PayPal, credit cards. Download editable-PDF and invoice in 1 second!

FZ/T 24019-2012 English PDF (FZT24019-2012)

FZ/T 24019-2012 English PDF (FZT24019-2012)

Precio habitual

$150.00 USD

Precio habitual

Precio de oferta

$150.00 USD

Precio unitario

/

por

Los gastos de envío se calculan en la pantalla de pago.

No se pudo cargar la disponibilidad de retiro

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click FZ/T 24019-2012

Historical versions: FZ/T 24019-2012

Preview True-PDF (Reload/Scroll if blank)

FZ/T 24019-2012: Priting cashmere knitting goods

FZ/T 24019-2012

GB

TEXTILE INDUSTRY STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 59.080.30

W 63

Printing cashmere knitting goods

印花羊绒针织品

ISSUED ON. DECEMBER 28, 2012

IMPLEMENTED ON. JUNE 1, 2013

Issued by. Ministry of Industry and Information Technology of the

People's Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Technical requirements ... 4

4 Test method ... 7

5 Inspection rules ... 7

6 Use instructions, packaging, transportation and storage ... 9

Annex A (Normative) Descriptions of appearance defects and degrees ... 10

Foreword

This Standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This Standard was proposed by China National Textile and Apparel Council.

This Standard shall be under the jurisdiction of the National Standardization Technical

Committee on Textile Cashmere Products Subcommittee (SAC/TC 209/SC9).

The main drafting organizations of this Standard. Inner Mongolia Erdos Group Co., Ltd.

and National Cashmere Products Engineering Technology Research Centre.

The main drafters of this Standard. Yang Guifen, Wang You, Tian Jun, Zhang Yun, An

Heli and Qu Xiulan.

Printing cashmere knitting goods

1 Scope

This Standard specifies the technical requirements, test methods, inspection rules, use

instructions, packaging, transportation and storage of printing cashmere knitting goods.

This Standard applies to combing, carding and semi-worsting pure cashmere knitting

products after printing and cashmere blended knitting goods containing more than 30%

of cashmere.

2 Normative references

The following referenced documents are indispensable for the application of this

document. For dated references, only the editions dated applies to this document. For

undated references, the latest editions of the referenced document (including any

amendments) apply to this Standard.

GB/T 250, Leather – Tests for colour fastness – Gray scale for assessing change in

colour

GB/T 1335 (all parts), Standard sizing systems for garments

GB/T 2828.1-2003,

GB/T 4841.3, Sampling procedures for inspection by attributes – Part1. Sampling

schemes indexed by acceptance quality limit (AQL) for lot-by-lot inspection

GB 5296.4, Instructions for use of products of consumer interest – Part 4. Textiles

and apparel

GB 18401, National general safety technical code for textile products

FZ/T 73009, Cashmere knitting goods

3 Technical requirements

3.1 Safety requirements

General safety specifications of printing cashmere knitting goods are specified in GB

18401.

