1

/

de

10

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

FZ/T 73031-2009 English PDF (FZT73031-2009)

FZ/T 73031-2009 English PDF (FZT73031-2009)

Prix habituel

$85.00 USD

Prix habituel

Prix promotionnel

$85.00 USD

Prix unitaire

/

par

Frais d'expédition calculés à l'étape de paiement.

Impossible de charger la disponibilité du service de retrait

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click FZ/T 73031-2009

Historical versions: FZ/T 73031-2009

Preview True-PDF (Reload/Scroll if blank)

FZ/T 73031-2009: Pressure socks

FZ/T 73031-2009

FZ

INDUSTRY STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 59.080.30

W 63

Pressure Socks

压力袜

ISSUED ON. NOVEMBER 17, 2009

IMPLEMENTED ON. APRIL 1, 2010

Issued by. Ministry of Industry and Information Technology of the

People's Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 5

4 Product Classification ... 5

5 Requirements ... 5

6 Test Methods ... 13

7 Judgment Rules ... 18

8 Product’s Instructions for Use, Packaging, Transportation and Storage ... 19

Foreword

This standard was proposed by China National Textile And Apparel Council.

This standard shall be under the jurisdiction of Technical Subcommittee on Knitwear of the

Technical Committee on Textiles of Standardization Administration of China (SAC/TC

209/SC 6).

Chief drafting organizations of this standard. Zhejiang Nai'er Group Co., Ltd., Langsha

Knitting Co., Ltd., Zhejiang Jiamengyi Hosiery Co., Ltd., Gaoyao City Gold Coast Knitting

Factory Co., Ltd. and National Quality Supervision and Inspection Center of Knitted

Products.

Chief drafting staffs of this standard. Shi Jigang, Liu Ailian, Jin Jianming, Yu Jianjun and

Dai Zhengyi.

Pressure Socks

1 Scope

This standard specifies pressure socks’ terms and definitions, product classification,

requirements, test methods, judgment rules as well as product’s instructions for use,

packaging, transportation and storage.

This standard is applicable to appraise the quality of chemical fiber pressure socks

and pressure socks that are interwoven of cotton (wool and chemical fiber blended

yarn) and chemical fiber. Other fiber pressure socks may be referred to this standard.

2 Normative References

The following standards contain the provisions which, through reference in this

standard, constitute the provisions of this standard. For dated reference, the

subsequent amendments (excluding corrigendum) or revisions of these publications

do not apply. However, all parties who reach into an agreement according to this

standard are encouraged to study whether the latest edition of these documents is

applicable. For undated references, the latest edition of the normative document

applies.

GB/T 250 Textiles - Tests for Colour Fastness - Grey Scale for Assessing Change

in Colour (GB/T 250-2008, ISO 105-A 02.1993, IDT)

GB/T 251 Textiles - Tests for Colour Fastness - Grey Scale for Assessing Staining

(GB/T 251-2008, ISO 105-A 03.1993, IDT)

GB/T 2910 (All Parts) Textiles - Quantitative Chemical Analysis

GB/T 2912.1 Textiles - Determination of Formaldehyde - Part 1. Free and

Hydrolized Formaldehyde (Water Extraction Method)

GB/T 3920 Textiles - Tests for Colour Fastness - Colour Fastness to Rubbing

(GB/T 3920-1997, eqv ISO 105-X 12.1993)

GB/T 3921 Textiles - Tests for Colour Fastness - Colour Fastness to Washing with

Soap or Soap and Soda (GB/T 3921-2008, ISO 105-C10.2006, MOD)

GB/T 3922 Textiles - Testing Method for Colour Fastness to Perspiration (GB/T

3922-1995, eqv ISO 105-E 04.1994)

GB/T 4856 Package of Cotton Goods and Knitwear

GB 5296.4 Instructions for Use of Products of Consumer Interest - Instructions for

