PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 38498-2020 English PDF (GBT38498-2020)

GB/T 38498-2020 English PDF (GBT38498-2020)

Precio habitual

$155.00 USD

Precio habitual

Precio de oferta

$155.00 USD

Precio unitario

/

por

Los gastos de envío se calculan en la pantalla de pago.

No se pudo cargar la disponibilidad de retiro

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 38498-2020

Historical versions: GB/T 38498-2020

Preview True-PDF (Reload/Scroll if blank)

GB/T 38498-2020: Evaluation method for determining metal corrosion of disinfectant

GB/T 38498-2020

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 11.080

C 50

Evaluation method for determining metal corrosion of

disinfectant

ISSUED ON: MARCH 06, 2020

IMPLEMENTED ON: OCTOBER 01, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Evaluation principle ... 5

5 Test methods ... 6

6 Calculation and report of metal corrosion rate ... 11

Evaluation method for determining metal corrosion of

disinfectant

1 Scope

This Standard specifies evaluation method for corrosion of disinfectants and

disinfection equipment to metals under the conditions of aerosol spray,

ultrasonic atomization, vaporization, gas, constant spray, wiping, immersion or

washing disinfection.

This Standard is applicable to evaluation on corrosion of metals by disinfectants

that come into contact with various metal and alloy materials during the

disinfection process and disinfection instruments that use chemical factors to

disinfect.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 700, Carbon structural steels

