1

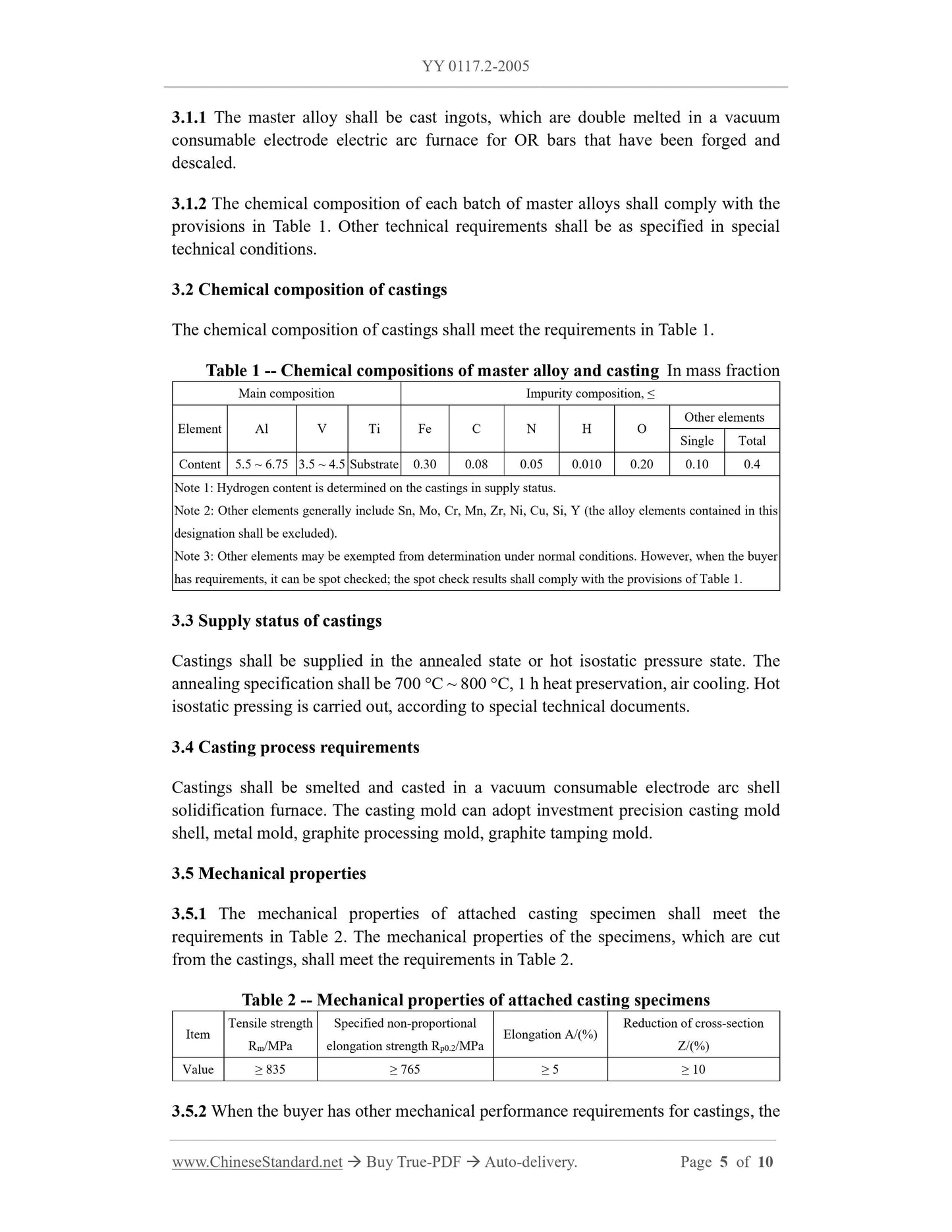

/

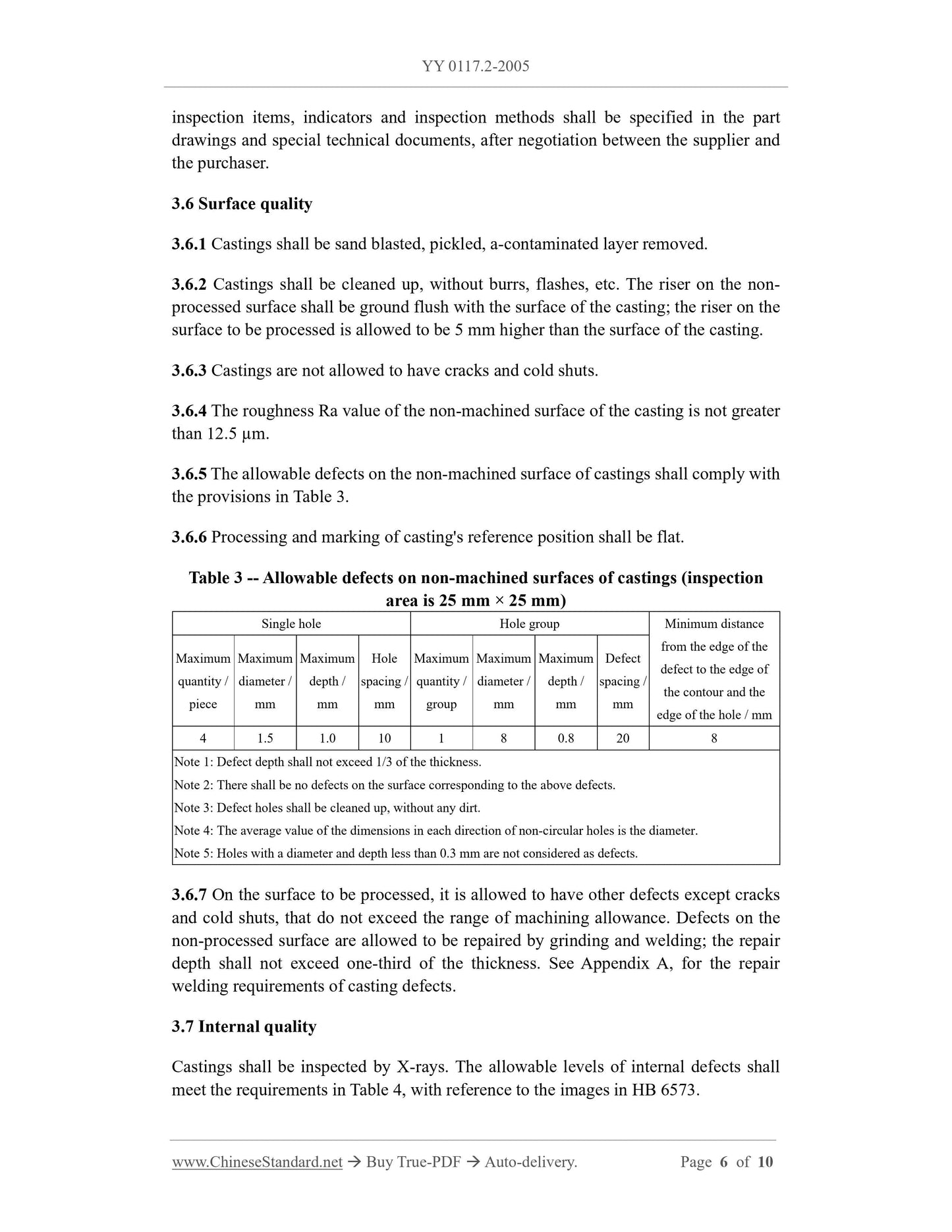

de

10

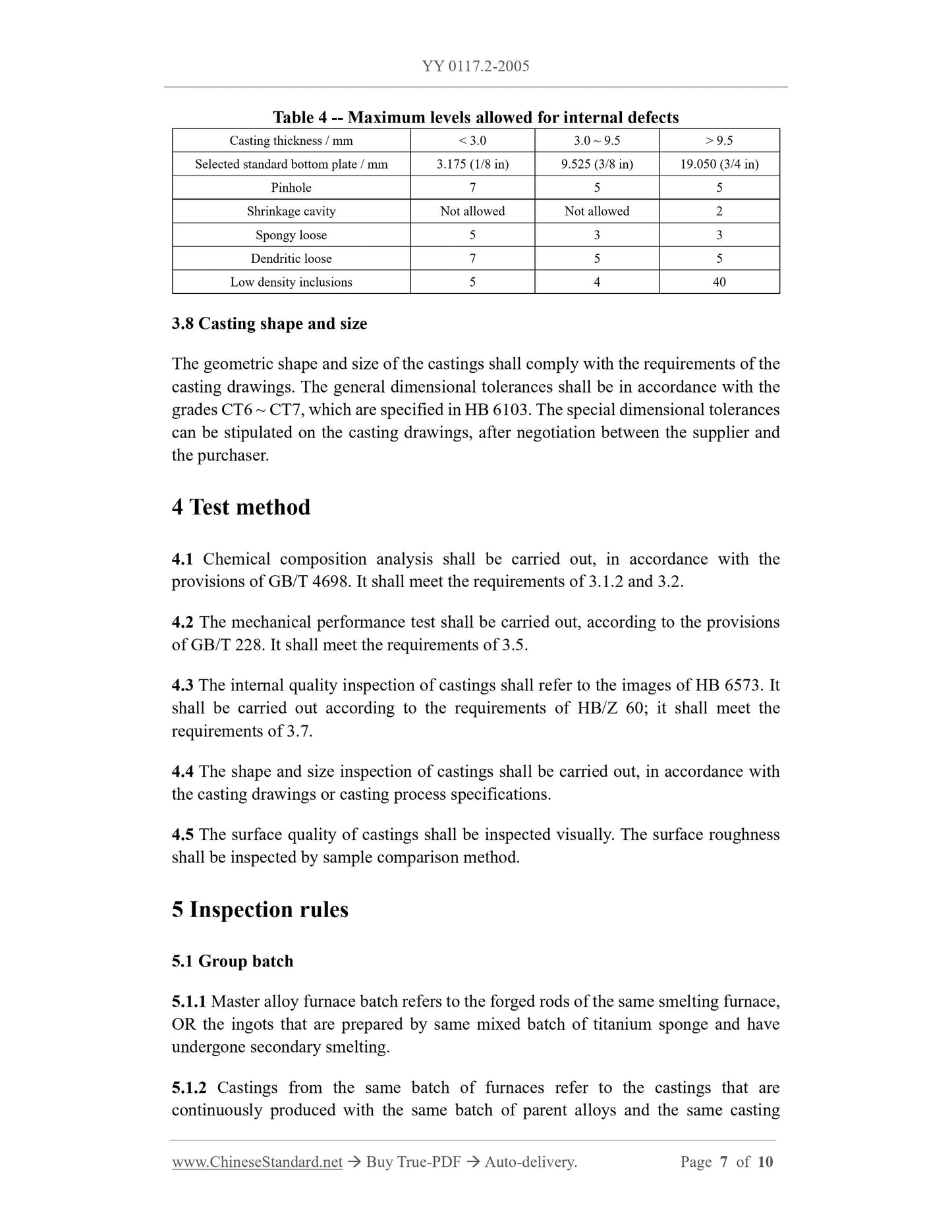

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY 0117.2-2005 English PDF (YY0117.2-2005)

YY 0117.2-2005 English PDF (YY0117.2-2005)

Prix habituel

$110.00 USD

Prix habituel

Prix promotionnel

$110.00 USD

Prix unitaire

/

par

Frais d'expédition calculés à l'étape de paiement.

Impossible de charger la disponibilité du service de retrait

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click YY 0117.2-2005

Historical versions: YY 0117.2-2005

Preview True-PDF (Reload/Scroll if blank)

YY 0117.2-2005: Implants for surgery. Forgings, castings for bone joint prostheses. ZTi6A14V titanium alloy castings

YY 0117.2-2005

YY

PHARMACEUTICALS INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.040.40

C 35

Replacing YY 0117.2-1993

Implants for surgery - Forgings, castings for bone joint

prostheses - ZTi6Al4V titanium alloy castings

ISSUED ON: DECEMBER 07, 2005

IMPLEMENTED ON: DECEMBER 01, 2006

Issued by: National Medical Products Administration

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Requirements ... 4

