1

/

de

5

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

GB/T 37619-2019 English PDF (GBT37619-2019)

GB/T 37619-2019 English PDF (GBT37619-2019)

Prix habituel

$150.00 USD

Prix habituel

Prix promotionnel

$150.00 USD

Prix unitaire

/

par

Frais d'expédition calculés à l'étape de paiement.

Impossible de charger la disponibilité du service de retrait

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 37619-2019

Historical versions: GB/T 37619-2019

Preview True-PDF (Reload/Scroll if blank)

GB/T 37619-2019: Corrosion of metals and alloys -- Potentiostatic test and evaluation method for determination of susceptibility to grooving corrosion of high frequency electric resistance welded steel pipes

GB/T 37619-2019

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.060

H 25

Corrosion of Metals and Alloys - Potentiostatic

Test and Evaluation Method for Determination of

Susceptibility to Grooving Corrosion of High

Frequency Electric Resistance Welded Steel Pipes

ISSUED ON: JUNE 04, 2019

IMPLEMENTED ON: MAY 01, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

Introduction ... 4

1 Scope ... 5

2 Normative References ... 5

3 Terms and Definitions ... 5

4 Principle ... 6

5 Devices and Materials ... 6

6 Preparation of Specimen and Solution ... 7

7 Procedures ... 8

8 Evaluation of Test Results ... 10

9 Test Report ... 10

Appendix A (Informative) Potential of Optional Reference Electrode at 25°C

corresponding to Standard Hydrogen Electrode (SHE) ... 11

Corrosion of Metals and Alloys - Potentiostatic

Test and Evaluation Method for Determination of

Susceptibility to Grooving Corrosion of High

Frequency Electric Resistance Welded Steel Pipes

1 Scope

This Standard specifies a method for evaluating the grooving corrosion of high-

frequency electric resistance welded steel pipes by using the constant potential anodic

polarization method in a 3.5% NaCl solution.

This Standard is applicable to the test of grooving corrosion for carbon steel high-

frequency electric resistance welded pipes.

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) are applicable to this document.

GB/T 16545 Corrosion of Metals and Alloys - Removal of Corrosion Products from

Corrosion Test Specimens

GB/T 18590-2001 Corrosion of Metals and Alloys - Evaluation of Pitting Corrosion

JB/T 10579-2006 Standard Practice for Applying Statistics of Corrosion Data

3 Terms and Definitions

For the purposes of this document, the following terms and definitions apply.

3.1 Grooving corrosion

The corrosion state that occurs at the weld junction and forms a deep-valley or

horseshoe-shaped narrow groove.

3.2 Grooving corrosion sensitivity coefficient

The ratio of the maximum corrosion depth (the sum of the average corrosion depth of

the specimen and the maximum grooving corrosion depth) and the average corrosion

depth of the specimen at the junction.

4 Principle

Since the difference in composition, structure and residual stress BETWEEN the high-

frequency electric resistance steel pipes weld-seam AND the base metal, the welded

steel pipes may form the corrosion groove at the weld junction during the serving

process. Such difference can be highlighted by applying appropriate anode potential

to the welded steel pipe weld-seam for polarization, and further rapidly characterize

the resistance of grooving corrosion of the high-frequency electric resistance welded

steel pipe weld-seam.

5 Devices and Materials

5.1 Potentiostat

The potentiostat shall meet the following requirements:

--- Voltage range: -2V ~ +2V;

--- Current range: -1A ~ +1A;

--- Voltage resolution shall be no less than 1mV;

--- Current resolution shall be no less than 0.01mA.

5.2 Tested electrolytic cell

The tested electrolytic cell shall contain a working electrode (specimen), one is used a

s the reference electrode for measuring the electrode potential; and one or two

auxiliary electrodes. The tested electrolytic cell shall have a gas inlet and a gas outlet.

The auxiliary electrode shall be placed reasonably so that the current on the sample

can evenly distributed. In order to minimize the solution resistance between the

reference electrode and the working electrode; the front end of the capillary shall be

placed approximately 2 times the capillary diameter away from the working electrode,

but no close than the position of 2 times the capillary diameter. The tested electrolytic

cell shall be made of a material that is inert under the test temperature environment.

The solution volume on the sample surface is greater than 500mL/cm2. The

composition and installation of the tested electrolytic cell can refer to Figure 1.