3.2 Classification provision

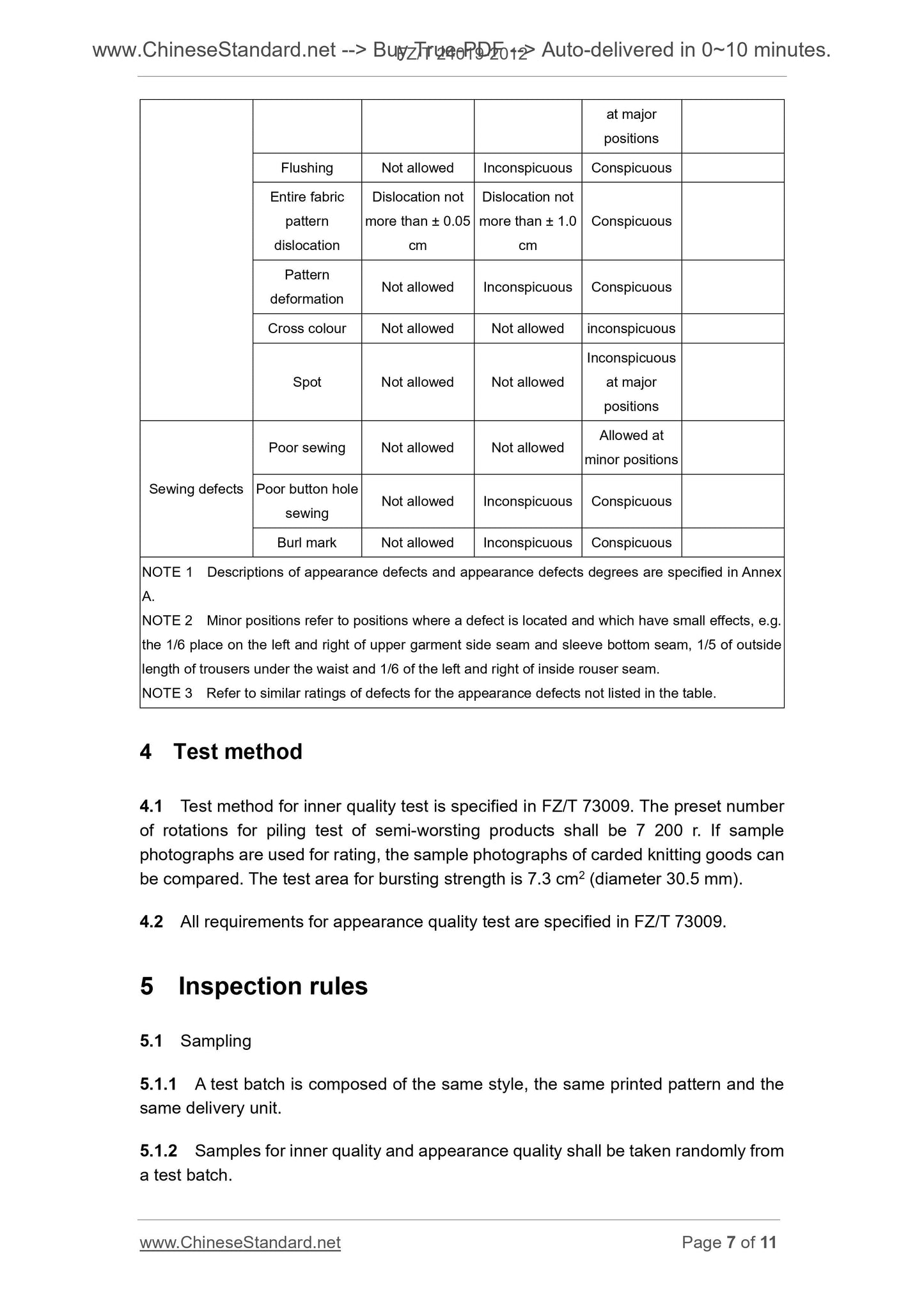

at major

positions

Flushing Not allowed Inconspicuous Conspicuous

Entire fabric

pattern

dislocation

Dislocation not

more than ± 0.05

cm

Dislocation not

more than ± 1.0

cm

Conspicuous

Pattern

deformation Not allowed Inconspicuous Conspicuous

Cross colour Not allowed Not allowed inconspicuous

Spot Not allowed Not allowed

Inconspicuous

at major

positions

Sewing defects

Poor sewing Not allowed Not allowed Allowed at minor positions

Poor button hole

sewing Not allowed Inconspicuous Conspicuous

Burl mark Not allowed Inconspicuous Conspicuous

NOTE 1 Descriptions of appearance defects and appearance defects degrees are specified in Annex

A.

NOTE 2 Minor positions refer to positions where a defect is located and which have small effects, e.g.

the 1/6 place on the left and right of upper garment side seam and sleeve bottom seam, 1/5 of outside

length of trousers under the waist and 1/6 of the left and right of inside rouser seam.

NOTE 3 Refer to similar ratings of defects for the appearance defects not listed in the table.