Use of Textiles and Apparel

GB/T 5713 Textiles - Tests for Colour Fastness - Colour Fastness to Water (GB/T

5713-1997, eqv ISO 105-E 01.1994)

GB/T 7573 Textiles - Determination of pH of the Aqueous Extract (GB/T 7573-2002,

ISO 3071.1980, MOD)

GB/T 8170 Rules of Rounding off for Numerical Values and Expression and

Judgment of Limiting Values

GB 18401 National General Safety Technical Code for Textile Products

GSB 16-2159-2007 Knitwear Standard Depth Scale (1/12)

FZ/T 01053 Textiles - Identification of Fiber Content

FZ/T 01057 (All Parts) Test Method for Identification of Textile Fibers

FZ/T 01095 Textile - Test Method of Elastane Fiber Content

3 Terms and Definitions

For the purpose of FZ/T 73031-2009, the following terms and definitions apply.

3.1

Pressure socks

The socks, with the pressure (mmHg) in the gradient decrease from the ankle to the

sock top, which gives people a sense of pressure when wearing and a sense of

relaxation during the movement.

4 Product Classification

The pressure socks, according to materials, are divided into pressure socks that are

woven of elastic nylon yarn (polyester yarn)/core-spun spandex yarn, pressure socks

that are woven of cotton (wool and chemical fiber blended yarn)/core-spun spandex

yarn, and pressure socks of chemical fiber/other fiber.

