PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 37536-2019 English PDF (GBT37536-2019)

GB/T 37536-2019 English PDF (GBT37536-2019)

Precio habitual

$500.00 USD

Precio habitual

Precio de oferta

$500.00 USD

Precio unitario

/

por

Los gastos de envío se calculan en la pantalla de pago.

No se pudo cargar la disponibilidad de retiro

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 37536-2019

Historical versions: GB/T 37536-2019

Preview True-PDF (Reload/Scroll if blank)

GB/T 37536-2019: Intermediate check specifications of measuring equipment for vehicle inspection body

GB/T 37536-2019

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 43.180

R 17

Intermediate Check Specifications of Measuring Equipment

for Vehicle Inspection Body

ISSUED ON: JUNE 4, 2019

IMPLEMENTED ON: JANUARY 1, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 4

4 Basic Requirements for Intermediate Check ... 5

5 Determination Principles for Intermediate Check Objects ... 6

6 Methods for Intermediate Check ... 6

7 Result Determination Principles and Processing of Intermediate Check ... 11

8 Records and Reports ... 12

Appendix A (Informative) Some Examples of Intermediate Check of Measuring

Equipment ... 13

Appendix B (informative) Examples of Intermediate Check Reports with Commonly

Used Intermediate Check Methods ... 44

Bibliography ... 48

Intermediate Check Specifications of Measuring Equipment

for Vehicle Inspection Body

1 Scope

This Standard specifies the basic requirements, determination principles for check objects,

methods for intermediate check, result determination principles and processing, as well as

records and reports of intermediate check of measuring equipment for vehicle inspection body

(hereinafter referred to as “intermediate check”).

This Standard applies to intermediate check conducted by vehicle inspection body on in-use

measuring equipment.

2 Normative References

The following documents are indispensable to the application of this document. In terms of

references with a specified date, only versions with a specified date are applicable to this

document. In terms of references without a specified date, the latest version (including all the

modifications) is applicable to this document.

GB/T 4091 Shewhart Control Charts

GB 7258 Technical Specifications for Safety of Power-driven Vehicles Operating on Roads

GB 18565 Composite Performance Requirement and Detecting Methods for Road Transport

Vehicles

JJF 1001 General Terms in Metrology and Their Definitions

RB/T 218 Competence Assessment for Inspection Body and Laboratory Mandatory Approval -

Requirements for Vehicles Inspection Body

3 Terms and Definitions

What is defined in GB 7258, GB 18565, JJF 1001 and RB/T 218, and the following terms and

definitions are applicable to this document.

3.1 Vehicle Safety Technology Inspection

Vehicle safety technology inspection refers to the activities of inspecting motor vehicles

operating on roads, including registration inspection of motor vehicles and inspection of in-use

motor vehicles pursuant to the Law of the People’s Republic of China on Road Traffic Safety

and the regulations for its implementation, and in accordance with the requirements of national

safety technology standards for motor vehicles.

3.2 Vehicle Emission Inspection

Vehicle emission inspection refers to the activities of conducting emission inspection on in-use

motor vehicles pursuant to the stipulations of the Law of the People’s Republic of China on the

Prevention and Control of Air Pollution, and in accordance with the standards and

specifications formulated by the environmental protection authority.

3.3 Automotive Multiple-function Inspection

Automotive multi-function inspection refers to the activities of inspecting the combination of

multiple technical properties, such as: vehicle dynamic quality, safety, fuel economy, service

reliability, exhaust pollutants and noise, as well as the completeness and status of vehicle

equipment, pursuant to the stipulations of the Regulations on the Administration of Road

Transport Vehicles, and in accordance with the standards and specifications formulated by the

competent transportation department of the State Council.

3.4 Vehicle Inspection

Vehicle inspection is a general term for three types of inspection activities: vehicle safety

technology inspection, vehicle emission inspection and automotive multiple-function

inspection.

3.5 Vehicle Inspection Body

Vehicle inspection body is a general term for inspection institutions engaged in three types of

inspection activities: vehicle safety technology inspection, vehicle emission inspection and

automotive multiple-function inspection.

3.6 Intermediate Check

Intermediate check refers to an operation carried out in accordance with the prescribed

procedures to determine whether the measuring equipment remains in the state at the time of

its verification / calibration.

