1

/

de

8

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

MT 141-2005 English PDF

MT 141-2005 English PDF

Prix habituel

$150.00 USD

Prix habituel

Prix promotionnel

$150.00 USD

Prix unitaire

/

par

Frais d'expédition calculés à l'étape de paiement.

Impossible de charger la disponibilité du service de retrait

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click MT 141-2005

Historical versions: MT 141-2005

Preview True-PDF (Reload/Scroll if blank)

MT 141-2005: Plastic net protecting top-plane in coal mining

MT 141-2005

MT

COAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 23.040.20;83.140.30

G 33

Registration number. 16782-2005

Replacing MT 141-1986

Plastic net protecting top-plane in coal mining

ISSUED ON. SEPTEMBER 23, 2005

IMPLEMENTED ON. FEBRUARY 01, 2006

Issued by. National Development and Reform Commission

3. No action is required - Full-copy of this standard will be automatically and

immediately delivered to your EMAIL address in 0~60 minutes.

Table of contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Top-plane protection plastic net model ... 4

4 Requirements ... 4

5 Test methods ... 6

6 Inspection rules ... 14

7 Marking, packaging, transportation and storage ... 15

Appendix A (Normative) General specifications of plastic net protecting

top-plane ... 17

Foreword

Clause 4.4, 4.5, 4.6, 4.7, 4.8 and 4.9 of this standard are mandatory, AND

the rest is recommended.

This standard is the revision of MT 141-1986 “Specification for inspection of

plastic net protecting top-plane in coal mining”. AND this standard replaces MT

141-1986 from the date of implementation.

As compared with MT 141-1986, the main changes of this standard are as

follows.

- ADD the tensile strength requirements (SEE 4.7);

- ADD the determination of the flame temperature of the alcohol torch (SEE

5.7.3.3);

- ADD the Appendix A;

- MODIFY the model preparation method (clause 1.1 of 1986 version;

clause 3 of this version);

- MODIFY the preparation of the sample the surface of which is coated with

a conductive layer (clause 9.2 of 1986 version; clause 5.6.1.1 of this

version);

- DELETE the contents of the fuel consumption amount (clause 5.2.5 of

1986 version);

- CANCEL the requirements for the width and thickness of plastic net

(clause 2.2.1 and 2.2.2 of 1986 version).

Appendix A of this standard is normative.

This standard was proposed by China Coal Industry Association Science and

Technology Development Department.

This standard shall be under the jurisdiction of the Coal Industry Coal Mine

Safety Standardization Technical Committee.

The drafting organization of this standard. Coal Science Research Institute

Shanghai Branch.

The main drafters of this standard. Ju Qinghua, Zheng Qi, Jiang Naiqiang,

Yuan Kailiang.

This standard was first published in July 1986.

Plastic net protecting top-plane in coal mining

1 Scope

This standard specifies the product model, requirements, test methods,

inspection rules, marking, packaging, transportation and storage of the plastic

net protecting top-plane in coal mining (hereinafter referred to as top-plane

protection net).

This standard applies to plastic net protecting top-plane in coal mining.

2 Normative references

The provisions in following documents become the provisions of this Standard

through reference in this Standard. For the dated references, the subsequent

amendments (excluding corrections) or revisions do not apply to this Standard;

however, parties who reach an agreement based on this Standard are

encouraged to study if the latest versions of these documents are applicable.

For undated references, the latest edition of the referenced document applies.

