PayPal, credit cards. Download editable-PDF & invoice in 1 second!

QC/T 798-2008 English PDF (QCT798-2008)

QC/T 798-2008 English PDF (QCT798-2008)

Precio habitual

$150.00 USD

Precio habitual

Precio de oferta

$150.00 USD

Precio unitario

/

por

Los gastos de envío se calculan en la pantalla de pago.

No se pudo cargar la disponibilidad de retiro

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click QC/T 798-2008

Historical versions: QC/T 798-2008

Preview True-PDF (Reload/Scroll if blank)

QC/T 798-2008: Multi-layers plastic tubing for automotive fuel system

QC/T 798-2008

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

Multilayers plastic tubing for automotive fuel system

ISSUED ON: FEBRUARY 01, 2008

IMPLEMENTED ON: JULY 01, 2008

Issued by: Ministry of Industry and Information Technology of PRC

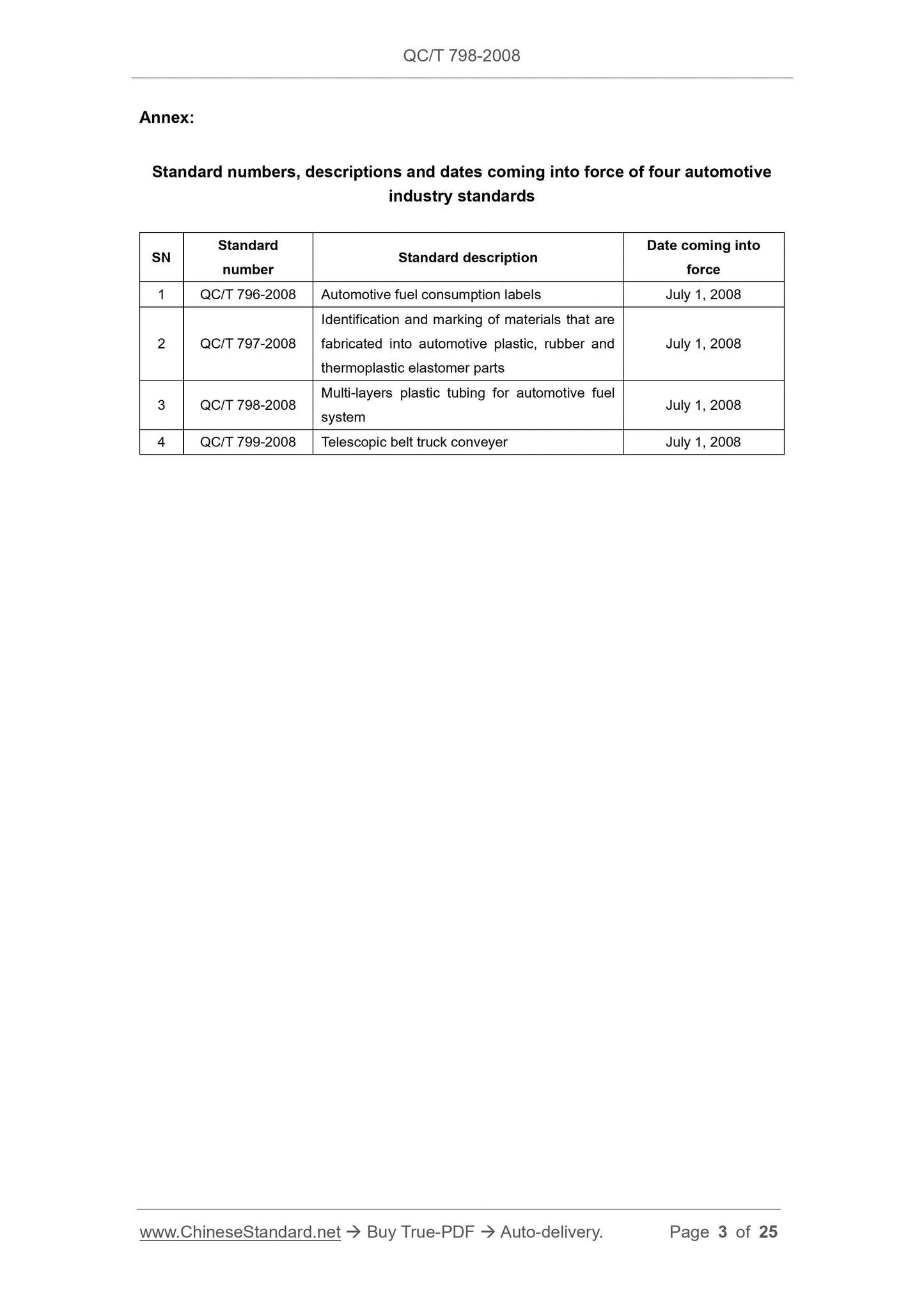

Annex:

Standard numbers, descriptions and dates coming into force of four automotive

industry standards

SN Standard number Standard description

Date coming into

force

1 QC/T 796-2008 Automotive fuel consumption labels July 1, 2008

2 QC/T 797-2008

Identification and marking of materials that are

fabricated into automotive plastic, rubber and

thermoplastic elastomer parts

July 1, 2008

3 QC/T 798-2008 Multi-layers plastic tubing for automotive fuel system July 1, 2008

4 QC/T 799-2008 Telescopic belt truck conveyer July 1, 2008

Table of Contents

Foreword ... 5

1 Scope ... 6

2 Normative references ... 6

3 Terms and definitions ... 6

4 Specification dimension ... 7

5 General requirements ... 8

6 Performance requirements ... 9

7 Test methods ... 10

8 Inspection rules ... 20

9 Markings and signs ... 21

10 Packaging, transportation, storage ... 22

Appendix A (Normative) Specifications for permeability resistance test ... 23

Multilayers plastic tubing for automotive fuel system

1 Scope

This standard specifies the dimensional specifications, appearance, technical

requirements, test methods, inspection rules, markings, packaging,

transportation, storage of multilayer plastic tubing for automotive fuel systems

(hereinafter referred to as multilayer tubing) and tube assemblies.

This standard is applicable to multilayer plastic fuel tubes which have a working

temperature between -40 °C and +115 °C (continuous use temperature shall

not exceed 90 °C) and maximum working pressure of not more than 0.7 MPa.

2 Normative references

The provisions in following documents become the provisions of this standard

through reference in this standard. For the dated references, the subsequent

amendments (excluding corrections) or revisions do not apply to this standard;

however, parties who reach an agreement based on this standard are

encouraged to study if the latest versions of these documents are applicable.

For undated references, the latest edition of the referenced document applies.

GB/T 528-1998 Determination of tensile stress-strain properties of

vulcanized rubber or thermoplastic rubber

GB/T 528-1998 Rubber, vulcanized or thermoplastic - Determination of

tensile stress-strain properties (ISO 527 -2: 1993 IDT)

GB/T 2828.1-2003 Sampling procedures for inspection by attributes - Part 1:

Sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot

inspection (ISO 2859-1:1999 IDT)

GB/T 2918-1998 Plastics - Standard atmospheres for conditioning and

testing (ISO 291:1997 IDT)

3 Terms and definitions

The following terms and definitions apply to this standard.

3.1

Multilayer plastic tubing

More than two layers of non-metallic plastic tubes which are made of

materials of different properties and different types, without connectors.

3.2

Tube assemblies

A combination of a multilayer tube and a tube joint which have a specified

length and shape.

4 Specification dimension

4.1 Structure

The multilayer tube is a multilayer structure which contains the wall-thickness

of the main body. The name of material is generally indicated on the drawing. If

specified, it shall identify each layer of all tube layers.

