PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY/T 0681.13-2014 English PDF (YYT0681.13-2014)

YY/T 0681.13-2014 English PDF (YYT0681.13-2014)

Precio habitual

$175.00 USD

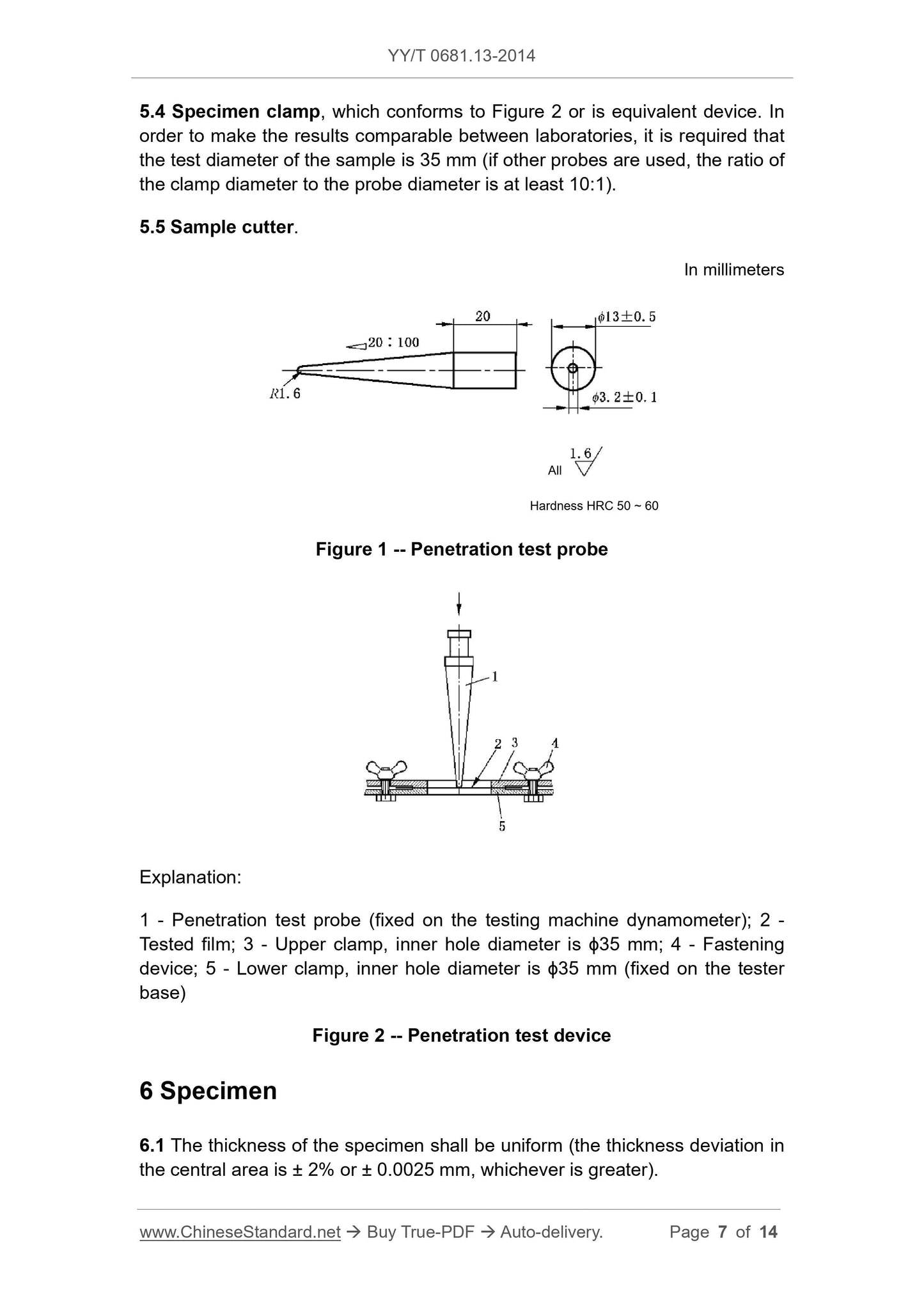

Precio habitual

Precio de oferta

$175.00 USD

Precio unitario

/

por

Los gastos de envío se calculan en la pantalla de pago.

