PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 11115-2009 English PDF (GBT11115-2009)

GB/T 11115-2009 English PDF (GBT11115-2009)

Precio habitual

$145.00 USD

Precio habitual

Precio de oferta

$145.00 USD

Precio unitario

/

por

Los gastos de envío se calculan en la pantalla de pago.

No se pudo cargar la disponibilidad de retiro

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 11115-2009

Historical versions: GB/T 11115-2009

Preview True-PDF (Reload/Scroll if blank)

GB/T 11115-2009: Polyethylene (PE) resin

GB/T 11115-2009

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 83.080.20

G 32

Replacing GB/T 11115〜11116-1989 and GB/T 15182-1994

Polyethylene (PE) resin

聚乙烯 (PE) 树脂

ISSUED ON. JULY 17, 2009

IMPLEMENTED ON. FEBRUARY 01, 2010

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Classification and designation ... 6

4 Hygienic requirements ... 6

5 Requirements ... 6

6 Test methods ... 17

7 Inspection rules ... 24

8 Mark ... 25

9 Package, transport and storage ... 26

Foreword

This Standard replaces GB/T 11115-1989 Low density polyethylene resin, GB/T

11116-1989 High density polyethylene resin and GB/T 15182-1994 Linear low density

polyethylene resin.

Compared with GB/T 11115, GB/T 11116 and GB/T 15182, the main differences of this

Standard are as follows.

- Combined GB/T 11115, GB/T 11116 and GB/T 15182 into one standard;

- In addition to hygienic standard, all normative references in Chapter 2 were

changed as dated references;

- Added Chapter 3 Classification and designation;

- In 5.1, deleted the requirements of “the particle size shall be (2〜5)mm in any

direction” in 3.1 in the original standard; and changed “without mechanical impurity”

into “without impurity”.

- Added “Sample preparation” in the table in Chapter 5 Requirements;

- Replaced “cleanliness (colored particle)” with “granular appearance” in the table in

Chapter 5 Requirements;

- Added “because the application field of each resin is different, the injection molding

sample proprieties can be different from that of compression molding sample” in

6.2.2. The specific prepare method of each resin is shown in Table 1 to Table 7;

- Adjusted the blow molding process of LLDPE film and LDPE film; and deleted

“reduced diameter of film” in 6.2.3;

- Specified two test methods for “fish-eye” in 6.10;

- Re-specified the test method for “strip” in 6.11;

- Added provisions on the shelf life of polyethylene resin in Chapter 9.

This Standard was proposed by China Petrochemical Corporation (Sinopec Group).

This Standard shall be under the jurisdiction of Petrochemical Plastic Resins Product

Branch of National Standardization Technical Committee of Plastic (SAC/TC 15/SC 1).

Responsible drafting organization of this Standard. Chemical Plant 1 of Beijing Yanshan

Branch of China Petroleum and Chemical Corporation; and Research Institute of Qilu

Branch of China Petroleum and Chemical Corporation.

Polyethylene (PE) resin

1 Scope

This Standard specified the classification and designation, requirements, test methods,

inspection rules, product labelling, packaging, transportation and storage for polyethylene

(PE) resin.

This Standard applies to ethylene homopolymer OR copolymer that takes ethylene and

other 1-olefin as monomer AND polymer that contains additives.

This Standard does not apply to ultra-high molecular weight polyethylene AND colored,

filled, modified, enhanced polyethylene resin AND masterbatch pellets.

