1

/

de

7

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

TB/T 1979-2014 English PDF (TBT1979-2014)

TB/T 1979-2014 English PDF (TBT1979-2014)

Prix habituel

$70.00 USD

Prix habituel

Prix promotionnel

$70.00 USD

Prix unitaire

/

par

Frais d'expédition calculés à l'étape de paiement.

Impossible de charger la disponibilité du service de retrait

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click TB/T 1979-2014

Historical versions: TB/T 1979-2014

Preview True-PDF (Reload/Scroll if blank)

TB/T 1979-2014: Atmospheric corrosion resisting steel for railway rolling stock

TB/T 1979-2014

TB

RAILWAY INDUSTRY STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 45.060.20

S 05

Replacing TB/T 1979-2003

Atmospheric corrosion resisting steel for

railway rolling stock

ISSUED ON. SEPTEMBER 26, 2014

IMPLEMENTED ON. MARCH 1, 2015

Issued by. State Railway Administration

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Dimension, shape, weight and allowable deviation ... 5

4 Representation method of steel grades ... 5

5 Technical requirements ... 6

6 Inspection methods ... 10

7 Inspection rules ... 11

8 Packaging, marking and quality certificate ... 12

Annex A (informative) Comparison table of atmospheric corrosion resisting steel

grades in old- and new- version standards ... 13

Foreword

This Standard is drafted according to the rules given in GB/T 1.1-2009.

This Standard replaces TB/T 1979-2003 “Ordering technical conditions of atmospheric

corrosion resisting steel for railway rolling stock”; compared with TB/T 1979-2003, main

technical changes are as follows.

- ADD the representation method of atmospheric corrosion resisting steel grades

(see Clause 4);

- The naming of atmospheric corrosion resistant steel grades is changed from the

naming by the main chemical composition in steel TO the naming by the lower

yield limit of steel (see 5.1.1 of this Standard, 4.1.1 of 2003 version);

- ADD the high-strength atmospheric corrosion resisting steel (see Table 1);

- MERGE the cold-rolled 05CuPCrNi steel and cold-rolled 09CuPCrNi-A in the

original standard (see Table 1);

- ADD the requirements for the control sample Q345B of corrosion resistance test

(see Table 6);

- MODIFY the batch weight of atmospheric corrosion resisting steel (see 7.2 of this

Standard, 6.3 of 2003 version);

- ADD the requirements for the corrosion resistance test frequency (see 7.2);

- ADD the comparison table of atmospheric corrosion resisting steel grades in new-

and old-version standards (see Annex A).

This Standard is proposed by and under the jurisdiction of Institute of Standards and

Metrology of Ministry of Railways.

Drafting organizations of this Standard. Institute of Standards and Metrology of Ministry

of Railways, Institute of Metals and Chemistry of Institute of Intercalary Railway,

Baoshan Iron and Steel Co., Ltd.

Main drafters of this Standard. Zhu Mei, Gao Junli, Zhang Bin, Yang Songbai, Qu

Zhaoxia.

The previous version of the standards replaced by this Standard are as follows.

- TB/T 1979-1987, TB/T 1979-2003.

Atmospheric corrosion resisting steel for railway

rolling stock

1 Scope

This Standard specifies the dimension, shape, weight and allowable deviation,

representation method of steel grades, technical requirements, inspection methods,

inspection rules, packaging, marking and quality certificates of atmospheric corrosion

resisting steel for railway rolling stock.

This Standard applies hot-rolled and cold-rolled steel sheet, plate and strip and

structural steel of atmospheric corrosion resisting steel for railway rolling stock.

2 Normative references

The following documents are indispensable for the application of this document. For

dated references, only the dated edition applies to this document. For undated

references, the latest edition (including all amendments) applies to this document.

