PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB/T 2999-2016 English PDF (GBT2999-2016)

GB/T 2999-2016 English PDF (GBT2999-2016)

Precio habitual

$90.00 USD

Precio habitual

Precio de oferta

$90.00 USD

Precio unitario

/

por

Los gastos de envío se calculan en la pantalla de pago.

No se pudo cargar la disponibilidad de retiro

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 2999-2016

Historical versions: GB/T 2999-2016

Preview True-PDF (Reload/Scroll if blank)

GB/T 2999-2016: Refractory materials -- Determination of bulk density of granular materials

GB/T 2999-2016

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 81.080

Q 40

Replacing GB/T 2999-2002

Refractory materials - Determination of

bulk density of granular materials

[ISO 8840.1987, Refractory materials - Determination of bulk density of

granular materials (grain density), MOD]

ISSUED ON. AUGUST 29, 2016

IMPLEMENTED ON. JULY 1, 2017

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People’s Republic of China;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Principle... 6

5 Sampling ... 6

6 Test pieces ... 7

7 Determination of the mass of dry test pieces (m1) ... 7

8 Determination of the test piece volume - Method 1. Weighing method ... 7

9 Determination of the test piece volume - Method 2. Burette method ... 10

10 Rounding off for numerical values ... 12

11 Permissible error ... 12

12 Test report ... 12

Annex A (Informative) Contrast between the section numbers of

this Standard and ISO 8840.1987 ... 14

Annex B (Informative) Technical differences between this Standard and

ISO 8840.1987 and corresponding causes ... 15

Foreword

This Standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This Standard replaces GB/T 2999-2002 Refractory materials - Determination

of bulk density of granular materials. Compared with GB/T 2999-2002, the

major content changes are as follows.

— MODIFY the relevant contents in normative references (SEE Chapter 2

of this Standard, Chapter 2 of 2002 edition);

— MODIFY the method of wiping the immersion liquid on the surfaces of

saturated test pieces (SEE Section 8.4.2 of this Standard, Section 8.4.2

of 2002 edition);

— DELETE the Annex A (SEE Annex A of 2002 edition).

This Standard was redrafted by reference to ISO 8840.1987 Refractory

materials - Determination of bulk density of granular materials (grain density)

after modification.