GB/T 1173, Casting aluminium alloys

GB/T 1175, Casting zinc alloys

GB/T 1176, Casting copper and copper alloys

GB/T 1220, Stainless steel bars

GB/T 2481.1, Bonded abrasives - Determination and designation of grain

size distribution - Part 1: Macrogrits F4 to F220

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 corrosion

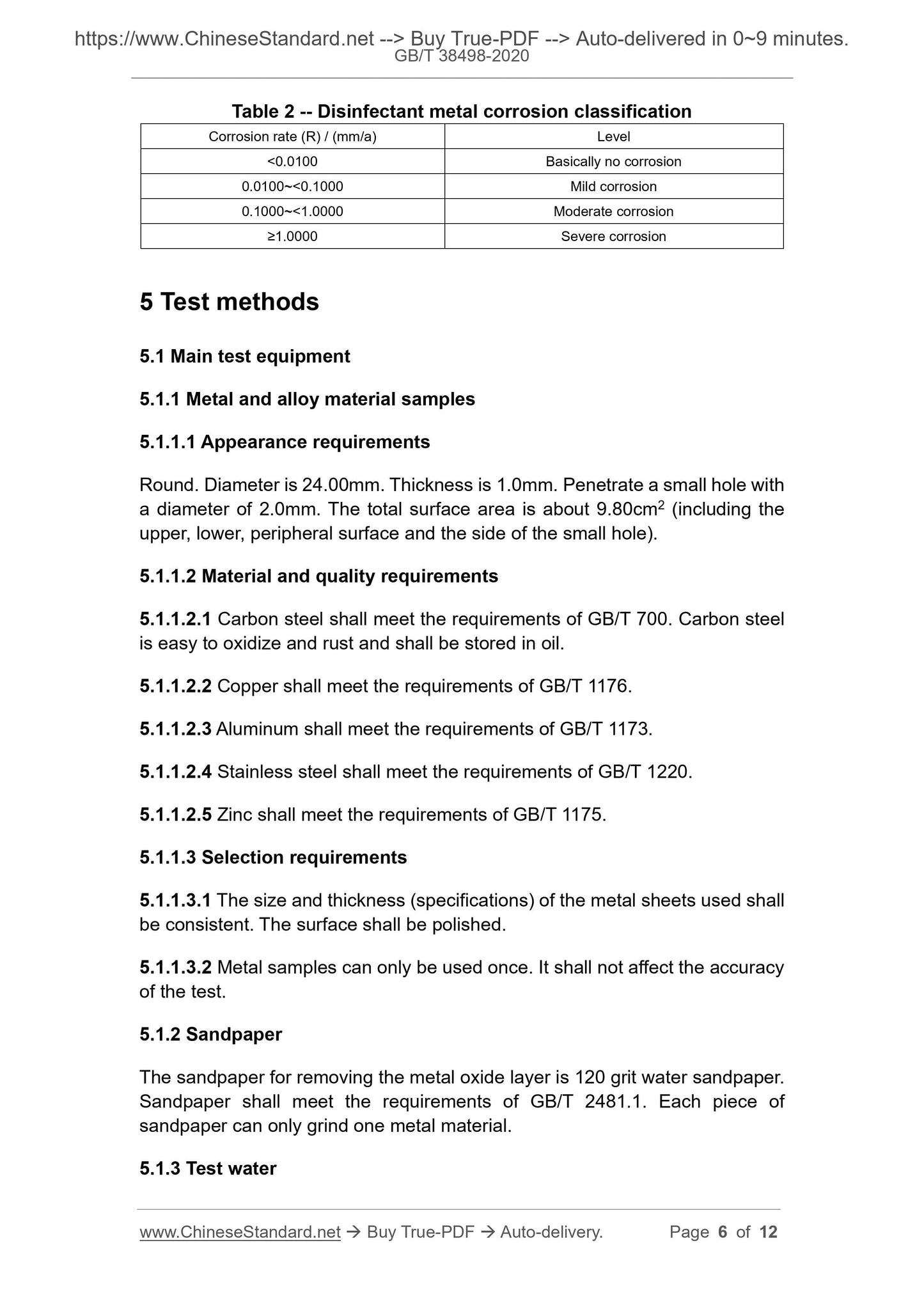

Table 2 -- Disinfectant metal corrosion classification

Corrosion rate (R) / (mm/a) Level

< 0.0100 Basically no corrosion

0.0100~< 0.1000 Mild corrosion

0.1000~< 1.0000 Moderate corrosion

≥1.0000 Severe corrosion

5 Test methods

5.1 Main test equipment

5.1.1 Metal and alloy material samples

5.1.1.1 Appearance requirements

Round. Diameter is 24.00mm. Thickness is 1.0mm. Penetrate a small hole with

a diameter of 2.0mm. The total surface area is about 9.80cm2 (including the

upper, lower, peripheral surface and the side of the small hole).

5.1.1.2 Material and quality requirements

5.1.1.2.1 Carbon steel shall meet the requirements of GB/T 700. Carbon steel

is easy to oxidize and rust and shall be stored in oil.

5.1.1.2.2 Copper shall meet the requirements of GB/T 1176.

5.1.1.2.3 Aluminum shall meet the requirements of GB/T 1173.

5.1.1.2.4 Stainless steel shall meet the requirements of GB/T 1220.

5.1.1.2.5 Zinc shall meet the requirements of GB/T 1175.

5.1.1.3 Selection requirements

5.1.1.3.1 The size and thickness (specifications) of the metal sheets used shall

be consistent. The surface shall be polished.

5.1.1.3.2 Metal samples can only be used once. It shall not affect the accuracy

of the test.

5.1.2 Sandpaper

The sandpaper for removing the metal oxide layer is 120 grit water sandpaper.

Sandpaper shall meet the requirements of GB/T 2481.1. Each piece of

sandpaper can only grind one metal material.

5.1.3 Test water

density is 1.19gcm-3) at room temperature for 1min~3min;

b) Carbon steel sheet: Soak in 75°C~90°C ammonium citrate solution (200g

of ammonium citrate is added with purified water to 1000mL) for 20min;

c) Aluminum sheet: Soak in nitric acid solution (100mL of 66%~68% nitric

acid is added with purified water to 1000mL; nitric acid density is 1.42gcm-

3) at room temperature for 1min~5min;

d) Stainless steel: Soak in 60°C nitric acid solution (100mL of 66%~68% nitric

acid is added with purified water to 1000mL; density of nitric acid is

1.42g·cm-3) for 20min;

e) Zinc: Soak in 70°C ammonium chloride solution (100g of ammonium

chloride is added with purified water to make 1000mL of solution) for

2min~5min.

5.2.2.2 After removing the corrosion products and cleaning the metal sample,

use coarse filter paper to absorb moisture. Place in a petri dish with filter paper.

Put into a 50°C incubator. Dry 1h. Use a plastic tweezer to clamp. Take out and

store in a desiccator. Place at room temperature and weigh.

5.2.3 Sample measurement

5.2.3.1 Use a Vernier caliper to measure the diameter, thickness and aperture

of the sample before the test (to the nearest of 0.1mm). Calculate the total

surface area of the sample.

5.2.3.2 Use an analytical balance to respectively weigh the sample before and

after cleaning. Zero the balance. Weigh each metal piece 3 times, to the nearest

of 0.1mg. Take the average value as the weight before and after the test.

5.2.3.3 When performing operations such as measuring size and weighing,

clean gloves shall be worn. The measuring tools used shall be clean and free

of oil. Use a plastic tweezer to clamp the sample. Do not touch the sample

directly with your hands.

