PayPal, credit cards. Download editable-PDF and invoice in 1 second!

FZ/T 70006-2022 English PDF (FZT70006-2022)

FZ/T 70006-2022 English PDF (FZT70006-2022)

Precio habitual

$245.00 USD

Precio habitual

Precio de oferta

$245.00 USD

Precio unitario

/

por

Los gastos de envío se calculan en la pantalla de pago.

No se pudo cargar la disponibilidad de retiro

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click FZ/T 70006-2022

Historical versions: FZ/T 70006-2022

Preview True-PDF (Reload/Scroll if blank)

FZ/T 70006-2022: Stretch and recovery testing method for knitted fabrics

FZ/T 70006-2022

FZ

NATIONAL STANDARD OF THE

PEOPLE'S REPUBLIC OF CHINA

ICS 59.080.01

CCS W 60

Replacing FZ/T 70006-2004

Stretch and recovery testing method for knitted fabrics

ISSUED ON: APRIL 8, 2022

IMPLEMENTED ON: OCTOBER 1, 2022

Issued by: Ministry of Industry and Information Technology of PRC;

Standards Press of China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Principles ... 6

5 Standard atmosphere for conditioning and testing ... 6

6 Instruments and tools ... 6

7 Samples and specimens ... 8

8 Procedures ... 9

9 Test report ... 14

Appendix A (Normative) Specimen cutting examples ... 16

Appendix B (Informative) Constant elongation (rate), constant tension, number of

repeated stretching, and relaxation time of constant rate of elongation method ... 18

Stretch and recovery testing method for knitted fabrics

1 Scope

This document specifies the test method for determining the tensile elasticity

deformation and plastic deformation of knitted fabrics using the constant elongation

and the constant tension methods.

This document is applicable to various knitted fabrics, and for others, it can be a

reference.

2 Normative references

The provisions of the following documents constitute the essential clauses of this

document through normative references in this text. Among them, for referenced

documents with dates, only the versions corresponding to the dates are applicable to

this document; for referenced documents without dates, the latest versions (including

all amendments) are applicable to this document.

GB/T 6529 Textiles - Standard atmospheres for conditioning and testing

GB/T 8170 Rules of rounding off for numerical values and expression and judgment

of limiting values

3 Terms and definitions

The following terms and definitions apply to this document.

3.1 elasticity deformation

The recoverable deformation of the sample after the external force is removed, which

is expressed by the tensile elastic recovery rate for knitted fabrics.

3.2 plastic deformation

The unrecoverable deformation of the sample after the external force is removed under

specified conditions, which is expressed as the plastic deformation rate.

3.3 tension under constant elongation

The force corresponding to the stretching of a specimen to a specified elongation.

3.4 elongation under constant tension

The elongation of a specimen when it is subjected to a specified tensile force.

3.5 pre-tension

The force applied to straighten a specimen before stretching without causing it to be

stretched.

4 Principles

4.1 Constant rate of elongation method: The specimen is stretched at a constant speed

by using special instruments and equipment to be deformed in length. After the load is

released, the tensile elastic recovery rate and plastic deformation rate are calculated

based on the deformation.

4.2 Delayed load stretching method: The specimen is stretched by using special

instruments and equipment to be deformed in length, and the deformation state is

maintained for a long time. After the load is released, the tensile elastic recovery rate is

calculated based on the deformation.

5 Standard atmosphere for conditioning and testing

5.1 The standard atmosphere specified in GB/T 6529 shall be used for conditioning and

testing.

5.2 After pre-conditioning, the samples are placed in the conditioning atmosphere to

allow them to absorb moisture in equilibrium. Cotton and blended fabrics should be

conditioned for 24 hours, and pure chemical fabrics should be conditioned for 4 hours.

6 Instruments and tools

6.1 The testing instrument for the constant rate of elongation method shall meet the

following requirements (using CRE type tensile tester):

a) Clamping distance length: 100 mm±1 mm;

b) The instrument shall be able to set the stretching speed within the range of 50

mm/min~300 mm/min with an accuracy of ±2%;

c) The maximum error of strength indication shall not exceed 1%, and the

maximum error of elongation indication shall not exceed 1%;

d) The instrument shall be able to set the pre-tension;

specimen flat on the table and make a pair of marks at the center of one side of the ring

specimen along the length direction of the specimen. The distance between the two

marking lines is 125 mm±3 mm.