4 Test method ... 7

5 Inspection rules ... 7

6 Quality certificate ... 9

7 Marking, packaging, transportation, storage ... 9

Appendix A (Normative) Special requirements for defect repair, repair welding and

correction of surgical implants - ZTi6Al4V titanium alloy castings for bone joint

prostheses ... 10

Implants for surgery - Forgings, castings for bone joint

prostheses - ZTi6Al4V titanium alloy castings

1 Scope

This Part of YY 0117 specifies the requirements, test methods, inspection rules, quality

certification, marking and packaging of implants for surgery - forgings, castings for

bone joint prostheses - ZTi6Al4V titanium alloy castings.

This Part applies to the production and acceptance of ZTi6Al4V titanium alloy castings

for bone joint prosthesis.

2 Normative references

The provisions in following documents become the provisions of this Part through

reference in this Part of YY 0117. For the dated references, the subsequent amendments

(excluding corrections) or revisions do not apply to this Part; however, parties who

reach an agreement based on this Part are encouraged to study if the latest versions of

these documents are applicable. For undated references, the latest edition of the

referenced document applies.

GB/T 228 Metallic materials - Tensile testing at ambient temperature (GB/T 228-

2000, eqv ISO 6892:1998)

GB/T 4698 Chemical analysis methods for titanium and titanium alloys

YY 0341 General technological requirements for non-active metallic surgical

implants for osteosynthesis

HB/Z 60 X-ray radiographic inspection

HB 5448 Titanium and titanium alloy investment castings

HB 6103 Dimensional tolerances of castings

HB 6573 Standard reference radiographs for investment steel castings

3 Requirements

3.1 Master alloy

process for not more than 10 smelting furnaces.

5.2 Chemical analysis

5.2.1 Specimens can be cut from cast test bars, casting systems or castings.

5.2.2 Take a specimen from each batch of castings for analysis. When the analysis result

is unqualified, it is allowed to retake the specimen, from the test bar, casting system or

casting that is sampled for the first time, to retest the unqualified elements. If the re-test

results are still unqualified, samples shall be taken from furnace one by one for analysis

of all items. The castings of unqualified furnace numbers shall be disqualified.

