PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 11982.1-2015 English PDF (GBT11982.1-2015)

GB/T 11982.1-2015 English PDF (GBT11982.1-2015)

Precio habitual

$270.00 USD

Precio habitual

Precio de oferta

$270.00 USD

Precio unitario

/

por

Los gastos de envío se calculan en la pantalla de pago.

No se pudo cargar la disponibilidad de retiro

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 11982.1-2015

Historical versions: GB/T 11982.1-2015

Preview True-PDF (Reload/Scroll if blank)

GB/T 11982.1-2015: Polyvinyl chloride floor coverings -- Part 1: Heterogeneous polyvinyl chloride floor coverings

GB/T 11982.1-2015

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 83.140

Q 22

Replacing GB/T 11982.1-2005

Polyvinyl chloride floor coverings - Part 1:

Heterogeneous polyvinyl chloride floor coverings

聚氯乙烯卷材地板

ISSUED ON: SEPTEMBER 11, 2015

IMPLEMENTED ON: AUGUST 01, 2016

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of the PRC;

Standardization Administration of the PRC.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Classification, grade, and designation ... 6

5 Requirements ... 7

6 Test methods ... 10

7 Inspection rules ... 25

8 Marking, transportation, and storage ... 26

Appendix A (Normative) Classification table of use grades ... 28

Appendix B (Normative) Chair caster test method ... 30

Appendix C (Normative) Pollution resistance test method ... 34

Polyvinyl chloride floor coverings - Part 1:

Heterogeneous polyvinyl chloride floor coverings

1 Scope

This Part of GB/T 11982 specifies the terms and definitions, classification, grade

and designation, requirements, test methods, inspection rules, marking,

transportation, and storage of heterogeneous polyvinyl chloride floor coverings

(hereinafter referred to as floor coverings).

This Part applies to floor coverings with polyvinyl chloride resin as the main raw

material laid on the floor of the building.

2 Normative references

The following documents are indispensable for the application of this document.

For the dated references, only the editions with the dates indicated are

applicable to this document. For the undated references, the latest edition

(including all the amendments) are applicable to this document.

GB/T 1033.1-2008 Plastics - Methods for determining the density of non-

cellular plastics - Part 1: Immersion method, liquid pycnometer method and

titration method

GB/T 4100-2006 Ceramic tiles

GB/T 8427-2008 Textiles - Tests for color fastness - Color fastness to artificial

light: Xenon arc fading lamp test

GB 8624 Classification for burning behavior of building materials and

products

GB 18586 Indoor decorating and refurbishing materials - Limit of harmful

substances of polyvinyl chloride floor coverings

3 Terms and definitions

The following terms and definitions apply to this document.

3.1 Heterogeneous polyvinyl chloride floor coverings

5.3.4.2 Pollution resistance

REPORT test results.

5.3.4.3 Welding strength

USE grade 32 and above floor covering to conduct welding strength test as

agreed by the supplier and the purchaser. The average welding strength is ≥240

N/50 mm; the minimum is ≥180 N/50 mm.

5.3.4.4 Skid resistance

REPORT test results.

6 Test methods

6.1 Standard test conditions

The test piece, before the test, shall be left for at least 24 h under standard

conditions of temperature (23±2)°C and relative humidity (50±5)%. The test

shall be performed under these conditions.

6.2 Appearance

Under the scattered sunlight or fluorescent lamp, at 1 m from the test piece,

obliquely visually check the appearance. RECORD whether there are various

defects listed in Table 2.

6.3 Dimensional tolerances

6.3.1 Length

PUT the wear layer of the entire floor covering under test upwards. Without

tensile stress, lay it on a hard plane; USE a steel tape with a division value of 1

mm to measure the length at two positions parallel to the longitudinal direction

at about 200 mm from both sides. TAKE the arithmetic mean of the two length

measurement results to indicate the length of the floor covering, accurate to 10

mm.

6.3.2 Width

According to the method of 6.3.1, use a steel tape with a division value of 1 mm

to measure the width at the middle and both ends perpendicular to the

longitudinal direction. TAKE the smallest width to indicate the width of the floor

covering, accurate to 1 mm.

PLACE the test piece with the section facing up on a microscope test bench;

READ the thickness of the wear layer. If there are concave and convex patterns,

measure the thickness of the protruding part. 3 measurements are performed

on each test piece. RECORD the single thickness measured value of wear layer,

accurate to 0.01 mm.

6.3.3.2.4 Test result

Calculate the deviation of the arithmetic mean of all wear layer thickness

measurements from the stated wear layer thickness value, accurate to 1%; and

the deviation of a single wear layer thickness measurement from the arithmetic

mean of all wear layer thickness measurements, accurate to 0.01 mm.