MT 182-1998 Alcohol blast burner structure and technical requirements

MT 113-1995 General test methods and judgment rules for fire-resistant

antistatic properties of polymer products for coal mine

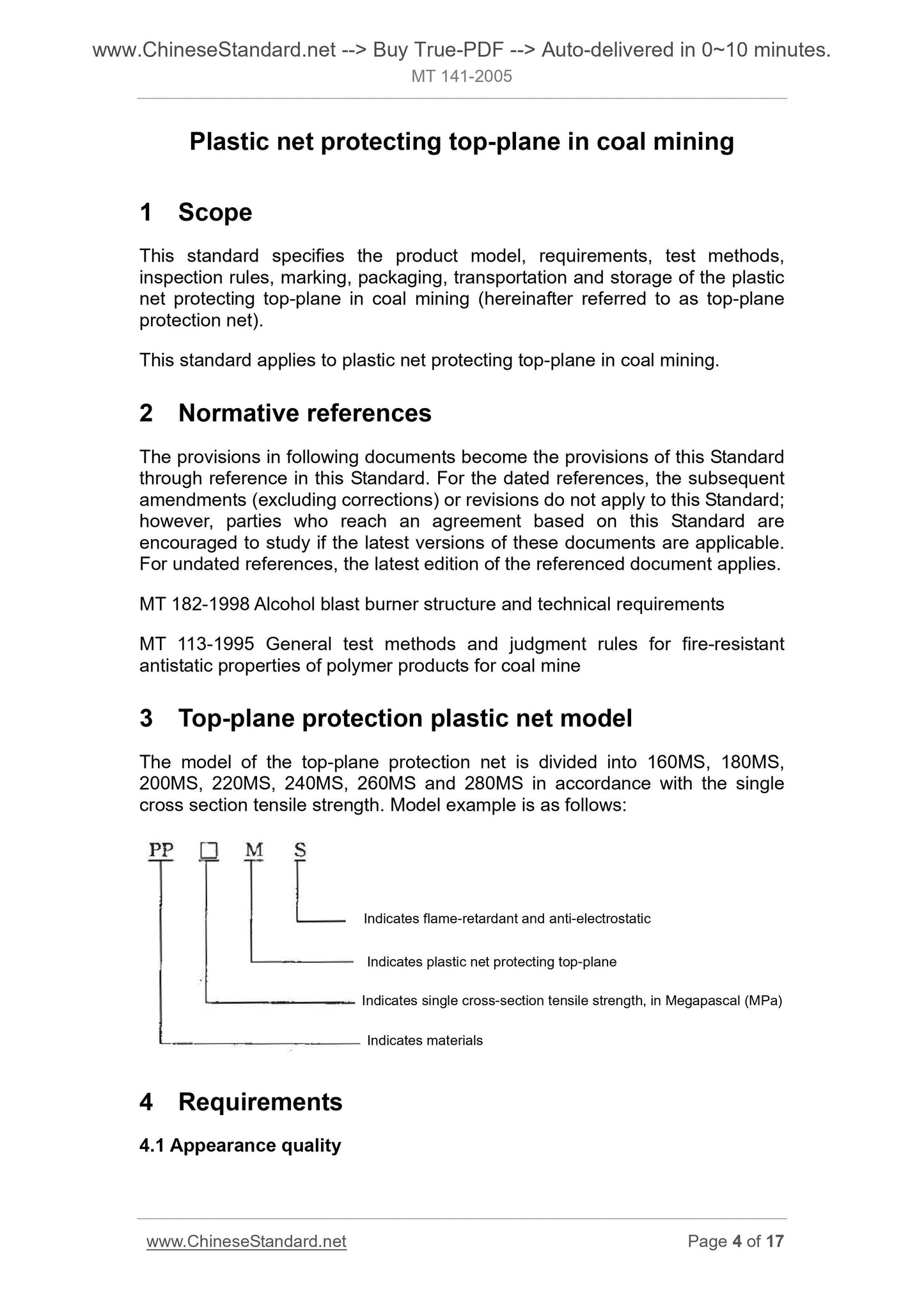

3 Top-plane protection plastic net model

The model of the top-plane protection net is divided into 160MS, 180MS,

200MS, 220MS, 240MS, 260MS and 280MS in accordance with the single

cross section tensile strength. Model example is as follows.

4 Requirements

4.1 Appearance quality

Indicates flame-retardant and anti-electrostatic

Indicates plastic net protecting top-plane

Indicates single cross-section tensile strength, in Megapascal (MPa)

Indicates materials

b) If started time keeping from the time when the sample flame is

extinguished, the arithmetic mean of the flameless combustion time of

the 6 samples shall be less than 10 s, wherein the single value of the

flameless combustion time of any one of the samples shall be less than

30 s.

4.9.2 Alcohol lamp combustion performance

The top-plane protection net shall, through the alcohol lamp combustion test,

comply with the following requirements.

a) After removing the alcohol lamp, the arithmetic mean of the flame

combustion time of the 6 samples shall be less than 6 s, wherein the

single value of the flame combustion time of any one of the samples shall

be less than 12 s.

b) If started time keeping from the time when the sample flame is

extinguished, the arithmetic mean of the flameless combustion time of

the 6 samples shall be less than 10 s, wherein the single value of the

flameless combustion time of any one of the samples shall be less than

30 s.

4.10 Specifications of top-plane protection plastic net

The general specifications of the top-plane protection plastic net are as shown

in Appendix A.

5 Test methods

5.1 Sample preparation

After the product was made 24 h, TAKE the sample.

5.2 Appearance quality

CUT one piece of sample having a length of not less than 10 m; PERFORM

visual inspection.