No se pudo cargar la disponibilidad de retiro

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click YY/T 0681.13-2014

Historical versions: YY/T 0681.13-2014

Preview True-PDF (Reload/Scroll if blank)

YY/T 0681.13-2014: Test methods for sterile medical device package. Part 13: Slow rate penetration resistance of flexible barrier films and laminates

YY/T 0681.13-2014

PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.080.040

C 31

Test methods for sterile medical device package -

Part 13: Slow rate penetration resistance of flexible

barrier films and laminates

ISSUED ON: JUNE 17, 2014

IMPLEMENTED ON: JULY 01, 2015

Issued by: China Food and Drug Administration

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terminology ... 5

4 Significance and application ... 6

5 Instruments ... 6

6 Specimen ... 7

7 Instrument preparation ... 8

8 Number of specimens ... 8

9 State conditioning ... 8

10 Procedure ... 8

11 Report ... 9

Appendix A (Informative) Precision and bias ... 11

Foreword

YY/T 0681 “Test methods for sterile medical device package” is divided into the

following parts:

- Part 1: Test guide for accelerated aging;

- Part 2: Seal strength of flexible battier materials;

- Part 3: Internal pressurization failure resistance of unrestrained packages;

- Part 4: Detecting seal leaks in porous packages by dye penetration;

- Part 5: Detecting gross leaks in medical packaging by internal

pressurization (bubble test)

- Part 6: Evaluation of chemical resistance of printed inks and coatings on

flexible packaging materials;

- Part 7: Evaluating inks or coating adhesion to flexible packaging materials

using tape;

- Part 8: Coating/adhesive weight determination;

- Part 9: Burst testing of flexible package seals using internal air

pressurization weight restraining plates;

- Part 10: Test for microbial barrier ranking of porous package material;

- Part 11: Determining integrity of seals for medical packaging by visual

inspection;

- Part 12: Flex durability of flexible barrier films;

- Part 13: Slow rate penetration resistance of flexible barrier films and

laminates.

This part is Part 13 of YY/T 0681.

This part was drafted in accordance with the rules given in GB/T 1.1-2009.

This part was formulated with reference to ASTM F1306-1990 "Slow rate

penetration resistance of flexible barrier films and laminates".

Please note that some elements of this document may involve patents. The

issuer of this document is not responsible for identifying these patents.

This part shall be under the jurisdiction of the National Technical Committee for

Test methods for sterile medical device package -

Part 13: Slow rate penetration resistance of flexible

barrier films and laminates

1 Scope

This part of YY/T 0681 is applicable to determine the penetration resistance of

the anti-drive probe of flexible barrier film and laminates. In this test, biaxial

stress is applied to the material at a constant test rate at room temperature,

until penetration occurs; the force, energy and elongation before penetration

are measured.

Note: Appendix A gives the precision and bias of the test methods as specified in this

part.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this standard.

GB/T 2918 Plastics - Standard atmospheres for conditioning and testing

(GB/T 2918-1998, idt ISO 291:1997)

3 Terminology

The following terms and definitions apply to this document.

3.1

Elongation

The elastic / plastic deformation of the driving probe when it penetrates the

flexible film.

3.2

Penetration resistance

6.2 The specimen size shall be 76 mm × 76 mm.

7 Instrument preparation

7.1 Set up and operate the instrument according to the instrument’s operation

manual.

7.2 Install the probe.

7.3 Place the probe above the clamp and align it.

8 Number of specimens

Test at least 5 specimens for each sample.

9 State conditioning

9.1 According to the provisions of GB/T 2918 before the test, condition the state

of the specimen under the conditions of temperature (23 ± 2) °C and relative

humidity (50 ± 5) % for at least 40 h.

9.2 Unless otherwise specified in this test method, the test is performed under

standard laboratory conditions with a temperature of (23 ± 2) °C and a relative

humidity of (50 ± 5) %.