GB/T 222 Permissible tolerances for chemical composition of steel products

GB/T 223 Methods for chemical analysis of iron, steel and alloy

GB/T 228.1 Metallic materials - Tensile testing - Part 1. Method of test at room

temperature

GB/T 229 Metallic materials - Charpy pendulum impact test method

GB/T 232 Metallic materials - Bend test

GB/T 247 General rule of package mark and certification for steel plates (sheets)

and strips

GB/T 706 Hot rolled section steel

GB/T 708 Dimension shape weight and tolerance for cold-rolled steel plates and

sheets

GB/T 709 Dimension, shape, weight and tolerances for hot-rolled steel plates and

sheets

GB/T 2101 General requirement of acceptance packaging marking and certification

for section steel

GB/T 2975 Steel and steel products - Location and preparation of test pieces for

mechanical testing

GB/T 4336 Carbon and low-alloy steel - Determination of multi-element contents -

Spark discharge atomic emission spectrometric method (routine method)

GB/T 6394 Metal - Methods for estimating the average grain size

GB/T 10561 Steel - Determination of content of nonmetallic inclusions -

Micrographic method using standards diagrams

GB/T 17505 Steel and steel products - General technical delivery requirements

GB/T 20066 Steel and iron - Sampling and preparation of samples for the

determination of chemical composition

GB/T 20125 Low-alloy steel - Determination of multi-element contents - Inductively

coupled plasma atomic emission spectrometric method

TB/T 2375 Test method for cyclic wetting corrosion of weathering steels for railway

applications

3 Dimension, shape, weight and allowable deviation

3.1 The dimension, shape, weight and allowable deviation of steel plates, sheets and

strips shall comply with the relevant specifications of GB/T 709, GB/T 708.

3.2 The dimension, shape, weight and allowable deviation of hot-rolled steels shall

comply with the relevant specifications of GB/T 706; the dimension, shape, weight and

allowable deviation of cold-formed steels shall comply with the corresponding product

specifications.

4 Representation method of steel grades

The steel grade consists of the lower yield strength code, lower yield strength limit

value, atmospheric corrosion resisting steel code, delivery state code and steel

category, the specific structure is as follows.