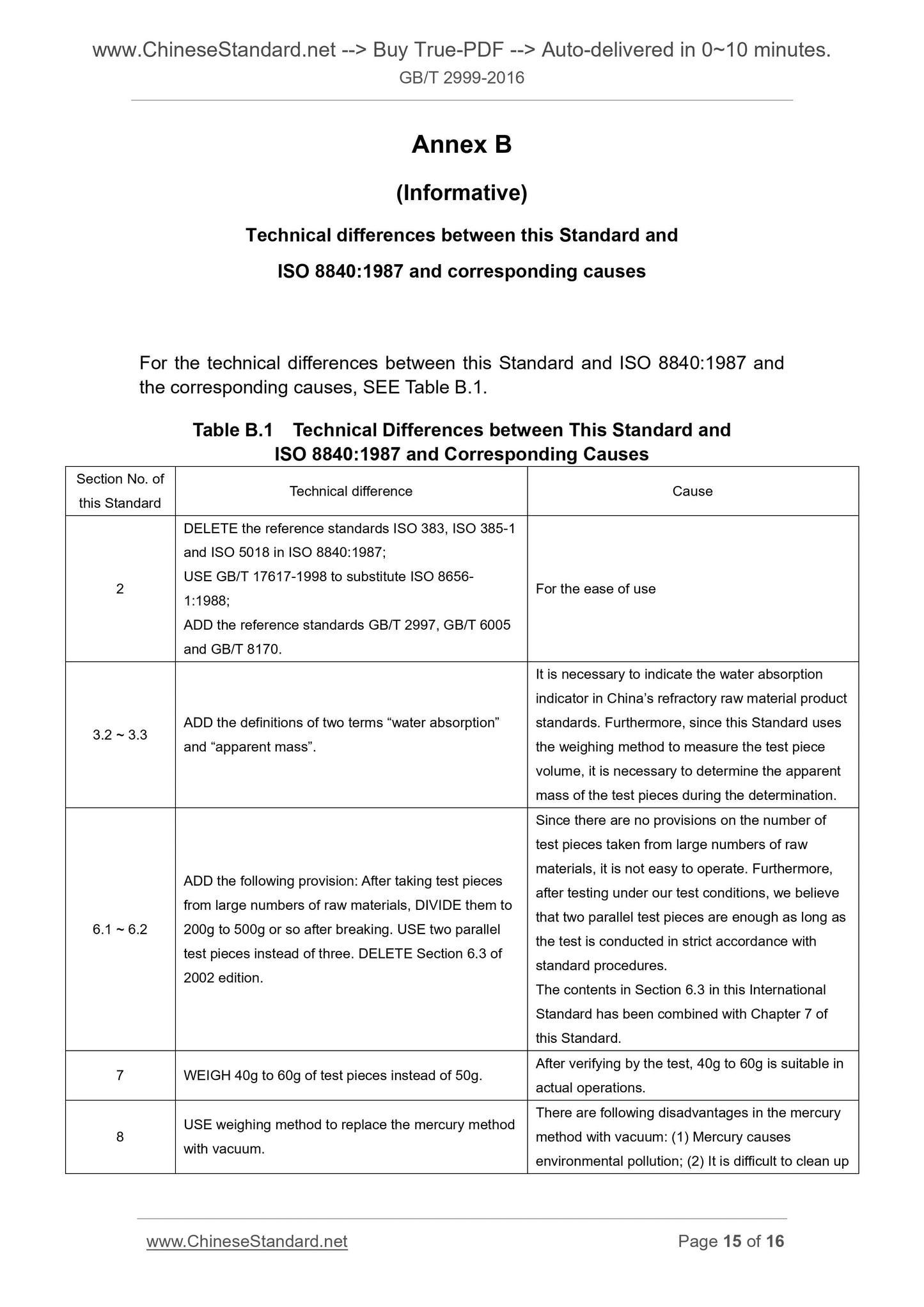

Compared with ISO 8840.1987, this Standard has made many structural

adjustments. The contrast table for the section numbers of this Standard and

ISO 8840.1987 is listed in Annex A.

There are technical differences between this Standard and ISO 8840.1987. For

the list of technical differences between this Standard and ISO 8840.1987 and

corresponding causes, SEE Annex B.

Some of the elements of this document may be the subject of patent rights. The

issuing authorities of this document shall not be held responsible for identifying

any or all such patent rights.

This Standard was proposed by and shall be under the jurisdiction of the

National Technical Committee for Standardization of Refractory Materials

(SAC/TC 193).

Main drafting organizations of this Standard. Central Research Institute of

Building and Construction Co., Ltd, Jiaozuo Jinxin Hengtuo High-temperature

Materials Co., Ltd, and Luoyang Institute of Science and Technology.

Main drafters of this Standard. Tian Zhihong, Zhang Xiuhua, Huang Jiangwen,

Wang Li, Mei Minghua, Xue Hongyan, Tian Jingjing, Yang Jing, Liu Xiang and

Sun Lijun.

The previous released editions substituted by this Standard are as follows.

Refractory materials - Determination of bulk

density of granular materials

1 Scope

This Standard specifies two methods for the determination of the bulk density

of granular refractory materials (grain density) with a grain size of larger than

2mm.

— Method 1. Weighing method;

— Method 2. Burette method.

Method 1 is intended as the referee method.

Depending on the nature of the material tested, the two methods may give

different results. Any statement of the value of a bulk density shall therefore be

accompanied by an indication of the method used or to be used in case of

dispute. The same method shall be used for the determination of the volume of

the sample, for selecting and preparing the sample, for calculating the bulk

density and for presenting the test report.

This Standard is applicable to the determination of the bulk density, water

absorption and apparent porosity of granular refractory materials.

2 Normative references

The following documents are essential to the application of this document. For

dated references, only the editions with the dates indicated are applicable to

this document. For undated references, only the latest editions (including all the

amendments) are applicable to this document.

GB/T 2997 Test method for bulk density, apparent porosity and true porosity

of dense shaped refractory products

GB/T 6005 Test sieves - Metal wire cloth, perforated metal plate and

electroformed sheet - Nominal sizes of openings

GB/T 8170 Rules of rounding off for numerical values and expression and

judgement of limiting values

8.1.5 Non-absorbent fiber cloth, such as polyester fiber cloth, nylon fiber cloth,

etc.

8.1.6 Vessel.

8.1.7 Vacuum equipment. It can decrease the absolute pressure to not greater

than 2,500MPa, and shall also be able to measure the absolute pressure value.

8.1.8 Immersion liquid. tap water or kerosene.

8.1.9 Mesh basket. It refers to the mesh basket with a handle, which is made

of sieve with a pore diameter of 1mm.