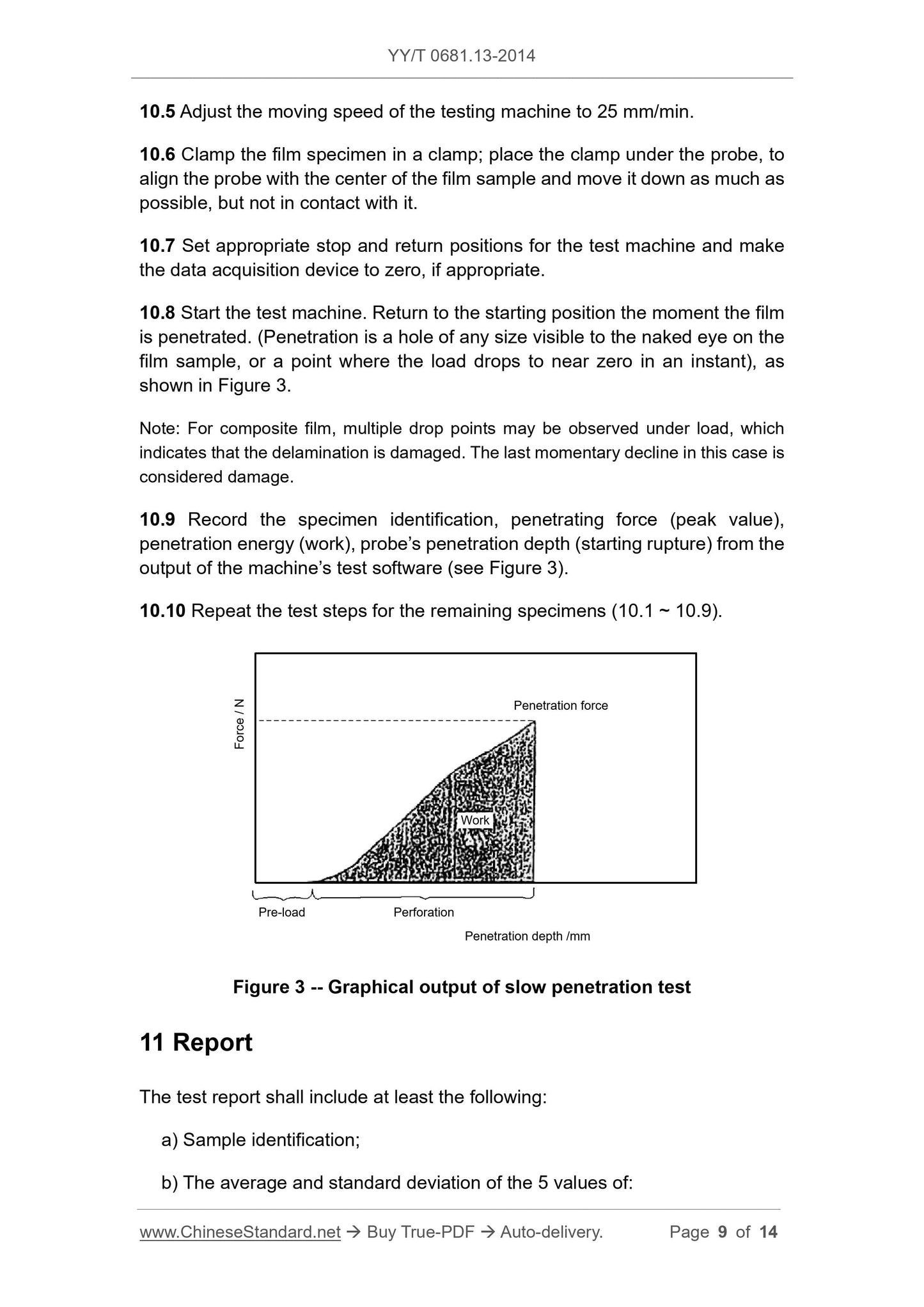

10 Procedure

10.1 Calibrate the test instrument according to the instrument manufacturer's

instructions.

