PayPal, credit cards. Download editable-PDF & invoice in 1 second!

QC/T 1150-2021 English PDF (QCT1150-2021)

QC/T 1150-2021 English PDF (QCT1150-2021)

Precio habitual

$260.00 USD

Precio habitual

Precio de oferta

$260.00 USD

Precio unitario

/

por

Los gastos de envío se calculan en la pantalla de pago.

No se pudo cargar la disponibilidad de retiro

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click QC/T 1150-2021

Historical versions: QC/T 1150-2021

Preview True-PDF (Reload/Scroll if blank)

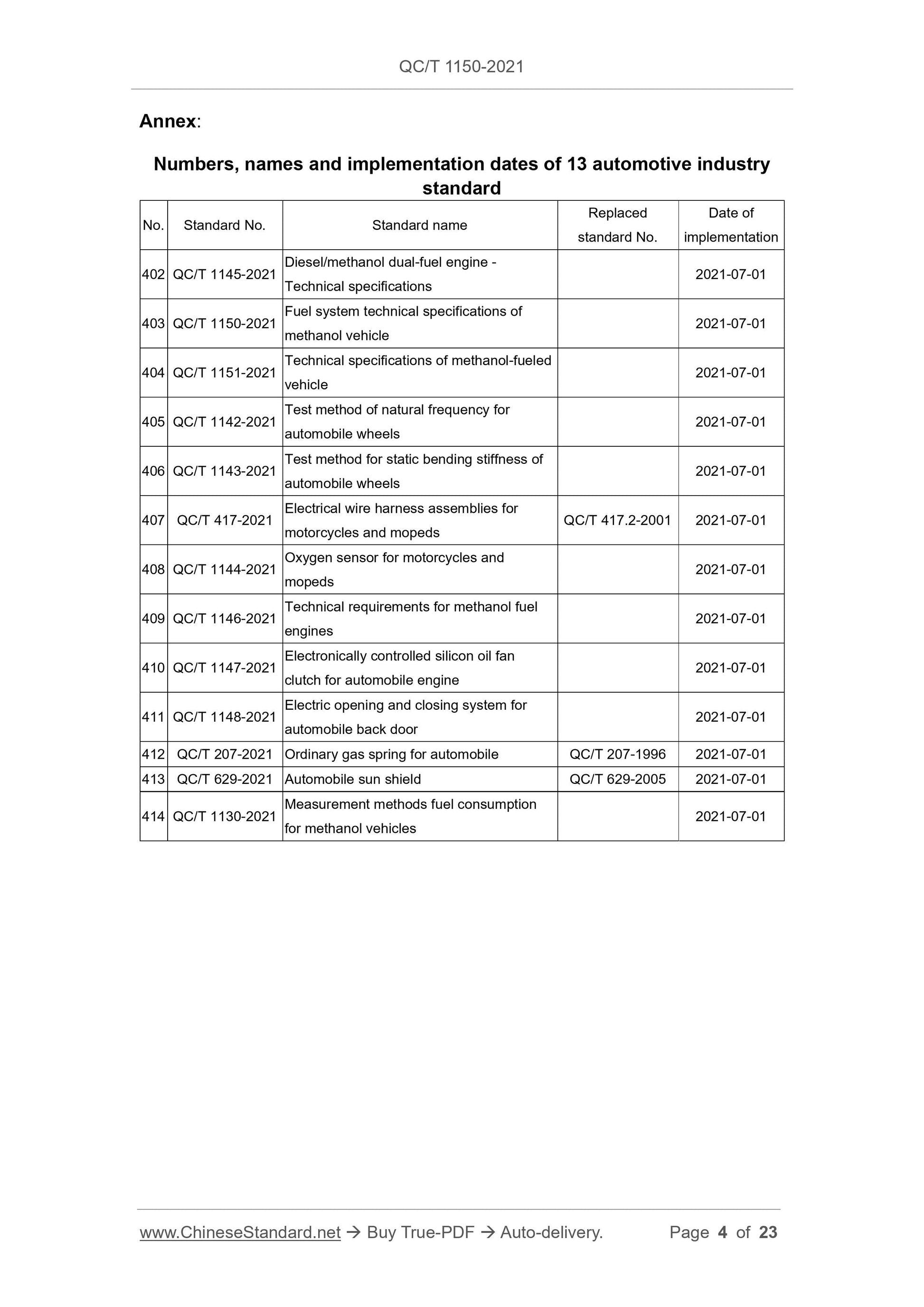

QC/T 1150-2021: Fuel system technical specifications of methanol vehicle

QC/T 1150-2021

QC

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.080.01

CCS T 47

Technical specifications of methanol automobile fuel

system

ISSUED ON: MARCH 05, 2021

IMPLEMENTED ON: JULY 01, 2021

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 5

1 Scope ... 6

2 Normative references ... 6

3 Terms and definitions ... 7

4 Technical requirements ... 8

5 Test method ... 14

Appendix A (Normative) Specification for life cycle test of methanol pipe joints

... 19

Technical specifications of methanol automobile fuel

system

1 Scope

This document specifies the terms and definitions, technical requirements, test

methods of methanol automobile fuel system.