4 Test method

4.1 Test method for inner quality test is specified in FZ/T 73009. The preset number

of rotations for piling test of semi-worsting products shall be 7 200 r. If sample

photographs are used for rating, the sample photographs of carded knitting goods can

be compared. The test area for bursting strength is 7.3 cm2 (diameter 30.5 mm).

4.2 All requirements for appearance quality test are specified in FZ/T 73009.

5 Inspection rules

5.1 Sampling

5.1.1 A test batch is composed of the same style, the same printed pattern and the

same delivery unit.

5.1.2 Samples for inner quality and appearance quality shall be taken randomly from

a test batch.

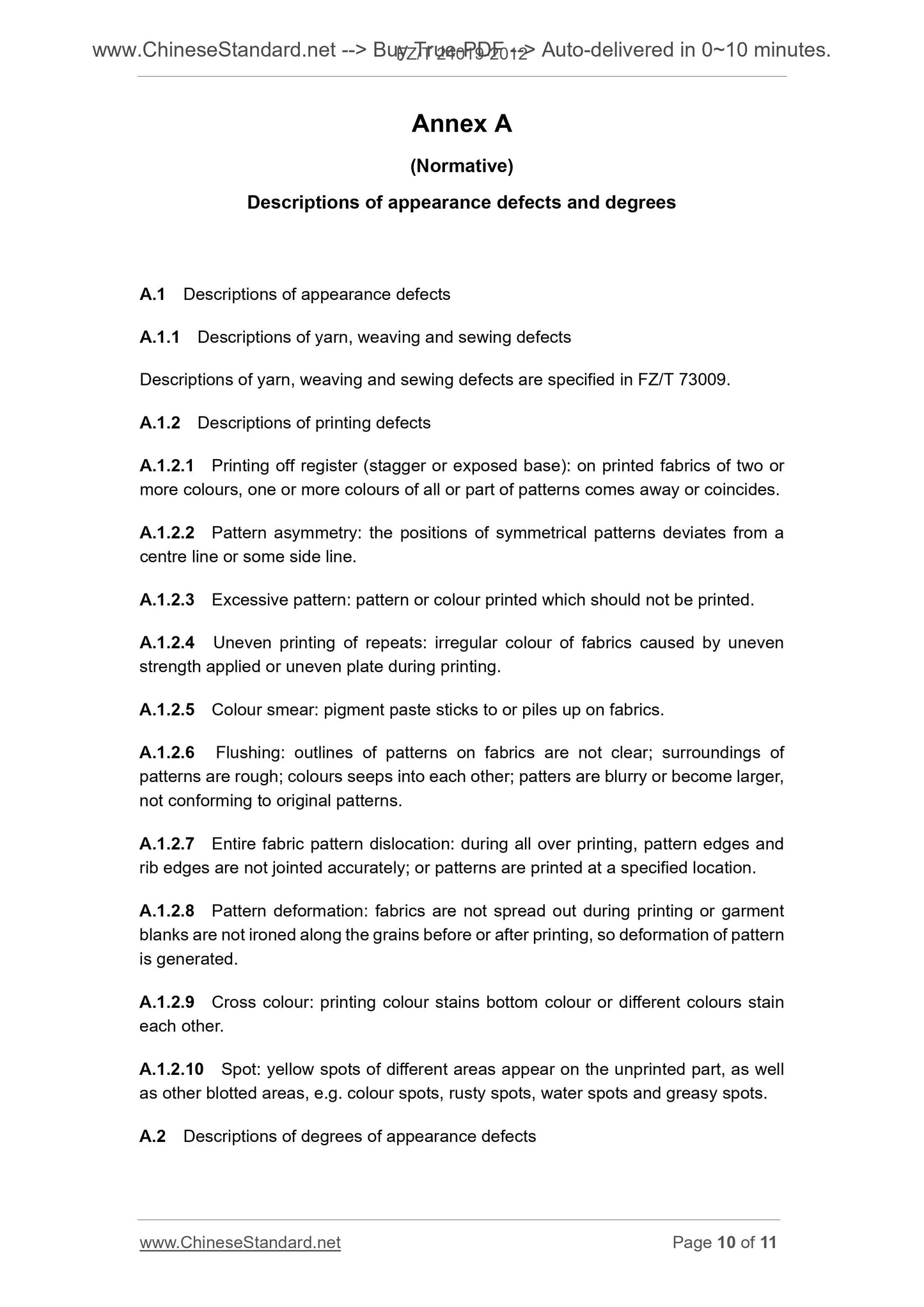

Annex A

(Normative)