10.2 Select the force of the dynamometer in the range of 20% ~ 80% of the

range when penetration occurs.

10.3 Use the sample cutter to cut at least five 76 mm × 76 mm specimens for

each sample.

10.4 Measure the thickness in the center of the film sample (average of 3

readings).

Note 1: The thickness can be measured by ASTM D374 or GB/T 6672. It is

recommended to use Method C or Method D of ASTM D374 first.

Note 2: The accuracy of the thickness measurement methods in Table A.3 is based on

ASTM D374.

Appendix A

(Informative)

Precision and bias

A.1 Precision

A.1.1 Precision data

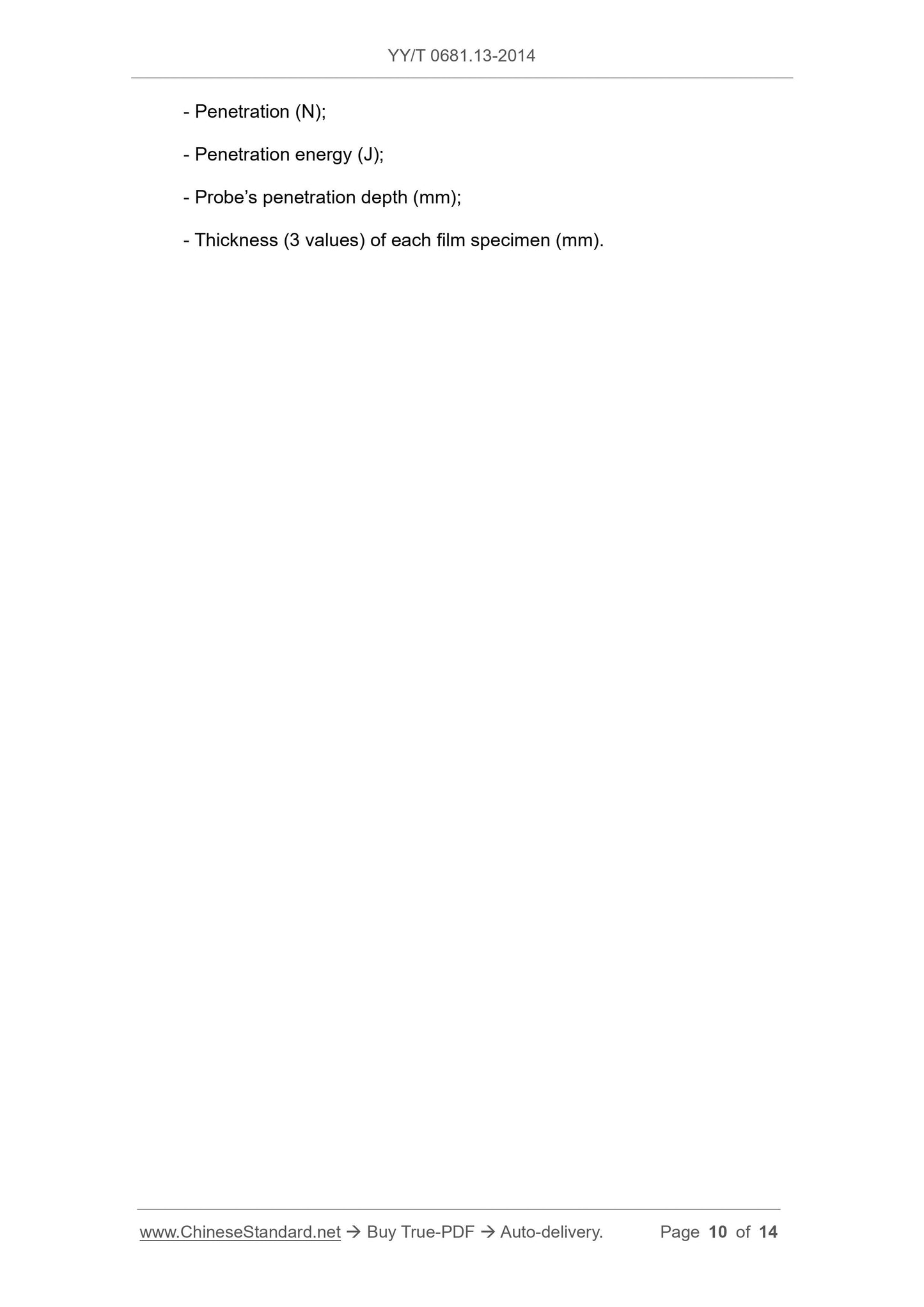

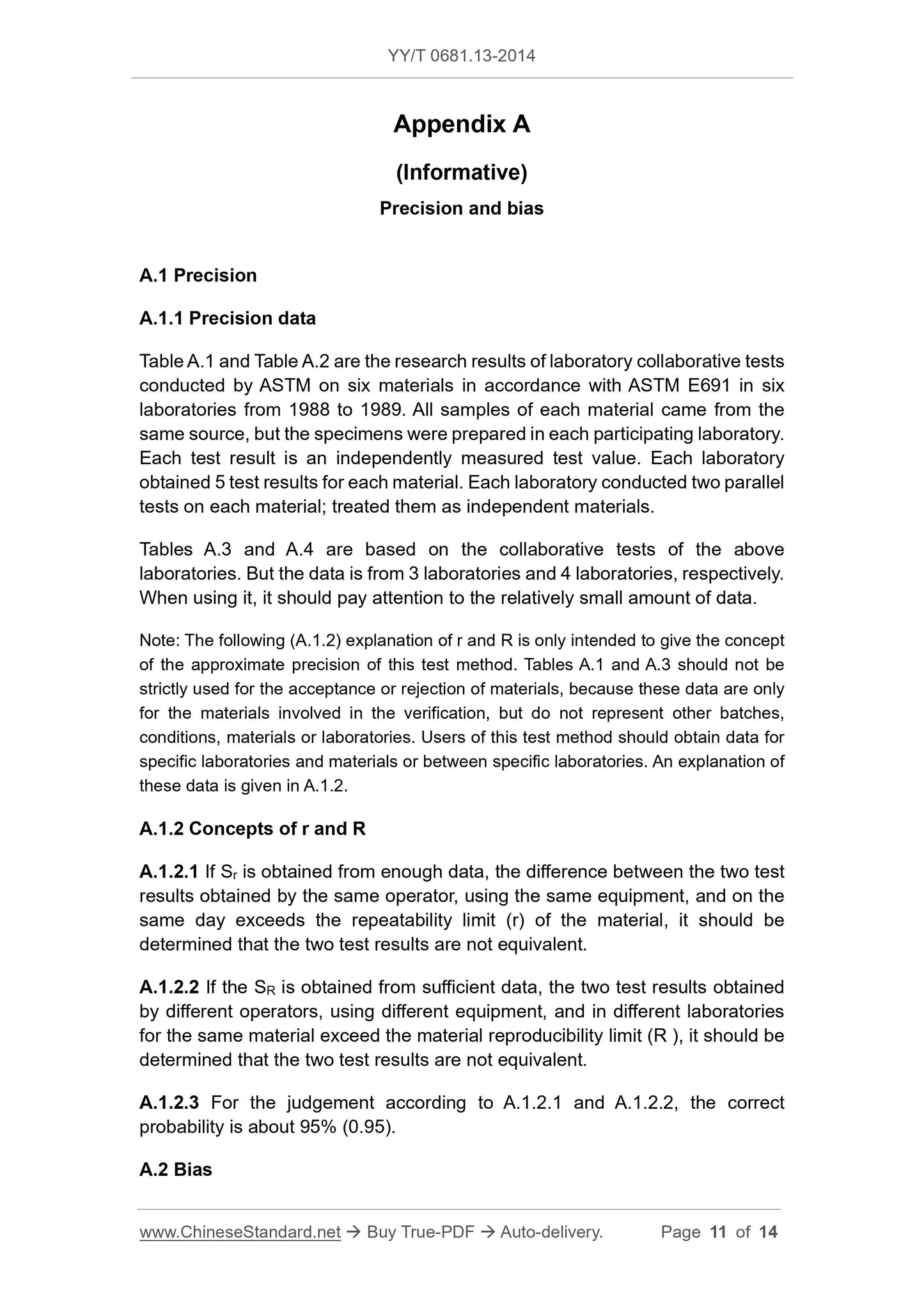