This document applies to vehicles, which are equipped with methanol single-

fuel engines or diesel/methanol dual-fuel engines.

2 Normative references

The contents of the following documents constitute the indispensable clauses

of this document through normative references in the text. Among them, for

dated reference documents, only the version corresponding to that date is

applicable to this document; for undated reference documents, the latest

version (including all amendments) is applicable to this document.

GB/T 1690 Rubber, vulcanized or thermoplastic - Determination of the effect

of liquids

GB/T 4334 Corrosion of metals and alloys - Test methods for intergranular

corrosion of austenitic and ferritic-austenitic (duplex) stainless steels

GB/T 5563 Rubber and plastic hoses and hose assemblies - Hydrostatic

testing

GB/T 5567 Rubber and plastic hoses and hose assemblies - Determination

of resistance to vacuum

GB 7258 Technical specifications for safety of power-driven vehicles

operating on roads

GB/T 7762 Rubber, vulcanized or thermoplastic - Resistance to ozone

cracking - Static strain testing

GB/T 11547 Plastic - Methods of test for the determination of the effects of

immersion in liquid chemicals

GB/T 14905 Rubber and plastics hoses - Determination of adhesion

between components

4.2.1 The methanol automobile fuel system shall be manufactured, in

accordance with the product drawings and other technical documents, which

are approved by the prescribed procedures. The safety protection of the fuel

system shall meet the requirements of GB 7258.

4.2.2 All electrical components, in the methanol automobile fuel system, shall

meet the requirements of QC/T 413.

4.2.3 All parts of the methanol automobile fuel system, in contact with methanol,

shall be resistant to methanol corrosion and swelling. Rubber parts shall comply

with the requirements of GB/T 1690; plastic parts shall comply with the

requirements of GB/T 11547; metal parts shall comply with the requirements of

GB/T 4334. Use the M100 automobile methanol fuel, to carry out 120 h

immersion test, at the test temperature of 40 °C ± 2 °C; the mass change rate

of the specimen, before and after immersion, shall not exceed 5%; the volume

change rate shall not exceed 15%; the mechanical properties change shall not

exceed 10%.

4.2.4 The methanol box shall have the function of pressure regulating and

control.

4.2.5 The working environment temperature shall meet the following

requirements:

a) Parts installed in the engine compartment: -40 °C ~ 120 °C;

b) Parts installed in other parts: -40 °C ~ 85 °C.

4.2.6 The methanol automobile fuel system shall have a methanol evaporation

control device.

4.2.7 There shall be obvious warning signs, at the methanol fuel filling port.

4.2.8 The design and installation of methanol automobile fuel system's pipelines

shall ensure the safety and reliability of the pipeline of whole vehicle.

4.2.9 Methanol delivery pipes and other fuel pipes shall be clearly distinguished

or marked in appearance.

4.3 System requirements

4.3.1 Technical requirements for methanol box assembly

4.3.1.1 The appearance of the metal methanol box assembly, the material of

the methanol box, the cleanliness of the interior of the methanol box, the

methanol box cover and the filling port, the safety performance of the methanol

box, shall meet the requirements of 4.2 ~ 4.4 and 4.6 ~ 4.7 in QC/T 644-2014.

4.3.1.2 The performance of the plastic methanol box assembly shall be

implemented in accordance with the provisions of GB 18296.

4.3.1.3 The methanol box assembly shall be equipped with a fuel evaporation

exhaust port, which shall be located above the methanol liquid level, when the

rated capacity of the methanol box is reached. The methanol vapor shall be

able to exit the methanol box, through the evaporation exhaust port.

4.3.2 Technical requirements for methanol level sensor

4.3.2.1 Normal working environment of methanol level sensor, appearance,

state of movable part, basic error, insulation pressure resistance, resistance to

temperature change, temperature influence, humidity resistance and resistance

to cyclic humidity change, vibration resistance, durability, airtightness shall

meet the requirements of 4.2 ~ 4.10 and 4.12 in QC/T 823-2009.