5.3 Aerosol corrosion test

5.3.1 Test preparation

For a pair of adjacent aerosol cabinets (1m3) or aerosol chambers (20m3), one

is used for test and the other for control. The environment (including

temperature, humidity, light, airtightness and ventilation conditions) of a pair of

aerosol cabinets or aerosol chambers shall be consistent. The cabinet (or

chamber) shall be constructed of stainless steel or aluminum alloy and glass.

Temperature and humidity adjustment devices, as well as ventilator devices and

corresponding pipes shall be installed.

test needs to be interrupted for a long time, the test samples of the test group

and the control group shall be taken out of the aerosol cabinet (or chamber) at

the same time. Perform sample treatment in the same way as the sample after

the test is completed. Store in a desiccator after processing until the test is

resumed.

5.3.4 Test control

In the control group, except for replacing the disinfectant with test water or

turning off the disinfection factor of the disinfector, the rest of the test steps and

processes are the same as the test group. After the cycle is over, remove the

metal piece. Use the same method to clean, chemically treat, rinse, dry, and

weigh the samples of the test group. Calculate its average weight loss.

5.4 Full immersion corrosion test

5.4.1 Disinfectant replacement

For disinfectors with volatile or unstable active ingredients, such as chlorine

dioxide, acid potential water and oxidizing disinfectants, the disinfectant used

to soak the sample is changed once a day. When replacing the disinfectant, the

operation shall be rapid. The sample shall not be exposed to the air for too long.

For disinfectors with stable active ingredients, such as guanidine, phenols,

quaternary ammonium salts, aldehydes, there is no need to change the

disinfectant used to soak the sample.

5.4.2 Test steps

5.4.2.1 Soaking method: Prepare the disinfectant for testing according to the

highest concentration of disinfectant. Use it to soak the test sample. When

soaking, each metal piece needs to be soaked in at least 200mL of disinfectant.

5.4.2.2 Continuous flushing method: Adjust the generator disinfection factor to

the highest concentration. Insert the outlet pipe (non-metallic) into the bottom

of the soaking container. Turn on the generator. Adjust the flow to make the

Get QUOTATION in 1-minute: Click GB/T 38498-2020

Historical versions: GB/T 38498-2020

Preview True-PDF (Reload/Scroll if blank)

GB/T 38498-2020: Evaluation method for determining metal corrosion of disinfectant

GB/T 38498-2020

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 11.080

C 50

Evaluation method for determining metal corrosion of

disinfectant

ISSUED ON: MARCH 06, 2020

IMPLEMENTED ON: OCTOBER 01, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of the People's Republic of

China.

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Evaluation principle ... 5

5 Test methods ... 6

6 Calculation and report of metal corrosion rate ... 11

Evaluation method for determining metal corrosion of

disinfectant

1 Scope

This Standard specifies evaluation method for corrosion of disinfectants and

disinfection equipment to metals under the conditions of aerosol spray,

ultrasonic atomization, vaporization, gas, constant spray, wiping, immersion or

washing disinfection.

This Standard is applicable to evaluation on corrosion of metals by disinfectants

that come into contact with various metal and alloy materials during the

disinfection process and disinfection instruments that use chemical factors to

disinfect.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 700, Carbon structural steels

GB/T 1173, Casting aluminium alloys

GB/T 1175, Casting zinc alloys

GB/T 1176, Casting copper and copper alloys

GB/T 1220, Stainless steel bars

GB/T 2481.1, Bonded abrasives - Determination and designation of grain

size distribution - Part 1: Macrogrits F4 to F220

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1 corrosion

Table 2 -- Disinfectant metal corrosion classification

Corrosion rate (R) / (mm/a) Level

< 0.0100 Basically no corrosion

0.0100~< 0.1000 Mild corrosion

0.1000~< 1.0000 Moderate corrosion

≥1.0000 Severe corrosion

5 Test methods

5.1 Main test equipment

5.1.1 Metal and alloy material samples

5.1.1.1 Appearance requirements

Round. Diameter is 24.00mm. Thickness is 1.0mm. Penetrate a small hole with

a diameter of 2.0mm. The total surface area is about 9.80cm2 (including the

upper, lower, peripheral surface and the side of the small hole).

5.1.1.2 Material and quality requirements

5.1.1.2.1 Carbon steel shall meet the requirements of GB/T 700. Carbon steel

is easy to oxidize and rust and shall be stored in oil.