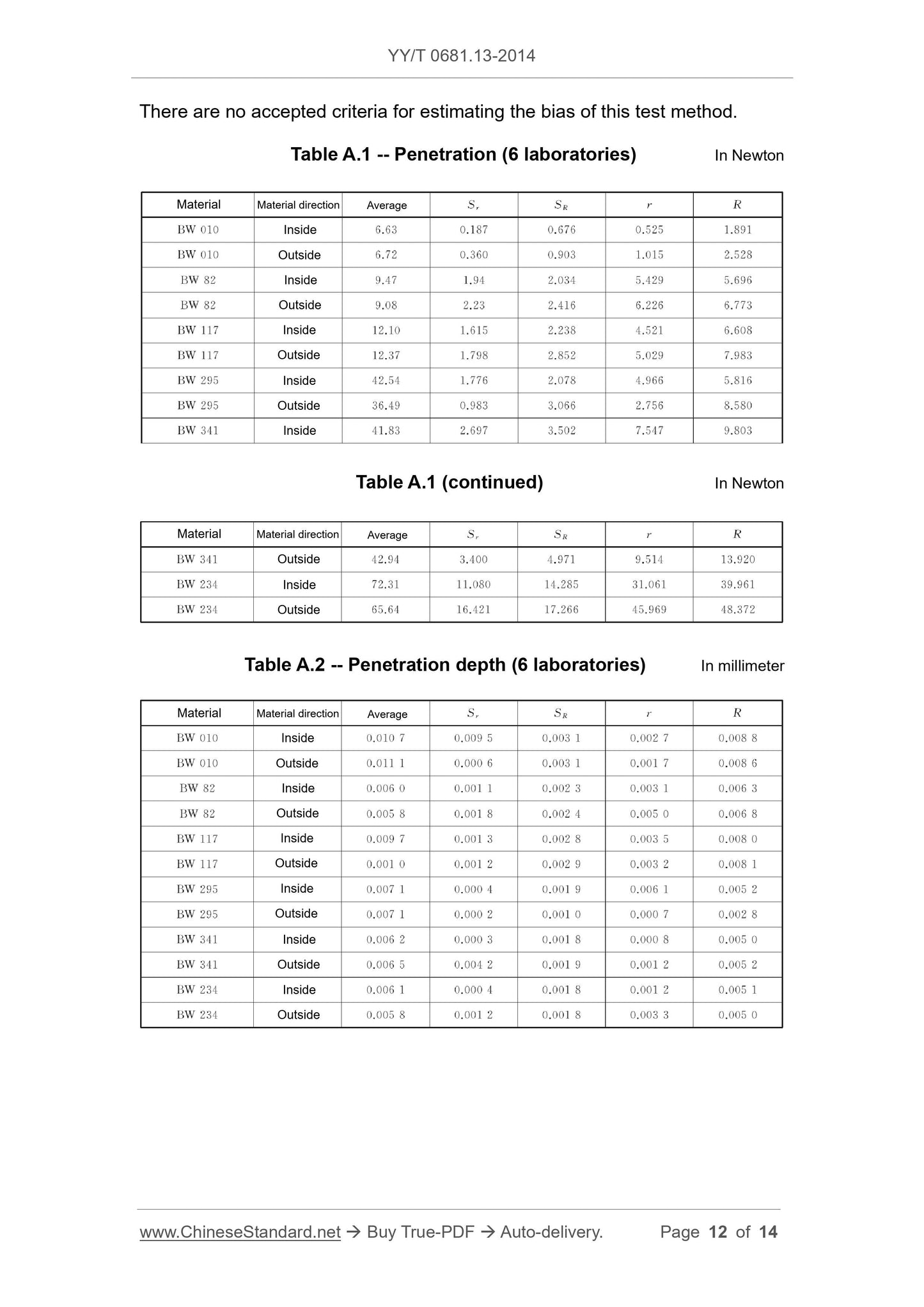

Table A.1 and Table A.2 are the research results of laboratory collaborative tests

conducted by ASTM on six materials in accordance with ASTM E691 in six

laboratories from 1988 to 1989. All samples of each material came from the

same source, but the specimens were prepared in each participating laboratory.