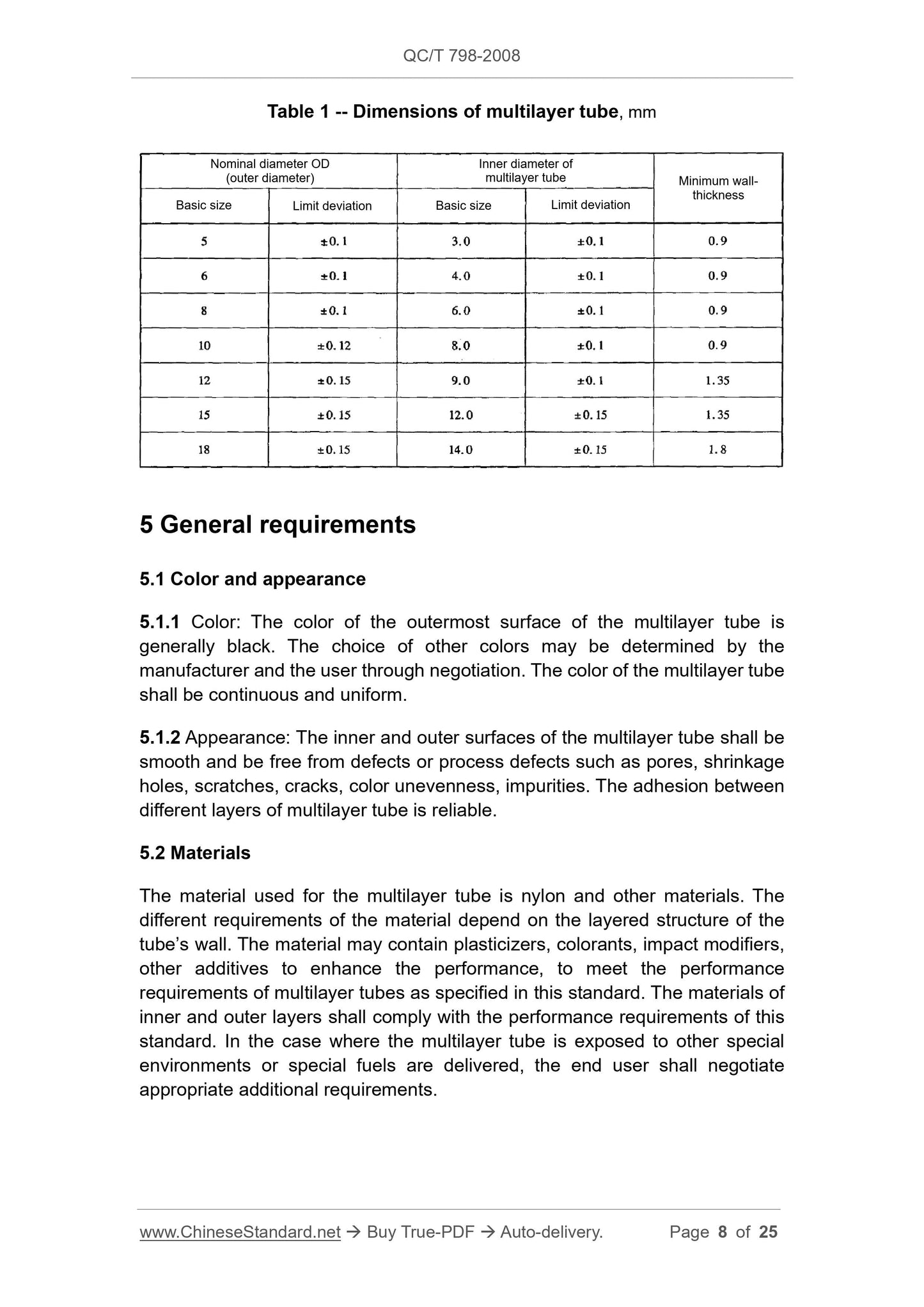

4.2 Dimensions and tolerances

Table 1 provides the dimensions and wall-thickness of various types of

multilayer tubes of this standard. The thickness and tolerance for each layer

may be determined by the manufacturer and the user through negotiation. The

dimensions and tolerances of the multilayer tube are indicated by mm.

4.3 Wall-thickness

Multilayer tubes of different sizes which are made by materials of different

grades have different wall-thicknesses. The minimum wall-thickness of a

straight tube which has a nominal diameter equal to 10 mm is 0.9 mm. The

larger the nominal diameter, the larger the wall-thickness. The requirements for

wall-thickness are as detailed in Table 1.

Note: Some of the following factors influence the choice of wall-thickness:

a) High burst-pressure requirements mean higher wall-thickness

requirements;

b) The thicker the wall-thickness, the greater the minimum bending radius.