5 Requirements

5.1 Required contents

3 Sole length of open-toe pressure socks is beyond the scope of the assessment.

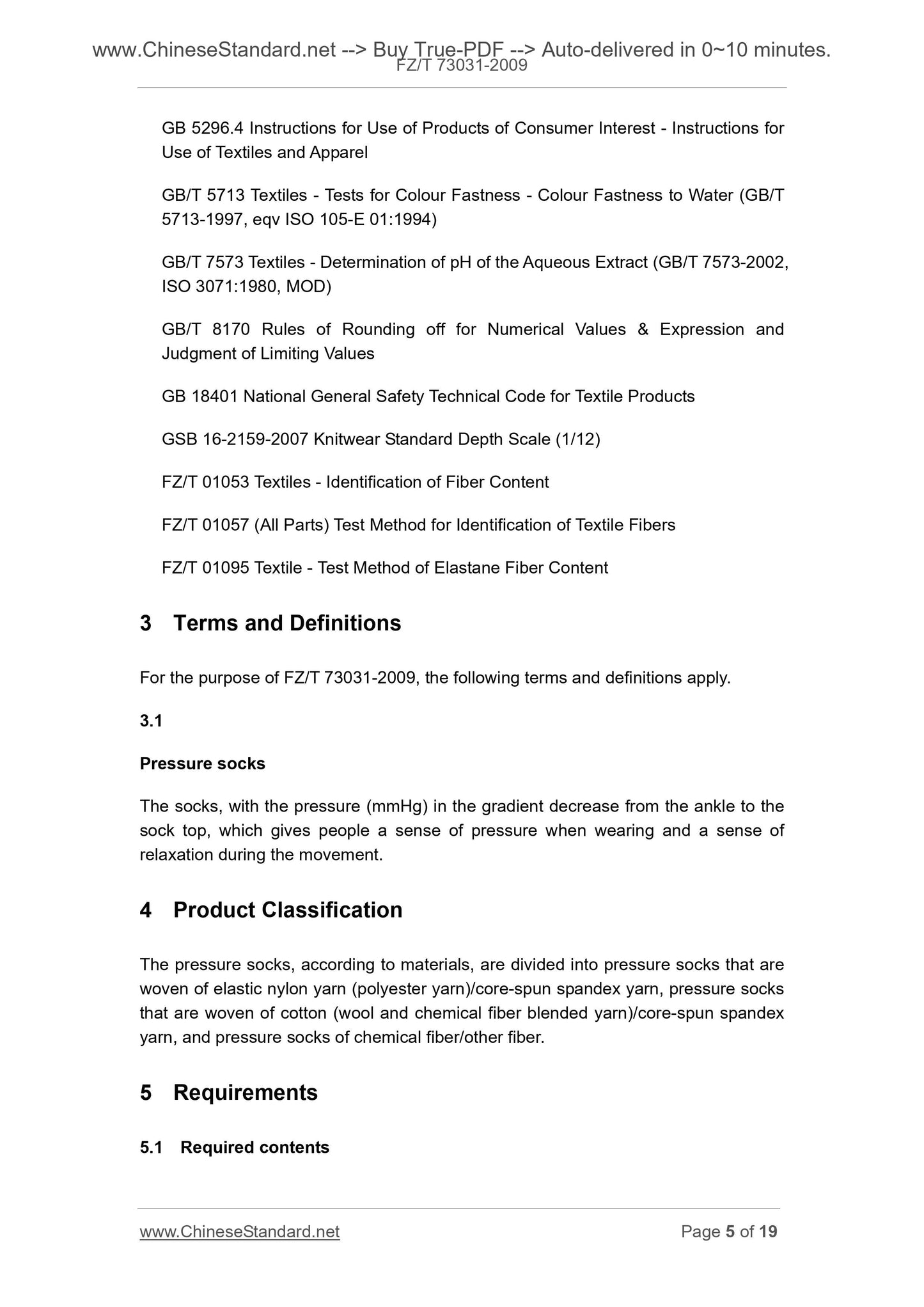

Table 5 Specification, Dimension and Tolerance for Over-knee Middle-leg Pressure Socks

Woven of Cotton (Wool and Chemical Fiber Blended Yarn)/Core-spun Spandex Yarn In mm

Size Sole length

Tolerance of

sole length

Total length

Top height

Top

width

Tolerance for

top width

22-24 19

±1 57 3 13.5 ±1

24-26 21

26-28 23

28-30 25

Notes.

1 The total length prevails when the middle and high parts of the top are aligned to the corresponding pressure test

point and the pressure socks are covered on the model leg.

2 If customers put forward additional requirements for the specification and dimension, customer requirements shall

prevail.

3 Sole length of open-toe pressure socks is beyond the scope of the assessment.

Table 6 Specification, Dimension and Tolerance for Long Pressure Socks Woven of Cotton

(Wool and Chemical Fiber Blended Yarn)/Core-spun Spandex Yarn In mm

Size Sole length Tolerance of sole length Total length≥ Top height≥

Top

width

Tolerance for

top width

22-24 19

±1 72 3 14.5 ±1

21-26 21

26-28 23

28-30 25

Notes.

1 The total length prevails when the middle and high parts of the top are aligned to the corresponding pressure test

point and the pressure socks are covered on the model leg.

2 If customers put forward additional requirements for the specification and dimension, customer requirements shall

prevail.

