PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 14215-2021 English PDF (GBT14215-2021)

GB/T 14215-2021 English PDF (GBT14215-2021)

Precio habitual

$170.00 USD

Precio habitual

Precio de oferta

$170.00 USD

Precio unitario

/

por

Los gastos de envío se calculan en la pantalla de pago.

No se pudo cargar la disponibilidad de retiro

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 14215-2021

Historical versions: GB/T 14215-2021

Preview True-PDF (Reload/Scroll if blank)

GB/T 14215-2021: General quality requirements for canned tomato paste

GB/T 14215-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 67.080.20

CCS X 77

Replacing GB/T 14215-2008

General Quality Requirements for Canned Tomato Paste

(CODEX STAN 57-2013, Codex

Standard for Processed Tomato Concentrates, NEQ)

ISSUED ON: AUGUST 20, 2021

IMPLEMENTED ON: SEPTEMBER 01, 2022

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Product Classification and Code ... 4

4 Requirements ... 5

5 Test Method ... 6

6 Inspection Rules ... 7

7 Marking, Packaging, Transportation and Storage ... 8

Appendix A (Normative) Method for Determination of Value of Chromatism of Tomato

Paste ... 9

Appendix B (Normative) Method for Determination of Lycopene Content in Tomato

Paste ... 10

Appendix C (Normative) Method for Determination of Viscosity of Tomato Paste ... 13

General Quality Requirements for Canned Tomato Paste

1 Scope

This Document specifies the product classification and code, requirements, test methods,

inspection rules, packaging, marking, transportation and storage of canned tomato paste.

This Document applies to canned tomato paste made from ripe tomatoes or tomato paste as the

main raw material, which is pretreated, concentrated, seasoned (or unseasoned), filled or sub-

packaged, sealed, sterilized or aseptically filled.

2 Normative References

The provisions in following documents become the essential provisions of this Document

through reference in this Document. For the dated documents, only the versions with the dates

indicated are applicable to this Document; for the undated documents, only the latest version

(including all the amendments) is applicable to this Document.

GB/T 317 White Granulated Sugar

GB 5009.44 National Food Safety Standard - Determination of Chloride in Foods

GB/T 5461 Edible Salt

GB/T 8269 Citric Acid

GB/T 10786 Test methods of canned foods

QB/T 1006 Inspection Rules for Canned Food

QB/T 4631 Packaging, Labeling, Transportation and Storage for Canned Food

3 Product Classification and Code

3.1 According to different tomato crushing processes, it is divided into:

--- Cold crushed canned tomato paste: products produced by cold crushing process (crushing

temperature no higher than 70°C);

--- Warm crushed canned tomato paste: products produced by warm crushing process

(crushing temperature at 70°C~85°C);

--- Hot-broken canned tomato paste: products produced by heat-broken process (the

crushing temperature at above 85°C).

3.2 According to whether sub-packaged, it is divided into:

--- Direct filled canned tomato paste: canned tomato paste that has not been sub-packaged;

--- Sub-packaged canned tomato paste: made from concentrated tomato paste; the canned

food that is diluted with water or without water; added or not added sugar, salt or citric

acid; and prepared by subpackaging, filling, sealing, sterilization or aseptic filling.

3.3 According to the different soluble solid contents, the direct filled canned tomato paste can

be divided into:

--- Canned tomato paste with low-concentration: tomato paste with a soluble solid content

of 12.5% to 22% (excluding 22%), the product code is 847 1;

--- Canned tomato paste with medium concentration: tomato paste with a soluble solid

content of 22%~28% (excluding 28%), the product code is 847 2;

--- Canned tomato paste with high-concentration: tomato paste with a soluble solid content

of 28% to 36% (excluding 36%), product code is 847;

--- Canned tomato paste with extra-high-concentration: tomato paste with a soluble solid

content of no less than 36%, product code is 847 3.

4 Requirements

4.1 Raw and auxiliary materials

4.1.1 Tomatoes

Use fresh or well-stored tomatoes that have not been attacked by diseases and insect pests.

4.1.2 Citric acid

It shall meet the requirements of GB/T 8269.

4.1.3 Edible salt

It shall meet the requirements of GB/T 5461.

4.1.4 White granulated sugar

It shall meet the requirements of GB/T 317.

