1

/

de

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

QC/T 1174-2022 English PDF (QCT1174-2022)

QC/T 1174-2022 English PDF (QCT1174-2022)

Prix habituel

$410.00 USD

Prix habituel

Prix promotionnel

$410.00 USD

Prix unitaire

/

par

Frais d'expédition calculés à l'étape de paiement.

Impossible de charger la disponibilité du service de retrait

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click QC/T 1174-2022

Historical versions: QC/T 1174-2022

Preview True-PDF (Reload/Scroll if blank)

QC/T 1174-2022: High voltage fuse for electric vehicles

QC/T 1174-2022

QC

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.020

CCS T 09

High voltage fuse for electric vehicles

ISSUED ON: APRIL 08, 2022

IMPLEMENTED ON: OCTOBER 01, 2022

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 6

1 Scope ... 7

2 Normative references ... 7

3 Terms and definitions ... 7

4 Symbols and abbreviations ... 9

5 Requirements ... 10

6 Test methods ... 13

7 Inspection rules ... 25

Appendix A (Informative) Fuse installation method and installation torque ... 28

Appendix B (Informative) Structure of H-type and J-type fuses ... 29

Appendix C (Informative) Guidelines for application of fuse ... 31

References ... 36

High voltage fuse for electric vehicles

1 Scope

This document specifies the technical requirements, test methods and inspection rules

for high voltage fuse for electric vehicles.

This document applies to high voltage fuse (referred to as fuse) for electric vehicles

with a DC working voltage of 60 V to 1500 V.

This document does not apply to smart fuses and circuit breakers for electric vehicles.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this

document and are indispensable for its application. For dated references, only the

version corresponding to that date is applicable to this document; for undated references,

the latest version (including all amendments) is applicable to this document.

GB/T 2423.18-2012, Environmental testing - Part 2: Test methods - Test Kb: Salt

mist, cyclic (sodium chloride solution)

GB/T 2423.34-2012, Environmental testing - Part 2: Test methods - Test Z/AD:

Composite temperature/humidity cyclic test

GB/T 2423.56-2018, Environmental testing - Part 2: Test methods - Test Fh:

Vibration, broadband random and guidance

GB/T 13539.1-2015, Low-voltage fuses - Part 1: General requirements

GB/T 28046.3-2011, Road vehicles - Environmental conditions and testing for

electrical and electronic equipment - Part 3: Mechanical loads

GB/T 31465.1-2015, Road vehicles - Fuse-link - Part 1: Definitions and general test

requirements

3 Terms and definitions

Terms and definitions determined by GB/T 13539.1-2015 and GB/T 31465.1-2015, as

well as the following, are applicable to this document.