5.3 Specification size inspection

CUT one piece of sample having a length of 1m; USE a Vernier caliper having

a precision of 0.02 mm to measure width at any 5 points along the parallel

direction; TAKE the arithmetic mean; LEAVE 2 places after the decimal point;

ROUND off to 1 place after the decimal point; USE a Vernier caliper having a

precision of 0.02 mm to measure thickness at any 5 points; TAKE the

arithmetic mean; LEAVE 2 places after the decimal point; ROUND off to 1

place after the decimal point.

5.4 Skewness test

c) Respectively CALCULATE the tensile strength and tensile elongation at

fracture of each group of 5 samples, and CALCULATE the arithmetic

mean of the tensile strength and the tensile elongation at fracture of each

group of samples, TAKE the integer.

5.6 Surface resistance test

5.6.1 Sample preparation

5.6.1.1 TAKE a certain number of top-plane protection nets; USE the hot

pressing method to prepare them into circular or square sheet samples the

surface of which is flat and smooth; the sample thickness is (1 ± 0.2) mm, the

sample diameter or edge length is not less than 100 mm, and the number of

sample is 3; AND if the sample surface is coated with conductive layer, it shall

arrange the top-plane protection nets in parallel into square sample, AND

press it flatly before using it as the sample for the measurement of the surface

resistance.

5.6.1.2 USE the clean silk cloth or sterilized cotton cloth which is dampened

with distilled water to clean the sample; then USE a clean dry cloth to wipe the

sample dry; PLACE it in a dry place for over 24 h; before the arbitration test,

PLACE the sample in a dry place for 7 days before making the test.

5.6.1.3 Before the test, PLACE the sample in an environment having a

temperature of (25 ± 5) °C and a relative temperature of 60% ~ 70% for at least

2 h.

5.6.2 Conductive liquid

The composition of the conductive liquid (mass percentage) is.

Anhydrous polyethylene glycol having a molecular weight of 600. 79.9%

Soft soap. 0.1%

Water. 20.0%

5.6.3 Instrument

5.6.3.1 Surface resistance tester.

The measuring range is 103 ~ 1010 Ω, the accuracy is 10%, the DC powe...

Get QUOTATION in 1-minute: Click MT 141-2005

Historical versions: MT 141-2005

Preview True-PDF (Reload/Scroll if blank)

MT 141-2005: Plastic net protecting top-plane in coal mining

MT 141-2005

MT

COAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 23.040.20;83.140.30

G 33

Registration number. 16782-2005

Replacing MT 141-1986

Plastic net protecting top-plane in coal mining

ISSUED ON. SEPTEMBER 23, 2005

IMPLEMENTED ON. FEBRUARY 01, 2006

Issued by. National Development and Reform Commission

3. No action is required - Full-copy of this standard will be automatically and

immediately delivered to your EMAIL address in 0~60 minutes.

Table of contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Top-plane protection plastic net model ... 4

4 Requirements ... 4

5 Test methods ... 6

6 Inspection rules ... 14

7 Marking, packaging, transportation and storage ... 15

Appendix A (Normative) General specifications of plastic net protecting

top-plane ... 17

Foreword

Clause 4.4, 4.5, 4.6, 4.7, 4.8 and 4.9 of this standard are mandatory, AND

the rest is recommended.

This standard is the revision of MT 141-1986 “Specification for inspection of

plastic net protecting top-plane in coal mining”. AND this standard replaces MT

141-1986 from the date of implementation.

As compared with MT 141-1986, the main changes of this standard are as

follows.

- ADD the tensile strength requirements (SEE 4.7);

- ADD the determination of the flame temperature of the alcohol torch (SEE

5.7.3.3);

- ADD the Appendix A;

- MODIFY the model preparation method (clause 1.1 of 1986 version;

clause 3 of this version);

- MODIFY the preparation of the sample the surface of which is coated with

a conductive layer (clause 9.2 of 1986 version; clause 5.6.1.1 of this

version);

- DELETE the contents of the fuel consumption amount (clause 5.2.5 of

1986 version);

- CANCEL the requirements for the width and thickness of plastic net

(clause 2.2.1 and 2.2.2 of 1986 version).

Appendix A of this standard is normative.

This standard was proposed by China Coal Industry Association Science and

Technology Development Department.

This standard shall be under the jurisdiction of the Coal Industry Coal Mine

Safety Standardization Technical Committee.

The drafting organization of this standard. Coal Science Research Institute

Shanghai Branch.

The main drafters of this standard. Ju Qinghua, Zheng Qi, Jiang Naiqiang,

Yuan Kailiang.

This standard was first published in July 1986.