7.6 The specimens shall be arranged in accordance with the method given in Appendix

A. In general, method B (parallel method) shall be used for cutting. In arbitration,

method A (step-shaped) cutting shall be used, and one side of the length direction shall

be parallel to the longitudinal coil (or horizontal coil) of the sample.

8 Procedures

8.1 Instrument calibration and preparation

8.1.1 Constant-rate of elongation method

8.1.1.1 Adjust the clamp gauge and check that the jaws are accurately aligned and

parallel to ensure that the applied force does not cause angular deviation.

8.1.1.2 Set up the test procedure according to the test requirements.

The stretching speed shall be selected within the range of 50 mm/min~300 mm/min

according to the product standard or the agreement between the relevant parties. If the

stretching speed is not specified, it can be set to 300 mm/min. The stretching speed

when applying pre-tension can be set at a speed that supports reading the elongation

value accurately when applying pre-tension according to the specific situation of the

test instrument, and it shall be stated in the test report.

The pre-tension can generally be set to 0.1 N. For specimens that will elongate when a

very small force is applied, the pre-tension should be set to 0.05 N.

8.1.2 Delayed load stretching method

Check whether the stand is stable to ensure the smooth progress of the test.

8.2 Determination of tensile force and elongation (constant rate of elongation

method)

8.2.1 Determination of tension under constant elongation

Tighten both ends of the specimen in the length direction in the clamp flatly, start the

instrument, apply pre-tension, and then stretch to the predetermined elongation value

(see Appendix B). Hold for 1 minute, and the instrument automatically records the

tensile force value. The test result is expressed as the average value of the test results

of the three specimens, rounded to one decimal place according to GB/T 8170.

8.2.2 Determination of elongation under constant tension

L1 -- The length of the specimen after pre-tensioning, in millimeters (mm).

