1

/

de

12

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

HG/T 20613-2009 English PDF (HGT20613-2009)

HG/T 20613-2009 English PDF (HGT20613-2009)

Prix habituel

$145.00 USD

Prix habituel

Prix promotionnel

$145.00 USD

Prix unitaire

/

par

Frais d'expédition calculés à l'étape de paiement.

Impossible de charger la disponibilité du service de retrait

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click HG/T 20613-2009

Historical versions: HG/T 20613-2009

Preview True-PDF (Reload/Scroll if blank)

HG/T 20613-2009: Bolting for use with steel pipe flanges (PN designated)

HG/T 20613-2009

Chemical Industry Standard

of the People's Republic of China

HG

Replacing HG 20613-1997

Bolting for Use with Steel Pipe Flanges

(PN designated)

(PN系列)

ISSUED ON. FEBRUARY 5, 2009

IMPLEMENTED ON. JULY 1, 2009

Issued by. Ministry of Industry and Information Technology of the People’s

Republic of China

[Including Corrigendum/Modification confirmed in May 2012. Text in RED]

Contents

1. Scope ... 3

2. Normative references ... 3

3. Pattern, specification and dimension of bolting ... 4

4. Materials... 7

5. Bolting service ... 9

6. Dimension tolerance ... 35

7. Surface treatment ... 35

8. Inspection ... 35

9. Acceptance, packaging and quality certificate ... 35

10. Marking and labeling ... 36

Appendix A (Informative) Flap Gasket for Pipe Flange Bolting ... 37

Appendix B (informative) Bolting and Bolting Insulation Parts for Insulating Flange 40

1. Scope

This standard specifies pattern, dimension, material, marking, technical requirement and

service provisions of bolting for use with steel pipe flanges (PN designated).

This Standard is applicable to HG/T 20592 Bolting for use with Steel Pipe Flange,

including hex bolt, double end studs (clamping type), full thread stud and nut.

2. Normative references

The following standards contain provisions which, through reference in this text,

constitute provisions of this Standard. For dated reference, subsequent amendments

(excluding content of corrigenda) to, or revisions of, any of these publications do not apply.

However, Parties to agreements based on this Code are encouraged to investigate the

possibility of applying the most recent editions of the standards indicated below. For undated

references, the latest edition of the normative document referred to applies.

"Fasteners--Ends of Parts with External Thread" GB/T 2

"Fasteners--Acceptance Inspection" GB/T 90.1

"Fasteners--Marking and Packaging" GB/T 90.2

"General Purpose Metric Screw Threads—Basic Dimensions" GB/T 196

"General Purpose Metric Screw Threads—Tolerances" GB/T197

"Double End Studs (Clamping Type)-Product Grade B" GB/T 901

"Stainless Steel Bars" GB/T 1220

"Alloy Structure Steels" GB/T 3077

"Mechanical Properties of Fasteners--Bolts, Screws and Studs" GB/T 3098.1

"Mechanical Properties of Fasteners--Nuts--Coarse Thread" GB/T 3098.2

"Mechanical Properties of Corrosion-resistant Stainless-steel Fasteners-Part 1. Bolts,

Screws and Studs" GB/T 3098.6

"Mechanical Properties of Fasteners-Nuts made of Stainless-steel" GB/T 3098.15

"Tolerances for Fasteners--Bolts, Screws, Studs and Nuts" GB/T 3103.1

"Laminated Rods" GB/T 5133

"Hexagon Head Bolts" GB/T 5782

"Hexagon Head Bolts with Fine Pitch Thread" GB/T 5785

"Hexagon Nuts, Style I" GB/T 6170

"Hexagon Nuts, Style I with Fine Pitch Thread" GB/T 6171

"Hexagon Nuts, Style II" GB/T 6175

"Hexagon Nuts, Style II with Fine Pitch Thread" GB/T 6176

"Fasteners-Surface Discontinuities-Bolts, Screws and Studs for General Requirements"

GB/T 5779.1

"Fasteners-Surface Discontinuities-Nuts" GB/T 5779.2

"Fasteners-Surface Discontinuities-Bolts, Screws and Studs for Special Requirements"

