2012

Issued by: Ministry of Housing and Urban-Rural Development of the People's

Republic of China

CJ/T 395-2012

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 5

4 Classification and Model ... 6

5 Material, Structure and Safety ... 7

6 Requirements ... 8

7 Test Method ... 11

8 Inspection Rules ... 13

9 Marking, Precaution and Instructions ... 15

10 Packing, Transport and Storage ... 16

Appendix A (Informative) Structural changes between this Standard and EN

677:1998 ... 17

Appendix B (Informative) Technical differences between this Standard and

EN 677:1998 and the reasons ... 18

Appendix C (Normative) Correction for the determined efficiency in the low

water temperature test of condensing boilers ... 19

Appendix D (Informative) Clauses number of this Standard that support the

basic requirements in GB 16914-2003 ... 21

CJ/T 395-2012

Gas-fired Heating and Hot Water

Condensing Combi-boilers

1 Scope

This Standard specifies the gas-fired heating and hot water condensing

combi-boilers’ (hereinafter referred to as "condensing boilers") terms and definitions;

classification and model; requirements for material, structure and safety;

performance requirements; test method; inspection rules; marking; precaution and

instruction; packing; transport and storage.

This Standard is applicable to condensing boilers such as -- rated heat input is not

greater than 70kW; maximum heating operating water pressure is not greater than

0.3MPa; the water temperature is not greater than 95°C in the operation; it adopts

the blower atmospheric burner or full premix burner. For the condensing boilers of

which the rated heat input in greater than 70 kW, it may refer to this Standard.

This Standard is applicable to combi-condensing boilers of heating and hot water,

or condensing boilers of heating-only.

This Standard is applicable to the condensing boilers of natural gas, liquefied

petroleum gas, and manufactured gas that comply with those specified in GB/T

13611.

This Standard is not applicable to condensing boilers of the following types:

-- Natural draught flue type, and natural draught balance type;

-- Outdoor type;

-- Volume type;

-- Condensing boilers that adopt two sets of independent combustion systems

respectively for heating and hot water within the same enclosure, including

the boilers with common flue.

2 Normative References

The following referenced documents are indispensable for the application of this

document. For dated references, only the edition cited applies. For undated

references, the latest edition of the normative document (including any

amendments) applies.

GB/T 13611 Classification and Essential Property of City Gas

GB 25034-2010 Gas-fired Heating and Hot Water Combi-boilers

GB/T 2828.1-2003 Sampling Procedures for Inspection by Attributes - Part 1:

CJ/T 395-2012

Sampling Schemes Indexed by Acceptance Quality Limit (AQL) for Lot-by-lot

Inspection

3 Terms and Definitions

For the purposes of this document, the terms and definitions defined in GB

25034-2010 AND the following terms and definitions apply.

3.1

Condensing gas-fired heating and hot water combi-boilers

The heating and hot water combi-device or heating-only device, in which the water

vapor in the combustion flue gas is partially condensated, and the latent heat that is

released during the condensation process is effectively utilized.

3.2

Reference conditions

The dry gas of which the reference conditions are: temperature is 15°C; absolute

pressure is 101.325 kPa.

The laboratory environment conditions are: temperature is 20°C; air humidity is

70%; absolute pressure is 101.325 kPa.

3.3

Condensate

The liquid that is formed by condensation of flue gas in the heat exchange.

3.4

Rated condensing output

The design heat output, in kW, when the supply- and return-water-temperature of

the condensing boilers are being operated at 50°C/30°C respectively, under the

reference conditions specified in this Standard.

3.5

Max-allowable working temperature

The temperature the materials can withstand over a long period of time, under

working conditions.

3.6

Running for condensing condition

The condition when the condensing boilers are operated such that the supply- and

return-water-temperature is 50°C/30°C respectively, under the reference conditions

CJ/T 395-2012

The condensate produced during the operation of the condensing boilers shall be

discharged after being collected or treated by the neutralizing treatment device. The

condensate after being treated by the neutralizing treatment device shall keep the

pH value between 6.5 and 8.5.

5.3.3 Collection and discharge of condensate

The structure to collect and discharge the condensate shall comply with the

following provisions:

a) It shall be easily installed, disassembled, inspected and cleaned, and difficult

to block;

b) The internal diameter of the condensate discharge system shall be at least

13mm;

c) For the water-sealed condensate collecting device, the water trap has a seal of

at least 25mm at the maximum flue duct length specified by the manufacturer;

d) The condensate collecting device shall be sealed well to avoid the leakage on

the surface;

e) The condensate collecting device shall be able to prevent the leakage of flue

gas during the operation of the condensing boilers;

f) The surfaces in contact with condensates (except provided drains, water traps,

neutralization system and siphons) shall be designed to prevent the

condensate retention.

g) The device to monitor the blocking of the condensate should be arranged;

h) The condensate discharge pipe shall be the standard accessories of the

condensing boilers.

5.4 Device for limiting flue gas system temperature

The temperature limitation of flue gas system of condensing boilers shall comply

with the following provisions:

a) For plastic flue duct, it shall adopt the device to limit the temperature in the flue

gas system; the condensing boilers shall be closed safely before the flue gas

temperature reaches that given by the temperature limiting device;

b) The temperature limiting device shall not be adjustable.

6 Requirements

6.1 General

The performance requirement for the condensing boilers shall comply with all the

requirements in Chapter 6 of GB 25034-2010, except 6.7. And it shall comply with

the following requirements in this Chapter.

CJ/T 395-2012

Under test conditions in 7.6.2:

a) For the boilers without range-rating device, the heating efficiency,

corresponding to rated heat input, shall not be less than (97+lgPn)%.

b) For the boilers with range-rating device, the heat efficiency, corresponding to

maximum heat input, shall not be less than (97+lgPmax)% and that,

corresponding to the arithmetic mean of maximum rated heat input and

minimum rated heat input, shall not be less than (97+lgPa)%.

Note 1: Pn is rated heat output, in kW.

Note 2: Pmax is maximum heat output, in kW.

Note 3: Pa is the arithmetic mean of the maximum rated heat output and the

minimum heat output for the boilers with range-rating device...

Share