3 Sole length of open-toe pressure socks is beyond the scope of the assessment.

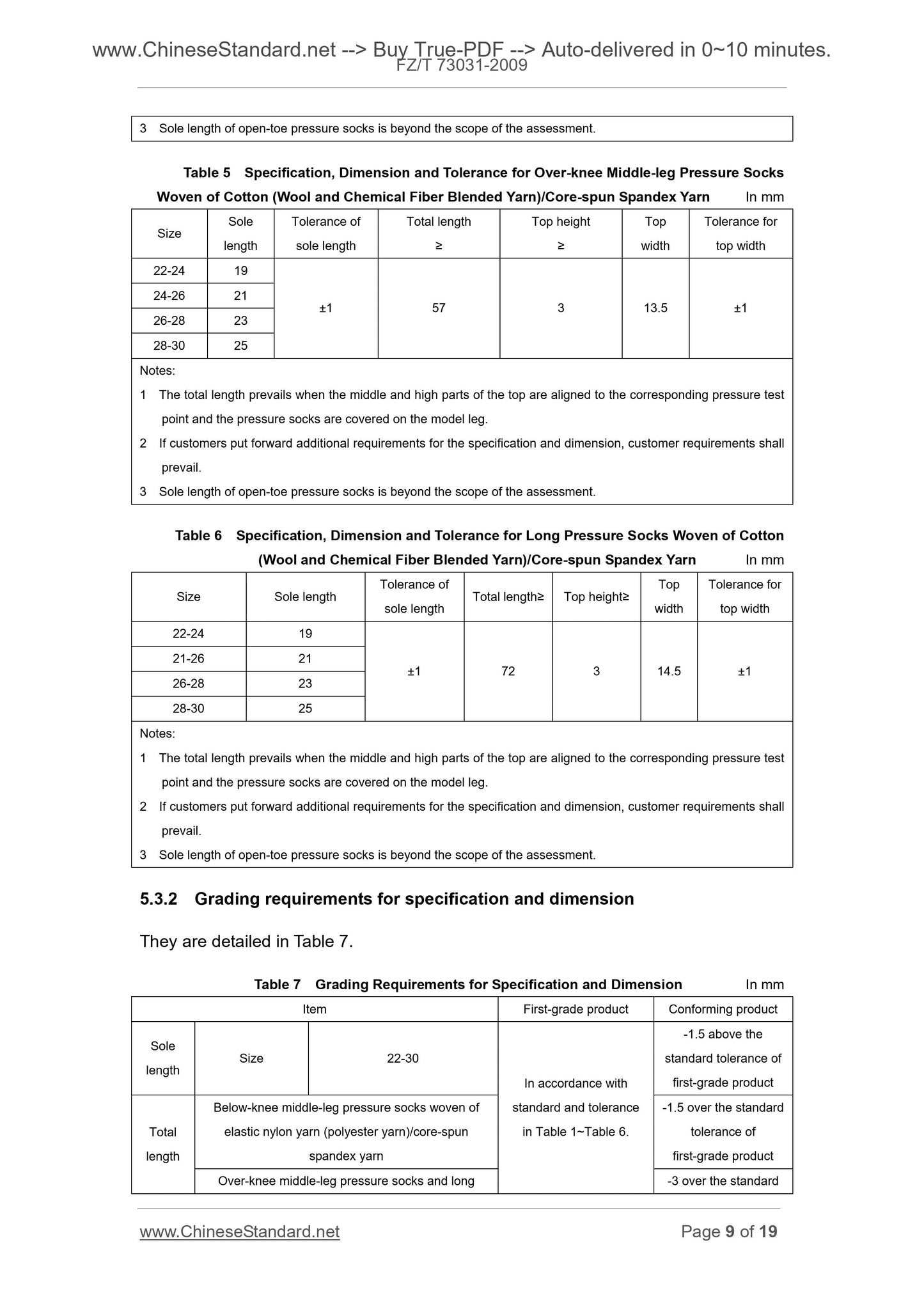

5.3.2 Grading requirements for specification and dimension

They are detailed in Table 7.

Table 7 Grading Requirements for Specification and Dimension In mm

Item First-grade product Conforming product

Sole

length Size 22-30

In accordance with

standard and tolerance

in Table 1~Table 6.