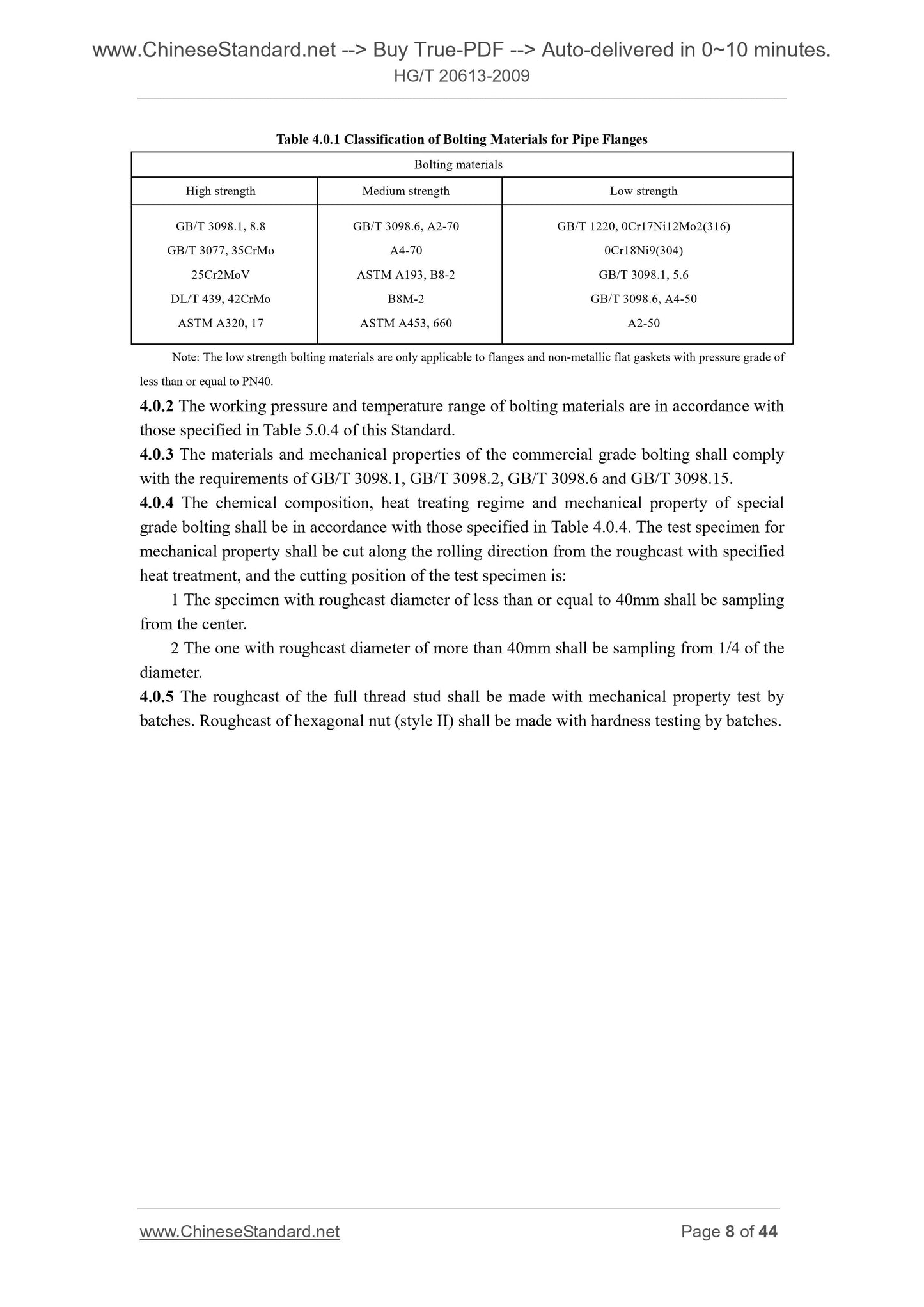

Table 4.0.1 Classification of Bolting Materials for Pipe Flanges

Bolting materials

High strength Medium strength Low strength

GB/T 3098.1, 8.8

GB/T 3077, 35CrMo

25Cr2MoV

DL/T 439, 42CrMo

ASTM A320, 17

GB/T 3098.6, A2-70

A4-70

ASTM A193, B8-2

B8M-2

ASTM A453, 660

GB/T 1220, 0Cr17Ni12Mo2(316)

0Cr18Ni9(304)

GB/T 3098.1, 5.6

GB/T 3098.6, A4-50

A2-50

Note. The low strength bolting materials are only applicable to flanges and non-metallic flat gaskets with pressure grade of

less than or equal to PN40.

4.0.2 The working pressure and temperature range of bolting materials are in accordance with

those specified in Table 5.0.4 of this Standard.

4.0.3 The materials and mechanical properties of the commercial grade bolting shall comply

with the requirements of GB/T 3098.1, GB/T 3098.2, GB/T 3098.6 and GB/T 3098.15.

4.0.4 The chemical composition, heat treating regime and mechanical property of special

grade bolting shall be in accordance with those specified in Table 4.0.4. The test specimen for

mechanical property shall be cut along the rolling direction from the roughcast with specified

heat treatment, and the cutting position of the test specimen is.

1 The specimen with roughcast diameter of less than or equal to 40mm shall be sampling

from the center.

2 The one with roughcast diameter of more than 40mm shall be sampling from 1/4 of the

diameter.

4.0.5 The roughcast of the full thread stud shall be made with mechanical property test by

batches. Roughcast of hexagonal nut (style II) shall be made with hardness testing by batches.