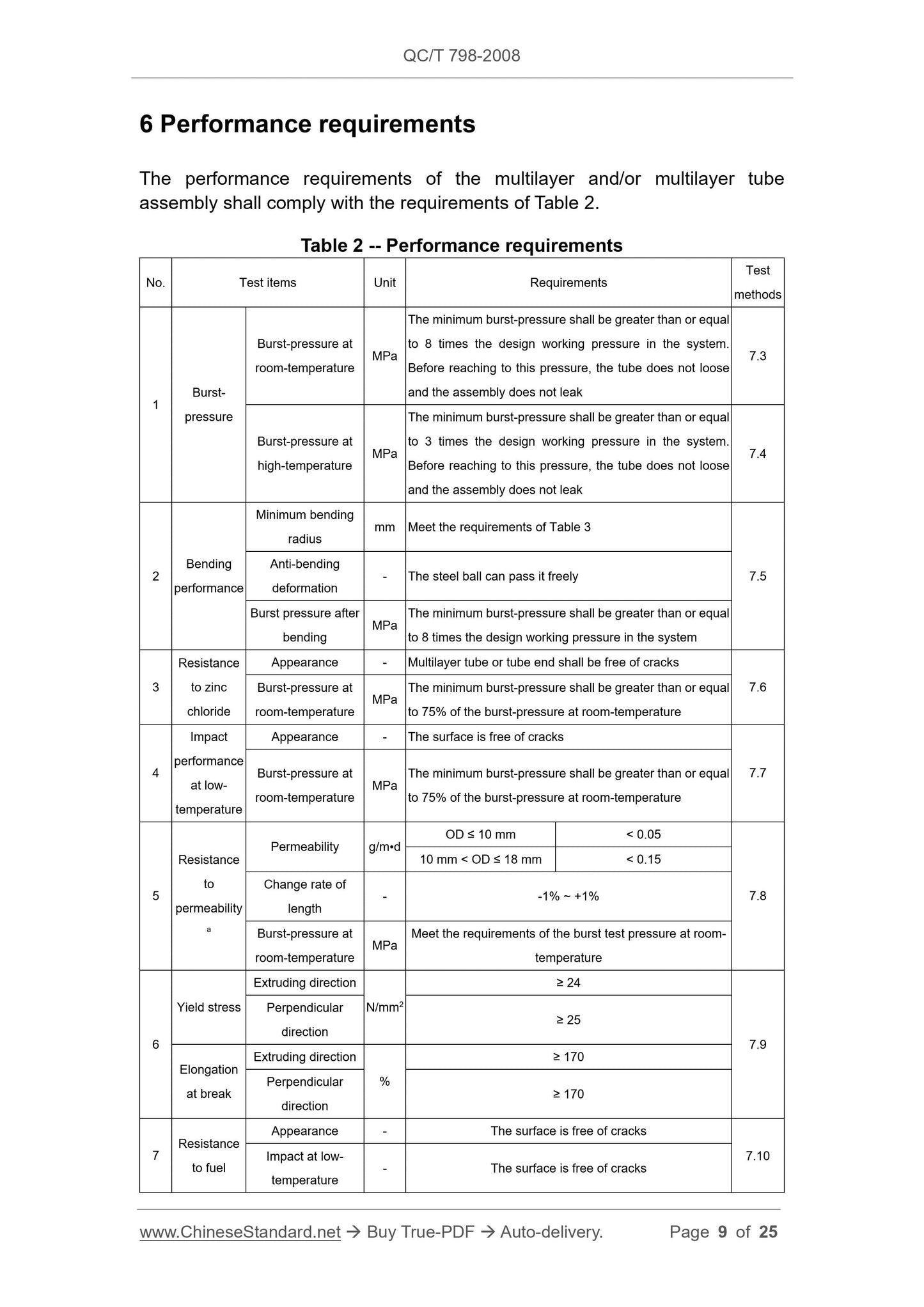

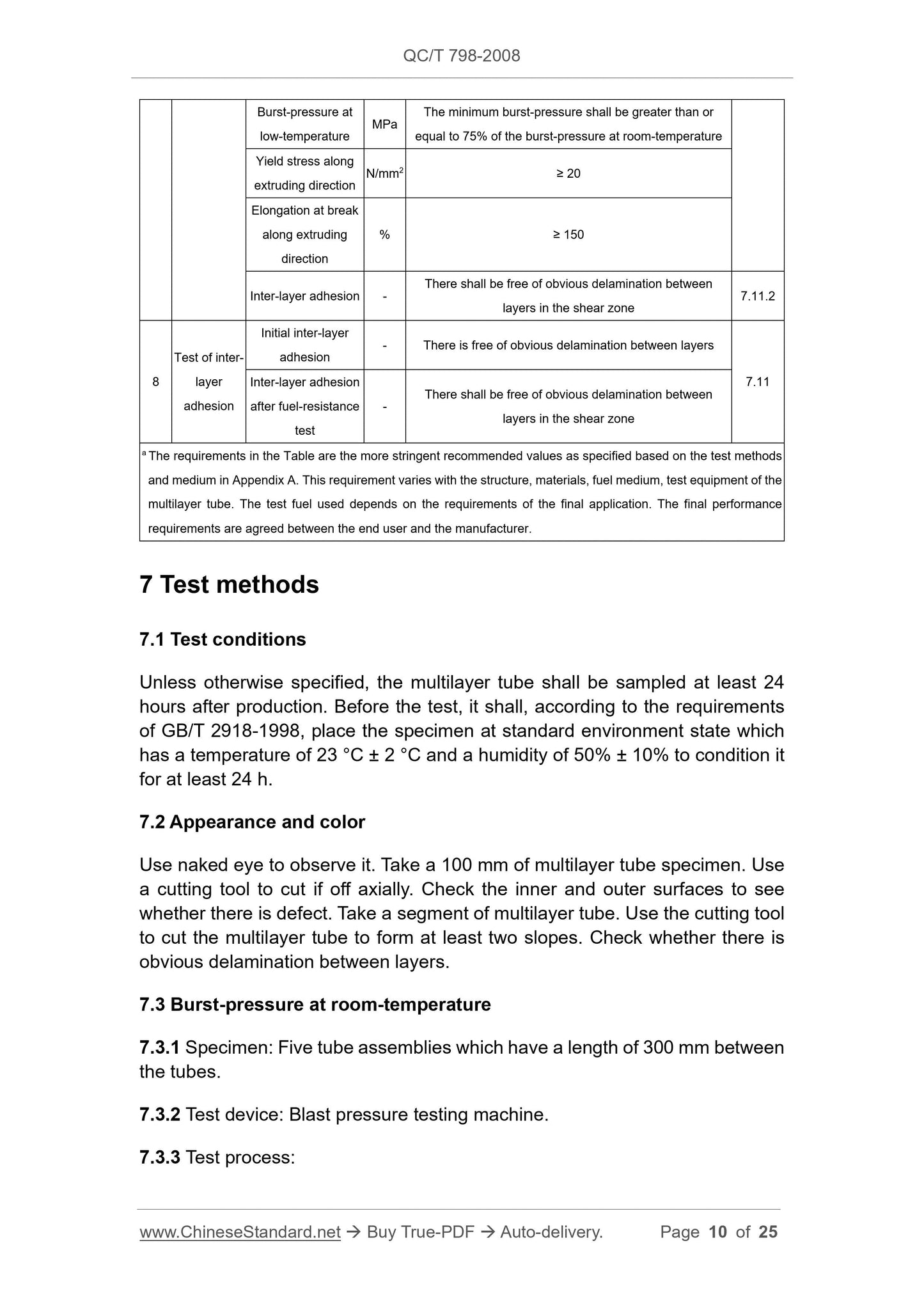

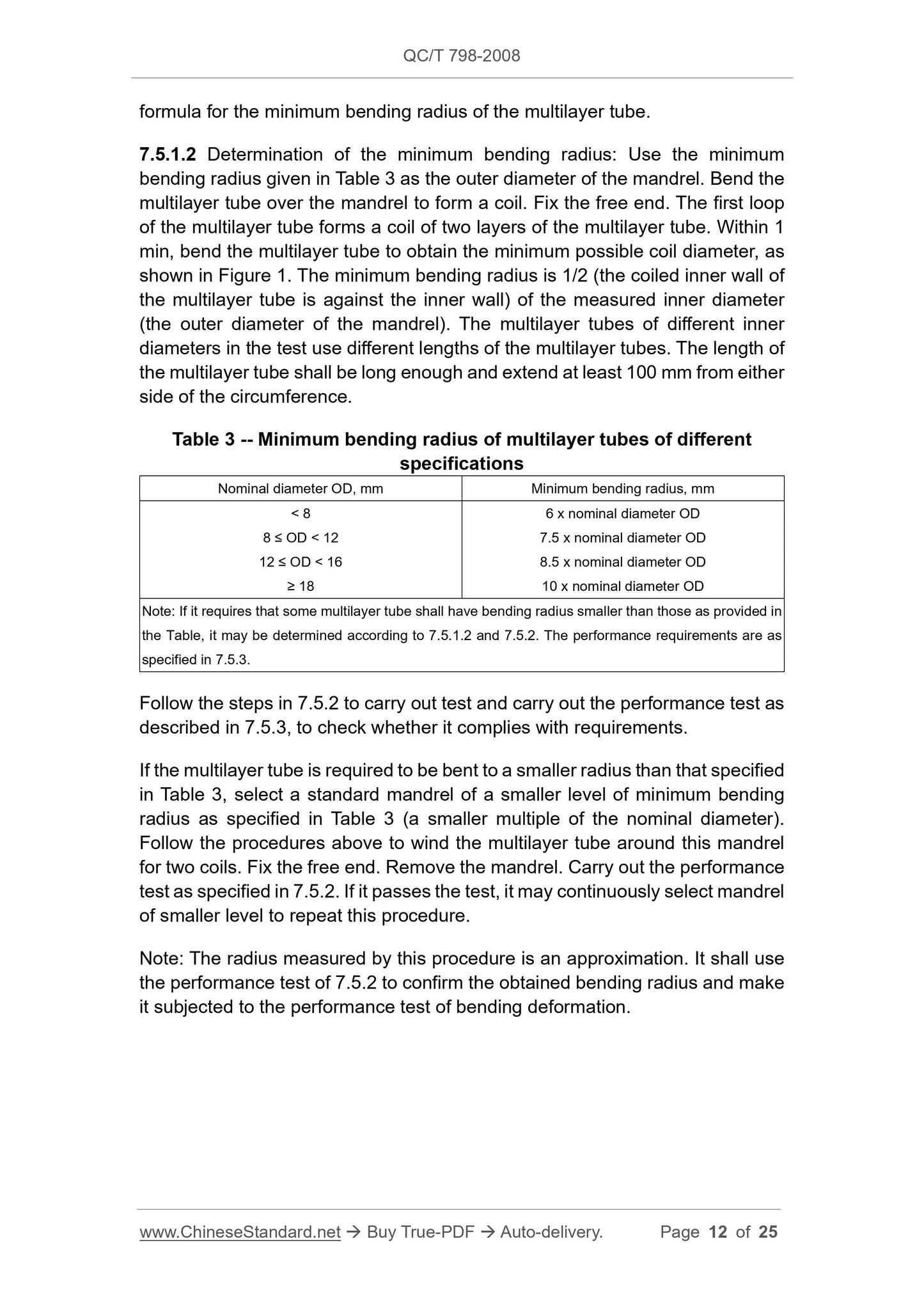

6 Performance requirements

The performance requirements of the multilayer and/or multilayer tube

assembly shall comply with the requirements of Table 2.