3.1 Fuse

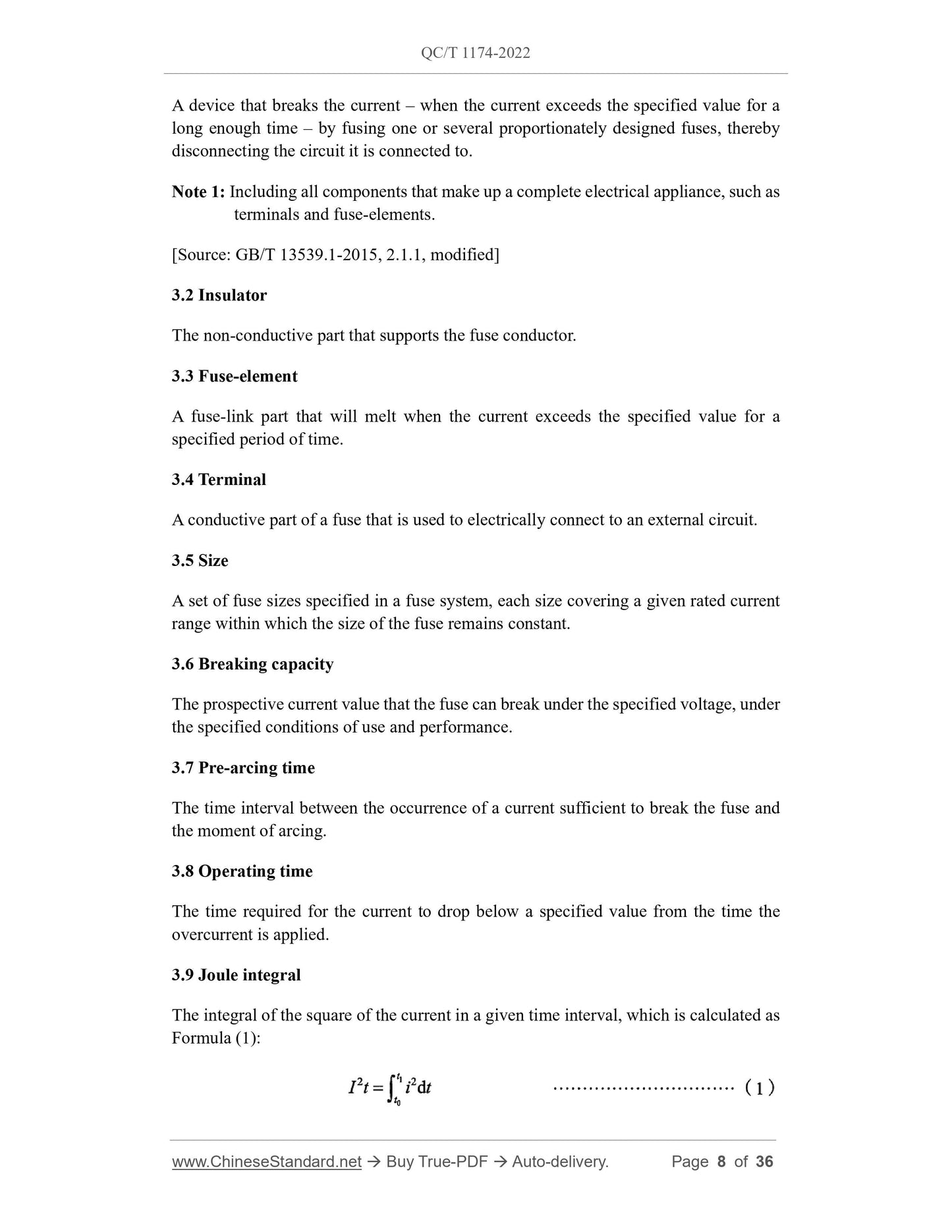

Note 1: Pre-arcing I2t is the integral of I2t within the pre-arcing time of the fuse.

Note 2: Operating I2t is the integral of I2t within the operating time of the fuse.

3.10 Rated current

The current value that is used to identify a fuse, which is measured in accordance with

a prescribed method.

Note: The continuous working current of the fuse should be lower than the rated current,

and the use of derating can be in accordance with Appendix C.

3.11 Rated voltage

The maximum supply voltage applicable to the fuse.

3.12 Prospective current

The current that would flow in a circuit if the fuse is replaced by a conductor of

negligible impedance.

3.13 Operation mode

The operation mode is defined as follows:

a) operation mode 1: the fuse is not connected to the cable or copper bar;

b) operation mode 2: the fuse is connected to the cable or copper bar, but not

energized;

c) operation mode 3: the fuse is connected to the cable or copper bar and energized.

Note: The installation method of the fuse is in accordance with Figure A.1 in the

appendix; the installation torque is in accordance with Table A.1 in the appendix.

4 Symbols and abbreviations

In addition to the symbols mentioned in 3.9, the following symbols also apply to this

document:

I2t: joule integral;

IR: rated current;

RT: room temperature;

UR: rated voltage.

5 Requirements

5.1 Working environment

Unless otherwise specified, the fuse shall be able to work normally in the following

environmental conditions:

a) Temperature: -40 °C ~ 85 °C;

b) Relative humidity: 5% ~ 95%;

c) Atmospheric pressure: 61.6 kPa ~ 106.2 kPa.

5.2 Appearance

The appearance and identification of the fuse shall meet the following requirements:

a) The surface of the enclosure shall be uniform in color, smooth, flat and dry, and

shall be free from obvious scratches, burrs, rust, deformation, cracks and other

defects;

b) Product nameplates, plates, labels or indications shall be correct, complete, clear,

and reliably and permanently attached to the enclosure.

5.3 Dimensions and tolerances

The dimensions and tolerances of the fuse shall meet the requirements of the product

drawings.

5.4 Electrical performance

5.4.1 Requirements for internal resistance

Carry out the test according to 6.4.1, and the relative deviation between the measured

value and the internal resistance value declared by the manufacturer shall not exceed

±10%.

5.4.2 Requirements for temperature rise

Carry out the test according to 6.4.2. The temperature rise value of the fuse terminal

shall not exceed 50 K, and the temperature rise value at the center of the insulator can

be determined through negotiation between the supplier and the buyer. After the test,

the overall fuse shall not have obvious discoloration, the terminal, terminal plating and

label shall not be burnt and peeled off, and the fuse shall meet the requirements of 5.4.1.