5.3 Soluble solids content

5.3.1 Determination method for hot-broken canned tomato paste products: cool the sample to

room temperature (20°C) and apply it on the prism surface of a refractometer (hand-held sugar

meter, Abbe refractometer, automatic refractometer, etc.); and spread evenly without gaps;

make sure that the prism is completely covered; cover the shading plate; and read the displayed

value.

5.3.2 Others shall be determined according to the methods specified in GB/T 10786.

5.4 pH

It is measured according to the method specified in GB/T 10786.

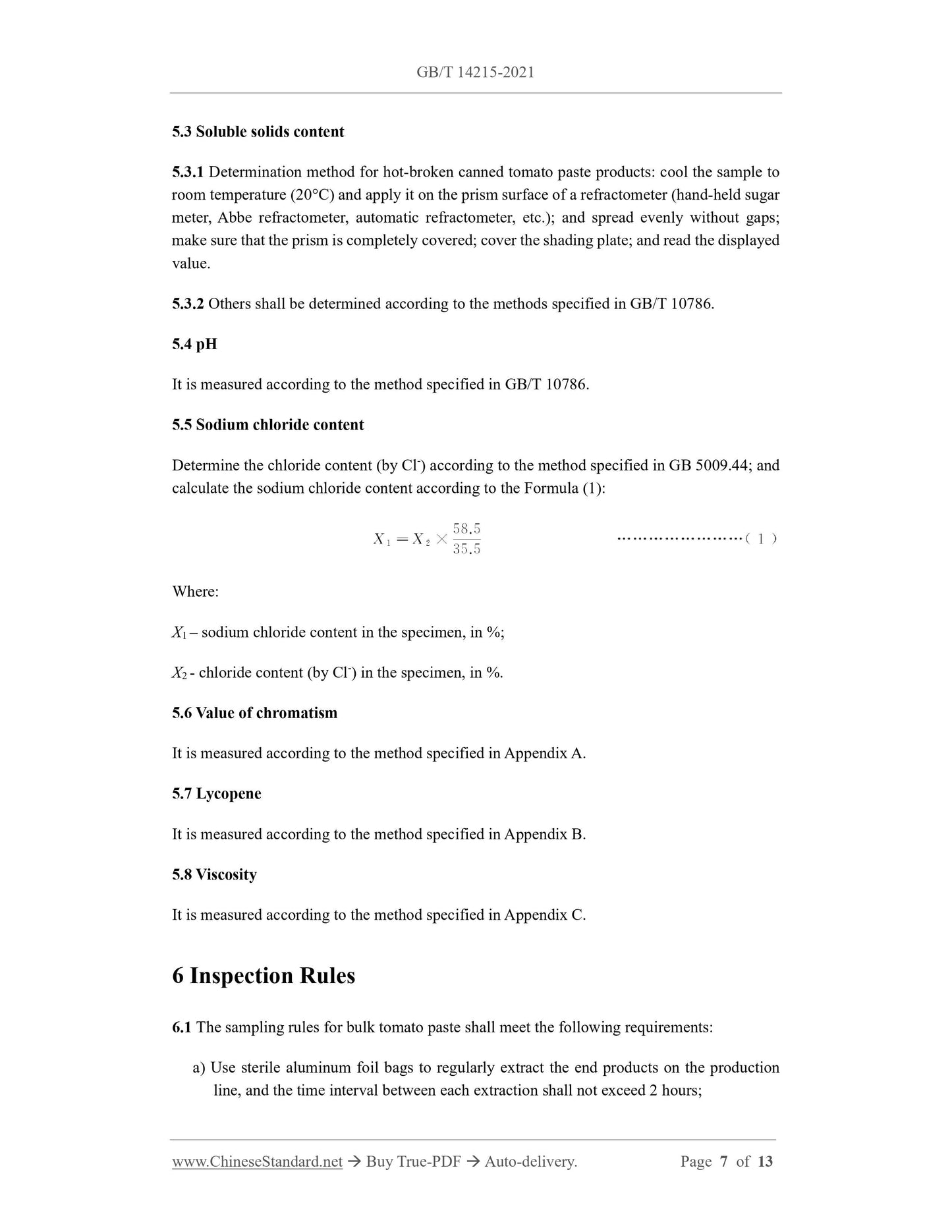