Table 2 -- Performance requirements

No. Test items Unit Requirements Test methods

1 Burst-pressure

Burst-pressure at

room-temperature MPa

The minimum burst-pressure shall be greater than or equal

to 8 times the design working pressure in the system.

Before reaching to this pressure, the tube does not loose

and the assembly does not leak

7.3

Burst-pressure at

high-temperature MPa

The minimum burst-pressure shall be greater than or equal

to 3 times the design working pressure in the system.

Before reaching to this pressure, the tube does not loose

and the assembly does not leak

7.4

2 Bending performance

Minimum bending

radius mm Meet the requirements of Table 3

7.5 Anti-bending deformation - The steel ball can pass it freely

Burst pressure after

bending MPa

The minimum burst-pressure shall be greater than or equal

to 8 times the design working pressure in the system

Resistance

to zinc

chloride

Appearance - Multilayer tube or tube end shall be free of cracks

7.6 Burst-pressure at

room-temperature MPa

The minimum burst-pressure shall be greater than or equal

to 75% of the burst-pressure at room-temperature

Impact

performance

at low-

temperature

Appearance - The surface is free of cracks

7.7 Burst-pressure at

room-temperature MPa

The minimum burst-pressure shall be greater than or equal

to 75% of the burst-pressure at room-temperature

Resistance

to

permeability

Permeability g/m•d

OD ≤ 10 mm < 0.05

7.8

10 mm < OD ≤ 18 mm < 0.15

Change rate of

length - -1% ~ +1%

Burst-pressure at

room-temperature MPa

Meet the requirements of the burst test pressure at room-

temperature

Yield stress

Extruding direction

N/mm2

≥ 24

7.9

Perpendicular

direction ≥ 25

Elongation

at break

Extruding direction

≥ 170

Perpendicular

direction ≥ 170

7 Resistance to fuel

Appearance - The surface is free of cracks

7.10 Impact at low-

temperature - The surface is free of cracks

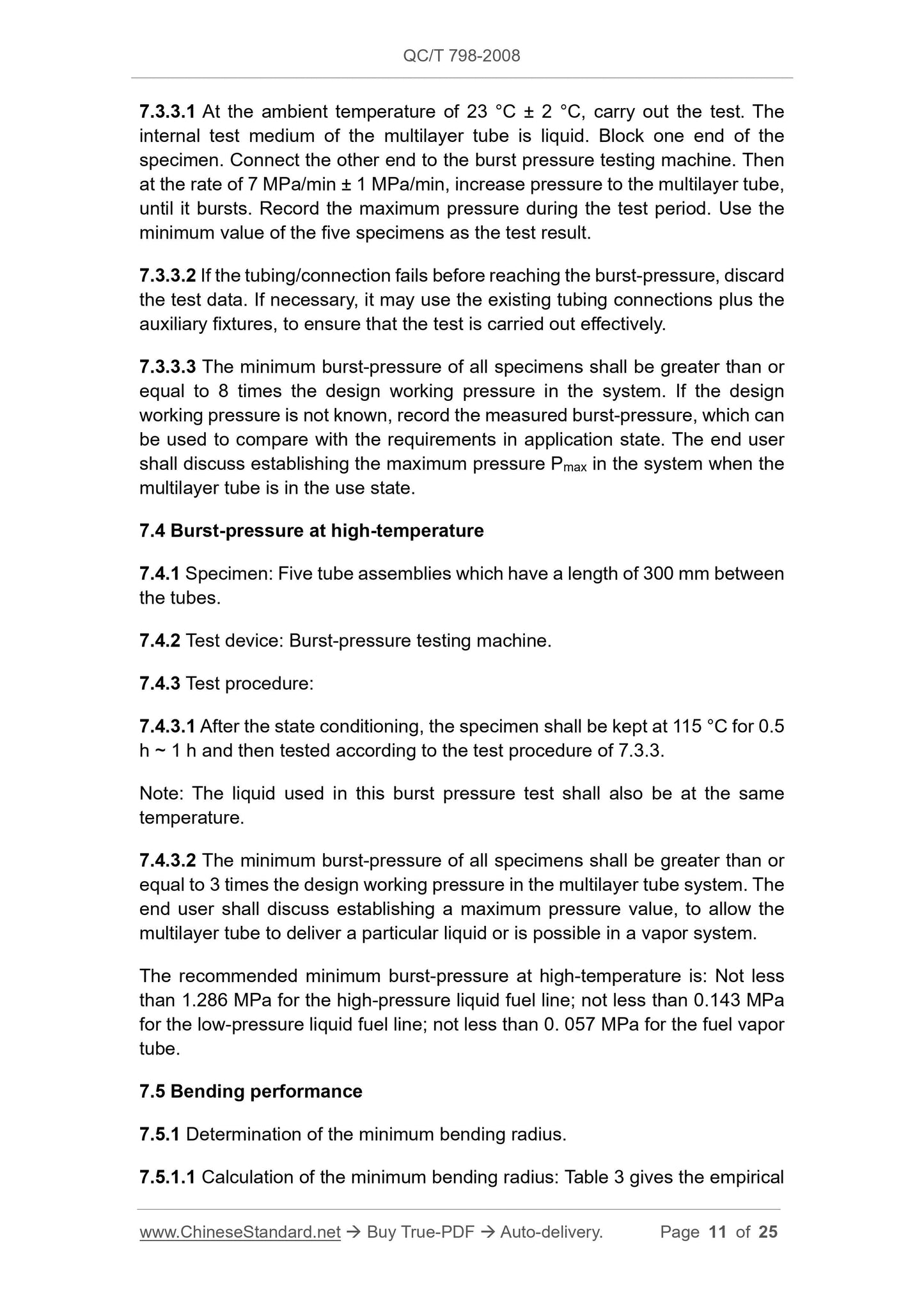

7.3.3.1 At the ambient temperature of 23 °C ± 2 °C, carry out the test. The

internal test medium of the multilayer tube is liquid. Block one end of the

specimen. Connect the other end to the burst pressure testing machine. Then

at the rate of 7 MPa/min ± 1 MPa/min, increase pressure to the multilayer tube,

until it bursts. Record the maximum pressure during the test period. Use the

minimum value of the five specimens as the test result.

7.3.3.2 If the tubing/connection fails before reaching the burst-pressure, discard

the test data. If necessary, it may use the existing tubing connections plus the

auxiliary fixtures, to ensure that the test is carried out effectively.