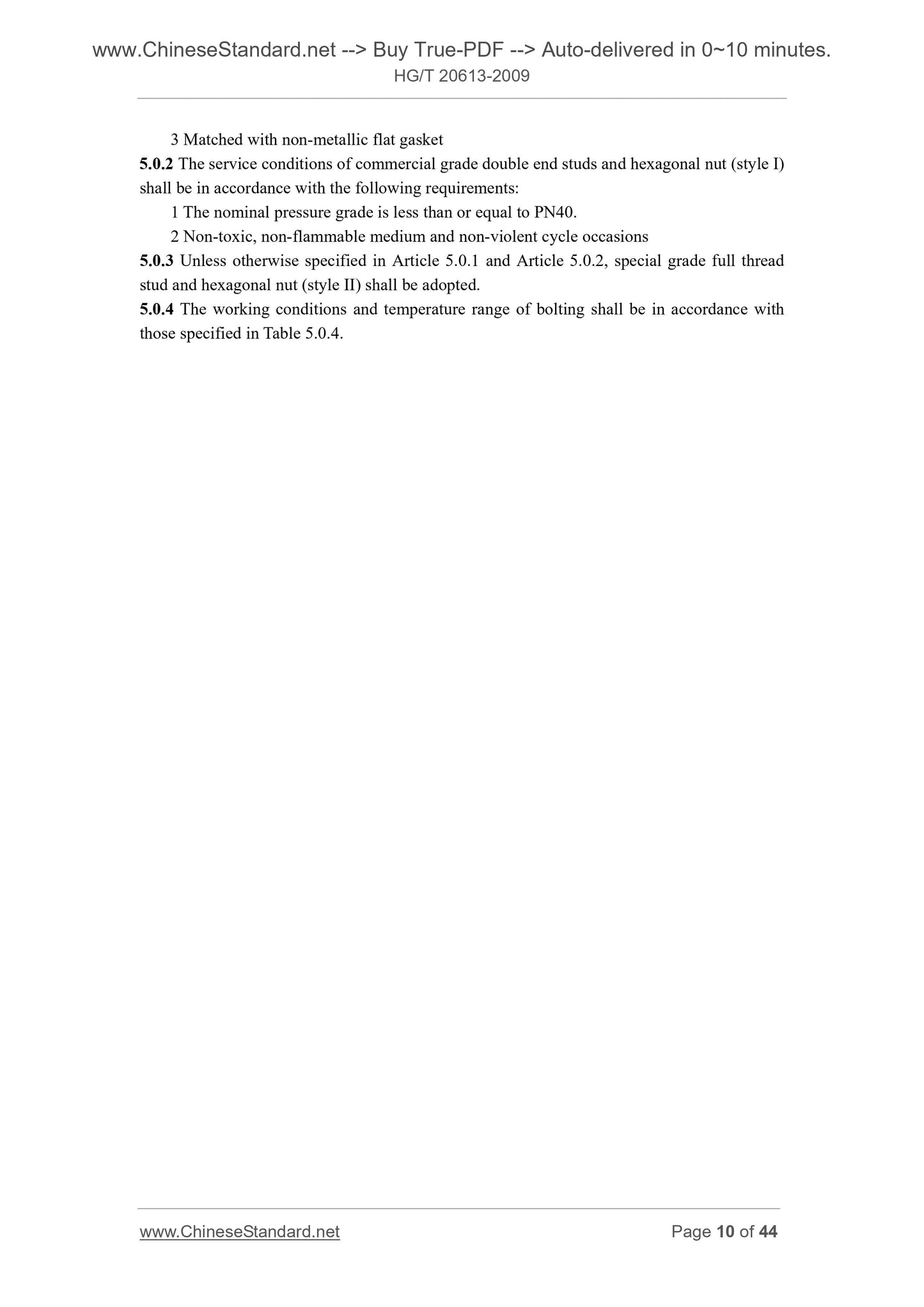

3 Matched with non-metallic flat gasket

5.0.2 The service conditions of commercial grade double end studs and hexagonal nut (style I)

shall be in accordance with the following requirements.

1 The nominal pressure grade is less than or equal to PN40.

2 Non-toxic, non-flammable medium and non-violent cycle occasions

5.0.3 Unless otherwise specified in Article 5.0.1 and Article 5.0.2, special grade full thread

stud and hexagonal nut (style II) shall be adopted.

5.0.4 The working conditions and temperature range of bolting shall be in accordance with

those specified in Table 5.0.4.

