PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB 16869-2005 English PDF (GB16869-2005)

GB 16869-2005 English PDF (GB16869-2005)

Precio habitual

$85.00 USD

Precio habitual

Precio de oferta

$85.00 USD

Precio unitario

/

por

Los gastos de envío se calculan en la pantalla de pago.

No se pudo cargar la disponibilidad de retiro

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB 16869-2005

Historical versions: GB 16869-2005

Preview True-PDF (Reload/Scroll if blank)

GB 16869-2005: Fresh and frozen poultry product

GB 16869-2005

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 67.120.20

X 18

Replacing GB 16869-2000

Fresh and Frozen Poultry Product

ISSUED ON: MARCH 23, 2005

IMPLEMENTED ON: JANUARY 01, 2006

Jointly issued by: General Administration of Quality Supervision,

Inspection and Quarantine (GAQSIQ);

Standardization Administration (SAC) of the People's

Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References... 5

3 Terms and Definitions ... 6

4 Technical Requirements ... 7

5 Inspection Method ... 9

6 Inspection Rules ... 12

7 Labeling, Marking, Packaging and Storing ... 16

Appendix A ... 18

Foreword

Chapter 6 of this Standard is recommendatory; and the rest are compulsory.

This Standard replaces GB 16869-2000 "Fresh and Frozen Poultry Product".

Compared with GB 16869-2000, the main differences of this Standard are as follows:

— Limit of detection of methamidophos and clenbuterol hydrochloride are not

specified any more;

— Add that stasis-blood with area ≤0.5 is negligible, calculation method of

stasis-blood number and hard feather, and inspection rules;

— Technical requirements are adjusted;

— Freezing center temperature for frozen poultry products is adjusted to 18°C at

maximum;

— Water loss rate due to unfreezing is adjusted up to 6%;

— Lead limit is adjusted to be up to 0.2mg/kg;

— Pesticide hexachlorocyclohexane residue limit is adjusted to be up to 0.1 mg/kg

(calculated by bulk sample), 1 mg/kg (calculated by fat);

— The coliform bacteria limit on the frozen poultry product is adjusted to be up to

5×103 MPN/100g;

— Salmonella limit of detection is adjusted to "0/25 g";

— Limit of detection for diarrhoea causative escherichia coli is adjusted to be that

the detextion limit of hemorrhagic escherichia coli (O157:H7) is 0/25 g;

— Determination method of stilbestrol is adjusted to be "Determine according to

methods as specified in SN 0672".

In Chapter 6, routine inspection, acceptance inspection sampling plans, and allowable

number of common defects are equivalently adopt inspection level I and inspection

level II in CAC/RM 42-1969 "Sampling Plan of Prepackaged Food".

Appendix A of this Standard is normative.

This Standard was jointly proposed by National Technical Committee 64 on Food

Industry of Standardization Administration of China, and Specialized Committee on

Foods Hygienic Standard of Technical Committee on Hygienic Standard of Ministry of

Health.

Fresh and Frozen Poultry Product

1 Scope

This Standard specifies technical requirements, inspection method, inspection rules

and the requirements for labelling, marking, packaging, storing of fresh and frozen

poultry products.

This Standard is applicable to fresh or frozen poultry products which are made of

healthy and live poultries, through butchering, processing and packing; it is also

applicable to the unpacked fresh or frozen poultry products.

2 Normative References

The following documents contain provisions which, through reference in this Standard,

constitute provisions of this Standard. For dated reference, subsequent amendments

(excluding corrections) or revisions of these publications do not apply. However, the

parties who enter into agreements based on this Standard are encouraged to

investigate the possibility of applying the most recent editions of the standards. For

undated references, the latest edition of the normative document referred to applies.

GB/T 191 Packaging-Pictorial Marking for Handling of Goods

GB/T 4789.2-2003 Microbiological Examination of Food Hygiene - Detection of

Aerobic Bacterial Count

GB/T 4789.3-2003 Microbiological Examination of Food Hygiene - Detection of

Coliform Bacteria

GB/T 4789.4-2003 Microbiological Examination of Food Hygiene - Examination

of Salmonella

GB/T 5009.11-2003 Determination of Total Arsenic and Abio-arsenic in Food

GB/T 5009.12-2003 Method for Determination of Lead in Foods

GB/T 5009.17-2003 Determination of Total Mercury and Organic-mercury in

Foods

GB/T 5009.19-2003 Determination of HCH and DDT Residues in Foods

GB/T 5009.44-2003 Method for Analysis of Hygienic Standard of Meat and Meat

Products

A.4.3 Milk and milk products: Mix uniformly.