4 Basic Requirements for Intermediate Check

4.1 The intermediate check shall be carried out in accordance with the prescribed procedures

and the formulated check plans.

4.2 The vehicle inspection body shall confirm the measuring instruments and equipment, select

the methods for checking and determining the frequency of checking in the intermediate check

plans.

4.3 The vehicle inspection body shall check certain parameters, ranges or measurement points

term stability, the shewhart control chart method may be used to perform the intermediate check

on the instruments and equipment. Usually, the instruments and equipment being checked are

used to periodically perform repeated measurements on the check standards, or the check

standards are used to periodically perform repeated measurements on the instruments and

equipment being checked, and the obtained characteristic values are used to draw the average

value control chart or the range control chart.

7 Result Determination Principles and Processing of

Intermediate Check

7.1 Determination Principles and Processing of Transfer Measurement Method

and Reference Substance Method

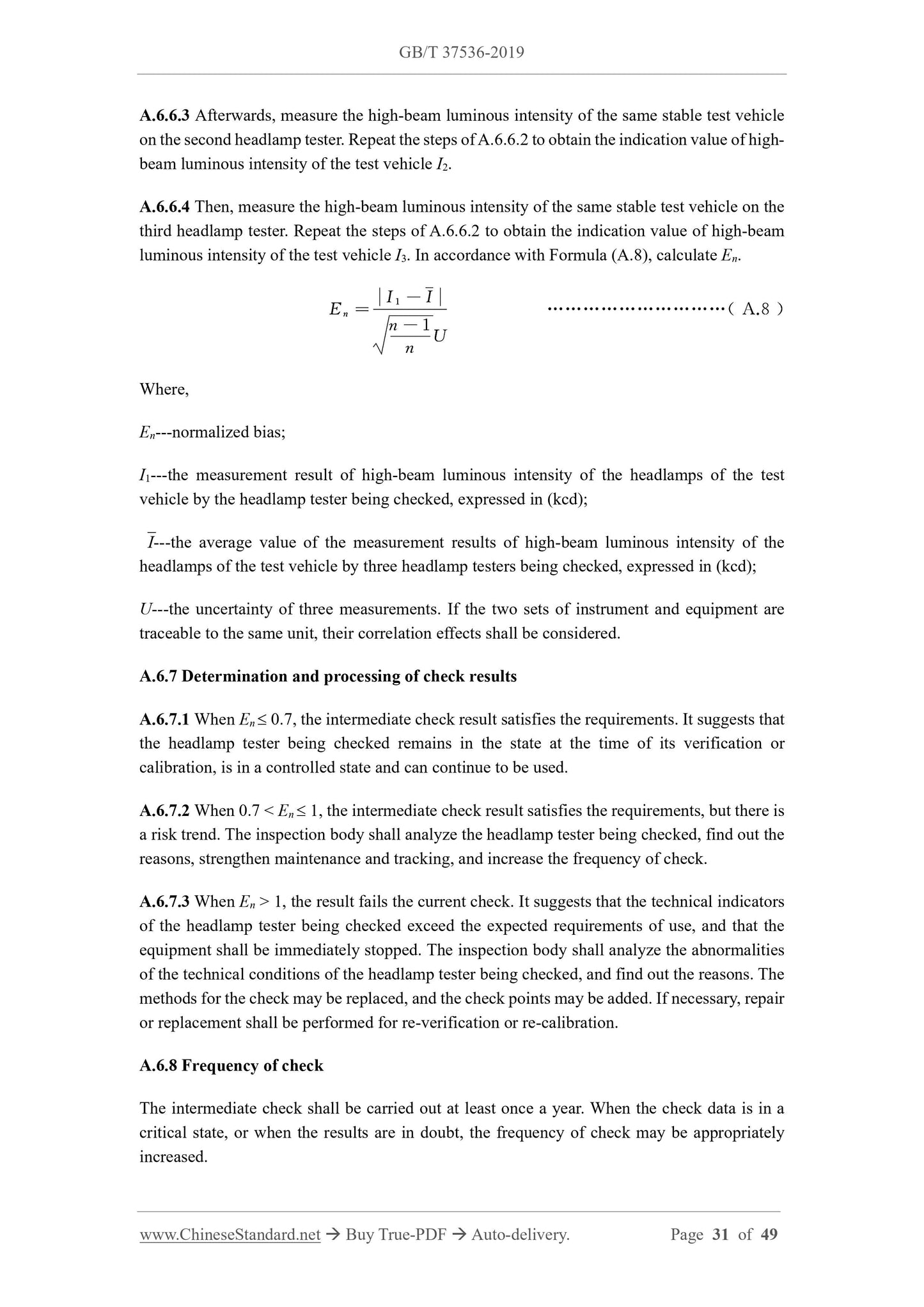

7.1.1 If Formula (1) or Formula (2), Formula (3) or Formula (4) is established, then, the result

passes the current check. It suggests that the measuring equipment remains in the state at the

time of its verification or calibration, is in a controlled state and can continue to be used.

7.1.2 Otherwise, Formula (1) or Formula (2), Formula (3) or Formula (4) do not hold, and the

result fails the current check. It suggests that the technical indicators of the measuring

equipment exceed the expected requirements of use, and that the equipment shall be

immediately stopped. The inspection body shall analyze the abnormalities of the technical

conditions of the measuring equipment being checked, and find out the reasons. The methods

for the check may be replaced, and the check points may be added. If necessary, repair or

replacement shall be performed for re-verification or re-calibration.

7.2 Determination Principles and Processing of Multi-set Comparison Method,

Two-set Comparison Method and Check Standard Method

7.2.1 When En 0.7, the intermediate check result satisfies the requirements, indicating that the

measuring equipment remains in the state at the time of its verification or calibration, is in a

controlled state and can continue to be used.

7.2.2 When 0.7 < En 1, the intermediate check result satisfies the requirements, but there is a

risk trend. The inspection body shall analyze the measuring equipment, find out the reasons,

strengthen maintenance and tracking, and increase the frequency of check.