4.3.2.2 The methanol level sensor shall be able to withstand methanol

immersion. After testing in accordance with the provisions of 5.1, the metal parts

and non-metal parts of the sensor shall meet the requirements of 4.2.3; the

functions shall meet the requirements of 4.3 and 4.4 of QC/T 823-2009.

4.3.3 Technical requirements for methanol pump

4.3.3.1 The flow rate shall be able to meet the requirements of the maximum

fuel consumption of the engine.

4.3.3.2 The methanol pump shall be marked with the flow direction of the

methanol in and out.

4.3.3.3 The allowable medium of the methanol pump shall meet the

requirements of M100 automobile methanol fuel.

4.3.3.4 Appearance, surface protection, materials shall meet the following

requirements:

a) The methanol pump shall have no obvious damage, cracks, shrinkage,

deformation, corrosion, or other defects, that affect the working

performance; the plastic components shall have no obvious color

difference;

b) The electroplated parts or chemically treated parts shall comply with the

provisions of 5.2 in QC/T 625-2013; there shall be no red rust after the

96h neutral salt spray test.

4.3.3.5 The working voltage shall meet the following requirements:

a) Nominal voltage: 12V, range 8V ~ 16V;

After processing in accordance with the provisions of 5.3.1, the initial burst

pressure of high-pressure pipelines, such as oil supply and return pipe, shall

not be less than 5 MPa. The initial burst pressure of low-pressure pipelines,

such as ventilation and refueling pipes, shall not be less than 0.35 MPa.

4.3.5.3 Initial bonding strength of methanol delivery pipe

After processing as specified in 5.3.2, the initial bonding strength between

adjacent adhesive layers shall not be less than 1.5 N/mm.

4.3.5.4 Vacuum resistance of methanol delivery pipe

When tested according to the requirements of 5.3.3, the vacuum degree shall

meet the requirements of Table 1 in 5.3.3; the pressure holding time shall be

within the range of 15 s ~ 60 s; the steel ball of the specified diameter can pass

freely.

4.3.5.5 Low temperature performance of methanol delivery pipe

After treatment in accordance with the provisions of 5.3.4, the inner and outer

walls of the methanol delivery hose shall be free of cracks AND meet the

requirements of 4.3.5.2.

4.3.5.6 High temperature resistance of methanol ...

Get QUOTATION in 1-minute: Click QC/T 1150-2021

Historical versions: QC/T 1150-2021

Preview True-PDF (Reload/Scroll if blank)

QC/T 1150-2021: Fuel system technical specifications of methanol vehicle

QC/T 1150-2021

QC

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.080.01

CCS T 47

Technical specifications of methanol automobile fuel

system

ISSUED ON: MARCH 05, 2021

IMPLEMENTED ON: JULY 01, 2021

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 5

1 Scope ... 6

2 Normative references ... 6

3 Terms and definitions ... 7

4 Technical requirements ... 8

5 Test method ... 14

Appendix A (Normative) Specification for life cycle test of methanol pipe joints

... 19

Technical specifications of methanol automobile fuel

system

1 Scope

This document specifies the terms and definitions, technical requirements, test

methods of methanol automobile fuel system.

This document applies to vehicles, which are equipped with methanol single-

fuel engines or diesel/methanol dual-fuel engines.

2 Normative references

The contents of the following documents constitute the indispensable clauses

of this document through normative references in the text. Among them, for

dated reference documents, only the version corresponding to that date is

applicable to this document; for undated reference documents, the latest

version (including all amendments) is applicable to this document.

GB/T 1690 Rubber, vulcanized or thermoplastic - Determination of the effect

of liquids

GB/T 4334 Corrosion of metals and alloys - Test methods for intergranular

corrosion of austenitic and ferritic-austenitic (duplex) stainless steels

GB/T 5563 Rubber and plastic hoses and hose assemblies - Hydrostatic

testing

GB/T 5567 Rubber and plastic hoses and hose assemblies - Determination

of resistance to vacuum

GB 7258 Technical specifications for safety of power-driven vehicles

operating on roads

GB/T 7762 Rubber, vulcanized or thermoplastic - Resistance to ozone

cracking - Static strain testing

GB/T 11547 Plastic - Methods of test for the determination of the effects of

immersion in liquid chemicals

GB/T 14905 Rubber and plastics hoses - Determination of adhesion

between components

4.2.1 The methanol automobile fuel system shall be manufactured, in

accordance with the product drawings and other technical documents, which

are approved by the prescribed procedures. The safety protection of the fuel

system shall meet the requirements of GB 7258.

4.2.2 All electrical components, in the methanol automobile fuel system, shall

meet the requirements of QC/T 413.