8.1.10 Vessel with an overflow pipe.

8.1.11 Cotton gauze. The dimension is about 60cm × 60cm.

8.1.12 Weighing bottle. with a diameter of 60mm and a height of 30mm.

8.1.13 Hydrostatic balance or hydrometer. with a division value of 0.001 g/cm3.

8.2 Test piece immersion

After weighing, carefully PLACE the test pieces on a piece of non-absorbent

fiber cloth (SEE Section 8.1.5). USE a string to wrap them firmly. PLACE in a

vessel (SEE Section 8.1.6). PLACE the vessel in the vacuum equipment (SEE

Section 8.1.7). VACUUM until the absolute pressure is less than 2,500MPa.

KEEP the test pieces at this degree of vacuum for 5min. Slowly INJECT the

immersion liquid (SEE Section 8.1.8) for absorption of test pieces within 5min,

until the test pieces are completely immersed. KEEP vacuuming for 5min.

STOP air exhaust. TAKE out the vessel. LET it stand in air, until the liquid inside

comes up to room temperature.

8.3 Determination of the apparent mass of saturated test pieces (m2)

HANG the mesh basket (SEE Section 8.1.9) on the balance hook so that the

mesh basket can completely immerse into the liquid. ZERO the balance. TAKE

out the mesh basket for standby application. OPEN the wrapping cloth.

Carefully SCRAPE the saturated test pieces into the mesh basket. Rapidly

MOVE the mesh basket into the immersion liquid in the vessel with an overflow

pipe. After the test pieces completely immerse into the immersion liquid, MOVE

the mesh basket up and down for several times so that the residual bubbles

can escape. HANG the mesh basket on the balance hook for weighing.

ACCURATE to 0.01g.

8.4 Determination of the mass of saturated test pieces (m3)

9.2 Determination of the test piece volume

After drying and weighing, PLACE the test pieces (SEE Chapter 7) into a beaker

(SEE Section 9.1.1). ADD the immersion liquid at room temperature until the

test pieces are completely submerged in it.

Before each use, REMOVE the grease in the burette (SEE Section 9.1.2).

FLUSH the burette afterwards until it becomes clean. ADD the immersion liquid

until it comes up to 20mL to 25mL. LET it stand for 1min. USE a magnifier (SEE

Section 9.1.3) to estimate the readi...

Get QUOTATION in 1-minute: Click GB/T 2999-2016

Historical versions: GB/T 2999-2016

Preview True-PDF (Reload/Scroll if blank)

GB/T 2999-2016: Refractory materials -- Determination of bulk density of granular materials

GB/T 2999-2016

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 81.080

Q 40

Replacing GB/T 2999-2002

Refractory materials - Determination of

bulk density of granular materials

[ISO 8840.1987, Refractory materials - Determination of bulk density of

granular materials (grain density), MOD]

ISSUED ON. AUGUST 29, 2016

IMPLEMENTED ON. JULY 1, 2017

Issued by. General Administration of Quality Supervision, Inspection and

Quarantine of the People’s Republic of China;

Standardization Administration of the People’s Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Principle... 6

5 Sampling ... 6

6 Test pieces ... 7

7 Determination of the mass of dry test pieces (m1) ... 7

8 Determination of the test piece volume - Method 1. Weighing method ... 7

9 Determination of the test piece volume - Method 2. Burette method ... 10

10 Rounding off for numerical values ... 12

11 Permissible error ... 12

12 Test report ... 12

Annex A (Informative) Contrast between the section numbers of

this Standard and ISO 8840.1987 ... 14

Annex B (Informative) Technical differences between this Standard and

ISO 8840.1987 and corresponding causes ... 15

Foreword

This Standard was drafted in accordance with the rules given in GB/T 1.1-2009.

This Standard replaces GB/T 2999-2002 Refractory materials - Determination

of bulk density of granular materials. Compared with GB/T 2999-2002, the

major content changes are as follows.

— MODIFY the relevant contents in normative references (SEE Chapter 2

of this Standard, Chapter 2 of 2002 edition);

— MODIFY the method of wiping the immersion liquid on the surfaces of

saturated test pieces (SEE Section 8.4.2 of this Standard, Section 8.4.2

of 2002 edition);

— DELETE the Annex A (SEE Annex A of 2002 edition).

This Standard was redrafted by reference to ISO 8840.1987 Refractory

materials - Determination of bulk density of granular materials (grain density)

after modification.

Compared with ISO 8840.1987, this Standard has made many structural

adjustments. The contrast table for the section numbers of this Standard and

ISO 8840.1987 is listed in Annex A.

There are technical differences between this Standard and ISO 8840.1987. For

the list of technical differences between this Standard and ISO 8840.1987 and

corresponding causes, SEE Annex B.

Some of the elements of this document may be the subject of patent rights. The

issuing authorities of this document shall not be held responsible for identifying

any or all such patent rights.