Descriptions of appearance defects and degrees

A.1 Descriptions of appearance defects

A.1.1 Descriptions of yarn, weaving and sewing defects

Descriptions of yarn, weaving and sewing defects are specified in FZ/T 73009.

A.1.2 Descriptions of printing defects

A.1.2.1 Printing off register (stagger or exposed base). on printed fabrics of two or

more colours, one or more colours of all or part of patterns comes away or coincides.

A.1.2.2 Pattern asymmetry. the positions of symmetrical patterns deviates from a

centre line or some side line.

A.1.2.3 Excessive pattern. pattern or colour printed which should not be printed.

A.1.2.4 Uneven printing of repeats. irregular colour of fabrics caused by uneven

strength applied or uneven plate during printing.

A.1.2.5 Colour smear. pigment paste sticks to or piles up on fabrics.

A.1.2.6 Flushing. outlines of patterns on fabrics are not clear; surroundings of

patterns are rough; colours seeps into each other; patters are blurry or become larger,

not conforming to original patterns.

A.1.2.7 Entire fabric pattern dislocation. during all over printing, pattern edges and

rib edges are not jointed accurately; or patterns are printed at a specified location.

A.1.2.8 Pattern deformation. fabrics are not spread out during printing or garment

blanks are not ironed along the grains before or after printing, so deformation of pattern

is generated.

A.1.2.9 Cross colour. printing colour stains bottom colour or different colours stain

each other.

A.1.2.10 Spot. yellow spots of different areas appear on the unprinted part, as well

as other blotted areas, e.g. colour spots, rusty spots, water spots and greasy spots.

A.2 Descriptions of degrees of appearance defects

Get QUOTATION in 1-minute: Click FZ/T 24019-2012

Historical versions: FZ/T 24019-2012

Preview True-PDF (Reload/Scroll if blank)

FZ/T 24019-2012: Priting cashmere knitting goods

FZ/T 24019-2012

GB

TEXTILE INDUSTRY STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 59.080.30

W 63

Printing cashmere knitting goods

印花羊绒针织品

ISSUED ON. DECEMBER 28, 2012

IMPLEMENTED ON. JUNE 1, 2013

Issued by. Ministry of Industry and Information Technology of the

People's Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Technical requirements ... 4

4 Test method ... 7

5 Inspection rules ... 7

6 Use instructions, packaging, transportation and storage ... 9

Annex A (Normative) Descriptions of appearance defects and degrees ... 10

Foreword

This Standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This Standard was proposed by China National Textile and Apparel Council.

This Standard shall be under the jurisdiction of the National Standardization Technical

Committee on Textile Cashmere Products Subcommittee (SAC/TC 209/SC9).

The main drafting organizations of this Standard. Inner Mongolia Erdos Group Co., Ltd.

and National Cashmere Products Engineering Technology Research Centre.

The main drafters of this Standard. Yang Guifen, Wang You, Tian Jun, Zhang Yun, An

Heli and Qu Xiulan.

Printing cashmere knitting goods

1 Scope

This Standard specifies the technical requirements, test methods, inspection rules, use

instructions, packaging, transportation and storage of printing cashmere knitting goods.

This Standard applies to combing, carding and semi-worsting pure cashmere knitting

products after printing and cashmere blended knitting goods containing more than 30%

of cashmere.

2 Normative references

The following referenced documents are indispensable for the application of this

document. For dated references, only the editions dated applies to this document. For

undated references, the latest editions of the referenced document (including any

amendments) apply to this Standard.