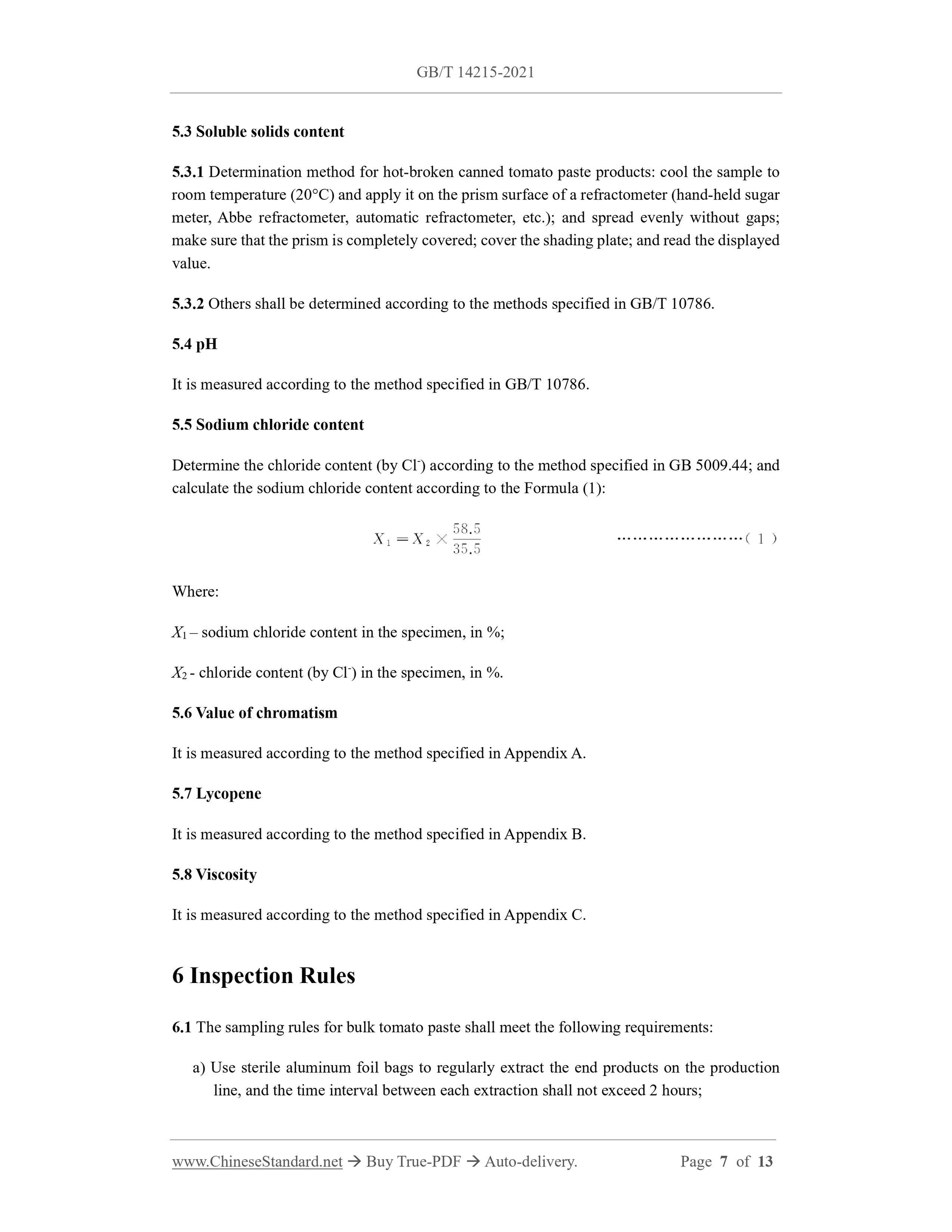

5.5 Sodium chloride content

Determine the chloride content (by Cl-) according to the method specified in GB 5009.44; and

calculate the sodium chloride content according to the Formula (1):

Where:

X1 – sodium chloride content in the specimen, in %;

X2 - chloride content (by Cl-) in the specimen, in %.

5.6 Value of chromatism

It is measured according to the method specified in Appendix A.

5.7 Lycopene

It is measured according to the method specified in Appendix B.

5.8 Viscosity

It is measured according to the method specified in Appendix C.