Each test result is an independently measured test value. Each laboratory

obtained 5 test results for each material. Each laboratory conducted two parallel

tests on each material; treated them as independent materials.

Tables A.3 and A.4 are based on the collaborative tests of the above

laboratories. But the data is from 3 laboratories and 4 laboratories, respectively.

When using it, it should pay attention to the relatively small amount of data.

Note: The following (A.1.2) explanation of r and R is only intended to give the concept

of the approximate precision of this test method. Tables A.1 and A.3 should not be

strictly used for the acceptance or rejection of materials, because these data are only

for the materials involved in the verification, but do not represent other batches,

conditions, materials or laboratories. Users of this test method should obtain data for

specific laboratories and materials or between specific laboratories. An explanation of

these data is given in A.1.2.

A.1.2 Concepts of r and R

A.1.2.1 If Sr is obtained from enough data, the difference between the two test

results obtained by the same operator, using the same equipment, and on the

same day exceeds the repeatability limit (r) of the material, it should be

determined that the two test results are not equivalent.

A.1.2.2 If the SR is obtained from sufficient data, the two test results obtained

by different operators, using different equipment, and in different laboratories

for the same material exceed the material reproducibility limit (R ), it should be

determined that the two test results are not equivalent.

A.1.2.3 For the judgement according to A.1.2.1 and A.1.2.2, the correct

probability is about 95% (0.95).

A.2 Bias

Get QUOTATION in 1-minute: Click YY/T 0681.13-2014

Historical versions: YY/T 0681.13-2014

Preview True-PDF (Reload/Scroll if blank)

YY/T 0681.13-2014: Test methods for sterile medical device package. Part 13: Slow rate penetration resistance of flexible barrier films and laminates

YY/T 0681.13-2014

PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.080.040

C 31

Test methods for sterile medical device package -

Part 13: Slow rate penetration resistance of flexible

barrier films and laminates

ISSUED ON: JUNE 17, 2014

IMPLEMENTED ON: JULY 01, 2015

Issued by: China Food and Drug Administration

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terminology ... 5

4 Significance and application ... 6

5 Instruments ... 6

6 Specimen ... 7

7 Instrument preparation ... 8

8 Number of specimens ... 8

9 State conditioning ... 8

10 Procedure ... 8

11 Report ... 9

Appendix A (Informative) Precision and bias ... 11

Foreword

YY/T 0681 “Test methods for sterile medical device package” is divided into the

following parts:

- Part 1: Test guide for accelerated aging;

- Part 2: Seal strength of flexible battier materials;

- Part 3: Internal pressurization failure resistance of unrestrained packages;

- Part 4: Detecting seal leaks in porous packages by dye penetration;

- Part 5: Detecting gross leaks in medical packaging by internal

pressurization (bubble test)

- Part 6: Evaluation of chemical resistance of printed inks and coatings on

flexible packaging materials;

- Part 7: Evaluating inks or coating adhesion to flexible packaging materials

using tape;

- Part 8: Coating/adhesive weight determination;

- Part 9: Burst testing of flexible package seals using internal air

pressurization weight restraining plates;

- Part 10: Test for microbial barrier ranking of porous package material;

- Part 11: Determining integrity of seals for medical packaging by visual

inspection;

- Part 12: Flex durability of flexible barrier films;

- Part 13: Slow rate penetration resistance of flexible barrier films and

laminates.

This part is Part 13 of YY/T 0681.

This part was drafted in accordance with the rules given in GB/T 1.1-2009.

This part was formulated with reference to ASTM F1306-1990 "Slow rate

penetration resistance of flexible barrier films and laminates".