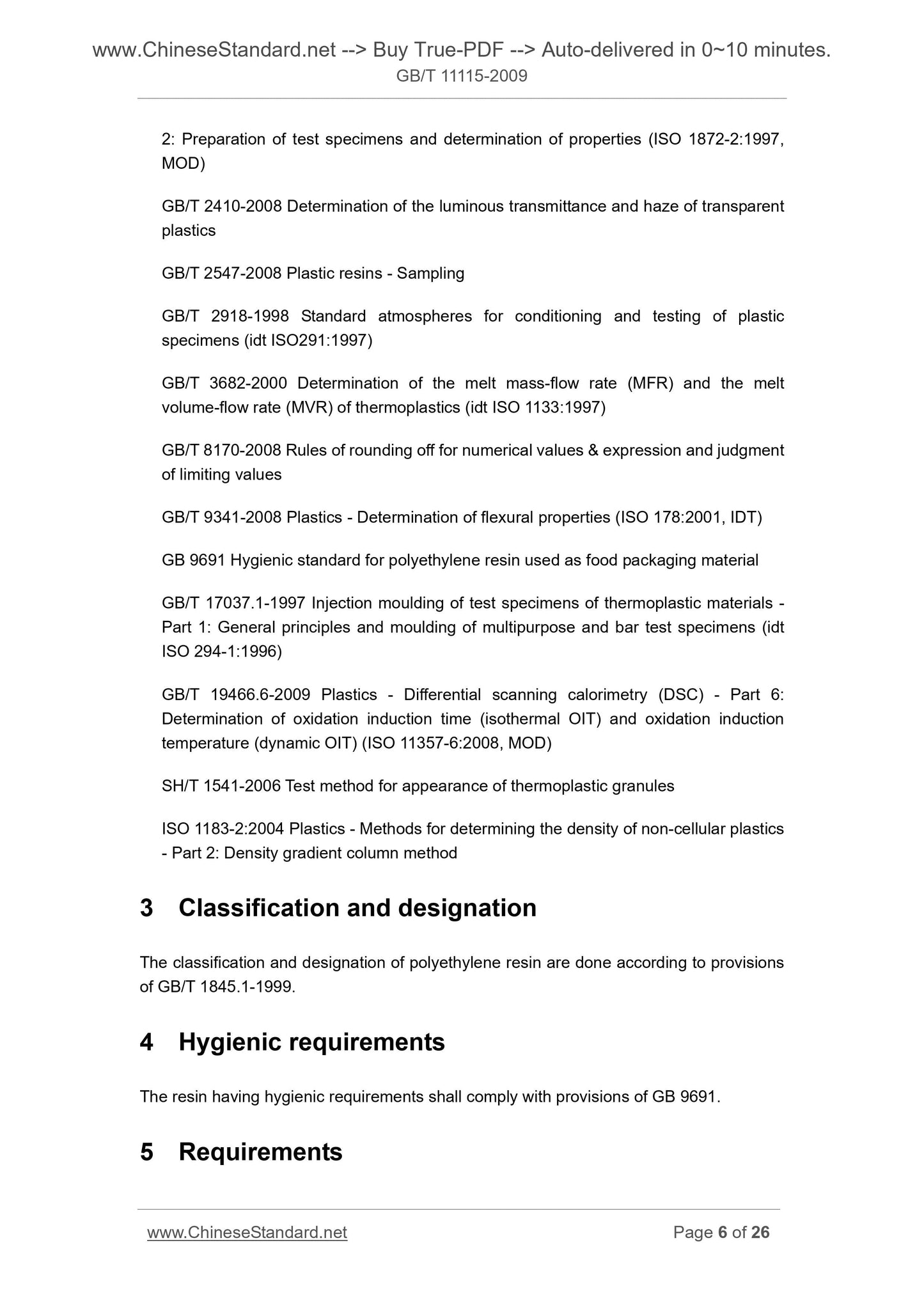

2 Normative references

The articles contained in the following documents have become part of this Standard

when they are quoted herein. For the dated documents so quoted, all the subsequent

modifications (including all corrections) or revisions made thereafter do not apply to this

standard. However, the parties who reach an agreement according to this standard are

encouraged to study whether the latest versions of these documents may be used. For

the undated documents so quoted, the latest versions (including all modification sheets)

apply to this document.

GB/T 1040.2-2006 Plastics - Determination of tensile properties - Part 2. Test

conditions for moulding and extrusion plastics (ISO 527-2.1993, IDT)

GB/T 1043.1-2008 Plastics - Determination of Charpy impact properties - Part 1.