A.5 Analytical procedures

A.5.1 Extraction, distribution and concentration

A.5.1.1 Eggs and egg products: Weigh 20 g of (accurate to 0.01 g) samples in 100

mL triangular flask-with-stopper; add 5 mL of water (water is added according to the

moisture content of the samples to make the total water to be about 20 g; generally

fresh eggs contains about 75% water, thus 5 mL of water is added); add 40 mL of

acetone and shake for 30 min. Add 6 g of sodium chloride; shake up well; then add 30

mL of methylene chloride; shake for 30 min. Take 35 mL of supernatant liquor; filter it

with anhydrous sodium sulfate into a rotating evaporative flask; concentrate to about 1

mL. Add 2 mL of ethyl acetate cyclohexane (1:1) solution to re-concentrate. Repeat

this operation for 3 times until the solution is concentrated to be about 1 mL.

A.5.1.2 Meat and meat products: Weigh 20 g of (accurate to 0.01 g) samples into a

100 mL triangular flask-with-stopper; add 6 mL of water (water is added according to

the moisture content of the samples to make the total water to be about 20 g;

generally fresh meat contains about 70% water, thus 6 mL of water is added). The

following processes are same as those in A.5.1.1.

A.5.1.3 Milk and milk products: Weigh 20 g of (accurate to 0.01 g) samples into a

100 mL triangular flask-with-stopper (water is not required for fresh milk; use acetone

to directly extract). The following processes are same as those in A.5.1.1.

A.5.2 Purification

Use ethyl acetate cyclohexane (1:1) solution, through the gel purification column, to

elute the prepared concentrated solution (A.5.1). Collect 35 mL ~ 70 mL of fraction;

rotate for evaporation and concentrate to 1mL. Then purify through the gel purification

column; collect 35 mL ~ 70 mL of fraction; rotate for evaporation and concentrate to

1mL. Transfer it into a 5 mL graduated test tube; wash the rotating evaporative flask

with about 5 mL of ethyl acetate for several times; transfer the washing liquor into the

above-mentioned test tube. Use nitrogen to blow it to be below 1 mL; then dilute with

ethyl acetate to 1 mL; standby for chromatographic analysis.

A.5.3 Chromatographic condition

A.5.3.1 Chromatographic column: Elastic capillary column, with the inner diameter

of 0.32 mm and length of 30 m; painted with SE-54 in thickness of 0.25 μm.