6 Inspection Rules

6.1 The sampling rules for bulk tomato paste shall meet the following requirements:

a) Use sterile aluminum foil bags to regularly extract the end products on the production

line, and the time interval between each extraction shall not exceed 2 hours;

Appendix B

(Normative)

Method for Determination of Lycopene Content in Tomato

Paste

B.1 Principle

The tomato paste is dehydrated with methanol to remove the yellow pigment; and then the

lycopene is extracted with toluene; the absorbance of the extract is measured by

spectrophotometry; and the lycopene content is calculated according to the standard curve.

B.2 Reagents

B.2.1 Methanol: analytically pure.

B.2.2 Toluene: analytically pure.

B.2.3 Absolute ethanol: analytically pure.

B.2.4 Sudan I pigment: refined product.

B.3 Instruments

B.3.1 Routine laboratory instruments.

B.3.2 Spectrophotometer: the wavelength range is 360nm~600nm, and the accuracy is ±3nm.

B.4 Analysis procedures

B.4.1 Drawing of standard curve

B.4.1.1 Preparation of standard solution

Weigh 0.025g of Sudan I pigment, accurate to 0.1mg; dissolve it with a small amount of

absolute ethanol; quantitatively transfer it into a 50mL volumetric flask; dilute to the mark with

absolute ethanol; and shake well.

B.4.1.2 Draw standard curve

Accurately pipette 0.26mL, 0.52mL, 0.78mL, 1.04mL, 1.30mL of the standard solution;

respectively inject them into a set of 50mL volumetric flasks; dilute to the mark with absolute

ethanol; shake well; namely, it is equivalent to mass concentration of 0.5μg/mL, 1.0μg/mL,