-1.5 above the

standard tolerance of

first-grade product

Total

length

Below-knee middle-leg pressure socks woven of

elastic nylon yarn (polyester yarn)/core-spun

spandex yarn

-1.5 over the standard

tolerance of

first-grade product

Over-knee middle-leg pressure socks and long -3 over the standard

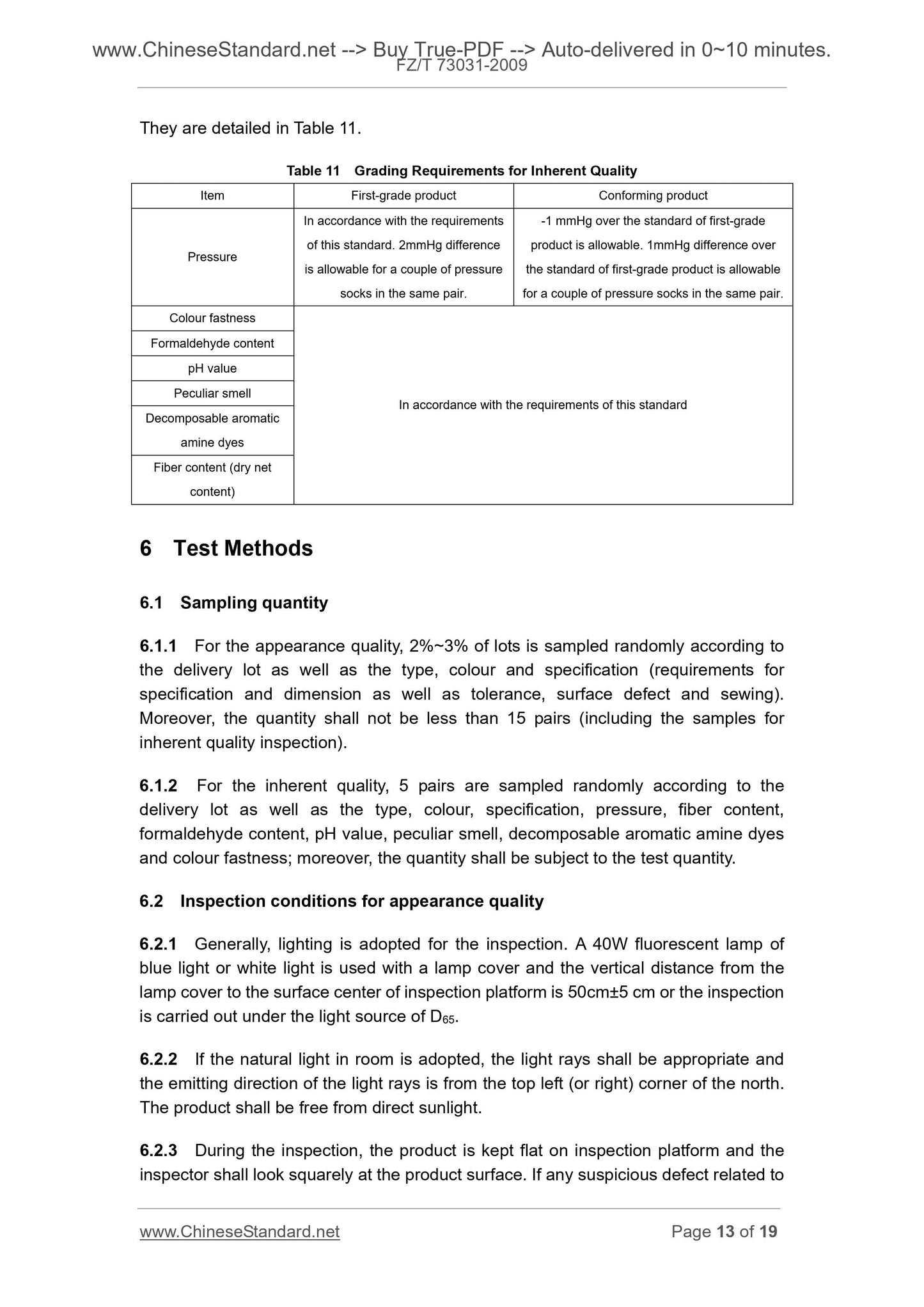

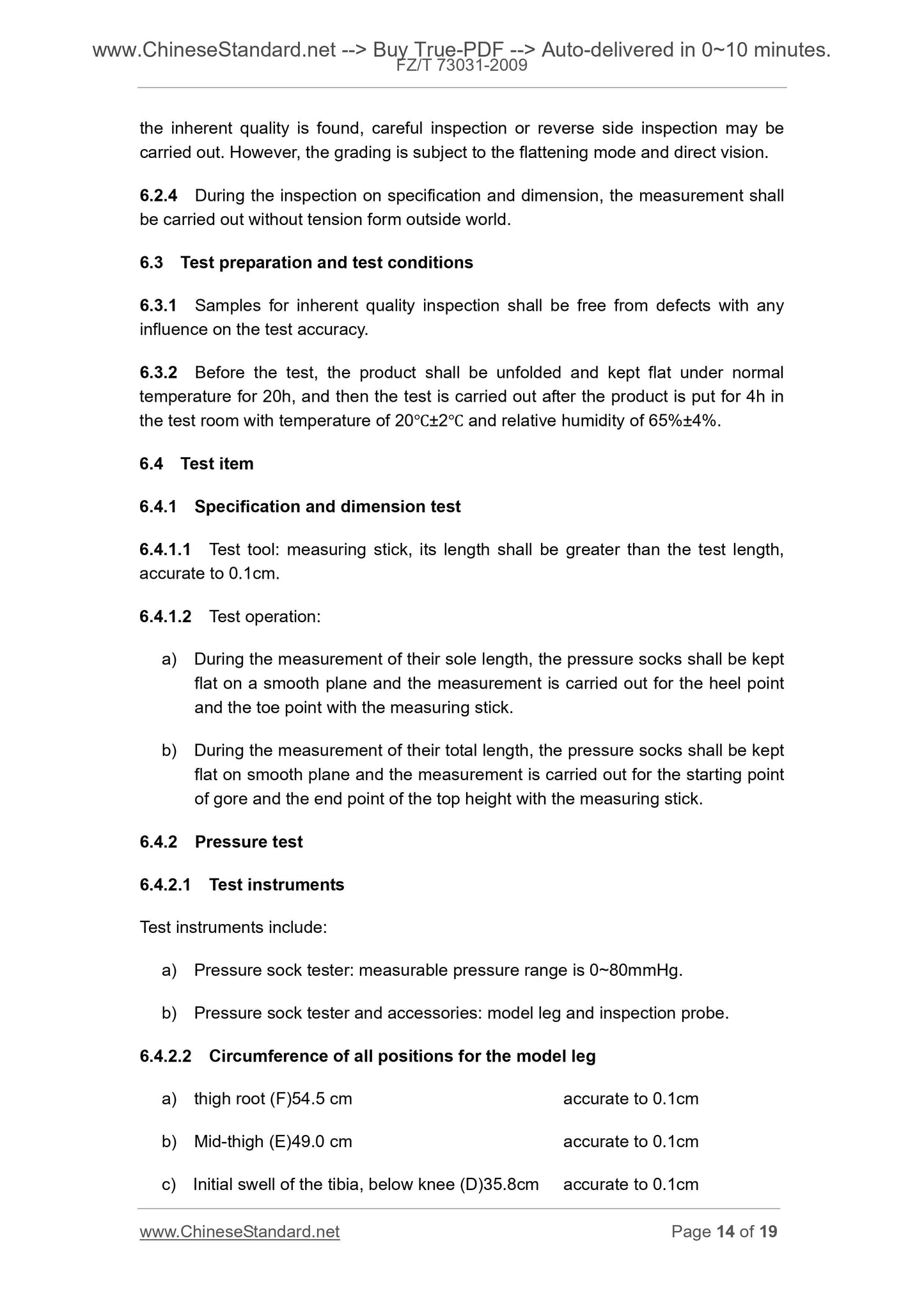

They are detailed in Table 11.

Table 11 Grading Requirements for Inherent Quality

Item First-grade product Conforming product

Pressure

In accordance with the requirements

of this standard. 2mmHg difference

is allowable for a couple of pressure

socks in the same pair.

-1 mmHg over the standard of first-grade

product is allowable. 1mmHg difference over

the standard of first-grade product is allowable

for a couple of pressure socks in the same pair.