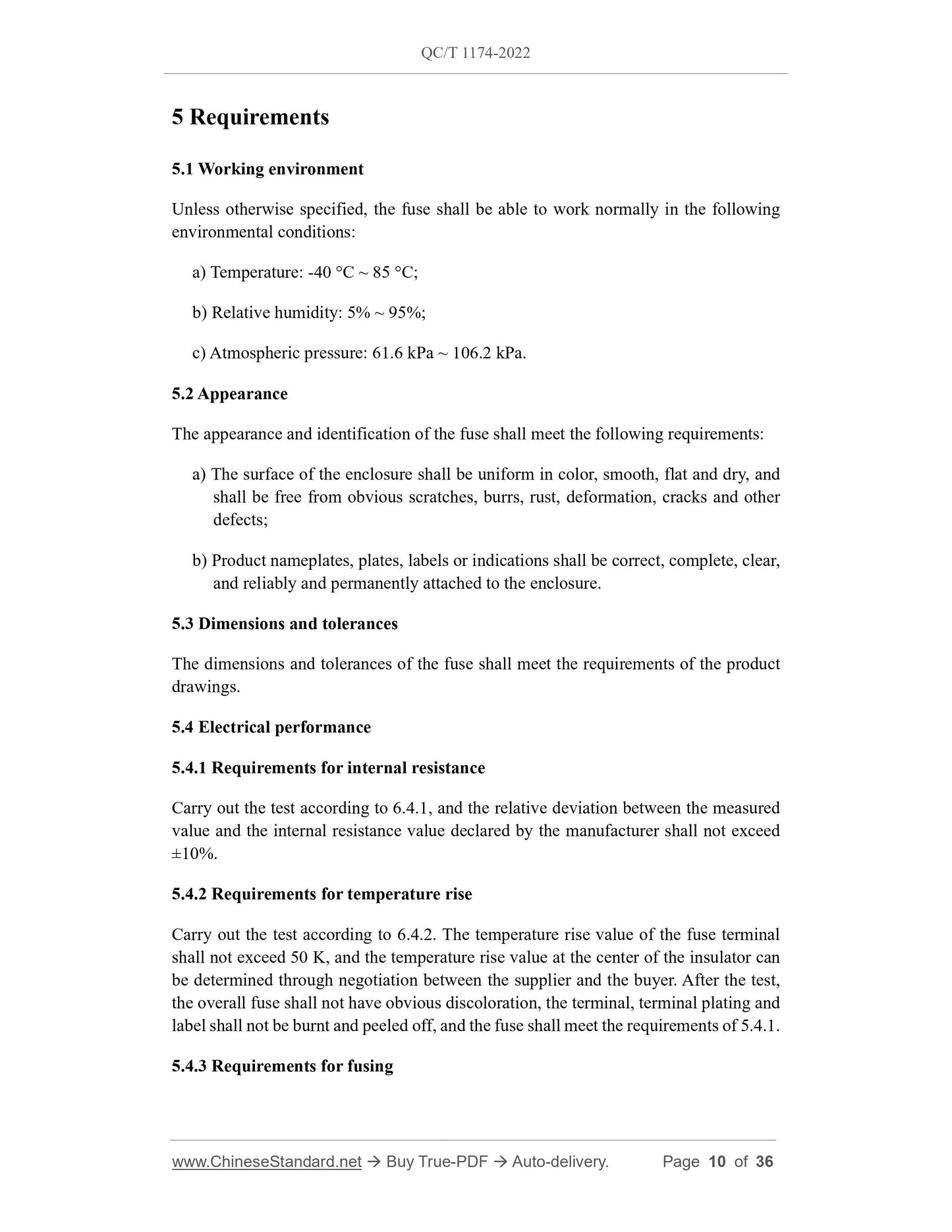

5.4.3 Requirements for fusing

5.5 Requirements for environmental adaptability

5.5.1 Requirements for salt spray resistance

Carry out the test according to 6.5.1. After the test, there shall be no problems such as

peeling, chipping, blistering, peeling off of the coating or bare basic metal on the fuse

coating, and the fuse shall meet the requirements of 5.4.1 and 5.4.4.

5.5.2 High temperature requirements

Carry out the test according to 6.5.2. After the test, the fuse shall meet the requirements

of 5.4.1, 5.4.3 and 5.4.4.