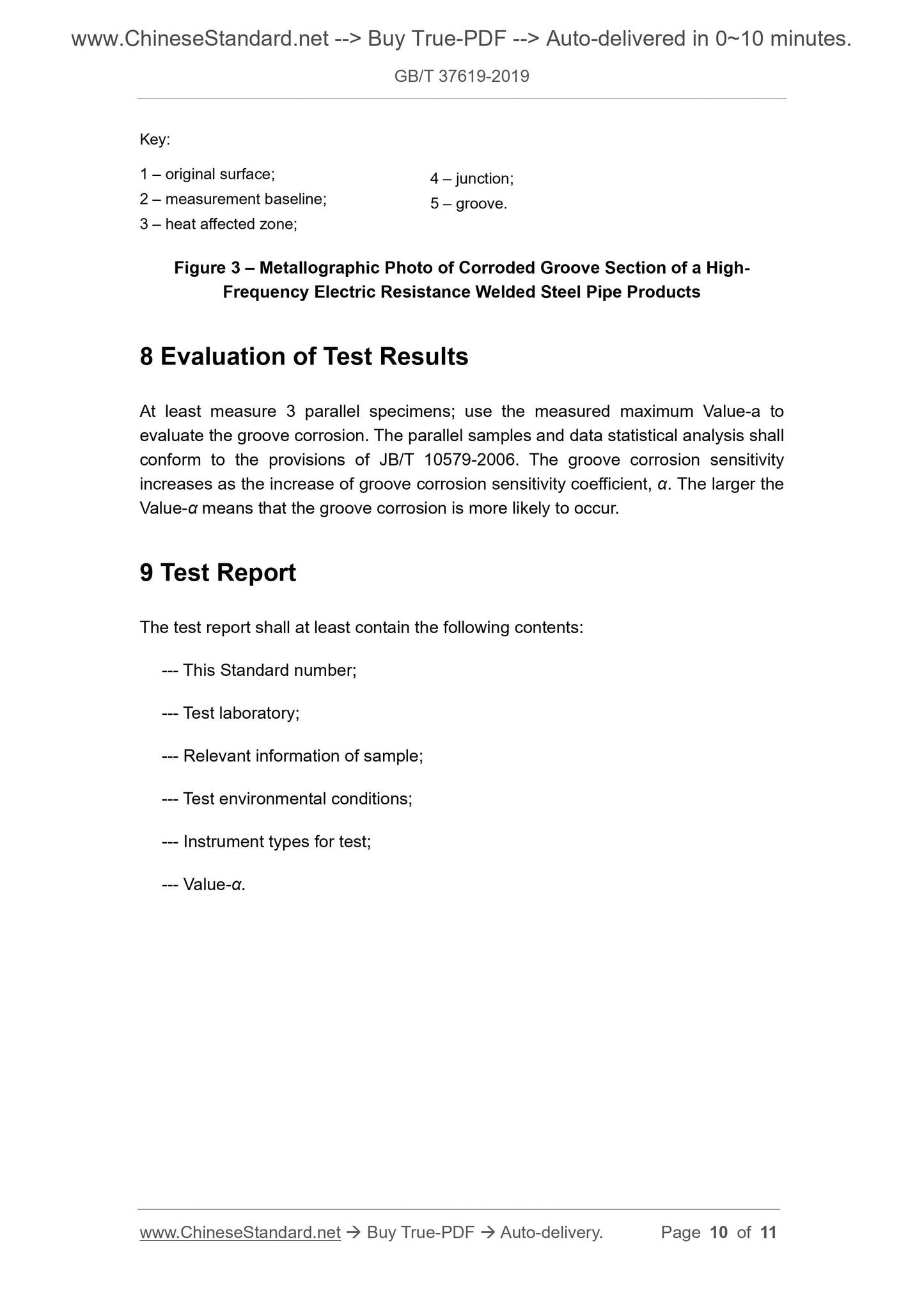

Key:

Figure 3 – Metallographic Photo of Corroded Groove Section of a High-

Frequency Electric Resistance Welded Steel Pipe Products

8 Evaluation of Test Results

At least measure 3 parallel specimens; use the measured maximum Value-a to

evaluate the groove corrosion. The parallel samples and data statistical analysis shall

conform to the provisions of JB/T 10579-2006. The groove corrosion sensitivity

increases as the increase of groove corrosion sensitivity coefficient, α. The larger the

Value-α means that the groove corrosion is more likely to occur.

9 Test Report

The test report shall at least contain the following contents:

--- This Standard number;

--- Test laboratory;

--- Relevant information of sample;

--- Test environmental conditions;

--- Instrument types for test;

--- Value-α.

1 – original surface;

2 – measurement baseline;

3 – heat affected zone;

4 – junction;

5 – groove.

Get QUOTATION in 1-minute: Click GB/T 37619-2019

Historical versions: GB/T 37619-2019

Preview True-PDF (Reload/Scroll if blank)

GB/T 37619-2019: Corrosion of metals and alloys -- Potentiostatic test and evaluation method for determination of susceptibility to grooving corrosion of high frequency electric resistance welded steel pipes

GB/T 37619-2019

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 77.060

H 25

Corrosion of Metals and Alloys - Potentiostatic

Test and Evaluation Method for Determination of

Susceptibility to Grooving Corrosion of High

Frequency Electric Resistance Welded Steel Pipes

ISSUED ON: JUNE 04, 2019

IMPLEMENTED ON: MAY 01, 2020

Issued by: State Administration for Market Regulation;

Standardization Administration of PRC.