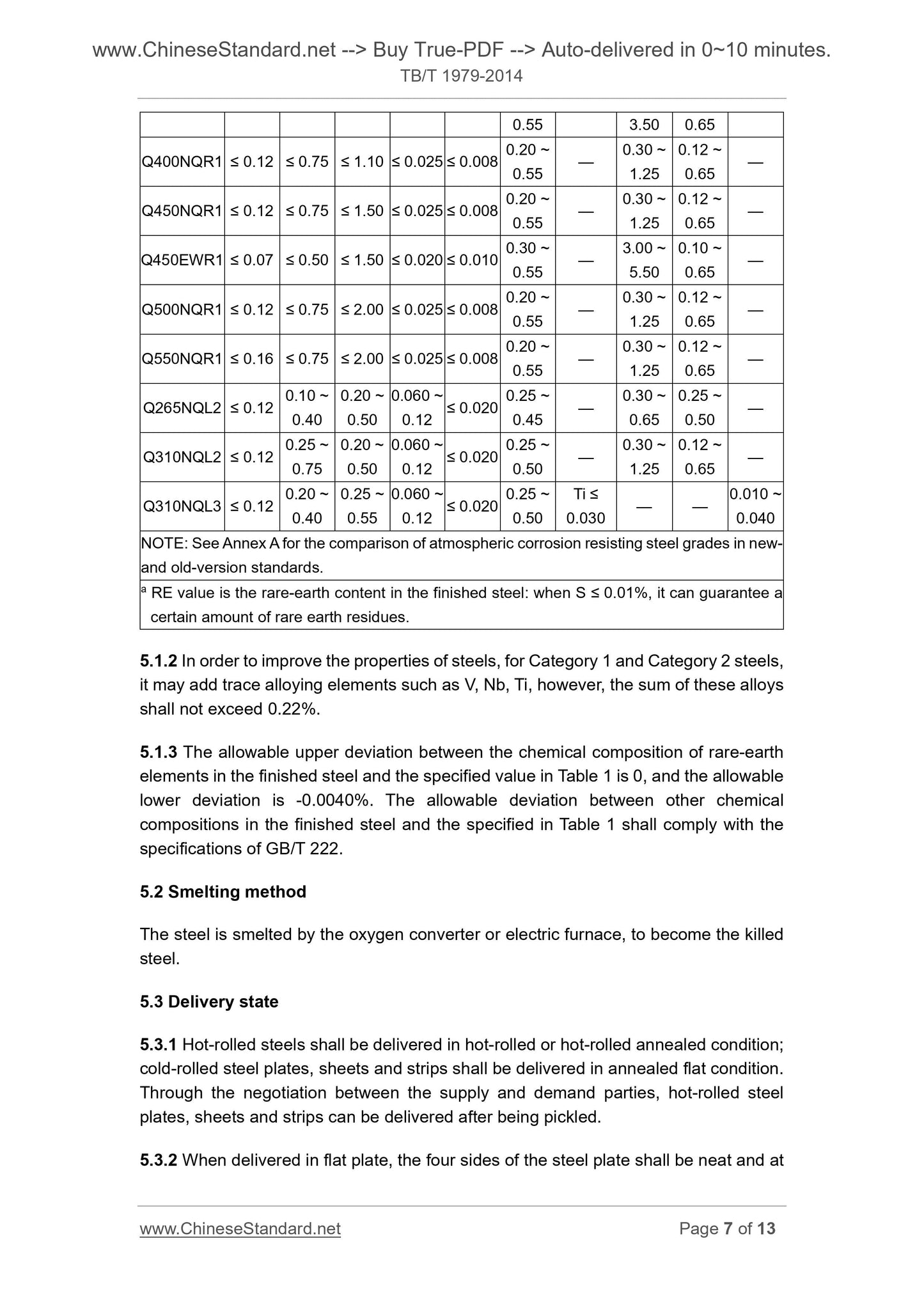

0.55 3.50 0.65

Q400NQR1 ≤ 0.12 ≤ 0.75 ≤ 1.10 ≤ 0.025 ≤ 0.008 0.20 ~0.55 —

0.30 ~

1.25

0.12 ~

0.65 —

Q450NQR1 ≤ 0.12 ≤ 0.75 ≤ 1.50 ≤ 0.025 ≤ 0.008 0.20 ~0.55 —

0.30 ~

1.25

0.12 ~

0.65 —

Q450EWR1 ≤ 0.07 ≤ 0.50 ≤ 1.50 ≤ 0.020 ≤ 0.010 0.30 ~0.55 —

3.00 ~

5.50

0.10 ~

0.65 —

Q500NQR1 ≤ 0.12 ≤ 0.75 ≤ 2.00 ≤ 0.025 ≤ 0.008 0.20 ~0.55 —

0.30 ~

1.25

0.12 ~

0.65 —

Q550NQR1 ≤ 0.16 ≤ 0.75 ≤ 2.00 ≤ 0.025 ≤ 0.008 0.20 ~0.55 —

0.30 ~

1.25

0.12 ~

0.65 —

Q265NQL2 ≤ 0.12 0.10 ~ 0.40

0.20 ~

0.50

0.060 ~

0.12 ≤ 0.020

0.25 ~

0.45 —

0.30 ~

0.65

0.25 ~

0.50 —

Q310NQL2 ≤ 0.12 0.25 ~ 0.75

0.20 ~

0.50

0.060 ~

0.12 ≤ 0.020

0.25 ~

0.50 —

0.30 ~

1.25

0.12 ~

0.65 —

Q310NQL3 ≤ 0.12 0.20 ~ 0.40

0.25 ~

0.55

0.060 ~

0.12 ≤ 0.020

0.25 ~

0.50

Ti ≤

0.030 — —

0.010 ~

0.040

NOTE. See Annex A for the comparison of atmospheric corrosion resisting steel grades in new-

and old-version standards.

a RE value is the rare-earth content in the finished steel. when S ≤ 0.01%, it can guarantee a

certain amount of rare earth residues.

5.1.2 In order to improve the properties of steels, for Category 1 and Category 2 steels,

it may add trace alloying elements such as V, Nb, Ti, however, the sum of these alloys

shall not exceed 0.22%.

5.1.3 The allowable upper deviation between the chemical composition of rare-earth

elements in the finished steel and the specified value in Table 1 is 0, and the allowable

lower deviation is -0.0040%. The allowable deviation between other chemical

compositions in the finished steel and the specified in Table 1 shall comp...