5.1.1.2.2 Copper shall meet the requirements of GB/T 1176.

5.1.1.2.3 Aluminum shall meet the requirements of GB/T 1173.

5.1.1.2.4 Stainless steel shall meet the requirements of GB/T 1220.

5.1.1.2.5 Zinc shall meet the requirements of GB/T 1175.

5.1.1.3 Selection requirements

5.1.1.3.1 The size and thickness (specifications) of the metal sheets used shall

be consistent. The surface shall be polished.

5.1.1.3.2 Metal samples can only be used once. It shall not affect the accuracy

of the test.

5.1.2 Sandpaper

The sandpaper for removing the metal oxide layer is 120 grit water sandpaper.

Sandpaper shall meet the requirements of GB/T 2481.1. Each piece of

sandpaper can only grind one metal material.

5.1.3 Test water

density is 1.19gcm-3) at room temperature for 1min~3min;

b) Carbon steel sheet: Soak in 75°C~90°C ammonium citrate solution (200g

of ammonium citrate is added with purified water to 1000mL) for 20min;

c) Aluminum sheet: Soak in nitric acid solution (100mL of 66%~68% nitric

acid is added with purified water to 1000mL; nitric acid density is 1.42gcm-

3) at room temperature for 1min~5min;

d) Stainless steel: Soak in 60°C nitric acid solution (100mL of 66%~68% nitric

acid is added with purified water to 1000mL; density of nitric acid is

1.42g·cm-3) for 20min;

e) Zinc: Soak in 70°C ammonium chloride solution (100g of ammonium

chloride is added with purified water to make 1000mL of solution) for

2min~5min.

5.2.2.2 After removing the corrosion products and cleaning the metal sample,

use coarse filter paper to absorb moisture. Place in a petri dish with filter paper.

Put into a 50°C incubator. Dry 1h. Use a plastic tweezer to clamp. Take out and

store in a desiccator. Place at room temperature and weigh.

5.2.3 Sample measurement

5.2.3.1 Use a Vernier caliper to measure the diameter, thickness and aperture

of the sample before the test (to the nearest of 0.1mm). Calculate the total

surface area of the sample.

5.2.3.2 Use an analytical balance to respectively weigh the sample before and

after cleaning. Zero the balance. Weigh each metal piece 3 times, to the nearest

of 0.1mg. Take the average value as the weight before and after the test.

5.2.3.3 When performing operations such as measuring size and weighing,

clean gloves shall be worn. The measuring tools used shall be clean and free

of oil. Use a plastic tweezer to clamp the sample. Do not touch the sample

directly with your hands.

5.3 Aerosol corrosion test

5.3.1 Test preparation

For a pair of adjacent aerosol cabinets (1m3) or aerosol chambers (20m3), one

is used for test and the other for control. The environment (including

temperature, humidity, light, airtightness and ventilation conditions) of a pair of

aerosol cabinets or aerosol chambers shall be consistent. The cabinet (or

chamber) shall be constructed of stainless steel or aluminum alloy and glass.

Temperature and humidity adjustment devices, as well as ventilator devices and

corresponding pipes shall be installed.

test needs to be interrupted for a long time, the test samples of the test group

and the control group shall be taken out of the aerosol cabinet (or chamber) at

the same time. Perform sample treatment in the same way as the sample after

the test is completed. Store in a desiccator after processing until the test is

resumed.

5.3.4 Test control

In the control group, except for replacing the disinfectant with test water or

turning off the disinfection factor of the disinfector, the rest of the test steps and

processes are the same as the test group. After the cycle is over, remove the

metal piece. Use the same method to clean, chemically treat, rinse, dry, and

weigh the samples of the test group. Calculate its average weight loss.

5.4 Full immersion corrosion test

5.4.1 Disinfectant replacement

For disinfectors with volatile or unstable active ingredients, such as chlorine

dioxide, acid potential water and oxidizing disinfectants, the disinfectant used

to soak the sample is changed once a day. When replacing the disinfectant, the

operation shall be rapid. The sample shall not be exposed to the air for too long.

For disinfectors with stable active ingredients, such as guanidine, phenols,

quaternary ammonium salts, aldehydes, there is no need to change the

disinfectant used to soak the sample.

5.4.2 Test steps

5.4.2.1 Soaking method: Prepare the disinfectant for testing according to the

highest concentration of disinfectant. Use it to soak the test sample. When

soaking, each metal piece needs to be soaked in at least 200mL of disinfectant.

5.4.2.2 Continuous flushing method: Adjust the generator disinfection factor to

the highest concentration. Insert the outlet pipe (non-metallic) into the bottom

of the soaking container. Turn on the generator. Adjust the flow to make the

Share