PayPal, credit cards. Download editable-PDF & invoice In 1 second!

CQC-C1106-2014 English PDF (CQC-C1106-2014)

CQC-C1106-2014 English PDF (CQC-C1106-2014)

Precio habitual

$145.00 USD

Precio habitual

Precio de oferta

$145.00 USD

Precio unitario

/

por

Los gastos de envío se calculan en la pantalla de pago.

No se pudo cargar la disponibilidad de retiro

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click CQC-C1106-2014

Historical versions: CQC-C1106-2014

Preview True-PDF (Reload/Scroll if blank)

CQC-C1106-2014: China Compulsory Certification Implementation Detailed-Rules - Motor vehicle brake hose

CQC-C1106-2014

Serial No.. CQC-C1106.2014

China Compulsory Certification

Implementation Detailed-Rules

Brake Hose of Motor Vehicle

ISSUED ON. DECEMBER 31, 2014

IMPLEMENTED ON. JANUARY 1, 2015

China Quality Certification Center

3. No action is required - Full-copy of this standard will be automatically and

immediately delivered to your EMAIL address in 0~60 minutes.

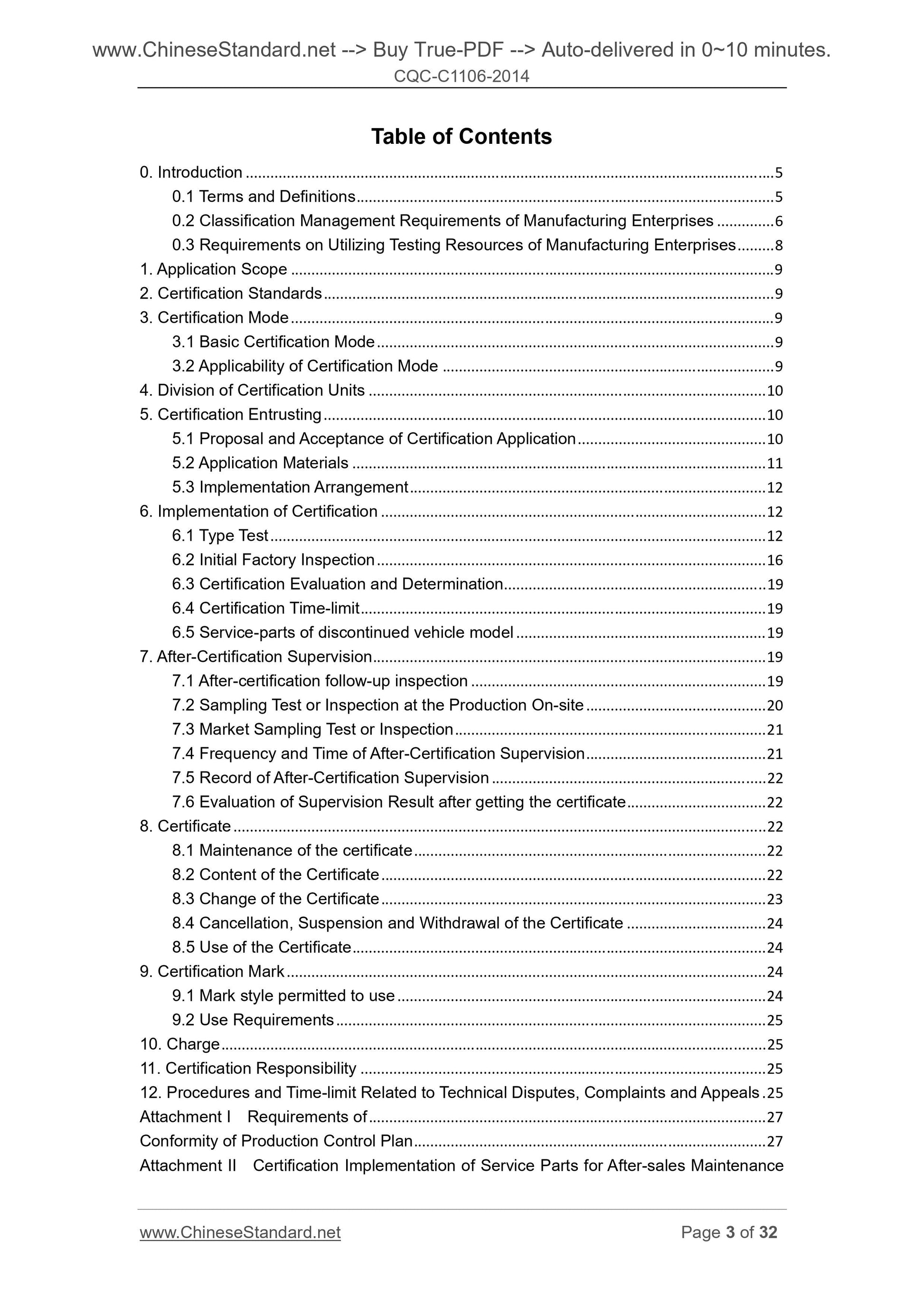

Table of Contents

0. Introduction ... 5

0.1 Terms and Definitions ... 5

0.2 Classification Management Requirements of Manufacturing Enterprises ... 6

0.3 Requirements on Utilizing Testing Resources of Manufacturing Enterprises ... 8

1. Application Scope ... 9

2. Certification Standards ... 9

3. Certification Mode ... 9

3.1 Basic Certification Mode ... 9

3.2 Applicability of Certification Mode ... 9

4. Division of Certification Units ... 10

5. Certification Entrusting ... 10

5.1 Proposal and Acceptance of Certification Application ... 10

5.2 Application Materials ... 11

5.3 Implementation Arrangement ... 12

6. Implementation of Certification ... 12

6.1 Type Test ... 12

6.2 Initial Factory Inspection ... 16

6.3 Certification Evaluation and Determination ... 19

6.4 Certification Time-limit ... 19

6.5 Service-parts of discontinued vehicle model ... 19

7. After-Certification Supervision ... 19

7.1 After-certification follow-up inspection ... 19

7.2 Sampling Test or Inspection at the Production On-site ... 20

7.3 Market Sampling Test or Inspection ... 21

7.4 Frequency and Time of After-Certification Supervision ... 21

7.5 Record of After-Certification Supervision ... 22

7.6 Evaluation of Supervision Result after getting the certificate ... 22

8. Certificate ... 22

8.1 Maintenance of the certificate ... 22

8.2 Content of the Certificate ... 22

8.3 Change of the Certificate ... 23

8.4 Cancellation, Suspension and Withdrawal of the Certificate ... 24

8.5 Use of the Certificate ... 24

9. Certification Mark ... 24