This Standard was proposed by and shall be under the jurisdiction of the

National Technical Committee for Standardization of Refractory Materials

(SAC/TC 193).

Main drafting organizations of this Standard. Central Research Institute of

Building and Construction Co., Ltd, Jiaozuo Jinxin Hengtuo High-temperature

Materials Co., Ltd, and Luoyang Institute of Science and Technology.

Main drafters of this Standard. Tian Zhihong, Zhang Xiuhua, Huang Jiangwen,

Wang Li, Mei Minghua, Xue Hongyan, Tian Jingjing, Yang Jing, Liu Xiang and

Sun Lijun.

The previous released editions substituted by this Standard are as follows.

Refractory materials - Determination of bulk

density of granular materials

1 Scope

This Standard specifies two methods for the determination of the bulk density

of granular refractory materials (grain density) with a grain size of larger than

2mm.

— Method 1. Weighing method;

— Method 2. Burette method.

Method 1 is intended as the referee method.

Depending on the nature of the material tested, the two methods may give

different results. Any statement of the value of a bulk density shall therefore be

accompanied by an indication of the method used or to be used in case of

dispute. The same method shall be used for the determination of the volume of

the sample, for selecting and preparing the sample, for calculating the bulk

density and for presenting the test report.

This Standard is applicable to the determination of the bulk density, water

absorption and apparent porosity of granular refractory materials.

2 Normative references

The following documents are essential to the application of this document. For

dated references, only the editions with the dates indicated are applicable to

this document. For undated references, only the latest editions (including all the

amendments) are applicable to this document.

GB/T 2997 Test method for bulk density, apparent porosity and true porosity

of dense shaped refractory products

GB/T 6005 Test sieves - Metal wire cloth, perforated metal plate and

electroformed sheet - Nominal sizes of openings

GB/T 8170 Rules of rounding off for numerical values and expression and

judgement of limiting values

8.1.5 Non-absorbent fiber cloth, such as polyester fiber cloth, nylon fiber cloth,

etc.

8.1.6 Vessel.

8.1.7 Vacuum equipment. It can decrease the absolute pressure to not greater

than 2,500MPa, and shall also be able to measure the absolute pressure value.

8.1.8 Immersion liquid. tap water or kerosene.

8.1.9 Mesh basket. It refers to the mesh basket with a handle, which is made

of sieve with a pore diameter of 1mm.

8.1.10 Vessel with an overflow pipe.

8.1.11 Cotton gauze. The dimension is about 60cm × 60cm.

8.1.12 Weighing bottle. with a diameter of 60mm and a height of 30mm.

8.1.13 Hydrostatic balance or hydrometer. with a division value of 0.001 g/cm3.

8.2 Test piece immersion

After weighing, carefully PLACE the test pieces on a piece of non-absorbent

fiber cloth (SEE Section 8.1.5). USE a string to wrap them firmly. PLACE in a

vessel (SEE Section 8.1.6). PLACE the vessel in the vacuum equipment (SEE

Section 8.1.7). VACUUM until the absolute pressure is less than 2,500MPa.

KEEP the test pieces at this degree of vacuum for 5min. Slowly INJECT the

immersion liquid (SEE Section 8.1.8) for absorption of test pieces within 5min,

until the test pieces are completely immersed. KEEP vacuuming for 5min.

STOP air exhaust. TAKE out the vessel. LET it stand in air, until the liquid inside

comes up to room temperature.

8.3 Determination of the apparent mass of saturated test pieces (m2)

HANG the mesh basket (SEE Section 8.1.9) on the balance hook so that the

mesh basket can completely immerse into the liquid. ZERO the balance. TAKE

out the mesh basket for standby application. OPEN the wrapping cloth.

Carefully SCRAPE the saturated test pieces into the mesh basket. Rapidly

MOVE the mesh basket into the immersion liquid in the vessel with an overflow

pipe. After the test pieces completely immerse into the immersion liquid, MOVE

the mesh basket up and down for several times so that the residual bubbles

can escape. HANG the mesh basket on the balance hook for weighing.

ACCURATE to 0.01g.

8.4 Determination of the mass of saturated test pieces (m3)

9.2 Determination of the test piece volume

After drying and weighing, PLACE the test pieces (SEE Chapter 7) into a beaker

(SEE Section 9.1.1). ADD the immersion liquid at room temperature until the

test pieces are completely submerged in it.

Before each use, REMOVE the grease in the burette (SEE Section 9.1.2).

FLUSH the burette afterwards until it becomes clean. ADD the immersion liquid

until it comes up to 20mL to 25mL. LET it stand for 1min. USE a magnifier (SEE

Section 9.1.3) to estimate the readi...

Share