5.5.3 Low temperature requirements

Carry out the test according to 6.5.3. After the test, the fuse shall meet the requirements

of 5.4.1, 5.4.3 and 5.4.4.

5.5.4 Constant damp and hot requirements

Carry out the test according to 6.5.4. After the test, the fuse shall meet the requirements

of 5.4.1, 5.4.3 and 5.4.4.

5.5.5 Requirements for combined temperature/humidity cycle

Carry out the test according to 6.5.5. After the test, the fuse shall meet the requirements

of 5.4.1, 5.4.3 and 5.4.4.

5.5.6 Requirements for cold and hot impact

Carry out the test according to 6.5.6. After the test, the fuse shall meet the requirements

of 5.4.1, 5.4.3 and 5.4.4.

5.6 Mechanical load

5.6.1 Mechanical vibration requirements

Carry out the test according to 6.6.1. After the test, the fuse shall not have problems

such as appearance change, loose screws, cracked and deformed insulators, and the fuse

shall meet the requirements of 5.4.1, 5.4.3 and 5.4.4.

5.6.2 Mechanical shock requirements

Carry out the test according to 6.6.2. After the test, the fuse shall not have problems

such as appearance change, loose screws, cracked and deformed insulators, and the fuse

shall meet the requirements of 5.4.1, 5.4.3 and 5.4.4.

6 Test methods

6.1 General conditions of test

6.1.1 Test standard atmospheric conditions

Unless otherwise specified, all tests shall be carried out under the following

environmental conditions:

a) Room temperature: 23 °C ± 5 °C;

b) Relative humidity: 5% ~ 95%;

c) Atmospheric pressure: 61.6 kPa ~ 106.2 kPa.

6.1.2 Test equipment

The instruments, equipment and loading conditions...

Get QUOTATION in 1-minute: Click QC/T 1174-2022

Historical versions: QC/T 1174-2022

Preview True-PDF (Reload/Scroll if blank)

QC/T 1174-2022: High voltage fuse for electric vehicles

QC/T 1174-2022

QC

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.020

CCS T 09

High voltage fuse for electric vehicles

ISSUED ON: APRIL 08, 2022

IMPLEMENTED ON: OCTOBER 01, 2022

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 6

1 Scope ... 7

2 Normative references ... 7

3 Terms and definitions ... 7

4 Symbols and abbreviations ... 9

5 Requirements ... 10

6 Test methods ... 13

7 Inspection rules ... 25

Appendix A (Informative) Fuse installation method and installation torque ... 28

Appendix B (Informative) Structure of H-type and J-type fuses ... 29

Appendix C (Informative) Guidelines for application of fuse ... 31

References ... 36

High voltage fuse for electric vehicles

1 Scope

This document specifies the technical requirements, test methods and inspection rules

for high voltage fuse for electric vehicles.

This document applies to high voltage fuse (referred to as fuse) for electric vehicles

with a DC working voltage of 60 V to 1500 V.

This document does not apply to smart fuses and circuit breakers for electric vehicles.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this

document and are indispensable for its application. For dated references, only the

version corresponding to that date is applicable to this document; for undated references,

the latest version (including all amendments) is applicable to this document.

GB/T 2423.18-2012, Environmental testing - Part 2: Test methods - Test Kb: Salt

mist, cyclic (sodium chloride solution)

GB/T 2423.34-2012, Environmental testing - Part 2: Test methods - Test Z/AD:

Composite temperature/humidity cyclic test

GB/T 2423.56-2018, Environmental testing - Part 2: Test methods - Test Fh:

Vibration, broadband random and guidance

GB/T 13539.1-2015, Low-voltage fuses - Part 1: General requirements

GB/T 28046.3-2011, Road vehicles - Environmental conditions and testing for

electrical and electronic equipment - Part 3: Mechanical loads

GB/T 31465.1-2015, Road vehicles - Fuse-link - Part 1: Definitions and general test

requirements

3 Terms and definitions

Terms and definitions determined by GB/T 13539.1-2015 and GB/T 31465.1-2015, as

well as the following, are applicable to this document.

3.1 Fuse

Note 1: Pre-arcing I2t is the integral of I2t within the pre-arcing time of the fuse.

Note 2: Operating I2t is the integral of I2t within the operating time of the fuse.

3.10 Rated current

The current value that is used to identify a fuse, which is measured in accordance with

a prescribed method.

Note: The continuous working current of the fuse should be lower than the rated current,

and the use of derating can be in accordance with Appendix C.

3.11 Rated voltage

The maximum supply voltage applicable to the fuse.