Colour fastness

In accordance with the requirements of this standard

Formaldehyde content

pH value

Peculiar smell

Decomposable aromatic

amine dyes

Fi...

Get QUOTATION in 1-minute: Click FZ/T 73031-2009

Historical versions: FZ/T 73031-2009

Preview True-PDF (Reload/Scroll if blank)

FZ/T 73031-2009: Pressure socks

FZ/T 73031-2009

FZ

INDUSTRY STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 59.080.30

W 63

Pressure Socks

压力袜

ISSUED ON. NOVEMBER 17, 2009

IMPLEMENTED ON. APRIL 1, 2010

Issued by. Ministry of Industry and Information Technology of the

People's Republic of China

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative References ... 4

3 Terms and Definitions ... 5

4 Product Classification ... 5

5 Requirements ... 5

6 Test Methods ... 13

7 Judgment Rules ... 18

8 Product’s Instructions for Use, Packaging, Transportation and Storage ... 19

Foreword

This standard was proposed by China National Textile And Apparel Council.

This standard shall be under the jurisdiction of Technical Subcommittee on Knitwear of the

Technical Committee on Textiles of Standardization Administration of China (SAC/TC

209/SC 6).

Chief drafting organizations of this standard. Zhejiang Nai'er Group Co., Ltd., Langsha

Knitting Co., Ltd., Zhejiang Jiamengyi Hosiery Co., Ltd., Gaoyao City Gold Coast Knitting

Factory Co., Ltd. and National Quality Supervision and Inspection Center of Knitted

Products.

Chief drafting staffs of this standard. Shi Jigang, Liu Ailian, Jin Jianming, Yu Jianjun and

Dai Zhengyi.

Pressure Socks

1 Scope

This standard specifies pressure socks’ terms and definitions, product classification,

requirements, test methods, judgment rules as well as product’s instructions for use,

packaging, transportation and storage.

This standard is applicable to appraise the quality of chemical fiber pressure socks

and pressure socks that are interwoven of cotton (wool and chemical fiber blended

yarn) and chemical fiber. Other fiber pressure socks may be referred to this standard.

2 Normative References

The following standards contain the provisions which, through reference in this

standard, constitute the provisions of this standard. For dated reference, the

subsequent amendments (excluding corrigendum) or revisions of these publications

do not apply. However, all parties who reach into an agreement according to this

standard are encouraged to study whether the latest edition of these documents is

applicable. For undated references, the latest edition of the normative document

applies.

GB/T 250 Textiles - Tests for Colour Fastness - Grey Scale for Assessing Change

in Colour (GB/T 250-2008, ISO 105-A 02.1993, IDT)

GB/T 251 Textiles - Tests for Colour Fastness - Grey Scale for Assessing Staining

(GB/T 251-2008, ISO 105-A 03.1993, IDT)

GB/T 2910 (All Parts) Textiles - Quantitative Chemical Analysis

GB/T 2912.1 Textiles - Determination of Formaldehyde - Part 1. Free and

Hydrolized Formaldehyde (Water Extraction Method)

GB/T 3920 Textiles - Tests for Colour Fastness - Colour Fastness to Rubbing

(GB/T 3920-1997, eqv ISO 105-X 12.1993)

GB/T 3921 Textiles - Tests for Colour Fastness - Colour Fastness to Washing with

Soap or Soap and Soda (GB/T 3921-2008, ISO 105-C10.2006, MOD)

GB/T 3922 Textiles - Testing Method for Colour Fastness to Perspiration (GB/T

3922-1995, eqv ISO 105-E 04.1994)

GB/T 4856 Package of Cotton Goods and Knitwear

GB 5296.4 Instructions for Use of Products of Consumer Interest - Instructions for

Use of Textiles and Apparel

GB/T 5713 Textiles - Tests for Colour Fastness - Colour Fastness to Water (GB/T

5713-1997, eqv ISO 105-E 01.1994)