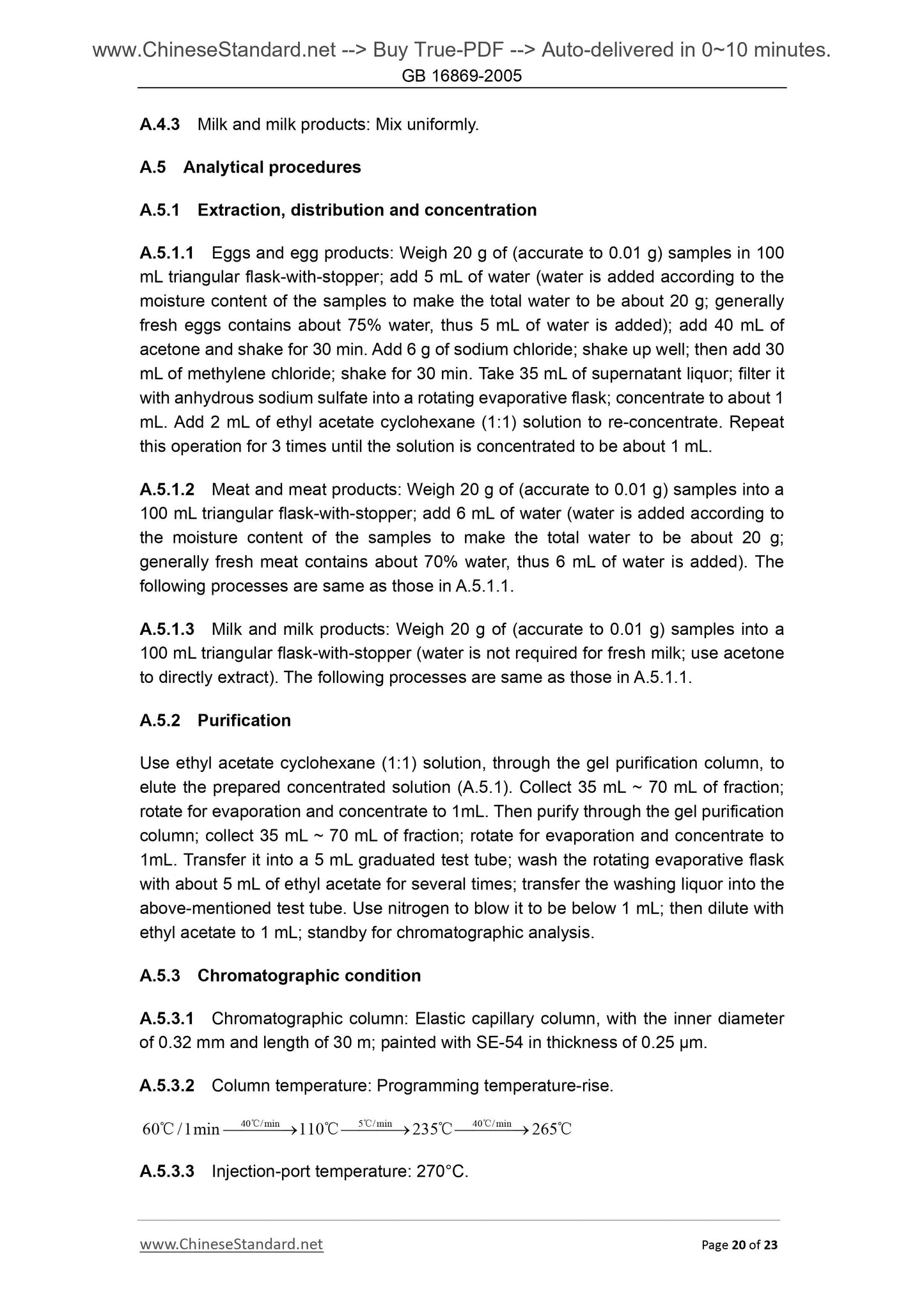

A.5.3.2 Column temperature: Programming temperature-rise.

40 / min 5 / min 40 / min60 /1min 110 235 265 ℃ ℃ ℃℃ ℃ ℃ ℃

A.5.3.3 Injection-port temperature: 270°C.

Get QUOTATION in 1-minute: Click GB 16869-2005

Historical versions: GB 16869-2005

Preview True-PDF (Reload/Scroll if blank)

GB 16869-2005: Fresh and frozen poultry product

GB 16869-2005

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 67.120.20

X 18

Replacing GB 16869-2000

Fresh and Frozen Poultry Product

ISSUED ON: MARCH 23, 2005

IMPLEMENTED ON: JANUARY 01, 2006

Jointly issued by: General Administration of Quality Supervision,

Inspection and Quarantine (GAQSIQ);

Standardization Administration (SAC) of the People's

Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative References... 5

3 Terms and Definitions ... 6

4 Technical Requirements ... 7

5 Inspection Method ... 9

6 Inspection Rules ... 12

7 Labeling, Marking, Packaging and Storing ... 16

Appendix A ... 18

Foreword

Chapter 6 of this Standard is recommendatory; and the rest are compulsory.

This Standard replaces GB 16869-2000 "Fresh and Frozen Poultry Product".

Compared with GB 16869-2000, the main differences of this Standard are as follows:

— Limit of detection of methamidophos and clenbuterol hydrochloride are not

specified any more;

— Add that stasis-blood with area ≤0.5 is negligible, calculation method of

stasis-blood number and hard feather, and inspection rules;

— Technical requirements are adjusted;

— Freezing center temperature for frozen poultry products is adjusted to 18°C at

maximum;

— Water loss rate due to unfreezing is adjusted up to 6%;

— Lead limit is adjusted to be up to 0.2mg/kg;

— Pesticide hexachlorocyclohexane residue limit is adjusted to be up to 0.1 mg/kg

(calculated by bulk sample), 1 mg/kg (calculated by fat);

— The coliform bacteria limit on the frozen poultry product is adjusted to be up to

5×103 MPN/100g;

— Salmonella limit of detection is adjusted to "0/25 g";

— Limit of detection for diarrhoea causative escherichia coli is adjusted to be that

the detextion limit of hemorrhagic escherichia coli (O157:H7) is 0/25 g;

— Determination method of stilbestrol is adjusted to be "Determine according to

methods as specified in SN 0672".

In Chapter 6, routine inspection, acceptance inspection sampling plans, and allowable

number of common defects are equivalently adopt inspection level I and inspection

level II in CAC/RM 42-1969 "Sampling Plan of Prepackaged Food".

Appendix A of this Standard is normative.