6.4 Surface mass deviation

6.4.1 Instrument

6.4.1.1 Vernier caliper

The division value is not greater than 0.1 mm.

6.4.1.2 Balance

The sensitivity is not more than 0.01 g.

6.4.2 Sampling

TAKE 5 square test pieces with a size of 100 mm×100 mm from the floor

covering. Any side of the test piece shall be at least 100 mm from the edge of

the floor covering.

6.4.3 Test procedure

MEASURE the side length of the middle of each test piece, accurate to 0.1 mm.

WEIGH and record the mass m0 of each test piece, accurate to 0.01 g.

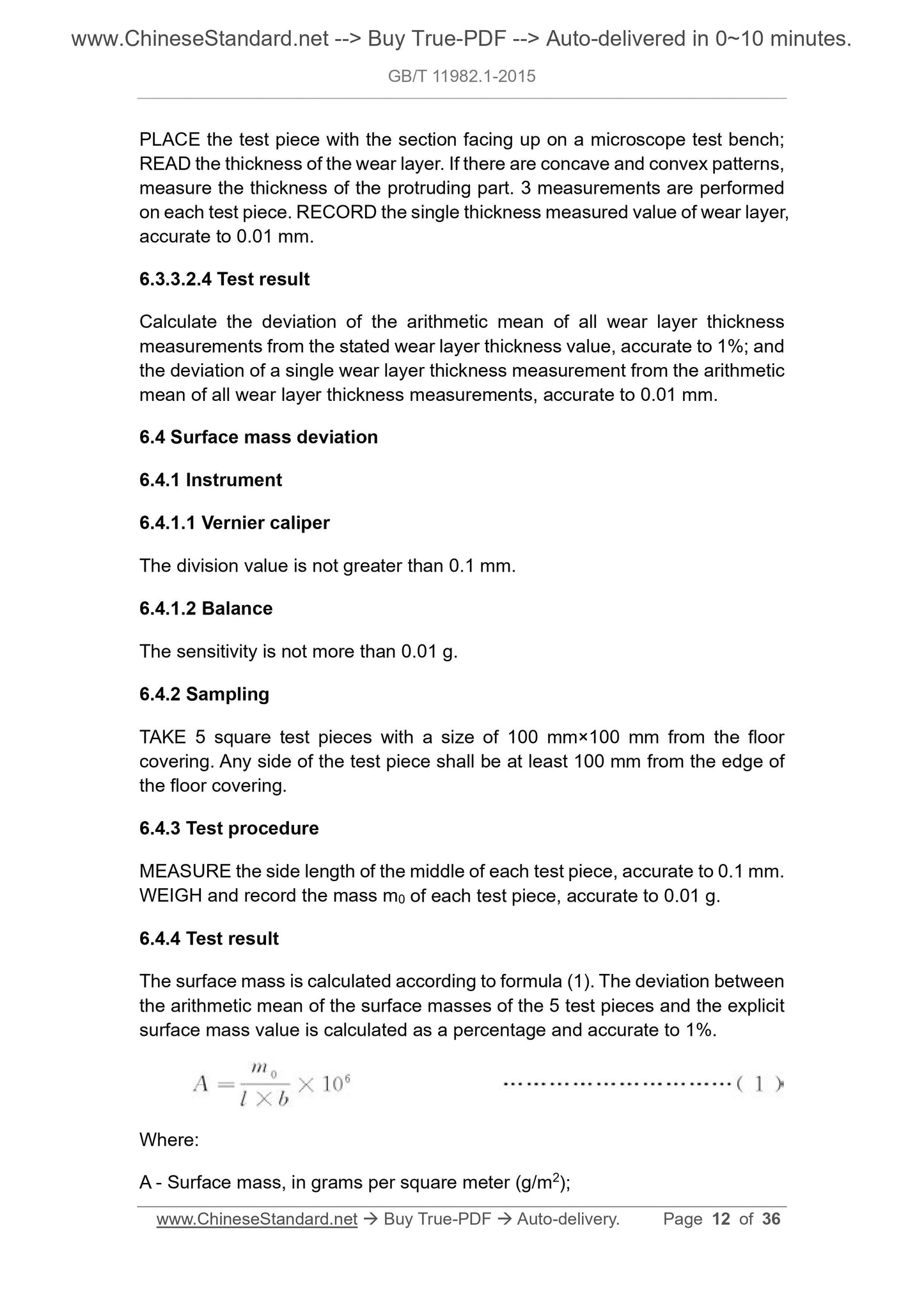

6.4.4 Test result

The surface mass is calculated according to formula (1). The deviation between

the arithmetic mean of the surface masses of the 5 test pieces and the explicit

surface mass value is calculated as a percentage and accurate to 1%.