Get QUOTATION in 1-minute: Click TB/T 1979-2014

Historical versions: TB/T 1979-2014

Preview True-PDF (Reload/Scroll if blank)

TB/T 1979-2014: Atmospheric corrosion resisting steel for railway rolling stock

TB/T 1979-2014

TB

RAILWAY INDUSTRY STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 45.060.20

S 05

Replacing TB/T 1979-2003

Atmospheric corrosion resisting steel for

railway rolling stock

ISSUED ON. SEPTEMBER 26, 2014

IMPLEMENTED ON. MARCH 1, 2015

Issued by. State Railway Administration

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Dimension, shape, weight and allowable deviation ... 5

4 Representation method of steel grades ... 5

5 Technical requirements ... 6

6 Inspection methods ... 10

7 Inspection rules ... 11

8 Packaging, marking and quality certificate ... 12

Annex A (informative) Comparison table of atmospheric corrosion resisting steel

grades in old- and new- version standards ... 13

Foreword

This Standard is drafted according to the rules given in GB/T 1.1-2009.

This Standard replaces TB/T 1979-2003 “Ordering technical conditions of atmospheric

corrosion resisting steel for railway rolling stock”; compared with TB/T 1979-2003, main

technical changes are as follows.

- ADD the representation method of atmospheric corrosion resisting steel grades

(see Clause 4);

- The naming of atmospheric corrosion resistant steel grades is changed from the

naming by the main chemical composition in steel TO the naming by the lower

yield limit of steel (see 5.1.1 of this Standard, 4.1.1 of 2003 version);

- ADD the high-strength atmospheric corrosion resisting steel (see Table 1);

- MERGE the cold-rolled 05CuPCrNi steel and cold-rolled 09CuPCrNi-A in the

original standard (see Table 1);

- ADD the requirements for the control sample Q345B of corrosion resistance test

(see Table 6);

- MODIFY the batch weight of atmospheric corrosion resisting steel (see 7.2 of this

Standard, 6.3 of 2003 version);

- ADD the requirements for the corrosion resistance test frequency (see 7.2);

- ADD the comparison table of atmospheric corrosion resisting steel grades in new-

and old-version standards (see Annex A).

This Standard is proposed by and under the jurisdiction of Institute of Standards and

Metrology of Ministry of Railways.

Drafting organizations of this Standard. Institute of Standards and Metrology of Ministry

of Railways, Institute of Metals and Chemistry of Institute of Intercalary Railway,

Baoshan Iron and Steel Co., Ltd.

Main drafters of this Standard. Zhu Mei, Gao Junli, Zhang Bin, Yang Songbai, Qu

Zhaoxia.

The previous version of the standards replaced by this Standard are as follows.

- TB/T 1979-1987, TB/T 1979-2003.

Atmospheric corrosion resisting steel for railway

rolling stock

1 Scope

This Standard specifies the dimension, shape, weight and allowable deviation,

representation method of steel grades, technical requirements, inspection methods,

inspection rules, packaging, marking and quality certificates of atmospheric corrosion

resisting steel for railway rolling stock.

This Standard applies hot-rolled and cold-rolled steel sheet, plate and strip and

structural steel of atmospheric corrosion resisting steel for railway rolling stock.

2 Normative references

The following documents are indispensable for the application of this document. For

dated references, only the dated edition applies to this document. For undated

references, the latest edition (including all amendments) applies to this document.

GB/T 222 Permissible tolerances for chemical composition of steel products

GB/T 223 Methods for chemical analysis of iron, steel and alloy

GB/T 228.1 Metallic materials - Tensile testing - Part 1. Method of test at room

temperature

GB/T 229 Metallic materials - Charpy pendulum impact test method

GB/T 232 Metallic materials - Bend test

GB/T 247 General rule of package mark and certification for steel plates (sheets)

and strips

GB/T 706 Hot rolled section steel

GB/T 708 Dimension shape weight and tolerance for cold-rolled steel plates and

sheets

GB/T 709 Dimension, shape, weight and tolerances for hot-rolled steel plates and

sheets

GB/T 2101 General requirement of acceptance packaging marking and certification

for section steel

GB/T 2975 Steel and steel products - Location and preparation of test pieces for

mechanical testing

GB/T 4336 Carbon and low-alloy steel - Determination of multi-element contents -

Spark discharge atomic emission spectrometric method (routine method)