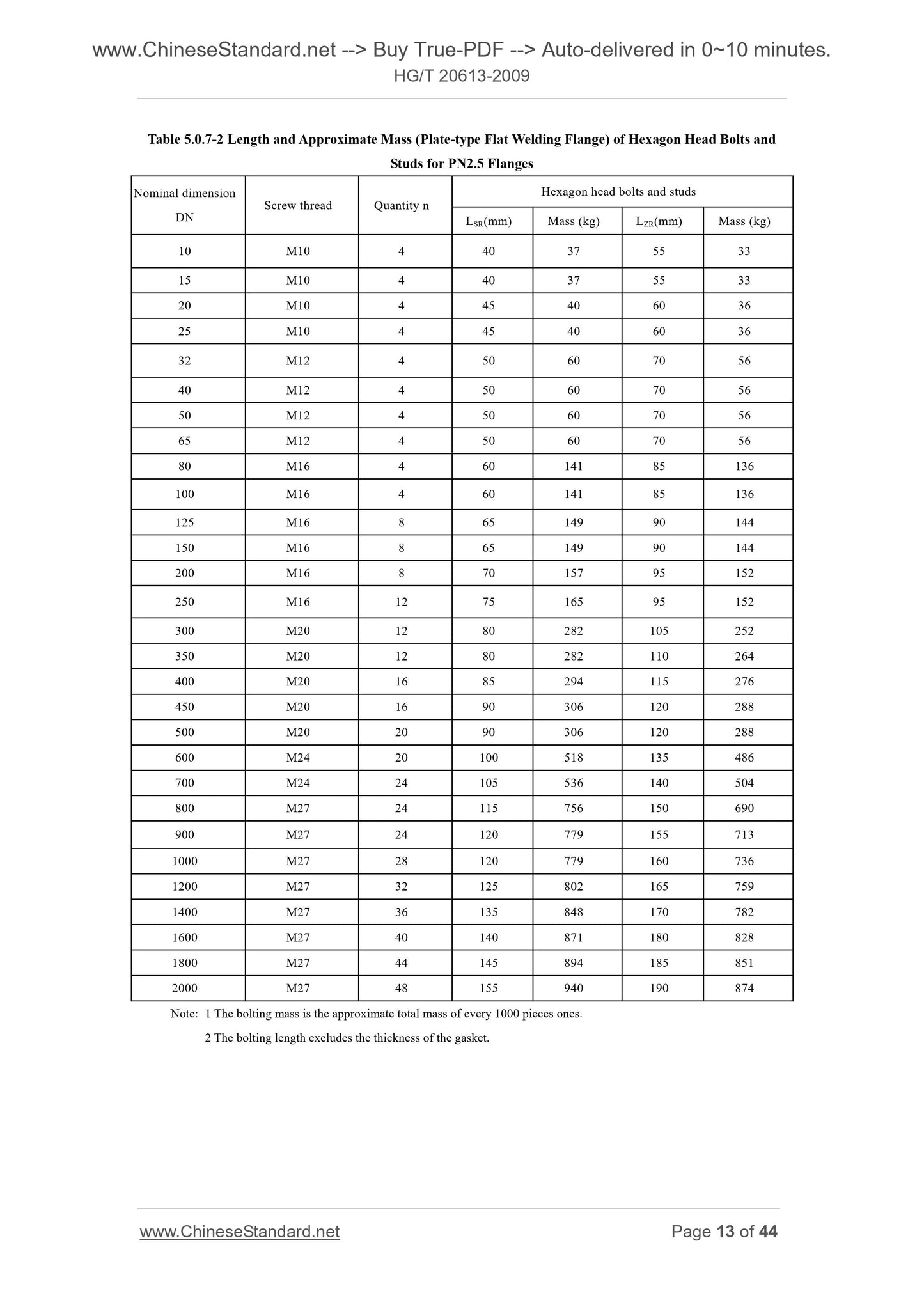

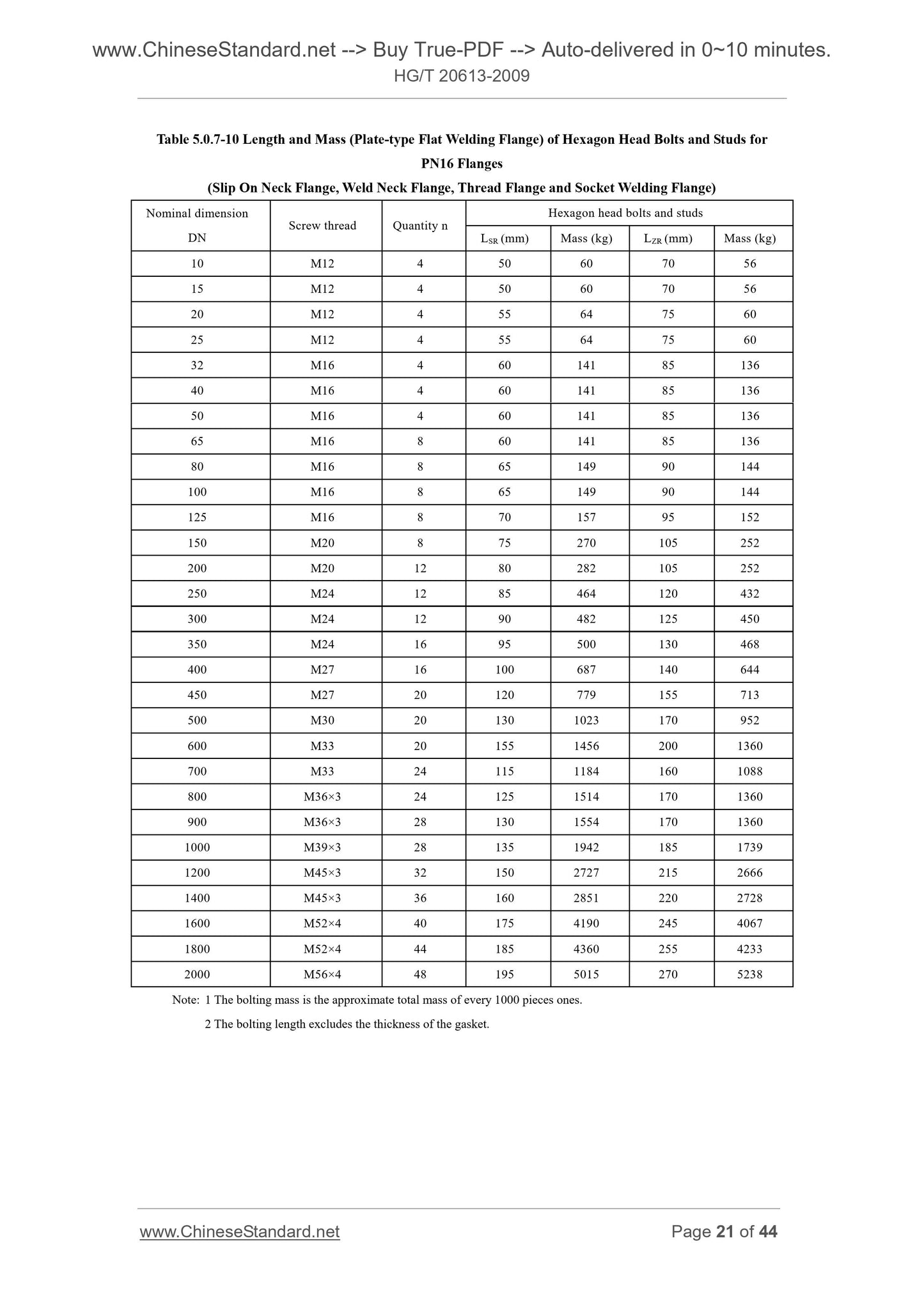

Table 5.0.7-2 Length and Approximate Mass (Plate-type Flat Welding Flange) of Hexagon Head Bolts and

Studs for PN2.5 Flanges

Nominal dimension

DN Screw thread Quantity n

Hexagon head bolts and studs

LSR(mm) Mass (kg) LZR(mm) Mass (kg)

10 M10 4 40 37 55 33

15 M10 4 40 37 55 33

20 M10 4 45 40 60 36

25 M10 4 45 40 60 36

32 M12 4 50 60 70 56

40 M12 4 50 60 70 56

50 M12 4 50 60 70 56

65 M12 4 50 60 70 56

80 M16 4 60 141 85 136

100 M16 4 60 141 85 136

125 M16 8 65 149 90 144

150 M16 8 65 149 90 144

200 M16 8 70 157 95 152

250 M16 12 75 165 95 152

300 M20 12 80 282 105 252

350 M20 12 80 282 110 264

400 M20 16 85 294 115 276

450 M20 16 90 306 120 288

500 M20 20 90 306 120 288

600 M24 20 100 518 135 486

700 M24 24 105 536 140 504

800 M27 24 115 756 150 690

900 M27 24 120 779 155 713

1000 M27 28 120 779 160 736

1200 M27 32 125 802 165 759

1400 M27 36 135 848 170 782

1600 M27 40 140 871 180 828

1800 M27 44 145 894 185 851

2000 M27 48 155 940 190 874

Note. 1 The bolting mass is the approximate total mass of every 1000 pieces ones.