7.3.3.3 The minimum burst-pressure of all specimens shall be greater than or

equal to 8 times the design wo...

Get QUOTATION in 1-minute: Click QC/T 798-2008

Historical versions: QC/T 798-2008

Preview True-PDF (Reload/Scroll if blank)

QC/T 798-2008: Multi-layers plastic tubing for automotive fuel system

QC/T 798-2008

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

Multilayers plastic tubing for automotive fuel system

ISSUED ON: FEBRUARY 01, 2008

IMPLEMENTED ON: JULY 01, 2008

Issued by: Ministry of Industry and Information Technology of PRC

Annex:

Standard numbers, descriptions and dates coming into force of four automotive

industry standards

SN Standard number Standard description

Date coming into

force

1 QC/T 796-2008 Automotive fuel consumption labels July 1, 2008

2 QC/T 797-2008

Identification and marking of materials that are

fabricated into automotive plastic, rubber and

thermoplastic elastomer parts

July 1, 2008

3 QC/T 798-2008 Multi-layers plastic tubing for automotive fuel system July 1, 2008

4 QC/T 799-2008 Telescopic belt truck conveyer July 1, 2008

Table of Contents

Foreword ... 5

1 Scope ... 6

2 Normative references ... 6

3 Terms and definitions ... 6

4 Specification dimension ... 7

5 General requirements ... 8

6 Performance requirements ... 9

7 Test methods ... 10

8 Inspection rules ... 20

9 Markings and signs ... 21

10 Packaging, transportation, storage ... 22

Appendix A (Normative) Specifications for permeability resistance test ... 23

Multilayers plastic tubing for automotive fuel system

1 Scope

This standard specifies the dimensional specifications, appearance, technical

requirements, test methods, inspection rules, markings, packaging,

transportation, storage of multilayer plastic tubing for automotive fuel systems

(hereinafter referred to as multilayer tubing) and tube assemblies.

This standard is applicable to multilayer plastic fuel tubes which have a working

temperature between -40 °C and +115 °C (continuous use temperature shall

not exceed 90 °C) and maximum working pressure of not more than 0.7 MPa.

2 Normative references

The provisions in following documents become the provisions of this standard

through reference in this standard. For the dated references, the subsequent

amendments (excluding corrections) or revisions do not apply to this standard;

however, parties who reach an agreement based on this standard are

encouraged to study if the latest versions of these documents are applicable.

For undated references, the latest edition of the referenced document applies.