4.2.3 All parts of the methanol automobile fuel system, in contact with methanol,

shall be resistant to methanol corrosion and swelling. Rubber parts shall comply

with the requirements of GB/T 1690; plastic parts shall comply with the

requirements of GB/T 11547; metal parts shall comply with the requirements of

GB/T 4334. Use the M100 automobile methanol fuel, to carry out 120 h

immersion test, at the test temperature of 40 °C ± 2 °C; the mass change rate

of the specimen, before and after immersion, shall not exceed 5%; the volume

change rate shall not exceed 15%; the mechanical properties change shall not

exceed 10%.

4.2.4 The methanol box shall have the function of pressure regulating and

control.

4.2.5 The working environment temperature shall meet the following

requirements:

a) Parts installed in the engine compartment: -40 °C ~ 120 °C;

b) Parts installed in other parts: -40 °C ~ 85 °C.

4.2.6 The methanol automobile fuel system shall have a methanol evaporation

control device.

4.2.7 There shall be obvious warning signs, at the methanol fuel filling port.

4.2.8 The design and installation of methanol automobile fuel system's pipelines

shall ensure the safety and reliability of the pipeline of whole vehicle.

4.2.9 Methanol delivery pipes and other fuel pipes shall be clearly distinguished

or marked in appearance.

4.3 System requirements

4.3.1 Technical requirements for methanol box assembly

4.3.1.1 The appearance of the metal methanol box assembly, the material of

the methanol box, the cleanliness of the interior of the methanol box, the

methanol box cover and the filling port, the safety performance of the methanol

box, shall meet the requirements of 4.2 ~ 4.4 and 4.6 ~ 4.7 in QC/T 644-2014.

4.3.1.2 The performance of the plastic methanol box assembly shall be

implemented in accordance with the provisions of GB 18296.

4.3.1.3 The methanol box assembly shall be equipped with a fuel evaporation

exhaust port, which shall be located above the methanol liquid level, when the

rated capacity of the methanol box is reached. The methanol vapor shall be

able to exit the methanol box, through the evaporation exhaust port.

4.3.2 Technical requirements for methanol level sensor

4.3.2.1 Normal working environment of methanol level sensor, appearance,

state of movable part, basic error, insulation pressure resistance, resistance to

temperature change, temperature influence, humidity resistance and resistance

to cyclic humidity change, vibration resistance, durability, airtightness shall

meet the requirements of 4.2 ~ 4.10 and 4.12 in QC/T 823-2009.

4.3.2.2 The methanol level sensor shall be able to withstand methanol

immersion. After testing in accordance with the provisions of 5.1, the metal parts

and non-metal parts of the sensor shall meet the requirements of 4.2.3; the

functions shall meet the requirements of 4.3 and 4.4 of QC/T 823-2009.

4.3.3 Technical requirements for methanol pump

4.3.3.1 The flow rate shall be able to meet the requirements of the maximum

fuel consumption of the engine.

4.3.3.2 The methanol pump shall be marked with the flow direction of the

methanol in and out.

4.3.3.3 The allowable medium of the methanol pump shall meet the

requirements of M100 automobile methanol fuel.

4.3.3.4 Appearance, surface protection, materials shall meet the following

requirements:

a) The methanol pump shall have no obvious damage, cracks, shrinkage,

deformation, corrosion, or other defects, that affect the working

performance; the plastic components shall have no obvious color

difference;

b) The electroplated parts or chemically treated parts shall comply with the

provisions of 5.2 in QC/T 625-2013; there shall be no red rust after the

96h neutral salt spray test.

4.3.3.5 The working voltage shall meet the following requirements:

a) Nominal voltage: 12V, range 8V ~ 16V;

After processing in accordance with the provisions of 5.3.1, the initial burst

pressure of high-pressure pipelines, such as oil supply and return pipe, shall

not be less than 5 MPa. The initial burst pressure of low-pressure pipelines,

such as ventilation and refueling pipes, shall not be less than 0.35 MPa.

4.3.5.3 Initial bonding strength of methanol delivery pipe

After processing as specified in 5.3.2, the initial bonding strength between

adjacent adhesive layers shall not be less than 1.5 N/mm.

4.3.5.4 Vacuum resistance of methanol delivery pipe

When tested according to the requirements of 5.3.3, the vacuum degree shall

meet the requirements of Table 1 in 5.3.3; the pressure holding time shall be

within the range of 15 s ~ 60 s; the steel ball of the specified diameter can pass

freely.

4.3.5.5 Low temperature performance of methanol delivery pipe

After treatment in accordance with the provisions of 5.3.4, the inner and outer

walls of the methanol delivery hose shall be free of cracks AND meet the

requirements of 4.3.5.2.

4.3.5.6 High temperature resistance of methanol ...

Share