2 The bolting length excludes the thickness of the gasket.

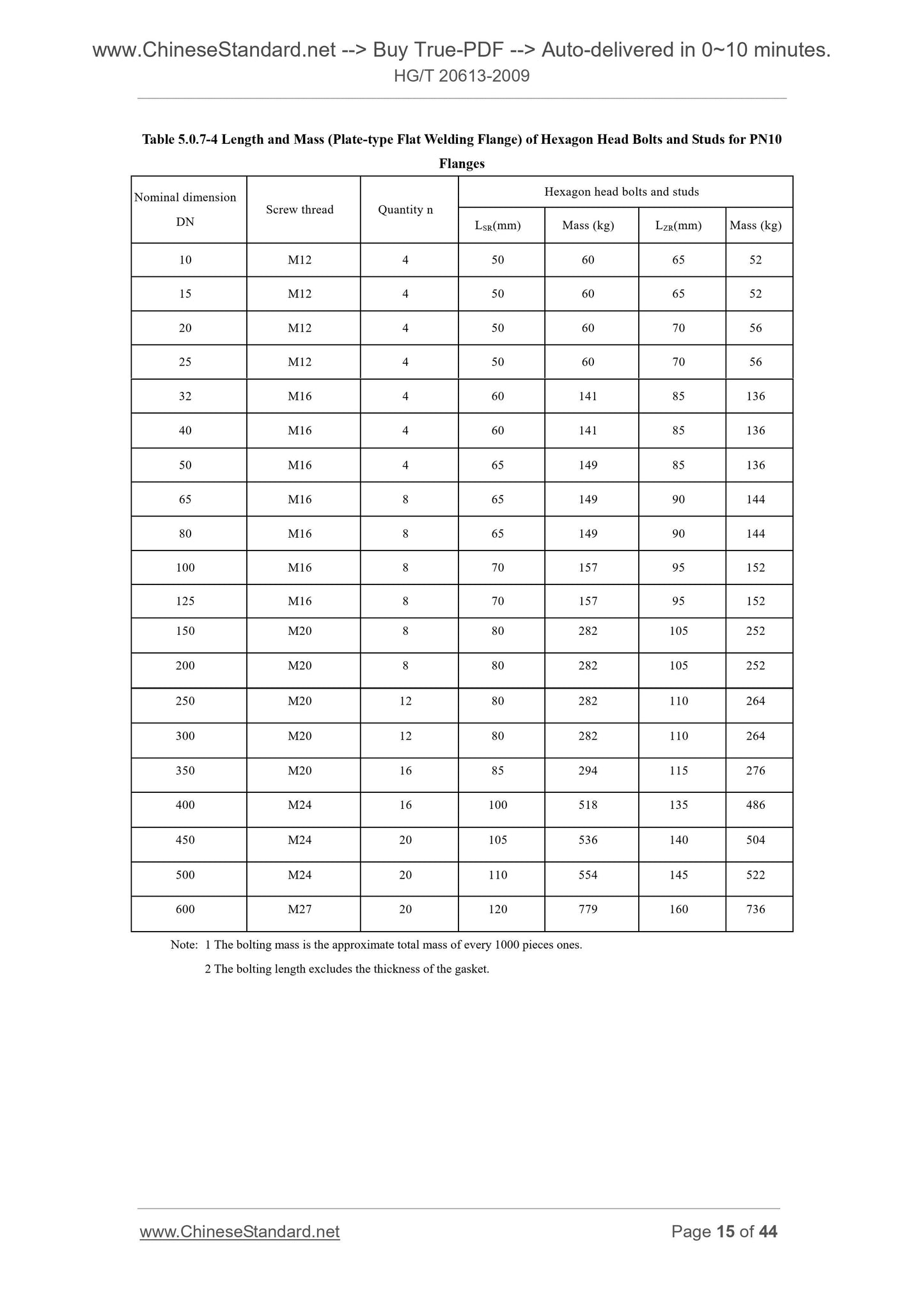

Table 5.0.7-4 Length and Mass (Plate-type Flat Welding Flange) of Hexagon Head Bolts and Studs for PN10

Flanges

Nominal dimension

DN Screw thread Quantity n

Hexagon head bolts and studs

LSR(mm) Mass (kg) LZR(mm) Mass (kg)

10 M12 4 50 60 65 52

15 M12 4 50 60 65 52

20 M12 4 50 60 70 56

25 M12 4 50 60 70 56

32 M16 4 60 141 85 136

40 M16 4 60 141 85 136

50 M16 4 65 149 85 136

65 M16 8 65 149 90 144

80 M16 8 65 149 90 144

100 M16 8 70 157 95 152

125 M16 8 70 157 95 152

150 M20 8 80 282 105 252

200 M20 8 80 282 105 252

250 M20 12 80 282 110 264

300 M20 12 80 282 110 264

350 M20 16 85 294 115 276

400 M24 16 100 518 135 486

450 M24 20 105 536 140 504

500 M24 20 110 554 145 522

600 M27 20 120 779 160 736

Note. 1 The bolting mass is the approximate total mass of every 1000 pieces ones.

2 The bolting length excludes the thickness ...

Get QUOTATION in 1-minute: Click HG/T 20613-2009

Historical versions: HG/T 20613-2009

Preview True-PDF (Reload/Scroll if blank)

HG/T 20613-2009: Bolting for use with steel pipe flanges (PN designated)

HG/T 20613-2009

Chemical Industry Standard

of the People's Republic of China

HG

Replacing HG 20613-1997

Bolting for Use with Steel Pipe Flanges

(PN designated)

(PN系列)

ISSUED ON. FEBRUARY 5, 2009

IMPLEMENTED ON. JULY 1, 2009

Issued by. Ministry of Industry and Information Technology of the People’s

Republic of China

[Including Corrigendum/Modification confirmed in May 2012. Text in RED]

Contents

1. Scope ... 3

2. Normative references ... 3

3. Pattern, specification and dimension of bolting ... 4

4. Materials... 7

5. Bolting service ... 9

6. Dimension tolerance ... 35

7. Surface treatment ... 35

8. Inspection ... 35

9. Acceptance, packaging and quality certificate ... 35

10. Marking and labeling ... 36

Appendix A (Informative) Flap Gasket for Pipe Flange Bolting ... 37

Appendix B (informative) Bolting and Bolting Insulation Parts for Insulating Flange 40

1. Scope

This standard specifies pattern, dimension, material, marking, technical requirement and

service provisions of bolting for use with steel pipe flanges (PN designated).

This Standard is applicable to HG/T 20592 Bolting for use with Steel Pipe Flange,

including hex bolt, double end studs (clamping type), full thread stud and nut.

2. Normative references

The following standards contain provisions which, through reference in this text,

constitute provisions of this Standard. For dated reference, subsequent amendments

(excluding content of corrigenda) to, or revisions of, any of these publications do not apply.

However, Parties to agreements based on this Code are encouraged to investigate the

possibility of applying the most recent editions of the standards indicated below. For undated

references, the latest edition of the normative document referred to applies.