Non-instrumented impact test (ISO 179-1.2000, IDT)

GB/T 1409-2006 Recommended methods for the determination of the permittivity and

dielectric dissipation factor of electrical insulating materials at power, audio and radio

frequencies including meter wavelengths (IEC 60250.1969, MOD)

GB/T 1842-2008 Plastics - Test method for environmental stress-cracking of

polyethylene

GB/T 1845.1-1999 Polyethylene (PE) moulding and extrusion materials - Part 1.

Designation system and basis for specifications (eqv ISO 1872-1.1993)

GB/T 1845.2-2006 Plastics - Polyethylene (PE) moulding and extrusion materials - Part

2. Preparation of test specimens and determination of properties (ISO 1872-2.1997,

MOD)

GB/T 2410-2008 Determination of the luminous transmittance and haze of transparent

plastics

GB/T 2547-2008 Plastic resins - Sampling

GB/T 2918-1998 Standard atmospheres for conditioning and testing of plastic

specimens (idt ISO291.1997)

GB/T 3682-2000 Determination of the melt mass-flow rate (MFR) and the melt

volume-flow rate (MVR) of thermoplastics (idt ISO 1133.1997)

GB/T 8170-2008 Rules of rounding off for numerical values and expression and judgment

of limiting values

GB/T 9341-2008 Plastics - Determination of flexural properties (ISO 178.2001, IDT)

GB 9691 Hygienic standard for polyethylene resin used as food packaging material

GB/T 17037.1-1997 Injection moulding of test specimens of thermoplastic materials -

Part 1. General principles and moulding of multipurpose and bar test specimens (idt

ISO 294-1.1996)

GB/T 19466.6-2009 Plastics - Differential scanning calorimetry (DSC) - Part 6.

Determination of oxidation induction time (isothermal OIT) and oxidation induction

temperature (dynamic OIT) (ISO 11357-6.2008, MOD)

SH/T 1541-2006 Test method for appearance of thermoplastic granules

ISO 1183-2.2004 Plastics - Methods for determining the density of non-cellular plastics

- Part 2. Density gradient column method

3 Classification and designation

The classification and designation of polyethylene resin are done according to provisions

of GB/T 1845.1-1999.

4 Hygienic requirements

The resin having hygienic requirements shall comply with provisions of GB 9691.