GB/T 250, Leather – Tests for colour fastness – Gray scale for assessing change in

colour

GB/T 1335 (all parts), Standard sizing systems for garments

GB/T 2828.1-2003,

GB/T 4841.3, Sampling procedures for inspection by attributes – Part1. Sampling

schemes indexed by acceptance quality limit (AQL) for lot-by-lot inspection

GB 5296.4, Instructions for use of products of consumer interest – Part 4. Textiles

and apparel

GB 18401, National general safety technical code for textile products

FZ/T 73009, Cashmere knitting goods

3 Technical requirements

3.1 Safety requirements

General safety specifications of printing cashmere knitting goods are specified in GB

18401.

3.2 Classification provision

at major

positions

Flushing Not allowed Inconspicuous Conspicuous

Entire fabric

pattern

dislocation

Dislocation not

more than ± 0.05

cm

Dislocation not

more than ± 1.0

cm

Conspicuous

Pattern

deformation Not allowed Inconspicuous Conspicuous

Cross colour Not allowed Not allowed inconspicuous

Spot Not allowed Not allowed

Inconspicuous

at major

positions

Sewing defects

Poor sewing Not allowed Not allowed Allowed at minor positions

Poor button hole

sewing Not allowed Inconspicuous Conspicuous

Burl mark Not allowed Inconspicuous Conspicuous

NOTE 1 Descriptions of appearance defects and appearance defects degrees are specified in Annex

A.

NOTE 2 Minor positions refer to positions where a defect is located and which have small effects, e.g.

the 1/6 place on the left and right of upper garment side seam and sleeve bottom seam, 1/5 of outside

length of trousers under the waist and 1/6 of the left and right of inside rouser seam.

NOTE 3 Refer to similar ratings of defects for the appearance defects not listed in the table.

4 Test method

4.1 Test method for inner quality test is specified in FZ/T 73009. The preset number

of rotations for piling test of semi-worsting products shall be 7 200 r. If sample

photographs are used for rating, the sample photographs of carded knitting goods can

be compared. The test area for bursting strength is 7.3 cm2 (diameter 30.5 mm).

4.2 All requirements for appearance quality test are specified in FZ/T 73009.

5 Inspection rules

5.1 Sampling

5.1.1 A test batch is composed of the same style, the same printed pattern and the

same delivery unit.

5.1.2 Samples for inner quality and appearance quality shall be taken randomly from

a test batch.

Annex A

(Normative)

Descriptions of appearance defects and degrees

A.1 Descriptions of appearance defects

A.1.1 Descriptions of yarn, weaving and sewing defects

Descriptions of yarn, weaving and sewing defects are specified in FZ/T 73009.

A.1.2 Descriptions of printing defects

A.1.2.1 Printing off register (stagger or exposed base). on printed fabrics of two or

more colours, one or more colours of all or part of patterns comes away or coincides.

A.1.2.2 Pattern asymmetry. the positions of symmetrical patterns deviates from a

centre line or some side line.

A.1.2.3 Excessive pattern. pattern or colour printed which should not be printed.

A.1.2.4 Uneven printing of repeats. irregular colour of fabrics caused by uneven

strength applied or uneven plate during printing.

A.1.2.5 Colour smear. pigment paste sticks to or piles up on fabrics.

A.1.2.6 Flushing. outlines of patterns on fabrics are not clear; surroundings of

patterns are rough; colours seeps into each other; patters are blurry or become larger,

not conforming to original patterns.

A.1.2.7 Entire fabric pattern dislocation. during all over printing, pattern edges and

rib edges are not jointed accurately; or patterns are printed at a specified location.

A.1.2.8 Pattern deformation. fabrics are not spread out during printing or garment

blanks are not ironed along the grains before or after printing, so deformation of pattern

is generated.

A.1.2.9 Cross colour. printing colour stains bottom colour or different colours stain

each other.

A.1.2.10 Spot. yellow spots of different areas appear on the unprinted part, as well

as other blotted areas, e.g. colour spots, rusty spots, water spots and greasy spots.

A.2 Descriptions of degrees of appearance defects

Share