"Fasteners--Ends of Parts with External Thread" GB/T 2

"Fasteners--Acceptance Inspection" GB/T 90.1

"Fasteners--Marking and Packaging" GB/T 90.2

"General Purpose Metric Screw Threads—Basic Dimensions" GB/T 196

"General Purpose Metric Screw Threads—Tolerances" GB/T197

"Double End Studs (Clamping Type)-Product Grade B" GB/T 901

"Stainless Steel Bars" GB/T 1220

"Alloy Structure Steels" GB/T 3077

"Mechanical Properties of Fasteners--Bolts, Screws and Studs" GB/T 3098.1

"Mechanical Properties of Fasteners--Nuts--Coarse Thread" GB/T 3098.2

"Mechanical Properties of Corrosion-resistant Stainless-steel Fasteners-Part 1. Bolts,

Screws and Studs" GB/T 3098.6

"Mechanical Properties of Fasteners-Nuts made of Stainless-steel" GB/T 3098.15

"Tolerances for Fasteners--Bolts, Screws, Studs and Nuts" GB/T 3103.1

"Laminated Rods" GB/T 5133

"Hexagon Head Bolts" GB/T 5782

"Hexagon Head Bolts with Fine Pitch Thread" GB/T 5785

"Hexagon Nuts, Style I" GB/T 6170

"Hexagon Nuts, Style I with Fine Pitch Thread" GB/T 6171

"Hexagon Nuts, Style II" GB/T 6175

"Hexagon Nuts, Style II with Fine Pitch Thread" GB/T 6176

"Fasteners-Surface Discontinuities-Bolts, Screws and Studs for General Requirements"

GB/T 5779.1

"Fasteners-Surface Discontinuities-Nuts" GB/T 5779.2

"Fasteners-Surface Discontinuities-Bolts, Screws and Studs for Special Requirements"

Table 4.0.1 Classification of Bolting Materials for Pipe Flanges

Bolting materials

High strength Medium strength Low strength

GB/T 3098.1, 8.8

GB/T 3077, 35CrMo

25Cr2MoV

DL/T 439, 42CrMo

ASTM A320, 17

GB/T 3098.6, A2-70

A4-70

ASTM A193, B8-2

B8M-2

ASTM A453, 660

GB/T 1220, 0Cr17Ni12Mo2(316)

0Cr18Ni9(304)

GB/T 3098.1, 5.6

GB/T 3098.6, A4-50

A2-50

Note. The low strength bolting materials are only applicable to flanges and non-metallic flat gaskets with pressure grade of

less than or equal to PN40.

4.0.2 The working pressure and temperature range of bolting materials are in accordance with

those specified in Table 5.0.4 of this Standard.

4.0.3 The materials and mechanical properties of the commercial grade bolting shall comply

with the requirements of GB/T 3098.1, GB/T 3098.2, GB/T 3098.6 and GB/T 3098.15.

4.0.4 The chemical composition, heat treating regime and mechanical property of special

grade bolting shall be in accordance with those specified in Table 4.0.4. The test specimen for

mechanical property shall be cut along the rolling direction from the roughcast with specified

heat treatment, and the cutting position of the test specimen is.

1 The specimen with roughcast diameter of less than or equal to 40mm shall be sampling

from the center.

2 The one with roughcast diameter of more than 40mm shall be sampling from 1/4 of the

diameter.

4.0.5 The roughcast of the full thread stud shall be made with mechanical property test by

batches. Roughcast of hexagonal nut (style II) shall be made with hardness testing by batches.

3 Matched with non-metallic flat gasket

5.0.2 The service conditions of commercial grade double end studs and hexagonal nut (style I)

shall be in accordance with the following requirements.

1 The nominal pressure grade is less than or equal to PN40.

2 Non-toxic, non-flammable medium and non-violent cycle occasions

5.0.3 Unless otherwise specified in Article 5.0.1 and Article 5.0.2, special grade full thread

stud and hexagonal nut (style II) shall be adopted.

5.0.4 The working conditions and temperature range of bolting shall be in accordance with

those specified in Table 5.0.4.