Plastic net protecting top-plane in coal mining

1 Scope

This standard specifies the product model, requirements, test methods,

inspection rules, marking, packaging, transportation and storage of the plastic

net protecting top-plane in coal mining (hereinafter referred to as top-plane

protection net).

This standard applies to plastic net protecting top-plane in coal mining.

2 Normative references

The provisions in following documents become the provisions of this Standard

through reference in this Standard. For the dated references, the subsequent

amendments (excluding corrections) or revisions do not apply to this Standard;

however, parties who reach an agreement based on this Standard are

encouraged to study if the latest versions of these documents are applicable.

For undated references, the latest edition of the referenced document applies.

MT 182-1998 Alcohol blast burner structure and technical requirements

MT 113-1995 General test methods and judgment rules for fire-resistant

antistatic properties of polymer products for coal mine

3 Top-plane protection plastic net model

The model of the top-plane protection net is divided into 160MS, 180MS,

200MS, 220MS, 240MS, 260MS and 280MS in accordance with the single

cross section tensile strength. Model example is as follows.

4 Requirements

4.1 Appearance quality

Indicates flame-retardant and anti-electrostatic

Indicates plastic net protecting top-plane

Indicates single cross-section tensile strength, in Megapascal (MPa)

Indicates materials

b) If started time keeping from the time when the sample flame is

extinguished, the arithmetic mean of the flameless combustion time of

the 6 samples shall be less than 10 s, wherein the single value of the

flameless combustion time of any one of the samples shall be less than

30 s.

4.9.2 Alcohol lamp combustion performance

The top-plane protection net shall, through the alcohol lamp combustion test,

comply with the following requirements.

a) After removing the alcohol lamp, the arithmetic mean of the flame

combustion time of the 6 samples shall be less than 6 s, wherein the

single value of the flame combustion time of any one of the samples shall

be less than 12 s.

b) If started time keeping from the time when the sample flame is

extinguished, the arithmetic mean of the flameless combustion time of

the 6 samples shall be less than 10 s, wherein the single value of the

flameless combustion time of any one of the samples shall be less than

30 s.

4.10 Specifications of top-plane protection plastic net

The general specifications of the top-plane protection plastic net are as shown

in Appendix A.

5 Test methods

5.1 Sample preparation

After the product was made 24 h, TAKE the sample.

5.2 Appearance quality

CUT one piece of sample having a length of not less than 10 m; PERFORM

visual inspection.

5.3 Specification size inspection

CUT one piece of sample having a length of 1m; USE a Vernier caliper having

a precision of 0.02 mm to measure width at any 5 points along the parallel

direction; TAKE the arithmetic mean; LEAVE 2 places after the decimal point;

ROUND off to 1 place after the decimal point; USE a Vernier caliper having a

precision of 0.02 mm to measure thickness at any 5 points; TAKE the

arithmetic mean; LEAVE 2 places after the decimal point; ROUND off to 1

place after the decimal point.

5.4 Skewness test

c) Respectively CALCULATE the tensile strength and tensile elongation at

fracture of each group of 5 samples, and CALCULATE the arithmetic

mean of the tensile strength and the tensile elongation at fracture of each

group of samples, TAKE the integer.

5.6 Surface resistance test

5.6.1 Sample preparation

5.6.1.1 TAKE a certain number of top-plane protection nets; USE the hot

pressing method to prepare them into circular or square sheet samples the

surface of which is flat and smooth; the sample thickness is (1 ± 0.2) mm, the

sample diameter or edge length is not less than 100 mm, and the number of

sample is 3; AND if the sample surface is coated with conductive layer, it shall

arrange the top-plane protection nets in parallel into square sample, AND

press it flatly before using it as the sample for the measurement of the surface

resistance.

5.6.1.2 USE the clean silk cloth or sterilized cotton cloth which is dampened

with distilled water to clean the sample; then USE a clean dry cloth to wipe the

sample dry; PLACE it in a dry place for over 24 h; before the arbitration test,

PLACE the sample in a dry place for 7 days before making the test.

5.6.1.3 Before the test, PLACE the sample in an environment having a

temperature of (25 ± 5) °C and a relative temperature of 60% ~ 70% for at least

2 h.

5.6.2 Conductive liquid

The composition of the conductive liquid (mass percentage) is.

Anhydrous polyethylene glycol having a molecular weight of 600. 79.9%

Soft soap. 0.1%

Water. 20.0%

5.6.3 Instrument

5.6.3.1 Surface resistance tester.

The measuring range is 103 ~ 1010 Ω, the accuracy is 10%, the DC powe...

Share