This Standard was jointly proposed by National Technical Committee 64 on Food

Industry of Standardization Administration of China, and Specialized Committee on

Foods Hygienic Standard of Technical Committee on Hygienic Standard of Ministry of

Health.

Fresh and Frozen Poultry Product

1 Scope

This Standard specifies technical requirements, inspection method, inspection rules

and the requirements for labelling, marking, packaging, storing of fresh and frozen

poultry products.

This Standard is applicable to fresh or frozen poultry products which are made of

healthy and live poultries, through butchering, processing and packing; it is also

applicable to the unpacked fresh or frozen poultry products.

2 Normative References

The following documents contain provisions which, through reference in this Standard,

constitute provisions of this Standard. For dated reference, subsequent amendments

(excluding corrections) or revisions of these publications do not apply. However, the

parties who enter into agreements based on this Standard are encouraged to

investigate the possibility of applying the most recent editions of the standards. For

undated references, the latest edition of the normative document referred to applies.

GB/T 191 Packaging-Pictorial Marking for Handling of Goods

GB/T 4789.2-2003 Microbiological Examination of Food Hygiene - Detection of

Aerobic Bacterial Count

GB/T 4789.3-2003 Microbiological Examination of Food Hygiene - Detection of

Coliform Bacteria

GB/T 4789.4-2003 Microbiological Examination of Food Hygiene - Examination

of Salmonella

GB/T 5009.11-2003 Determination of Total Arsenic and Abio-arsenic in Food

GB/T 5009.12-2003 Method for Determination of Lead in Foods

GB/T 5009.17-2003 Determination of Total Mercury and Organic-mercury in

Foods

GB/T 5009.19-2003 Determination of HCH and DDT Residues in Foods

GB/T 5009.44-2003 Method for Analysis of Hygienic Standard of Meat and Meat

Products

A.4.3 Milk and milk products: Mix uniformly.

A.5 Analytical procedures

A.5.1 Extraction, distribution and concentration

A.5.1.1 Eggs and egg products: Weigh 20 g of (accurate to 0.01 g) samples in 100

mL triangular flask-with-stopper; add 5 mL of water (water is added according to the

moisture content of the samples to make the total water to be about 20 g; generally

fresh eggs contains about 75% water, thus 5 mL of water is added); add 40 mL of

acetone and shake for 30 min. Add 6 g of sodium chloride; shake up well; then add 30

mL of methylene chloride; shake for 30 min. Take 35 mL of supernatant liquor; filter it

with anhydrous sodium sulfate into a rotating evaporative flask; concentrate to about 1

mL. Add 2 mL of ethyl acetate cyclohexane (1:1) solution to re-concentrate. Repeat

this operation for 3 times until the solution is concentrated to be about 1 mL.

A.5.1.2 Meat and meat products: Weigh 20 g of (accurate to 0.01 g) samples into a

100 mL triangular flask-with-stopper; add 6 mL of water (water is added according to

the moisture content of the samples to make the total water to be about 20 g;

generally fresh meat contains about 70% water, thus 6 mL of water is added). The

following processes are same as those in A.5.1.1.

A.5.1.3 Milk and milk products: Weigh 20 g of (accurate to 0.01 g) samples into a

100 mL triangular flask-with-stopper (water is not required for fresh milk; use acetone

to directly extract). The following processes are same as those in A.5.1.1.

A.5.2 Purification

Use ethyl acetate cyclohexane (1:1) solution, through the gel purification column, to

elute the prepared concentrated solution (A.5.1). Collect 35 mL ~ 70 mL of fraction;

rotate for evaporation and concentrate to 1mL. Then purify through the gel purification

column; collect 35 mL ~ 70 mL of fraction; rotate for evaporation and concentrate to

1mL. Transfer it into a 5 mL graduated test tube; wash the rotating evaporative flask

with about 5 mL of ethyl acetate for several times; transfer the washing liquor into the

above-mentioned test tube. Use nitrogen to blow it to be below 1 mL; then dilute with

ethyl acetate to 1 mL; standby for chromatographic analysis.

A.5.3 Chromatographic condition

A.5.3.1 Chromatographic column: Elastic capillary column, with the inner diameter

of 0.32 mm and length of 30 m; painted with SE-54 in thickness of 0.25 μm.

A.5.3.2 Column temperature: Programming temperature-rise.

40 / min 5 / min 40 / min60 /1min 110 235 265 ℃ ℃ ℃℃ ℃ ℃ ℃

A.5.3.3 Injection-port temperature: 270°C.

Share