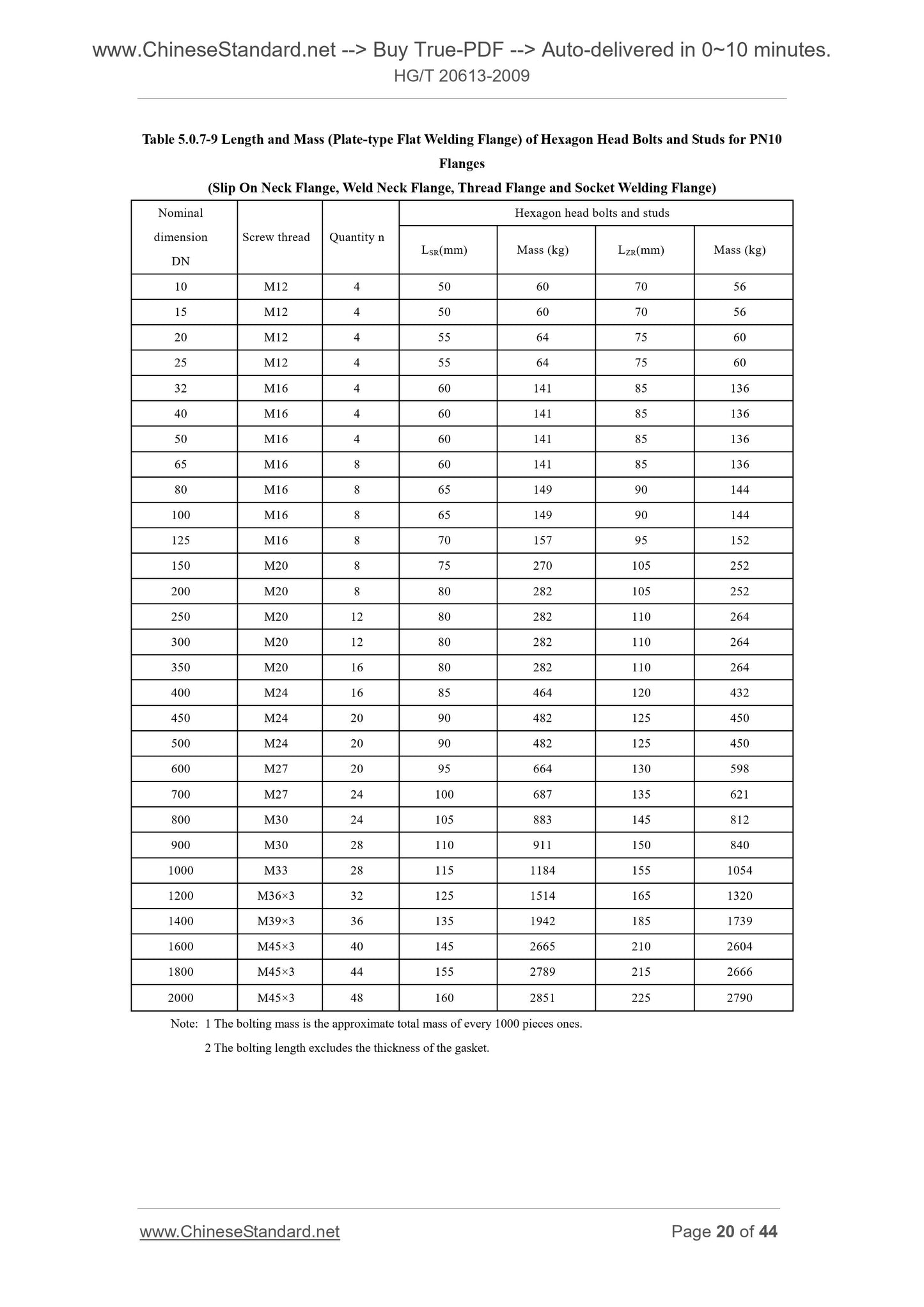

Table 5.0.7-2 Length and Approximate Mass (Plate-type Flat Welding Flange) of Hexagon Head Bolts and

Studs for PN2.5 Flanges

Nominal dimension

DN Screw thread Quantity n

Hexagon head bolts and studs

LSR(mm) Mass (kg) LZR(mm) Mass (kg)

10 M10 4 40 37 55 33

15 M10 4 40 37 55 33

20 M10 4 45 40 60 36

25 M10 4 45 40 60 36

32 M12 4 50 60 70 56

40 M12 4 50 60 70 56

50 M12 4 50 60 70 56

65 M12 4 50 60 70 56

80 M16 4 60 141 85 136

100 M16 4 60 141 85 136

125 M16 8 65 149 90 144

150 M16 8 65 149 90 144

200 M16 8 70 157 95 152

250 M16 12 75 165 95 152

300 M20 12 80 282 105 252

350 M20 12 80 282 110 264

400 M20 16 85 294 115 276

450 M20 16 90 306 120 288

500 M20 20 90 306 120 288

600 M24 20 100 518 135 486

700 M24 24 105 536 140 504

800 M27 24 115 756 150 690

900 M27 24 120 779 155 713

1000 M27 28 120 779 160 736

1200 M27 32 125 802 165 759

1400 M27 36 135 848 170 782

1600 M27 40 140 871 180 828

1800 M27 44 145 894 185 851

2000 M27 48 155 940 190 874

Note. 1 The bolting mass is the approximate total mass of every 1000 pieces ones.

2 The bolting length excludes the thickness of the gasket.

Table 5.0.7-4 Length and Mass (Plate-type Flat Welding Flange) of Hexagon Head Bolts and Studs for PN10

Flanges

Nominal dimension

DN Screw thread Quantity n

Hexagon head bolts and studs

LSR(mm) Mass (kg) LZR(mm) Mass (kg)

10 M12 4 50 60 65 52

15 M12 4 50 60 65 52

20 M12 4 50 60 70 56

25 M12 4 50 60 70 56

32 M16 4 60 141 85 136

40 M16 4 60 141 85 136

50 M16 4 65 149 85 136

65 M16 8 65 149 90 144

80 M16 8 65 149 90 144

100 M16 8 70 157 95 152

125 M16 8 70 157 95 152

150 M20 8 80 282 105 252

200 M20 8 80 282 105 252

250 M20 12 80 282 110 264

300 M20 12 80 282 110 264

350 M20 16 85 294 115 276

400 M24 16 100 518 135 486

450 M24 20 105 536 140 504

500 M24 20 110 554 145 522

600 M27 20 120 779 160 736

Note. 1 The bolting mass is the approximate total mass of every 1000 pieces ones.

2 The bolting length excludes the thickness ...

Share