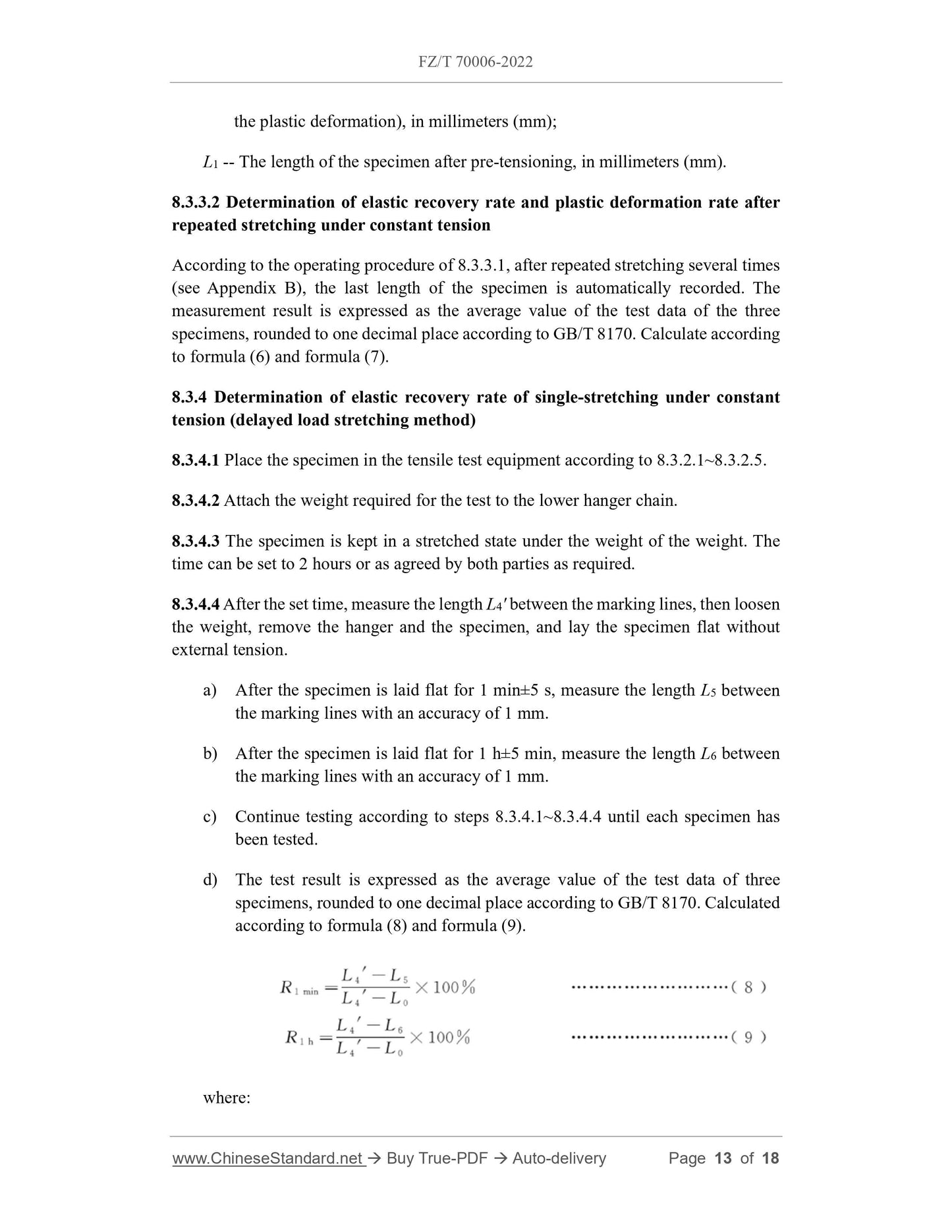

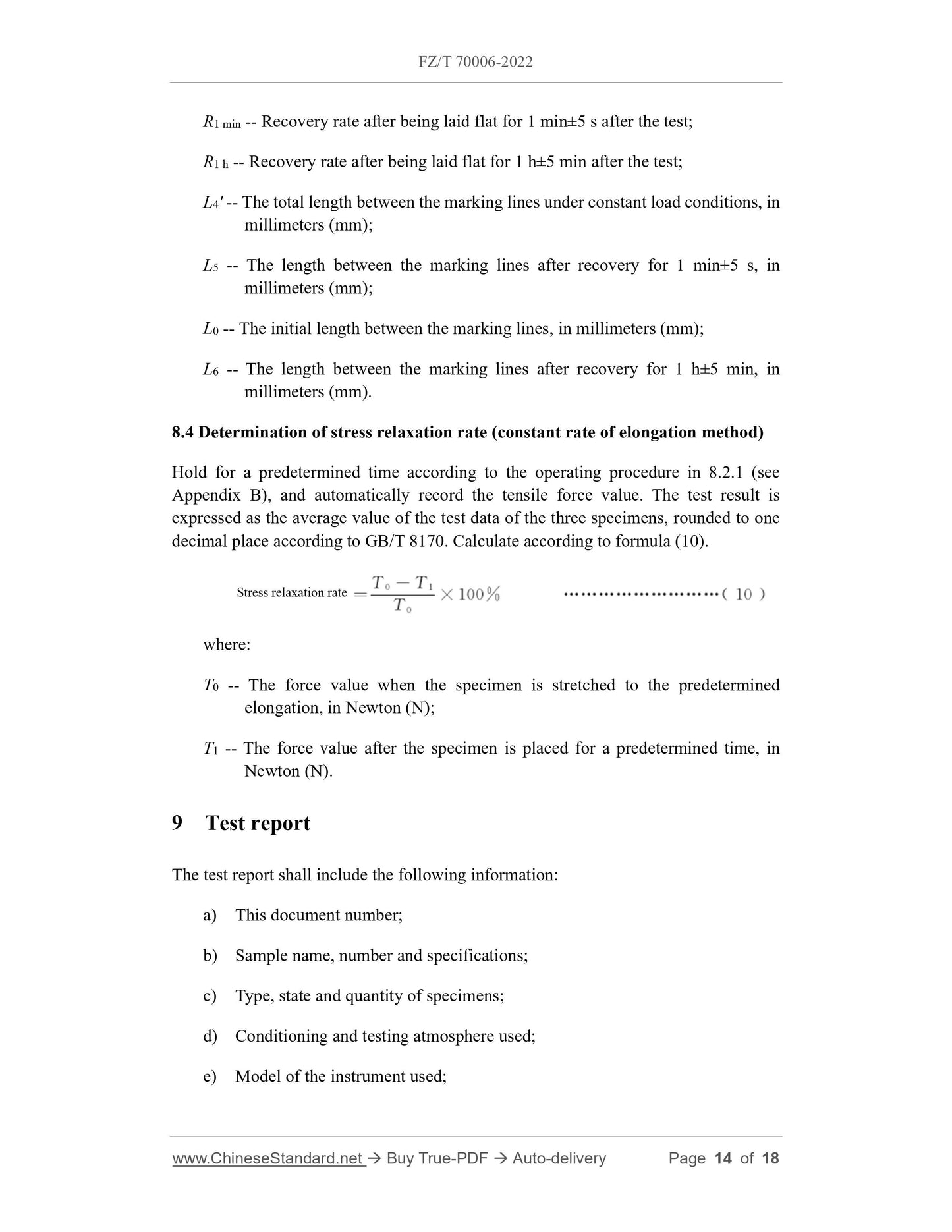

8.3.1.2 Determination of elastic recovery rate and plastic deformation rate when

repeatedly stretched under constant elongation (rate)

Repeatedly stretch several times according to the operating procedure of 8.3.1.1 (see

Appendix B), and automatically record the last specimen length. The test result is

expressed as the average value of the test data of the three specimens, rounded to one

decimal place according to GB/T 8170. Calculate according to formula (2) and formula

(3).

8.3.2 Determination of elastic recovery rate of single-stretching under constant

elongation (rate) (delayed load stretching method)

8.3.2.1 Lay the specimen flat, measure and record the length L0 between the two

marking lines.

8.3.2.2 Place the specimen on the upper hanger rod and then fix the hanger rod in the

upper hanger, with the seam of the specimen parallel to the hanger rod.

8.3.2.3 Slide the other end of the specimen onto the lower hanger rod and secure the

hanger rod in th...

Get QUOTATION in 1-minute: Click FZ/T 70006-2022

Historical versions: FZ/T 70006-2022

Preview True-PDF (Reload/Scroll if blank)

FZ/T 70006-2022: Stretch and recovery testing method for knitted fabrics

FZ/T 70006-2022

FZ

NATIONAL STANDARD OF THE

PEOPLE'S REPUBLIC OF CHINA

ICS 59.080.01

CCS W 60

Replacing FZ/T 70006-2004

Stretch and recovery testing method for knitted fabrics

ISSUED ON: APRIL 8, 2022

IMPLEMENTED ON: OCTOBER 1, 2022

Issued by: Ministry of Industry and Information Technology of PRC;

Standards Press of China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Principles ... 6

5 Standard atmosphere for conditioning and testing ... 6

6 Instruments and tools ... 6

7 Samples and specimens ... 8

8 Procedures ... 9

9 Test report ... 14