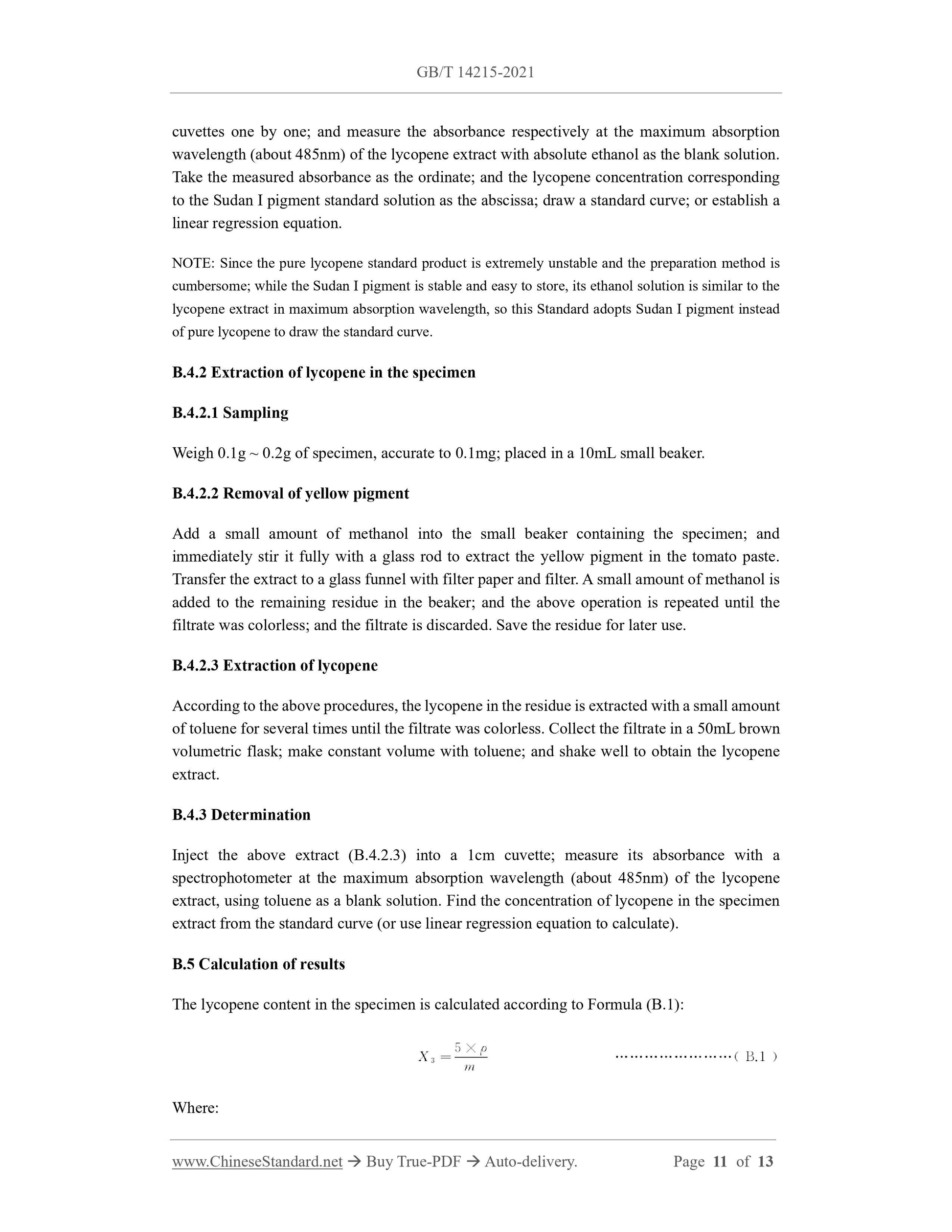

1.5μg/mL, 2.0μg/mL, 2.5μg/mL of lycopene standard solution. Then, pour them into 1cm

cuvettes one by one; and measure the absorbance respectively at the maximum absorption

wavelength (about 485nm) of the lycopene extract with absolute ethanol as the blank solution.

Take the measured absorbance as the ordinate; and the lycopene concentration corresponding

to the Sudan Ⅰ pigment standard solution as the abscissa; draw a standard curve; or establish a

linear regression equation.

NOTE: Since the pure lycopene standard product is extremely unstable and the preparation method is

cumbersome; while the Sudan Ⅰ pigment is stable and ...

Get QUOTATION in 1-minute: Click GB/T 14215-2021

Historical versions: GB/T 14215-2021

Preview True-PDF (Reload/Scroll if blank)

GB/T 14215-2021: General quality requirements for canned tomato paste

GB/T 14215-2021

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 67.080.20

CCS X 77

Replacing GB/T 14215-2008

General Quality Requirements for Canned Tomato Paste

(CODEX STAN 57-2013, Codex

Standard for Processed Tomato Concentrates, NEQ)

ISSUED ON: AUGUST 20, 2021

IMPLEMENTED ON: SEPTEMBER 01, 2022

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Product Classification and Code ... 4

4 Requirements ... 5

5 Test Method ... 6

6 Inspection Rules ... 7

7 Marking, Packaging, Transportation and Storage ... 8

Appendix A (Normative) Method for Determination of Value of Chromatism of Tomato

Paste ... 9

Appendix B (Normative) Method for Determination of Lycopene Content in Tomato

Paste ... 10

Appendix C (Normative) Method for Determination of Viscosity of Tomato Paste ... 13

General Quality Requirements for Canned Tomato Paste

1 Scope

This Document specifies the product classification and code, requirements, test methods,

inspection rules, packaging, marking, transportation and storage of canned tomato paste.

This Document applies to canned tomato paste made from ripe tomatoes or tomato paste as the

main raw material, which is pretreated, concentrated, seasoned (or unseasoned), filled or sub-

packaged, sealed, sterilized or aseptically filled.

2 Normative References

The provisions in following documents become the essential provisions of this Document

through reference in this Document. For the dated documents, only the versions with the dates

indicated are applicable to this Document; for the undated documents, only the latest version

(including all the amendments) is applicable to this Document.

GB/T 317 White Granulated Sugar

GB 5009.44 National Food Safety Standard - Determination of Chloride in Foods

GB/T 5461 Edible Salt

GB/T 8269 Citric Acid

GB/T 10786 Test methods of canned foods

QB/T 1006 Inspection Rules for Canned Food

QB/T 4631 Packaging, Labeling, Transportation and Storage for Canned Food

3 Product Classification and Code

3.1 According to different tomato crushing processes, it is divided into:

--- Cold crushed canned tomato paste: products produced by cold crushing process (crushing

temperature no higher than 70°C);

--- Warm crushed canned tomato paste: products produced by warm crushing process

(crushing temperature at 70°C~85°C);

--- Hot-broken canned tomato paste: products produced by heat-broken process (the

crushing temperature at above 85°C).

3.2 According to whether sub-packaged, it is divided into:

--- Direct filled canned tomato paste: canned tomato paste that has not been sub-packaged;

--- Sub-packaged canned tomato paste: made from concentrated tomato paste; the canned

food that is diluted with water or without water; added or not added sugar, salt or citric

acid; and prepared by subpackaging, filling, sealing, sterilization or aseptic filling.