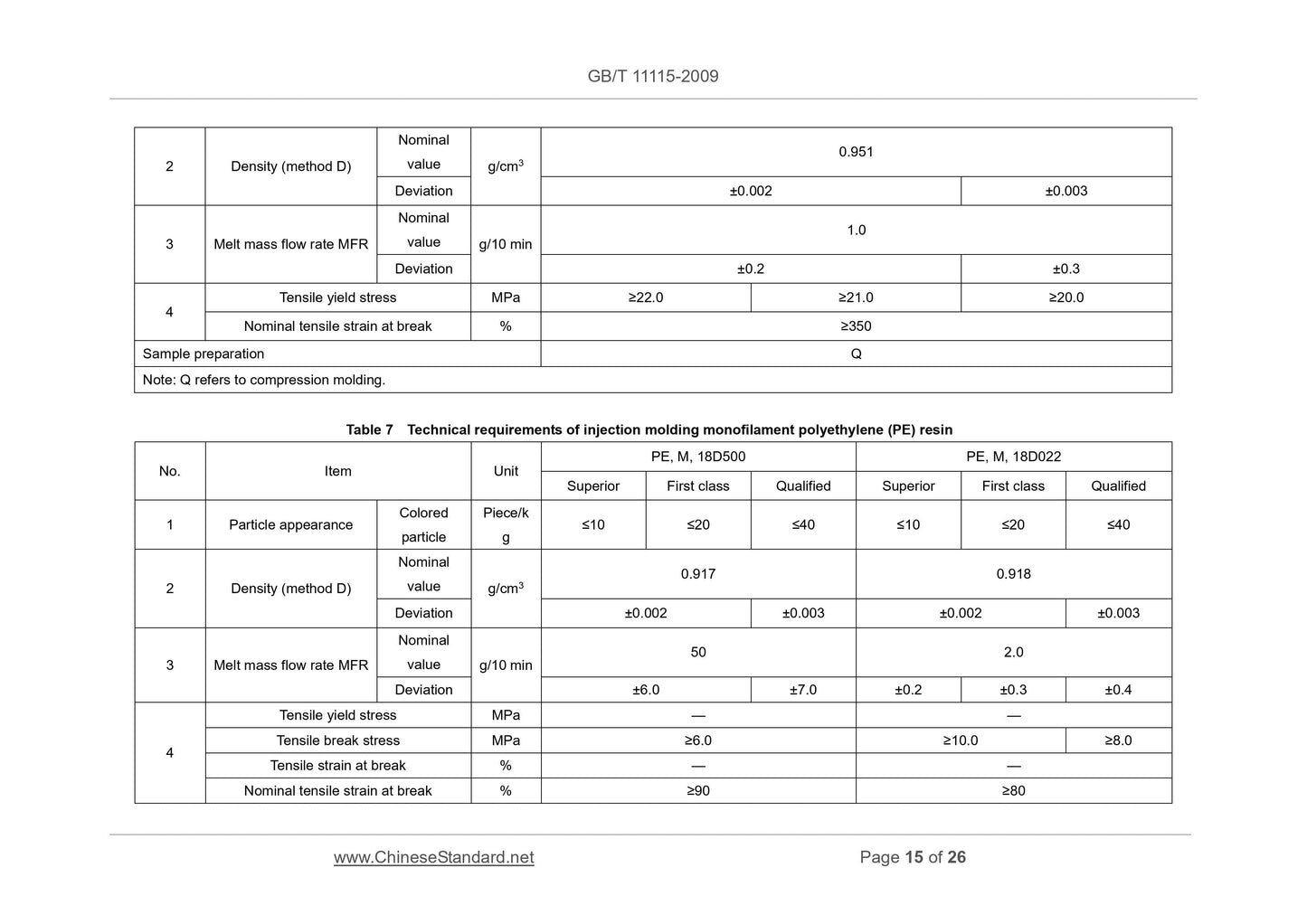

5 Requirements

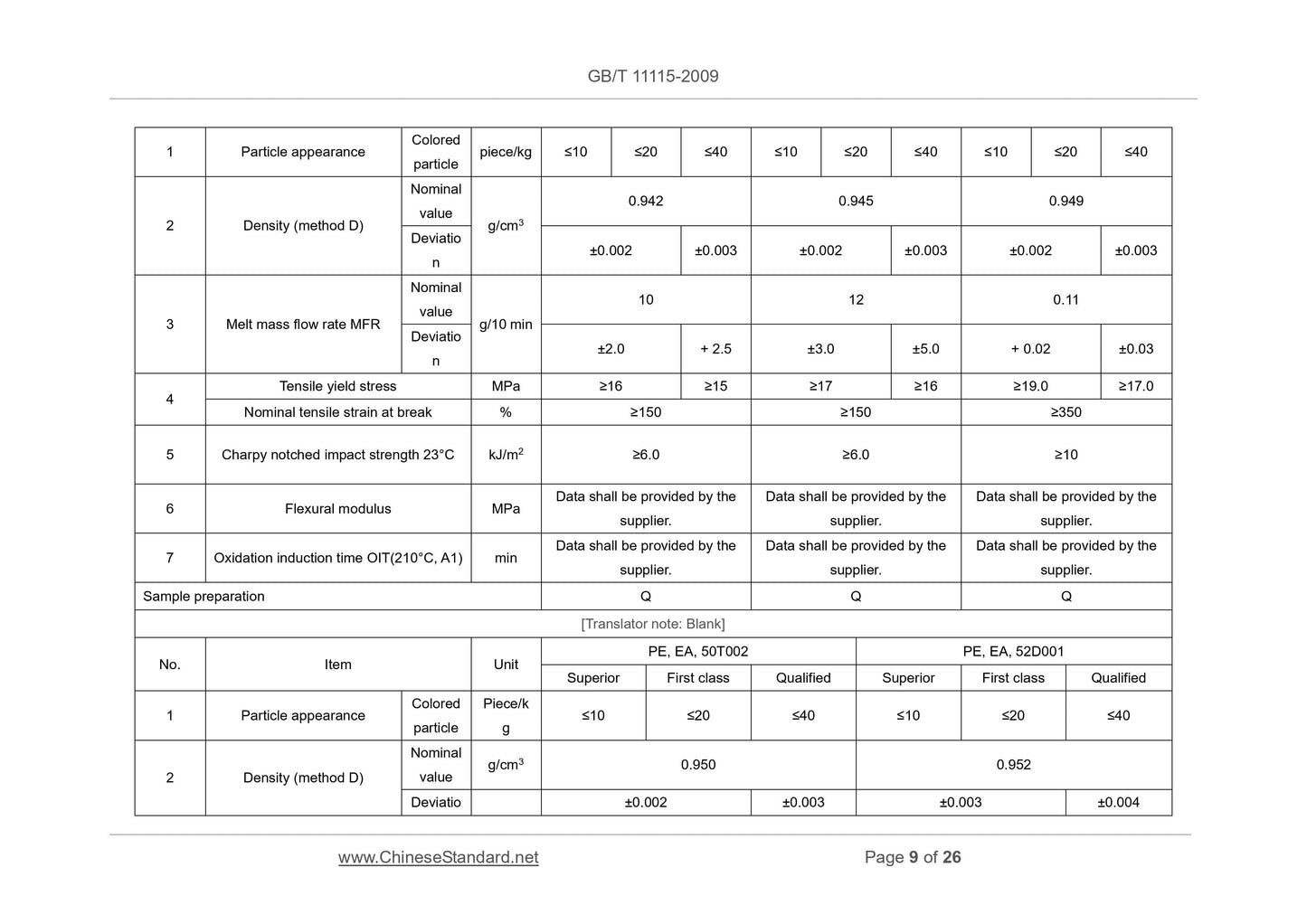

1 Particle appearance Colored particle piece/kg ≤10 ≤20 ≤40 ≤10 ≤20 ≤40 ≤10 ≤20 ≤40

2 Density (method D)

Nominal

value g/cm3

0.942 0.945 0.949

Deviatio

n ±0.002 ±0.003 ±0.002 ±0.003 ±0.002 ±0.003

3 Melt mass flow rate MFR

Nominal

value g/10 min

10 12 0.11

Deviatio

n ±2.0 + 2.5 ±3.0 ±5.0 + 0.02 ±0.03

4 Tensile yield stress MPa ≥16 ≥15 ≥17 ≥16 ≥19.0 ≥17.0 Nominal tensile strain at break % ≥150 ≥150 ≥350

5 Charpy notched impact strength 23°C kJ/m2 ≥6.0 ≥6.0 ≥10

6 Flexural modulus MPa Data shall be provided by the supplier.

Data shall be provided by the

supplier.

Data shall be provided by the

supplier.

7 Oxidation induction time OIT(210°C, A1) min Data shall be provided by the supplier.

Data shall be provided by the

supplier.

Data shall be provided by the

supplier.