7.2.3 When En > 1, the result fails the current intermediate check, indicating that the technical

indicators of the measuring equipment exceed the expected requirements of use, and that the

equipment shall be immediately stopped. The insp...

Get QUOTATION in 1-minute: Click GB/T 37536-2019

Historical versions: GB/T 37536-2019

Preview True-PDF (Reload/Scroll if blank)

GB/T 37536-2019: Intermediate check specifications of measuring equipment for vehicle inspection body

GB/T 37536-2019

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 43.180

R 17

Intermediate Check Specifications of Measuring Equipment

for Vehicle Inspection Body

ISSUED ON: JUNE 4, 2019

IMPLEMENTED ON: JANUARY 1, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 4

4 Basic Requirements for Intermediate Check ... 5

5 Determination Principles for Intermediate Check Objects ... 6

6 Methods for Intermediate Check ... 6

7 Result Determination Principles and Processing of Intermediate Check ... 11

8 Records and Reports ... 12

Appendix A (Informative) Some Examples of Intermediate Check of Measuring

Equipment ... 13

Appendix B (informative) Examples of Intermediate Check Reports with Commonly

Used Intermediate Check Methods ... 44

Bibliography ... 48

Intermediate Check Specifications of Measuring Equipment

for Vehicle Inspection Body

1 Scope

This Standard specifies the basic requirements, determination principles for check objects,

methods for intermediate check, result determination principles and processing, as well as

records and reports of intermediate check of measuring equipment for vehicle inspection body

(hereinafter referred to as “intermediate check”).

This Standard applies to intermediate check conducted by vehicle inspection body on in-use

measuring equipment.

2 Normative References

The following documents are indispensable to the application of this document. In terms of

references with a specified date, only versions with a specified date are applicable to this

document. In terms of references without a specified date, the latest version (including all the

modifications) is applicable to this document.

GB/T 4091 Shewhart Control Charts

GB 7258 Technical Specifications for Safety of Power-driven Vehicles Operating on Roads

GB 18565 Composite Performance Requirement and Detecting Methods for Road Transport

Vehicles

JJF 1001 General Terms in Metrology and Their Definitions

RB/T 218 Competence Assessment for Inspection Body and Laboratory Mandatory Approval -

Requirements for Vehicles Inspection Body

3 Terms and Definitions

What is defined in GB 7258, GB 18565, JJF 1001 and RB/T 218, and the following terms and

definitions are applicable to this document.