Appendix A (Normative) Specimen cutting examples ... 16

Appendix B (Informative) Constant elongation (rate), constant tension, number of

repeated stretching, and relaxation time of constant rate of elongation method ... 18

Stretch and recovery testing method for knitted fabrics

1 Scope

This document specifies the test method for determining the tensile elasticity

deformation and plastic deformation of knitted fabrics using the constant elongation

and the constant tension methods.

This document is applicable to various knitted fabrics, and for others, it can be a

reference.

2 Normative references

The provisions of the following documents constitute the essential clauses of this

document through normative references in this text. Among them, for referenced

documents with dates, only the versions corresponding to the dates are applicable to

this document; for referenced documents without dates, the latest versions (including

all amendments) are applicable to this document.

GB/T 6529 Textiles - Standard atmospheres for conditioning and testing

GB/T 8170 Rules of rounding off for numerical values and expression and judgment

of limiting values

3 Terms and definitions

The following terms and definitions apply to this document.

3.1 elasticity deformation

The recoverable deformation of the sample after the external force is removed, which

is expressed by the tensile elastic recovery rate for knitted fabrics.

3.2 plastic deformation

The unrecoverable deformation of the sample after the external force is removed under

specified conditions, which is expressed as the plastic deformation rate.

3.3 tension under constant elongation

The force corresponding to the stretching of a specimen to a specified elongation.

3.4 elongation under constant tension

The elongation of a specimen when it is subjected to a specified tensile force.