Sample preparation Q Q Q

[Translator note. Blank]

No. Item Unit PE, EA, 50T002 PE, EA, 52D001 Superior First class Qualified Superior First class Qualified

1 Particle appearance Colored particle

Piece/k

g ≤10 ≤20 ≤40 ≤10 ≤20 ≤40

2 Density (method D)

Nominal

value g/cm

3 0.950 0.952

Deviatio ±0.002 ±0.003 ±0.003 ±0.004

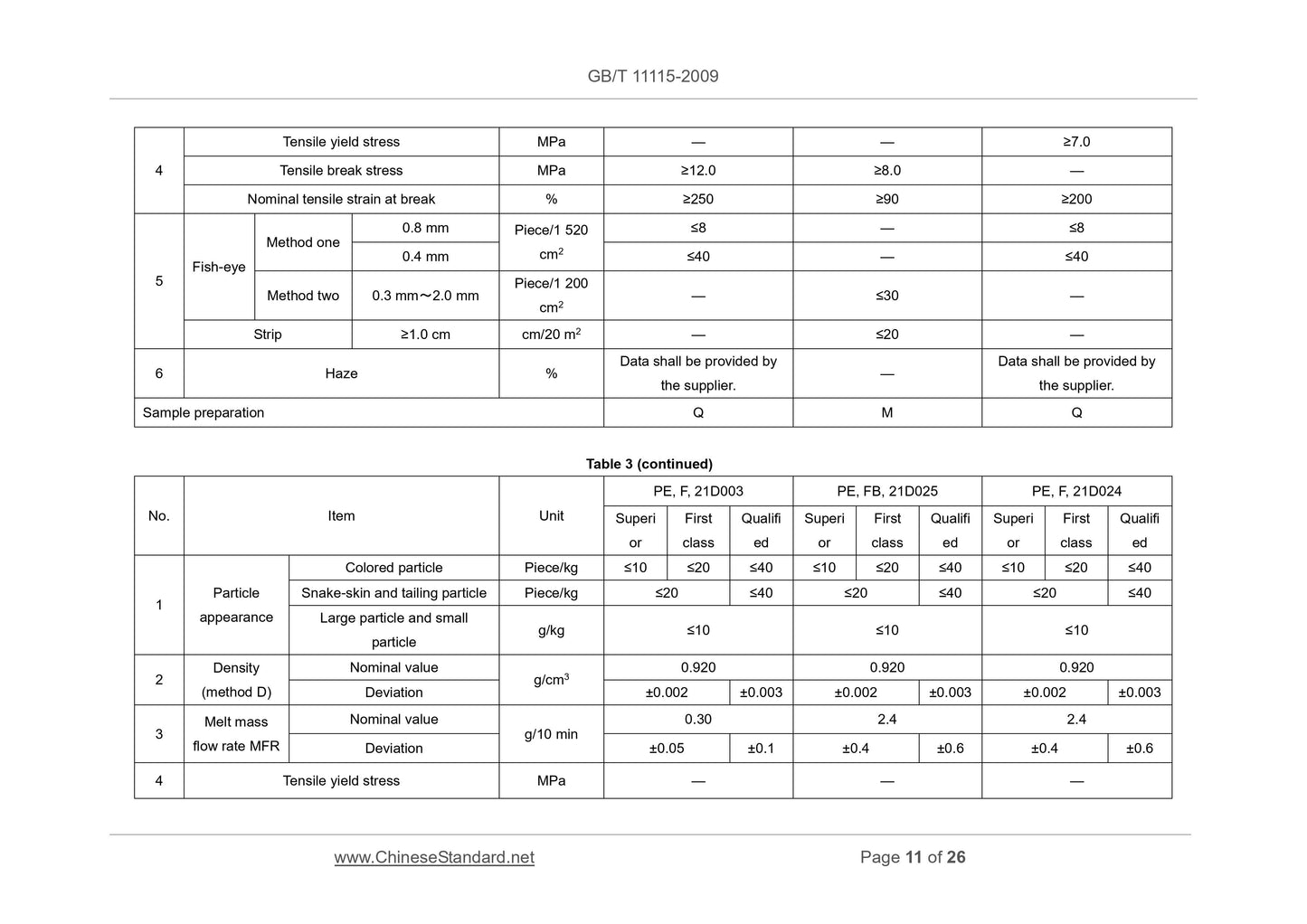

Tensile yield stress MPa — — ≥7.0

Tensile ...