Where:

A - Surface mass, in grams per square meter (g/m2);

m0 - The mass of test piece, in grams (g);

l - The length of test piece, in millimeters (mm);

b - The width of test piece, in millimeters (mm).

6.5 Variation rate of heating sizes

6.5.1 Instrument

6.5.1.1 Constant-temperature blast oven

Thermostat sensitivity is ±1 °C.

6.5.1.2 Vernier caliper

The division value is 0.02 mm.

6.5.2 Sampling

Before taking the test piece, the floor covering shall be laid as flat as possible.

TAKE 3 square test pieces with a size of 240 mm×240 mm from the floor

covering. Any side of the test piece shall be at least 100 mm from the edge of

the floor covering. Each side of each test piece shall be parallel or perpendicular

to the length or width direction of the product.

6.5.3 Test procedure

MARK the longitudinal and transverse directions on the test piece. As shown in

Figure 1, along the longitudinal and transverse distances of the test piece, at

20 mm from the edge of the test piece, draw two parallel lines with a distance

of 200 mm and mark 4 intersections. USE a Vernier caliper to measure the

distance L0 between each pair of marked lines in the longitudinal and transverse

directions, accurate to 0.02 mm. Then put the wear layer of the test piece

upward and lay it flat on a smooth glass plate or stainless steel plate sprinkled

with talcum powder. The distance between the test pieces shall be more than

50 mm; they shall be placed together in a constant-temperature blast oven with

a temperature of (80±2)°C. The distance between the flat plate and the inner

wall of the oven shall not be less than 50 mm. The vertical distance between

the flat plates and between the flat plate and the oven shall not be less than

100 mm. TAKE out after holding for 6 h; LEAVE them for 24 h under standard

test conditions. A 180 mm×180 mm×13 mm steel flat plate is pressed on the

test pieces. Then, measure the distance L between each pair of marked lines

of each test piece, accurate to 0.02 mm.

6.6.1.1 Constant-temperature blast oven

The...

Get QUOTATION in 1-minute: Click GB/T 11982.1-2015

Historical versions: GB/T 11982.1-2015

Preview True-PDF (Reload/Scroll if blank)

GB/T 11982.1-2015: Polyvinyl chloride floor coverings -- Part 1: Heterogeneous polyvinyl chloride floor coverings

GB/T 11982.1-2015

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 83.140

Q 22

Replacing GB/T 11982.1-2005

Polyvinyl chloride floor coverings - Part 1:

Heterogeneous polyvinyl chloride floor coverings

聚氯乙烯卷材地板

ISSUED ON: SEPTEMBER 11, 2015

IMPLEMENTED ON: AUGUST 01, 2016

Issued by: General Administration of Quality Supervision, Inspection and

Quarantine of the PRC;

Standardization Administration of the PRC.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Classification, grade, and designation ... 6

5 Requirements ... 7

6 Test methods ... 10

7 Inspection rules ... 25

8 Marking, transportation, and storage ... 26

Appendix A (Normative) Classification table of use grades ... 28

Appendix B (Normative) Chair caster test method ... 30

Appendix C (Normative) Pollution resistance test method ... 34

Polyvinyl chloride floor coverings - Part 1:

Heterogeneous polyvinyl chloride floor coverings

1 Scope

This Part of GB/T 11982 specifies the terms and definitions, classification, grade

and designation, requirements, test methods, inspection rules, marking,

transportation, and storage of heterogeneous polyvinyl chloride floor coverings

(hereinafter referred to as floor coverings).

This Part applies to floor coverings with polyvinyl chloride resin as the main raw

material laid on the floor of the building.

2 Normative references

The following documents are indispensable for the application of this document.

For the dated references, only the editions with the dates indicated are

applicable to this document. For the undated references, the latest edition

(including all the amendments) are applicable to this document.

GB/T 1033.1-2008 Plastics - Methods for determining the density of non-

cellular plastics - Part 1: Immersion method, liquid pycnometer method and

titration method

GB/T 4100-2006 Ceramic tiles

GB/T 8427-2008 Textiles - Tests for color fastness - Color fastness to artificial

light: Xenon arc fading lamp test

GB 8624 Classification for burning behavior of building materials and

products

GB 18586 Indoor decorating and refurbishing materials - Limit of harmful

substances of polyvinyl chloride floor coverings

3 Terms and definitions

The following terms and definitions apply to this document.

3.1 Heterogeneous polyvinyl chloride floor coverings

5.3.4.2 Pollution resistance

REPORT test results.