GB/T 7573 Textiles - Determination of pH of the Aqueous Extract (GB/T 7573-2002,

ISO 3071.1980, MOD)

GB/T 8170 Rules of Rounding off for Numerical Values and Expression and

Judgment of Limiting Values

GB 18401 National General Safety Technical Code for Textile Products

GSB 16-2159-2007 Knitwear Standard Depth Scale (1/12)

FZ/T 01053 Textiles - Identification of Fiber Content

FZ/T 01057 (All Parts) Test Method for Identification of Textile Fibers

FZ/T 01095 Textile - Test Method of Elastane Fiber Content

3 Terms and Definitions

For the purpose of FZ/T 73031-2009, the following terms and definitions apply.

3.1

Pressure socks

The socks, with the pressure (mmHg) in the gradient decrease from the ankle to the

sock top, which gives people a sense of pressure when wearing and a sense of

relaxation during the movement.

4 Product Classification

The pressure socks, according to materials, are divided into pressure socks that are

woven of elastic nylon yarn (polyester yarn)/core-spun spandex yarn, pressure socks

that are woven of cotton (wool and chemical fiber blended yarn)/core-spun spandex

yarn, and pressure socks of chemical fiber/other fiber.

5 Requirements

5.1 Required contents

3 Sole length of open-toe pressure socks is beyond the scope of the assessment.

Table 5 Specification, Dimension and Tolerance for Over-knee Middle-leg Pressure Socks

Woven of Cotton (Wool and Chemical Fiber Blended Yarn)/Core-spun Spandex Yarn In mm

Size Sole length

Tolerance of

sole length

Total length

Top height

Top

width

Tolerance for

top width

22-24 19

±1 57 3 13.5 ±1

24-26 21

26-28 23

28-30 25

Notes.

1 The total length prevails when the middle and high parts of the top are aligned to the corresponding pressure test

point and the pressure socks are covered on the model leg.

2 If customers put forward additional requirements for the specification and dimension, customer requirements shall

prevail.

3 Sole length of open-toe pressure socks is beyond the scope of the assessment.

Table 6 Specification, Dimension and Tolerance for Long Pressure Socks Woven of Cotton

(Wool and Chemical Fiber Blended Yarn)/Core-spun Spandex Yarn In mm

Size Sole length Tolerance of sole length Total length≥ Top height≥

Top

width

Tolerance for

top width

22-24 19

±1 72 3 14.5 ±1

21-26 21

26-28 23

28-30 25

Notes.

1 The total length prevails when the middle and high parts of the top are aligned to the corresponding pressure test

point and the pressure socks are covered on the model leg.

2 If customers put forward additional requirements for the specification and dimension, customer requirements shall

prevail.

3 Sole length of open-toe pressure socks is beyond the scope of the assessment.

5.3.2 Grading requirements for specification and dimension

They are detailed in Table 7.

Table 7 Grading Requirements for Specification and Dimension In mm

Item First-grade product Conforming product

Sole

length Size 22-30

In accordance with

standard and tolerance

in Table 1~Table 6.

-1.5 above the

standard tolerance of

first-grade product

Total

length

Below-knee middle-leg pressure socks woven of

elastic nylon yarn (polyester yarn)/core-spun

spandex yarn

-1.5 over the standard

tolerance of

first-grade product

Over-knee middle-leg pressure socks and long -3 over the standard

They are detailed in Table 11.

Table 11 Grading Requirements for Inherent Quality

Item First-grade product Conforming product

Pressure

In accordance with the requirements

of this standard. 2mmHg difference

is allowable for a couple of pressure

socks in the same pair.

-1 mmHg over the standard of first-grade

product is allowable. 1mmHg difference over

the standard of first-grade product is allowable

for a couple of pressure socks in the same pair.

Colour fastness

In accordance with the requirements of this standard

Formaldehyde content

pH value

Peculiar smell

Decomposable aromatic

amine dyes

Fi...

Share