Get QUOTATION in 1-minute: Click GB/T 11115-2009

Historical versions: GB/T 11115-2009

Preview True-PDF (Reload/Scroll if blank)

GB/T 11115-2009: Polyethylene (PE) resin

GB/T 11115-2009

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 83.080.20

G 32

Replacing GB/T 11115〜11116-1989 and GB/T 15182-1994

Polyethylene (PE) resin

聚乙烯 (PE) 树脂

ISSUED ON. JULY 17, 2009

IMPLEMENTED ON. FEBRUARY 01, 2010

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People's Republic of China;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Classification and designation ... 6

4 Hygienic requirements ... 6

5 Requirements ... 6

6 Test methods ... 17

7 Inspection rules ... 24

8 Mark ... 25

9 Package, transport and storage ... 26

Foreword

This Standard replaces GB/T 11115-1989 Low density polyethylene resin, GB/T

11116-1989 High density polyethylene resin and GB/T 15182-1994 Linear low density

polyethylene resin.

Compared with GB/T 11115, GB/T 11116 and GB/T 15182, the main differences of this

Standard are as follows.

- Combined GB/T 11115, GB/T 11116 and GB/T 15182 into one standard;

- In addition to hygienic standard, all normative references in Chapter 2 were

changed as dated references;

- Added Chapter 3 Classification and designation;

- In 5.1, deleted the requirements of “the particle size shall be (2〜5)mm in any

direction” in 3.1 in the original standard; and changed “without mechanical impurity”

into “without impurity”.

- Added “Sample preparation” in the table in Chapter 5 Requirements;

- Replaced “cleanliness (colored particle)” with “granular appearance” in the table in

Chapter 5 Requirements;

- Added “because the application field of each resin is different, the injection molding

sample proprieties can be different from that of compression molding sample” in

6.2.2. The specific prepare method of each resin is shown in Table 1 to Table 7;

- Adjusted the blow molding process of LLDPE film and LDPE film; and deleted

“reduced diameter of film” in 6.2.3;

- Specified two test methods for “fish-eye” in 6.10;

- Re-specified the test method for “strip” in 6.11;

- Added provisions on the shelf life of polyethylene resin in Chapter 9.

This Standard was proposed by China Petrochemical Corporation (Sinopec Group).

This Standard shall be under the jurisdiction of Petrochemical Plastic Resins Product

Branch of National Standardization Technical Committee of Plastic (SAC/TC 15/SC 1).

Responsible drafting organization of this Standard. Chemical Plant 1 of Beijing Yanshan

Branch of China Petroleum and Chemical Corporation; and Research Institute of Qilu

Branch of China Petroleum and Chemical Corporation.

Polyethylene (PE) resin

1 Scope

This Standard specified the classification and designation, requirements, test methods,

inspection rules, product labelling, packaging, transportation and storage for polyethylene

(PE) resin.

This Standard applies to ethylene homopolymer OR copolymer that takes ethylene and

other 1-olefin as monomer AND polymer that contains additives.

This Standard does not apply to ultra-high molecular weight polyethylene AND colored,

filled, modified, enhanced polyethylene resin AND masterbatch pellets.

2 Normative references

The articles contained in the following documents have become part of this Standard

when they are quoted herein. For the dated documents so quoted, all the subsequent

modifications (including all corrections) or revisions made thereafter do not apply to this

standard. However, the parties who reach an agreement according to this standard are

encouraged to study whether the latest versions of these documents may be used. For

the undated documents so quoted, the latest versions (including all modification sheets)

apply to this document.

GB/T 1040.2-2006 Plastics - Determination of tensile properties - Part 2. Test

conditions for moulding and extrusion plastics (ISO 527-2.1993, IDT)

GB/T 1043.1-2008 Plastics - Determination of Charpy impact properties - Part 1.