Please note that some elements of this document may involve patents. The

issuer of this document is not responsible for identifying these patents.

This part shall be under the jurisdiction of the National Technical Committee for

Test methods for sterile medical device package -

Part 13: Slow rate penetration resistance of flexible

barrier films and laminates

1 Scope

This part of YY/T 0681 is applicable to determine the penetration resistance of

the anti-drive probe of flexible barrier film and laminates. In this test, biaxial

stress is applied to the material at a constant test rate at room temperature,

until penetration occurs; the force, energy and elongation before penetration

are measured.

Note: Appendix A gives the precision and bias of the test methods as specified in this

part.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this standard.

GB/T 2918 Plastics - Standard atmospheres for conditioning and testing

(GB/T 2918-1998, idt ISO 291:1997)

3 Terminology

The following terms and definitions apply to this document.

3.1

Elongation

The elastic / plastic deformation of the driving probe when it penetrates the

flexible film.

3.2

Penetration resistance

6.2 The specimen size shall be 76 mm × 76 mm.

7 Instrument preparation

7.1 Set up and operate the instrument according to the instrument’s operation

manual.

7.2 Install the probe.

7.3 Place the probe above the clamp and align it.

8 Number of specimens

Test at least 5 specimens for each sample.

9 State conditioning

9.1 According to the provisions of GB/T 2918 before the test, condition the state

of the specimen under the conditions of temperature (23 ± 2) °C and relative

humidity (50 ± 5) % for at least 40 h.

9.2 Unless otherwise specified in this test method, the test is performed under

standard laboratory conditions with a temperature of (23 ± 2) °C and a relative

humidity of (50 ± 5) %.

10 Procedure

10.1 Calibrate the test instrument according to the instrument manufacturer's

instructions.

10.2 Select the force of the dynamometer in the range of 20% ~ 80% of the

range when penetration occurs.

10.3 Use the sample cutter to cut at least five 76 mm × 76 mm specimens for

each sample.

10.4 Measure the thickness in the center of the film sample (average of 3

readings).

Note 1: The thickness can be measured by ASTM D374 or GB/T 6672. It is

recommended to use Method C or Method D of ASTM D374 first.

Note 2: The accuracy of the thickness measurement methods in Table A.3 is based on

ASTM D374.

Appendix A

(Informative)

Precision and bias

A.1 Precision

A.1.1 Precision data

Table A.1 and Table A.2 are the research results of laboratory collaborative tests

conducted by ASTM on six materials in accordance with ASTM E691 in six

laboratories from 1988 to 1989. All samples of each material came from the

same source, but the specimens were prepared in each participating laboratory.

Each test result is an independently measured test value. Each laboratory

obtained 5 test results for each material. Each laboratory conducted two parallel

tests on each material; treated them as independent materials.

Tables A.3 and A.4 are based on the collaborative tests of the above

laboratories. But the data is from 3 laboratories and 4 laboratories, respectively.

When using it, it should pay attention to the relatively small amount of data.

Note: The following (A.1.2) explanation of r and R is only intended to give the concept

of the approximate precision of this test method. Tables A.1 and A.3 should not be

strictly used for the acceptance or rejection of materials, because these data are only

for the materials involved in the verification, but do not represent other batches,

conditions, materials or laboratories. Users of this test method should obtain data for

specific laboratories and materials or between specific laboratories. An explanation of

these data is given in A.1.2.

A.1.2 Concepts of r and R

A.1.2.1 If Sr is obtained from enough data, the difference between the two test

results obtained by the same operator, using the same equipment, and on the

same day exceeds the repeatability limit (r) of the material, it should be

determined that the two test results are not equivalent.

A.1.2.2 If the SR is obtained from sufficient data, the two test results obtained

by different operators, using different equipment, and in different laboratories

for the same material exceed the material reproducibility limit (R ), it should be

determined that the two test results are not equivalent.

A.1.2.3 For the judgement according to A.1.2.1 and A.1.2.2, the correct

probability is about 95% (0.95).

A.2 Bias

Share