3.1 Vehicle Safety Technology Inspection

Vehicle safety technology inspection refers to the activities of inspecting motor vehicles

operating on roads, including registration inspection of motor vehicles and inspection of in-use

motor vehicles pursuant to the Law of the People’s Republic of China on Road Traffic Safety

and the regulations for its implementation, and in accordance with the requirements of national

safety technology standards for motor vehicles.

3.2 Vehicle Emission Inspection

Vehicle emission inspection refers to the activities of conducting emission inspection on in-use

motor vehicles pursuant to the stipulations of the Law of the People’s Republic of China on the

Prevention and Control of Air Pollution, and in accordance with the standards and

specifications formulated by the environmental protection authority.

3.3 Automotive Multiple-function Inspection

Automotive multi-function inspection refers to the activities of inspecting the combination of

multiple technical properties, such as: vehicle dynamic quality, safety, fuel economy, service

reliability, exhaust pollutants and noise, as well as the completeness and status of vehicle

equipment, pursuant to the stipulations of the Regulations on the Administration of Road

Transport Vehicles, and in accordance with the standards and specifications formulated by the

competent transportation department of the State Council.

3.4 Vehicle Inspection

Vehicle inspection is a general term for three types of inspection activities: vehicle safety

technology inspection, vehicle emission inspection and automotive multiple-function

inspection.

3.5 Vehicle Inspection Body

Vehicle inspection body is a general term for inspection institutions engaged in three types of

inspection activities: vehicle safety technology inspection, vehicle emission inspection and

automotive multiple-function inspection.

3.6 Intermediate Check

Intermediate check refers to an operation carried out in accordance with the prescribed

procedures to determine whether the measuring equipment remains in the state at the time of

its verification / calibration.

4 Basic Requirements for Intermediate Check

4.1 The intermediate check shall be carried out in accordance with the prescribed procedures

and the formulated check plans.

4.2 The vehicle inspection body shall confirm the measuring instruments and equipment, select

the methods for checking and determining the frequency of checking in the intermediate check

plans.

4.3 The vehicle inspection body shall check certain parameters, ranges or measurement points

term stability, the shewhart control chart method may be used to perform the intermediate check

on the instruments and equipment. Usually, the instruments and equipment being checked are

used to periodically perform repeated measurements on the check standards, or the check

standards are used to periodically perform repeated measurements on the instruments and

equipment being checked, and the obtained characteristic values are used to draw the average

value control chart or the range control chart.

7 Result Determination Principles and Processing of

Intermediate Check

7.1 Determination Principles and Processing of Transfer Measurement Method

and Reference Substance Method

7.1.1 If Formula (1) or Formula (2), Formula (3) or Formula (4) is established, then, the result

passes the current check. It suggests that the measuring equipment remains in the state at the

time of its verification or calibration, is in a controlled state and can continue to be used.

7.1.2 Otherwise, Formula (1) or Formula (2), Formula (3) or Formula (4) do not hold, and the

result fails the current check. It suggests that the technical indicators of the measuring

equipment exceed the expected requirements of use, and that the equipment shall be

immediately stopped. The inspection body shall analyze the abnormalities of the technical

conditions of the measuring equipment being checked, and find out the reasons. The methods

for the check may be replaced, and the check points may be added. If necessary, repair or

replacement shall be performed for re-verification or re-calibration.

7.2 Determination Principles and Processing of Multi-set Comparison Method,

Two-set Comparison Method and Check Standard Method

7.2.1 When En 0.7, the intermediate check result satisfies the requirements, indicating that the

measuring equipment remains in the state at the time of its verification or calibration, is in a

controlled state and can continue to be used.

7.2.2 When 0.7 < En 1, the intermediate check result satisfies the requirements, but there is a

risk trend. The inspection body shall analyze the measuring equipment, find out the reasons,

strengthen maintenance and tracking, and increase the frequency of check.

7.2.3 When En > 1, the result fails the current intermediate check, indicating that the technical

indicators of the measuring equipment exceed the expected requirements of use, and that the

equipment shall be immediately stopped. The insp...

Share