Non-instrumented impact test (ISO 179-1.2000, IDT)

GB/T 1409-2006 Recommended methods for the determination of the permittivity and

dielectric dissipation factor of electrical insulating materials at power, audio and radio

frequencies including meter wavelengths (IEC 60250.1969, MOD)

GB/T 1842-2008 Plastics - Test method for environmental stress-cracking of

polyethylene

GB/T 1845.1-1999 Polyethylene (PE) moulding and extrusion materials - Part 1.

Designation system and basis for specifications (eqv ISO 1872-1.1993)

GB/T 1845.2-2006 Plastics - Polyethylene (PE) moulding and extrusion materials - Part

2. Preparation of test specimens and determination of properties (ISO 1872-2.1997,

MOD)

GB/T 2410-2008 Determination of the luminous transmittance and haze of transparent

plastics

GB/T 2547-2008 Plastic resins - Sampling

GB/T 2918-1998 Standard atmospheres for conditioning and testing of plastic

specimens (idt ISO291.1997)

GB/T 3682-2000 Determination of the melt mass-flow rate (MFR) and the melt

volume-flow rate (MVR) of thermoplastics (idt ISO 1133.1997)

GB/T 8170-2008 Rules of rounding off for numerical values and expression and judgment

of limiting values

GB/T 9341-2008 Plastics - Determination of flexural properties (ISO 178.2001, IDT)

GB 9691 Hygienic standard for polyethylene resin used as food packaging material

GB/T 17037.1-1997 Injection moulding of test specimens of thermoplastic materials -

Part 1. General principles and moulding of multipurpose and bar test specimens (idt

ISO 294-1.1996)

GB/T 19466.6-2009 Plastics - Differential scanning calorimetry (DSC) - Part 6.

Determination of oxidation induction time (isothermal OIT) and oxidation induction

temperature (dynamic OIT) (ISO 11357-6.2008, MOD)

SH/T 1541-2006 Test method for appearance of thermoplastic granules

ISO 1183-2.2004 Plastics - Methods for determining the density of non-cellular plastics

- Part 2. Density gradient column method

3 Classification and designation

The classification and designation of polyethylene resin are done according to provisions

of GB/T 1845.1-1999.

4 Hygienic requirements

The resin having hygienic requirements shall comply with provisions of GB 9691.

5 Requirements

1 Particle appearance Colored particle piece/kg ≤10 ≤20 ≤40 ≤10 ≤20 ≤40 ≤10 ≤20 ≤40

2 Density (method D)

Nominal

value g/cm3

0.942 0.945 0.949

Deviatio

n ±0.002 ±0.003 ±0.002 ±0.003 ±0.002 ±0.003

3 Melt mass flow rate MFR

Nominal

value g/10 min

10 12 0.11

Deviatio

n ±2.0 + 2.5 ±3.0 ±5.0 + 0.02 ±0.03

4 Tensile yield stress MPa ≥16 ≥15 ≥17 ≥16 ≥19.0 ≥17.0 Nominal tensile strain at break % ≥150 ≥150 ≥350

5 Charpy notched impact strength 23°C kJ/m2 ≥6.0 ≥6.0 ≥10

6 Flexural modulus MPa Data shall be provided by the supplier.

Data shall be provided by the

supplier.

Data shall be provided by the

supplier.

7 Oxidation induction time OIT(210°C, A1) min Data shall be provided by the supplier.

Data shall be provided by the

supplier.

Data shall be provided by the

supplier.

Sample preparation Q Q Q

[Translator note. Blank]

No. Item Unit PE, EA, 50T002 PE, EA, 52D001 Superior First class Qualified Superior First class Qualified

1 Particle appearance Colored particle

Piece/k

g ≤10 ≤20 ≤40 ≤10 ≤20 ≤40

2 Density (method D)

Nominal

value g/cm

3 0.950 0.952

Deviatio ±0.002 ±0.003 ±0.003 ±0.004

Tensile yield stress MPa — — ≥7.0

Tensile ...

Share