GB/T 528-1998 Determination of tensile stress-strain properties of

vulcanized rubber or thermoplastic rubber

GB/T 528-1998 Rubber, vulcanized or thermoplastic - Determination of

tensile stress-strain properties (ISO 527 -2: 1993 IDT)

GB/T 2828.1-2003 Sampling procedures for inspection by attributes - Part 1:

Sampling schemes indexed by acceptance quality limit (AQL) for lot-by-lot

inspection (ISO 2859-1:1999 IDT)

GB/T 2918-1998 Plastics - Standard atmospheres for conditioning and

testing (ISO 291:1997 IDT)

3 Terms and definitions

The following terms and definitions apply to this standard.

3.1

Multilayer plastic tubing

More than two layers of non-metallic plastic tubes which are made of

materials of different properties and different types, without connectors.

3.2

Tube assemblies

A combination of a multilayer tube and a tube joint which have a specified

length and shape.

4 Specification dimension

4.1 Structure

The multilayer tube is a multilayer structure which contains the wall-thickness

of the main body. The name of material is generally indicated on the drawing. If

specified, it shall identify each layer of all tube layers.

4.2 Dimensions and tolerances

Table 1 provides the dimensions and wall-thickness of various types of

multilayer tubes of this standard. The thickness and tolerance for each layer

may be determined by the manufacturer and the user through negotiation. The

dimensions and tolerances of the multilayer tube are indicated by mm.

4.3 Wall-thickness

Multilayer tubes of different sizes which are made by materials of different

grades have different wall-thicknesses. The minimum wall-thickness of a

straight tube which has a nominal diameter equal to 10 mm is 0.9 mm. The

larger the nominal diameter, the larger the wall-thickness. The requirements for

wall-thickness are as detailed in Table 1.

Note: Some of the following factors influence the choice of wall-thickness:

a) High burst-pressure requirements mean higher wall-thickness

requirements;

b) The thicker the wall-thickness, the greater the minimum bending radius.

6 Performance requirements

The performance requirements of the multilayer and/or multilayer tube

assembly shall comply with the requirements of Table 2.

Table 2 -- Performance requirements

No. Test items Unit Requirements Test methods

1 Burst-pressure

Burst-pressure at

room-temperature MPa

The minimum burst-pressure shall be greater than or equal

to 8 times the design working pressure in the system.

Before reaching to this pressure, the tube does not loose

and the assembly does not leak

7.3

Burst-pressure at

high-temperature MPa

The minimum burst-pressure shall be greater than or equal

to 3 times the design working pressure in the system.

Before reaching to this pressure, the tube does not loose

and the assembly does not leak

7.4

2 Bending performance

Minimum bending

radius mm Meet the requirements of Table 3

7.5 Anti-bending deformation - The steel ball can pass it freely

Burst pressure after

bending MPa

The minimum burst-pressure shall be greater than or equal

to 8 times the design working pressure in the system

Resistance

to zinc

chloride

Appearance - Multilayer tube or tube end shall be free of cracks

7.6 Burst-pressure at

room-temperature MPa

The minimum burst-pressure shall be greater than or equal

to 75% of the burst-pressure at room-temperature

Impact

performance

at low-

temperature

Appearance - The surface is free of cracks

7.7 Burst-pressure at

room-temperature MPa

The minimum burst-pressure shall be greater than or equal

to 75% of the burst-pressure at room-temperature

Resistance

to

permeability

Permeability g/m•d

OD ≤ 10 mm < 0.05

7.8

10 mm < OD ≤ 18 mm < 0.15

Change rate of

length - -1% ~ +1%

Burst-pressure at

room-temperature MPa

Meet the requirements of the burst test pressure at room-

temperature

Yield stress

Extruding direction

N/mm2

≥ 24

7.9

Perpendicular

direction ≥ 25

Elongation

at break

Extruding direction

≥ 170

Perpendicular

direction ≥ 170

7 Resistance to fuel

Appearance - The surface is free of cracks

7.10 Impact at low-

temperature - The surface is free of cracks

7.3.3.1 At the ambient temperature of 23 °C ± 2 °C, carry out the test. The

internal test medium of the multilayer tube is liquid. Block one end of the

specimen. Connect the other end to the burst pressure testing machine. Then

at the rate of 7 MPa/min ± 1 MPa/min, increase pressure to the multilayer tube,

until it bursts. Record the maximum pressure during the test period. Use the

minimum value of the five specimens as the test result.

7.3.3.2 If the tubing/connection fails before reaching the burst-pressure, discard

the test data. If necessary, it may use the existing tubing connections plus the

auxiliary fixtures, to ensure that the test is carried out effectively.

7.3.3.3 The minimum burst-pressure of all specimens shall be greater than or

equal to 8 times the design wo...

Share