3.3 According to the different soluble solid contents, the direct filled canned tomato paste can

be divided into:

--- Canned tomato paste with low-concentration: tomato paste with a soluble solid content

of 12.5% to 22% (excluding 22%), the product code is 847 1;

--- Canned tomato paste with medium concentration: tomato paste with a soluble solid

content of 22%~28% (excluding 28%), the product code is 847 2;

--- Canned tomato paste with high-concentration: tomato paste with a soluble solid content

of 28% to 36% (excluding 36%), product code is 847;

--- Canned tomato paste with extra-high-concentration: tomato paste with a soluble solid

content of no less than 36%, product code is 847 3.

4 Requirements

4.1 Raw and auxiliary materials

4.1.1 Tomatoes

Use fresh or well-stored tomatoes that have not been attacked by diseases and insect pests.

4.1.2 Citric acid

It shall meet the requirements of GB/T 8269.

4.1.3 Edible salt

It shall meet the requirements of GB/T 5461.

4.1.4 White granulated sugar

It shall meet the requirements of GB/T 317.

5.3 Soluble solids content

5.3.1 Determination method for hot-broken canned tomato paste products: cool the sample to

room temperature (20°C) and apply it on the prism surface of a refractometer (hand-held sugar

meter, Abbe refractometer, automatic refractometer, etc.); and spread evenly without gaps;

make sure that the prism is completely covered; cover the shading plate; and read the displayed

value.

5.3.2 Others shall be determined according to the methods specified in GB/T 10786.

5.4 pH

It is measured according to the method specified in GB/T 10786.

5.5 Sodium chloride content

Determine the chloride content (by Cl-) according to the method specified in GB 5009.44; and

calculate the sodium chloride content according to the Formula (1):

Where:

X1 – sodium chloride content in the specimen, in %;

X2 - chloride content (by Cl-) in the specimen, in %.

5.6 Value of chromatism

It is measured according to the method specified in Appendix A.

5.7 Lycopene

It is measured according to the method specified in Appendix B.

5.8 Viscosity

It is measured according to the method specified in Appendix C.

6 Inspection Rules

6.1 The sampling rules for bulk tomato paste shall meet the following requirements:

a) Use sterile aluminum foil bags to regularly extract the end products on the production

line, and the time interval between each extraction shall not exceed 2 hours;

Appendix B

(Normative)

Method for Determination of Lycopene Content in Tomato

Paste

B.1 Principle

The tomato paste is dehydrated with methanol to remove the yellow pigment; and then the

lycopene is extracted with toluene; the absorbance of the extract is measured by

spectrophotometry; and the lycopene content is calculated according to the standard curve.

B.2 Reagents

B.2.1 Methanol: analytically pure.

B.2.2 Toluene: analytically pure.

B.2.3 Absolute ethanol: analytically pure.

B.2.4 Sudan I pigment: refined product.

B.3 Instruments

B.3.1 Routine laboratory instruments.

B.3.2 Spectrophotometer: the wavelength range is 360nm~600nm, and the accuracy is ±3nm.

B.4 Analysis procedures

B.4.1 Drawing of standard curve

B.4.1.1 Preparation of standard solution

Weigh 0.025g of Sudan I pigment, accurate to 0.1mg; dissolve it with a small amount of

absolute ethanol; quantitatively transfer it into a 50mL volumetric flask; dilute to the mark with

absolute ethanol; and shake well.

B.4.1.2 Draw standard curve

Accurately pipette 0.26mL, 0.52mL, 0.78mL, 1.04mL, 1.30mL of the standard solution;

respectively inject them into a set of 50mL volumetric flasks; dilute to the mark with absolute

ethanol; shake well; namely, it is equivalent to mass concentration of 0.5μg/mL, 1.0μg/mL,

1.5μg/mL, 2.0μg/mL, 2.5μg/mL of lycopene standard solution. Then, pour them into 1cm

cuvettes one by one; and measure the absorbance respectively at the maximum absorption

wavelength (about 485nm) of the lycopene extract with absolute ethanol as the blank solution.

Take the measured absorbance as the ordinate; and the lycopene concentration corresponding

to the Sudan Ⅰ pigment standard solution as the abscissa; draw a standard curve; or establish a

linear regression equation.

NOTE: Since the pure lycopene standard product is extremely unstable and the preparation method is

cumbersome; while the Sudan Ⅰ pigment is stable and ...

Share