9.1 Mark style permitted to use ... 24

9.2 Use Requirements ... 25

10. Charge ... 25

11. Certification Responsibility ... 25

12. Procedures and Time-limit Related to Technical Disputes, Complaints and Appeals . 25

Attachment I Requirements of ... 27

Conformity of Production Control Plan ... 27

Attachment II Certification Implementation of Service Parts for After-sales Maintenance

for Discontinued Vehicle Model ... 30

0. Introduction

“China Compulsory Certification Implementation Detailed-Rules - Brake Hose of Motor

Vehicle” (hereinafter referred to as Implementation Detailed-Rules) is compiled based

on the requirements of “Implementation Rules for China Compulsory Certification -

Brake Hose of Motor Vehicle” (CNCA-C11-04.2014) (hereinafter referred to as

Implementation Rules). This Implementation Detailed-Rules is used together with the

Implementation Rules as supportive document.

The product scope, certification basis and all other contents of this Implementation

Detailed-Rules shall comply with relevant provisions of Implementation Rules. It shall

also be adjusted according to the Notices such as defined directory and directory

adjustment that are issued by Certification and Accreditation Administration of the

People’s Republic of China (hereafter referred to as CNCA).

In accordance with the provisions of Implementation Rules, following the principles of

maintaining the effectiveness of product certification, improving quality of product,

serving certification companies, and controlling risk of certification, CQC formulates

and issues this Certification Implementation Detailed-Rules. Through establishing the

classification management requirements of manufacturing enterprises, and combining

the classification of manufacturing enterprises, this Detailed-Rules determines the

implementation requirements for China compulsory certification of brake hose of motor

vehicles.

0.1 Terms and Definitions

0.1.1 Brake hose. flexible hoses used to transmit or store hydraulic pressure,

pneumatic pressure or vacuum to provide braking force to the braking system. The

following also referred to as hose.

Brake hose assembly. composed by brake hose and brake hose end fitting, and brake

hose and brake hose end fitting are permanently connected.

0.1.2 Testing at Manufacturer’s Premises (abbreviated as TMP mode)

It means that the engineers of designated laboratory use the testing equipment in the

factory laboratory to conduct testing. The factory shall dispatch test personnel to

provide assistance. The designated laboratory will examine, approve and issue the

test report.