5.3.4.3 Welding strength

USE grade 32 and above floor covering to conduct welding strength test as

agreed by the supplier and the purchaser. The average welding strength is ≥240

N/50 mm; the minimum is ≥180 N/50 mm.

5.3.4.4 Skid resistance

REPORT test results.

6 Test methods

6.1 Standard test conditions

The test piece, before the test, shall be left for at least 24 h under standard

conditions of temperature (23±2)°C and relative humidity (50±5)%. The test

shall be performed under these conditions.

6.2 Appearance

Under the scattered sunlight or fluorescent lamp, at 1 m from the test piece,

obliquely visually check the appearance. RECORD whether there are various

defects listed in Table 2.

6.3 Dimensional tolerances

6.3.1 Length

PUT the wear layer of the entire floor covering under test upwards. Without

tensile stress, lay it on a hard plane; USE a steel tape with a division value of 1

mm to measure the length at two positions parallel to the longitudinal direction

at about 200 mm from both sides. TAKE the arithmetic mean of the two length

measurement results to indicate the length of the floor covering, accurate to 10

mm.

6.3.2 Width

According to the method of 6.3.1, use a steel tape with a division value of 1 mm

to measure the width at the middle and both ends perpendicular to the

longitudinal direction. TAKE the smallest width to indicate the width of the floor

covering, accurate to 1 mm.

PLACE the test piece with the section facing up on a microscope test bench;

READ the thickness of the wear layer. If there are concave and convex patterns,

measure the thickness of the protruding part. 3 measurements are performed

on each test piece. RECORD the single thickness measured value of wear layer,

accurate to 0.01 mm.

6.3.3.2.4 Test result

Calculate the deviation of the arithmetic mean of all wear layer thickness

measurements from the stated wear layer thickness value, accurate to 1%; and

the deviation of a single wear layer thickness measurement from the arithmetic

mean of all wear layer thickness measurements, accurate to 0.01 mm.

6.4 Surface mass deviation

6.4.1 Instrument

6.4.1.1 Vernier caliper

The division value is not greater than 0.1 mm.

6.4.1.2 Balance

The sensitivity is not more than 0.01 g.

6.4.2 Sampling

TAKE 5 square test pieces with a size of 100 mm×100 mm from the floor

covering. Any side of the test piece shall be at least 100 mm from the edge of

the floor covering.

6.4.3 Test procedure

MEASURE the side length of the middle of each test piece, accurate to 0.1 mm.

WEIGH and record the mass m0 of each test piece, accurate to 0.01 g.

6.4.4 Test result

The surface mass is calculated according to formula (1). The deviation between

the arithmetic mean of the surface masses of the 5 test pieces and the explicit

surface mass value is calculated as a percentage and accurate to 1%.

Where:

A - Surface mass, in grams per square meter (g/m2);

m0 - The mass of test piece, in grams (g);

l - The length of test piece, in millimeters (mm);

b - The width of test piece, in millimeters (mm).

6.5 Variation rate of heating sizes

6.5.1 Instrument

6.5.1.1 Constant-temperature blast oven

Thermostat sensitivity is ±1 °C.

6.5.1.2 Vernier caliper

The division value is 0.02 mm.

6.5.2 Sampling

Before taking the test piece, the floor covering shall be laid as flat as possible.

TAKE 3 square test pieces with a size of 240 mm×240 mm from the floor

covering. Any side of the test piece shall be at least 100 mm from the edge of

the floor covering. Each side of each test piece shall be parallel or perpendicular

to the length or width direction of the product.

6.5.3 Test procedure

MARK the longitudinal and transverse directions on the test piece. As shown in

Figure 1, along the longitudinal and transverse distances of the test piece, at

20 mm from the edge of the test piece, draw two parallel lines with a distance

of 200 mm and mark 4 intersections. USE a Vernier caliper to measure the

distance L0 between each pair of marked lines in the longitudinal and transverse

directions, accurate to 0.02 mm. Then put the wear layer of the test piece

upward and lay it flat on a smooth glass plate or stainless steel plate sprinkled

with talcum powder. The distance between the test pieces shall be more than

50 mm; they shall be placed together in a constant-temperature blast oven with

a temperature of (80±2)°C. The distance between the flat plate and the inner

wall of the oven shall not be less than 50 mm. The vertical distance between

the flat plates and between the flat plate and the oven shall not be less than

100 mm. TAKE out after holding for 6 h; LEAVE them for 24 h under standard

test conditions. A 180 mm×180 mm×13 mm steel flat plate is pressed on the

test pieces. Then, measure the distance L between each pair of marked lines

of each test piece, accurate to 0.02 mm.

6.6.1.1 Constant-temperature blast oven

The...

Share