3.5 pre-tension

The force applied to straighten a specimen before stretching without causing it to be

stretched.

4 Principles

4.1 Constant rate of elongation method: The specimen is stretched at a constant speed

by using special instruments and equipment to be deformed in length. After the load is

released, the tensile elastic recovery rate and plastic deformation rate are calculated

based on the deformation.

4.2 Delayed load stretching method: The specimen is stretched by using special

instruments and equipment to be deformed in length, and the deformation state is

maintained for a long time. After the load is released, the tensile elastic recovery rate is

calculated based on the deformation.

5 Standard atmosphere for conditioning and testing

5.1 The standard atmosphere specified in GB/T 6529 shall be used for conditioning and

testing.

5.2 After pre-conditioning, the samples are placed in the conditioning atmosphere to

allow them to absorb moisture in equilibrium. Cotton and blended fabrics should be

conditioned for 24 hours, and pure chemical fabrics should be conditioned for 4 hours.

6 Instruments and tools

6.1 The testing instrument for the constant rate of elongation method shall meet the

following requirements (using CRE type tensile tester):

a) Clamping distance length: 100 mm±1 mm;

b) The instrument shall be able to set the stretching speed within the range of 50

mm/min~300 mm/min with an accuracy of ±2%;

c) The maximum error of strength indication shall not exceed 1%, and the

maximum error of elongation indication shall not exceed 1%;

d) The instrument shall be able to set the pre-tension;

specimen flat on the table and make a pair of marks at the center of one side of the ring

specimen along the length direction of the specimen. The distance between the two

marking lines is 125 mm±3 mm.

7.6 The specimens shall be arranged in accordance with the method given in Appendix

A. In general, method B (parallel method) shall be used for cutting. In arbitration,

method A (step-shaped) cutting shall be used, and one side of the length direction shall

be parallel to the longitudinal coil (or horizontal coil) of the sample.

8 Procedures

8.1 Instrument calibration and preparation

8.1.1 Constant-rate of elongation method

8.1.1.1 Adjust the clamp gauge and check that the jaws are accurately aligned and

parallel to ensure that the applied force does not cause angular deviation.

8.1.1.2 Set up the test procedure according to the test requirements.

The stretching speed shall be selected within the range of 50 mm/min~300 mm/min

according to the product standard or the agreement between the relevant parties. If the

stretching speed is not specified, it can be set to 300 mm/min. The stretching speed

when applying pre-tension can be set at a speed that supports reading the elongation

value accurately when applying pre-tension according to the specific situation of the

test instrument, and it shall be stated in the test report.

The pre-tension can generally be set to 0.1 N. For specimens that will elongate when a

very small force is applied, the pre-tension should be set to 0.05 N.

8.1.2 Delayed load stretching method

Check whether the stand is stable to ensure the smooth progress of the test.

8.2 Determination of tensile force and elongation (constant rate of elongation

method)

8.2.1 Determination of tension under constant elongation

Tighten both ends of the specimen in the length direction in the clamp flatly, start the

instrument, apply pre-tension, and then stretch to the predetermined elongation value

(see Appendix B). Hold for 1 minute, and the instrument automatically records the

tensile force value. The test result is expressed as the average value of the test results

of the three specimens, rounded to one decimal place according to GB/T 8170.

8.2.2 Determination of elongation under constant tension

L1 -- The length of the specimen after pre-tensioning, in millimeters (mm).

8.3.1.2 Determination of elastic recovery rate and plastic deformation rate when

repeatedly stretched under constant elongation (rate)

Repeatedly stretch several times according to the operating procedure of 8.3.1.1 (see

Appendix B), and automatically record the last specimen length. The test result is

expressed as the average value of the test data of the three specimens, rounded to one

decimal place according to GB/T 8170. Calculate according to formula (2) and formula

(3).

8.3.2 Determination of elastic recovery rate of single-stretching under constant

elongation (rate) (delayed load stretching method)

8.3.2.1 Lay the specimen flat, measure and record the length L0 between the two

marking lines.

8.3.2.2 Place the specimen on the upper hanger rod and then fix the hanger rod in the

upper hanger, with the seam of the specimen parallel to the hanger rod.

8.3.2.3 Slide the other end of the specimen onto the lower hanger rod and secure the

hanger rod in th...

Share