0.1.3 Witnessed Manufacturer’s Testing (abbreviated as WMT mode)

It means that the engineer of designated laboratory witnesses the factory laboratory’s

test conditions and all tests completed by using the laboratory’s equipment or

according to the test plan submitted; or witnesses part of the test conditions and the

test items. Test personnel of the factory laboratory shall provide the original records

In case there is any change, the documents publicized by CQC shall prevail. In

principle, the classification result of manufacturing enterprises shall be upgraded

according to the sequence of D-C-B-A; and downgraded according to the sequence of

A-B-C-D or it may be directly downgraded to the corresponding category according to

the risk evaluation.

0.3 Requirements on Utilizing Testing Resources of Manufacturing Enterprises

0.3.1 Scope

Applicable to after-certification supervision sampling test and supplementary

difference-test when the certificate is changed.

0.3.2 Implementation

If the manufacturing enterprise has the testing equipment and testing capacity that are

required by “Implementation Rules for China Compulsory Certification. Utilization

Requirements of Testing Resources and Other Certification Results of the

Manufacturing Enterprise” and the certification standards, then the CLIENT,

manufacturer, or manufacturing enterprise can apply for testing to utilize the testing

resources of the manufacturing enterprise (hereinafter referred to as the factory

laboratory) and perform the self-inspection. The self-inspection result and relevant

materials shall be submitted to CQC for review. The factory laboratories of which the

materials pass the review are allowed to perform TMP or WMT (hereinafter also

referred to as on-site test) with factory laboratory resources.

In principle, CQC shall not organize inspection only for factory laboratory. Generally,

factory laboratory inspection application of the CLIENT shall be proposed together with

on-site test application. CQC shall organize the technical specialists from designated

laboratories to perform both inspections. Inspection group shall inspect the laboratory

capability first; and keep the relevant inspection and assessment record; after

conformance, then perform production on-site inspection.

0.3.3 Qualification maintenance

CQC shall perform regular (such as once a year, or adjusted according to frequency)

supervision to the certified factory laboratory. In principle, laboratory supervision shall

be made together with after-certification supervision. Factory laboratory shall take part

in contrast test to ensure the test accuracy and maintain the qualification.

When it is needed by the manufacturing enterprise, it can perform single test in

response to the on-site test raised by CLIENT; the test result is only applicable to this

on-site test. The factory laboratory may be exempted from superv...

Get QUOTATION in 1-minute: Click CQC-C1106-2014

Historical versions: CQC-C1106-2014

Preview True-PDF (Reload/Scroll if blank)

CQC-C1106-2014: China Compulsory Certification Implementation Detailed-Rules - Motor vehicle brake hose

CQC-C1106-2014

Serial No.. CQC-C1106.2014

China Compulsory Certification

Implementation Detailed-Rules

Brake Hose of Motor Vehicle

ISSUED ON. DECEMBER 31, 2014

IMPLEMENTED ON. JANUARY 1, 2015

China Quality Certification Center

3. No action is required - Full-copy of this standard will be automatically and

immediately delivered to your EMAIL address in 0~60 minutes.

Table of Contents

0. Introduction ... 5

0.1 Terms and Definitions ... 5

0.2 Classification Management Requirements of Manufacturing Enterprises ... 6

0.3 Requirements on Utilizing Testing Resources of Manufacturing Enterprises ... 8

1. Application Scope ... 9

2. Certification Standards ... 9

3. Certification Mode ... 9

3.1 Basic Certification Mode ... 9

3.2 Applicability of Certification Mode ... 9

4. Division of Certification Units ... 10

5. Certification Entrusting ... 10

5.1 Proposal and Acceptance of Certification Application ... 10

5.2 Application Materials ... 11

5.3 Implementation Arrangement ... 12

6. Implementation of Certification ... 12

6.1 Type Test ... 12

6.2 Initial Factory Inspection ... 16

6.3 Certification Evaluation and Determination ... 19

6.4 Certification Time-limit ... 19

6.5 Service-parts of discontinued vehicle model ... 19

7. After-Certification Supervision ... 19

7.1 After-certification follow-up inspection ... 19

7.2 Sampling Test or Inspection at the Production On-site ... 20

7.3 Market Sampling Test or Inspection ... 21

7.4 Frequency and Time of After-Certification Supervision ... 21

7.5 Record of After-Certification Supervision ... 22

7.6 Evaluation of Supervision Result after getting the certificate ... 22

8. Certificate ... 22

8.1 Maintenance of the certificate ... 22

8.2 Content of the Certificate ... 22

8.3 Change of the Certificate ... 23

8.4 Cancellation, Suspension and Withdrawal of the Certificate ... 24

8.5 Use of the Certificate ... 24

9. Certification Mark ... 24

9.1 Mark style permitted to use ... 24

9.2 Use Requirements ... 25

10. Charge ... 25

11. Certification Responsibility ... 25

12. Procedures and Time-limit Related to Technical Disputes, Complaints and Appeals . 25

Attachment I Requirements of ... 27

Conformity of Production Control Plan ... 27

Attachment II Certification Implementation of Service Parts for After-sales Maintenance

for Discontinued Vehicle Model ... 30

0. Introduction

“China Compulsory Certification Implementation Detailed-Rules - Brake Hose of Motor