Table of Contents

Foreword ... 3

Introduction ... 4

1 Scope ... 5

2 Normative References ... 5

3 Terms and Definitions ... 5

4 Principle ... 6

5 Devices and Materials ... 6

6 Preparation of Specimen and Solution ... 7

7 Procedures ... 8

8 Evaluation of Test Results ... 10

9 Test Report ... 10

Appendix A (Informative) Potential of Optional Reference Electrode at 25°C

corresponding to Standard Hydrogen Electrode (SHE) ... 11

Corrosion of Metals and Alloys - Potentiostatic

Test and Evaluation Method for Determination of

Susceptibility to Grooving Corrosion of High

Frequency Electric Resistance Welded Steel Pipes

1 Scope

This Standard specifies a method for evaluating the grooving corrosion of high-

frequency electric resistance welded steel pipes by using the constant potential anodic

polarization method in a 3.5% NaCl solution.

This Standard is applicable to the test of grooving corrosion for carbon steel high-

frequency electric resistance welded pipes.

2 Normative References

The following documents are essential to the application of this document. For the

dated documents, only the versions with the dates indicated are applicable to this

document; for the undated documents, only the latest version (including all the

amendments) are applicable to this document.

GB/T 16545 Corrosion of Metals and Alloys - Removal of Corrosion Products from

Corrosion Test Specimens

GB/T 18590-2001 Corrosion of Metals and Alloys - Evaluation of Pitting Corrosion

JB/T 10579-2006 Standard Practice for Applying Statistics of Corrosion Data

3 Terms and Definitions

For the purposes of this document, the following terms and definitions apply.

3.1 Grooving corrosion

The corrosion state that occurs at the weld junction and forms a deep-valley or

horseshoe-shaped narrow groove.

3.2 Grooving corrosion sensitivity coefficient

The ratio of the maximum corrosion depth (the sum of the average corrosion depth of

the specimen and the maximum grooving corrosion depth) and the average corrosion

depth of the specimen at the junction.

4 Principle

Since the difference in composition, structure and residual stress BETWEEN the high-

frequency electric resistance steel pipes weld-seam AND the base metal, the welded

steel pipes may form the corrosion groove at the weld junction during the serving

process. Such difference can be highlighted by applying appropriate anode potential

to the welded steel pipe weld-seam for polarization, and further rapidly characterize

the resistance of grooving corrosion of the high-frequency electric resistance welded

steel pipe weld-seam.

5 Devices and Materials

5.1 Potentiostat

The potentiostat shall meet the following requirements:

--- Voltage range: -2V ~ +2V;

--- Current range: -1A ~ +1A;

--- Voltage resolution shall be no less than 1mV;

--- Current resolution shall be no less than 0.01mA.

5.2 Tested electrolytic cell

The tested electrolytic cell shall contain a working electrode (specimen), one is used a

s the reference electrode for measuring the electrode potential; and one or two

auxiliary electrodes. The tested electrolytic cell shall have a gas inlet and a gas outlet.

The auxiliary electrode shall be placed reasonably so that the current on the sample

can evenly distributed. In order to minimize the solution resistance between the

reference electrode and the working electrode; the front end of the capillary shall be

placed approximately 2 times the capillary diameter away from the working electrode,

but no close than the position of 2 times the capillary diameter. The tested electrolytic

cell shall be made of a material that is inert under the test temperature environment.

The solution volume on the sample surface is greater than 500mL/cm2. The

composition and installation of the tested electrolytic cell can refer to Figure 1.

Key:

Figure 3 – Metallographic Photo of Corroded Groove Section of a High-

Frequency Electric Resistance Welded Steel Pipe Products

8 Evaluation of Test Results

At least measure 3 parallel specimens; use the measured maximum Value-a to

evaluate the groove corrosion. The parallel samples and data statistical analysis shall

conform to the provisions of JB/T 10579-2006. The groove corrosion sensitivity

increases as the increase of groove corrosion sensitivity coefficient, α. The larger the

Value-α means that the groove corrosion is more likely to occur.

9 Test Report

The test report shall at least contain the following contents:

--- This Standard number;

--- Test laboratory;

--- Relevant information of sample;

--- Test environmental conditions;

--- Instrument types for test;

--- Value-α.

1 – original surface;

2 – measurement baseline;

3 – heat affected zone;

4 – junction;

5 – groove.

Share