3.12 Prospective current

The current that would flow in a circuit if the fuse is replaced by a conductor of

negligible impedance.

3.13 Operation mode

The operation mode is defined as follows:

a) operation mode 1: the fuse is not connected to the cable or copper bar;

b) operation mode 2: the fuse is connected to the cable or copper bar, but not

energized;

c) operation mode 3: the fuse is connected to the cable or copper bar and energized.

Note: The installation method of the fuse is in accordance with Figure A.1 in the

appendix; the installation torque is in accordance with Table A.1 in the appendix.

4 Symbols and abbreviations

In addition to the symbols mentioned in 3.9, the following symbols also apply to this

document:

I2t: joule integral;

IR: rated current;

RT: room temperature;

UR: rated voltage.

5 Requirements

5.1 Working environment

Unless otherwise specified, the fuse shall be able to work normally in the following

environmental conditions:

a) Temperature: -40 °C ~ 85 °C;

b) Relative humidity: 5% ~ 95%;

c) Atmospheric pressure: 61.6 kPa ~ 106.2 kPa.

5.2 Appearance

The appearance and identification of the fuse shall meet the following requirements:

a) The surface of the enclosure shall be uniform in color, smooth, flat and dry, and

shall be free from obvious scratches, burrs, rust, deformation, cracks and other

defects;

b) Product nameplates, plates, labels or indications shall be correct, complete, clear,

and reliably and permanently attached to the enclosure.

5.3 Dimensions and tolerances

The dimensions and tolerances of the fuse shall meet the requirements of the product

drawings.

5.4 Electrical performance

5.4.1 Requirements for internal resistance

Carry out the test according to 6.4.1, and the relative deviation between the measured

value and the internal resistance value declared by the manufacturer shall not exceed

±10%.

5.4.2 Requirements for temperature rise

Carry out the test according to 6.4.2. The temperature rise value of the fuse terminal

shall not exceed 50 K, and the temperature rise value at the center of the insulator can

be determined through negotiation between the supplier and the buyer. After the test,

the overall fuse shall not have obvious discoloration, the terminal, terminal plating and

label shall not be burnt and peeled off, and the fuse shall meet the requirements of 5.4.1.

5.4.3 Requirements for fusing

5.5 Requirements for environmental adaptability

5.5.1 Requirements for salt spray resistance

Carry out the test according to 6.5.1. After the test, there shall be no problems such as

peeling, chipping, blistering, peeling off of the coating or bare basic metal on the fuse

coating, and the fuse shall meet the requirements of 5.4.1 and 5.4.4.

5.5.2 High temperature requirements

Carry out the test according to 6.5.2. After the test, the fuse shall meet the requirements

of 5.4.1, 5.4.3 and 5.4.4.

5.5.3 Low temperature requirements

Carry out the test according to 6.5.3. After the test, the fuse shall meet the requirements

of 5.4.1, 5.4.3 and 5.4.4.

5.5.4 Constant damp and hot requirements

Carry out the test according to 6.5.4. After the test, the fuse shall meet the requirements

of 5.4.1, 5.4.3 and 5.4.4.

5.5.5 Requirements for combined temperature/humidity cycle

Carry out the test according to 6.5.5. After the test, the fuse shall meet the requirements

of 5.4.1, 5.4.3 and 5.4.4.

5.5.6 Requirements for cold and hot impact

Carry out the test according to 6.5.6. After the test, the fuse shall meet the requirements

of 5.4.1, 5.4.3 and 5.4.4.

5.6 Mechanical load

5.6.1 Mechanical vibration requirements

Carry out the test according to 6.6.1. After the test, the fuse shall not have problems

such as appearance change, loose screws, cracked and deformed insulators, and the fuse

shall meet the requirements of 5.4.1, 5.4.3 and 5.4.4.

5.6.2 Mechanical shock requirements

Carry out the test according to 6.6.2. After the test, the fuse shall not have problems

such as appearance change, loose screws, cracked and deformed insulators, and the fuse

shall meet the requirements of 5.4.1, 5.4.3 and 5.4.4.

6 Test methods

6.1 General conditions of test

6.1.1 Test standard atmospheric conditions

Unless otherwise specified, all tests shall be carried out under the following

environmental conditions:

a) Room temperature: 23 °C ± 5 °C;

b) Relative humidity: 5% ~ 95%;

c) Atmospheric pressure: 61.6 kPa ~ 106.2 kPa.

6.1.2 Test equipment

The instruments, equipment and loading conditions...

Share