Vehicle” (hereinafter referred to as Implementation Detailed-Rules) is compiled based

on the requirements of “Implementation Rules for China Compulsory Certification -

Brake Hose of Motor Vehicle” (CNCA-C11-04.2014) (hereinafter referred to as

Implementation Rules). This Implementation Detailed-Rules is used together with the

Implementation Rules as supportive document.

The product scope, certification basis and all other contents of this Implementation

Detailed-Rules shall comply with relevant provisions of Implementation Rules. It shall

also be adjusted according to the Notices such as defined directory and directory

adjustment that are issued by Certification and Accreditation Administration of the

People’s Republic of China (hereafter referred to as CNCA).

In accordance with the provisions of Implementation Rules, following the principles of

maintaining the effectiveness of product certification, improving quality of product,

serving certification companies, and controlling risk of certification, CQC formulates

and issues this Certification Implementation Detailed-Rules. Through establishing the

classification management requirements of manufacturing enterprises, and combining

the classification of manufacturing enterprises, this Detailed-Rules determines the

implementation requirements for China compulsory certification of brake hose of motor

vehicles.

0.1 Terms and Definitions

0.1.1 Brake hose. flexible hoses used to transmit or store hydraulic pressure,

pneumatic pressure or vacuum to provide braking force to the braking system. The

following also referred to as hose.

Brake hose assembly. composed by brake hose and brake hose end fitting, and brake

hose and brake hose end fitting are permanently connected.

0.1.2 Testing at Manufacturer’s Premises (abbreviated as TMP mode)

It means that the engineers of designated laboratory use the testing equipment in the

factory laboratory to conduct testing. The factory shall dispatch test personnel to

provide assistance. The designated laboratory will examine, approve and issue the

test report.

0.1.3 Witnessed Manufacturer’s Testing (abbreviated as WMT mode)

It means that the engineer of designated laboratory witnesses the factory laboratory’s

test conditions and all tests completed by using the laboratory’s equipment or

according to the test plan submitted; or witnesses part of the test conditions and the

test items. Test personnel of the factory laboratory shall provide the original records

In case there is any change, the documents publicized by CQC shall prevail. In

principle, the classification result of manufacturing enterprises shall be upgraded

according to the sequence of D-C-B-A; and downgraded according to the sequence of

A-B-C-D or it may be directly downgraded to the corresponding category according to

the risk evaluation.

0.3 Requirements on Utilizing Testing Resources of Manufacturing Enterprises

0.3.1 Scope

Applicable to after-certification supervision sampling test and supplementary

difference-test when the certificate is changed.

0.3.2 Implementation

If the manufacturing enterprise has the testing equipment and testing capacity that are

required by “Implementation Rules for China Compulsory Certification. Utilization

Requirements of Testing Resources and Other Certification Results of the

Manufacturing Enterprise” and the certification standards, then the CLIENT,

manufacturer, or manufacturing enterprise can apply for testing to utilize the testing

resources of the manufacturing enterprise (hereinafter referred to as the factory

laboratory) and perform the self-inspection. The self-inspection result and relevant

materials shall be submitted to CQC for review. The factory laboratories of which the

materials pass the review are allowed to perform TMP or WMT (hereinafter also

referred to as on-site test) with factory laboratory resources.

In principle, CQC shall not organize inspection only for factory laboratory. Generally,

factory laboratory inspection application of the CLIENT shall be proposed together with

on-site test application. CQC shall organize the technical specialists from designated

laboratories to perform both inspections. Inspection group shall inspect the laboratory

capability first; and keep the relevant inspection and assessment record; after

conformance, then perform production on-site inspection.

0.3.3 Qualification maintenance

CQC shall perform regular (such as once a year, or adjusted according to frequency)

supervision to the certified factory laboratory. In principle, laboratory supervision shall

be made together with after-certification supervision. Factory laboratory shall take part

in contrast test to ensure the test accuracy and maintain the qualification.

When it is needed by the manufacturing enterprise, it can perform single test in

response to the on-site test raised by CLIENT; the test result is only applicable to this

on-site test. The factory laboratory may be exempted from superv...

Share