GB/T 6394 Metal - Methods for estimating the average grain size

GB/T 10561 Steel - Determination of content of nonmetallic inclusions -

Micrographic method using standards diagrams

GB/T 17505 Steel and steel products - General technical delivery requirements

GB/T 20066 Steel and iron - Sampling and preparation of samples for the

determination of chemical composition

GB/T 20125 Low-alloy steel - Determination of multi-element contents - Inductively

coupled plasma atomic emission spectrometric method

TB/T 2375 Test method for cyclic wetting corrosion of weathering steels for railway

applications

3 Dimension, shape, weight and allowable deviation

3.1 The dimension, shape, weight and allowable deviation of steel plates, sheets and

strips shall comply with the relevant specifications of GB/T 709, GB/T 708.

3.2 The dimension, shape, weight and allowable deviation of hot-rolled steels shall

comply with the relevant specifications of GB/T 706; the dimension, shape, weight and

allowable deviation of cold-formed steels shall comply with the corresponding product

specifications.

4 Representation method of steel grades

The steel grade consists of the lower yield strength code, lower yield strength limit

value, atmospheric corrosion resisting steel code, delivery state code and steel

category, the specific structure is as follows.

0.55 3.50 0.65

Q400NQR1 ≤ 0.12 ≤ 0.75 ≤ 1.10 ≤ 0.025 ≤ 0.008 0.20 ~0.55 —

0.30 ~

1.25

0.12 ~

0.65 —

Q450NQR1 ≤ 0.12 ≤ 0.75 ≤ 1.50 ≤ 0.025 ≤ 0.008 0.20 ~0.55 —

0.30 ~

1.25

0.12 ~

0.65 —

Q450EWR1 ≤ 0.07 ≤ 0.50 ≤ 1.50 ≤ 0.020 ≤ 0.010 0.30 ~0.55 —

3.00 ~

5.50

0.10 ~

0.65 —

Q500NQR1 ≤ 0.12 ≤ 0.75 ≤ 2.00 ≤ 0.025 ≤ 0.008 0.20 ~0.55 —

0.30 ~

1.25

0.12 ~

0.65 —

Q550NQR1 ≤ 0.16 ≤ 0.75 ≤ 2.00 ≤ 0.025 ≤ 0.008 0.20 ~0.55 —

0.30 ~

1.25

0.12 ~

0.65 —

Q265NQL2 ≤ 0.12 0.10 ~ 0.40

0.20 ~

0.50

0.060 ~

0.12 ≤ 0.020

0.25 ~

0.45 —

0.30 ~

0.65

0.25 ~

0.50 —

Q310NQL2 ≤ 0.12 0.25 ~ 0.75

0.20 ~

0.50

0.060 ~

0.12 ≤ 0.020

0.25 ~

0.50 —

0.30 ~

1.25

0.12 ~

0.65 —

Q310NQL3 ≤ 0.12 0.20 ~ 0.40

0.25 ~

0.55

0.060 ~

0.12 ≤ 0.020

0.25 ~

0.50

Ti ≤

0.030 — —

0.010 ~

0.040

NOTE. See Annex A for the comparison of atmospheric corrosion resisting steel grades in new-

and old-version standards.

a RE value is the rare-earth content in the finished steel. when S ≤ 0.01%, it can guarantee a

certain amount of rare earth residues.

5.1.2 In order to improve the properties of steels, for Category 1 and Category 2 steels,

it may add trace alloying elements such as V, Nb, Ti, however, the sum of these alloys

shall not exceed 0.22%.

5.1.3 The allowable upper deviation between the chemical composition of rare-earth

elements in the finished steel and the specified value in Table 1 is 0, and the allowable

lower deviation is -0.0040%. The allowable deviation between other chemical

compositions in the finished steel and the specified in Table 1 shall comp...

Share