5.3 Mechanical properties

5.3.1 The mechanical properties of castings can be tested, by using the attached casting

specimens OR cutting specimens from castings. It shall be inspected according to the

requirements of 3.5.

5.3.2 Take two tensile specimens from each furnace batch of castings; inspect them

according to the requirements in Table 2.

5.3.3 When one specimen is unqualified in the test results, it is allowed to take double

quantity of specimens from the same batch of castings for re-inspection. If the re-

inspection result still has one disqualified piece, it is allowed to take specimen from

each furnace for test. The castings from unqualified furnaces are disqualified.

5.3.4 Tensile specimens for mechanical performance testing shall, according to the

provisions of GB/T 228, select a proportioned specimen, which has a diameter of Φ5

mm and a gauge length of 25 mm.

5.4 Surface quality

Castings shall be 100% inspected for surface quality, according to the requirements of

3.6.

5.5 Internal quality

5.5.1 Castings shall be 100% X-ray inspected, according to the requirements in Table

4.

5.5.2 When the buyer requires metallographic inspection, the inspection shall be carried

out, according to the special technical documents as negotiated by the supplier and the

buyer.

5.6 Casting shape and size

The shape and size of castings are 100% inspected, according to the requirements of

3.8.

5.7 Correction and repair welding

See Appendix A, for the correction and repair welding inspection requirements of

casting defects. It is carried out, according to the special technical documents, as

negotiated between the supplier and the purchaser.

6 Quality certificate

Each batch (number) of castings shall be accompanied by a quality inspection report.

The report shall state the following: supplier name, casting name (code), alloy

designation, furnace batch number of castings, supply status of castings, quantity of

castings, inspection results of casting numbers, this standard number, date of exit-

factory, etc.

7 Marking, packaging, transportation, storage

7.1 Marking

Steel stamps are not allowed on the castings; however, the steel number (referring to

the casting number) can be printed on the gate or riser of the casting.

7.2 Packaging, transportation, storage

7.2.1 Castings shall be packed well. The same batch of castings shall be packaged in

the same package, to prevent mechanical damage, surface pollution, deformation and

other influences, during transportation. The package shall indicate the making

organization, address, zip code, casting name, material designation, furnace batch

number, casting quantity, etc.

7.2.2 The requirements for preventing mechanical damage shall be indicated during the

transportation of castings.

7.2.3 Pollution, corrosion and rust shall be prevented during the storage of castings; it

shall be stored in a neat and orderly manner.

Get QUOTATION in 1-minute: Click YY 0117.2-2005

Historical versions: YY 0117.2-2005

Preview True-PDF (Reload/Scroll if blank)

YY 0117.2-2005: Implants for surgery. Forgings, castings for bone joint prostheses. ZTi6A14V titanium alloy castings

YY 0117.2-2005

YY

PHARMACEUTICALS INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.040.40

C 35

Replacing YY 0117.2-1993

Implants for surgery - Forgings, castings for bone joint

prostheses - ZTi6Al4V titanium alloy castings

ISSUED ON: DECEMBER 07, 2005

IMPLEMENTED ON: DECEMBER 01, 2006

Issued by: National Medical Products Administration

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Requirements ... 4

4 Test method ... 7

5 Inspection rules ... 7

6 Quality certificate ... 9

7 Marking, packaging, transportation, storage ... 9

Appendix A (Normative) Special requirements for defect repair, repair welding and

correction of surgical implants - ZTi6Al4V titanium alloy castings for bone joint

prostheses ... 10

Implants for surgery - Forgings, castings for bone joint

prostheses - ZTi6Al4V titanium alloy castings

1 Scope

This Part of YY 0117 specifies the requirements, test methods, inspection rules, quality

certification, marking and packaging of implants for surgery - forgings, castings for

bone joint prostheses - ZTi6Al4V titanium alloy castings.

This Part applies to the production and acceptance of ZTi6Al4V titanium alloy castings

for bone joint prosthesis.

2 Normative references

The provisions in following documents become the provisions of this Part through

reference in this Part of YY 0117. For the dated references, the subsequent amendments

(excluding corrections) or revisions do not apply to this Part; however, parties who

reach an agreement based on this Part are encouraged to study if the latest versions of

these documents are applicable. For undated references, the latest edition of the

referenced document applies.

GB/T 228 Metallic materials - Tensile testing at ambient temperature (GB/T 228-

2000, eqv ISO 6892:1998)

GB/T 4698 Chemical analysis methods for titanium and titanium alloys

YY 0341 General technological requirements for non-active metallic surgical

implants for osteosynthesis

HB/Z 60 X-ray radiographic inspection

HB 5448 Titanium and titanium alloy investment castings

HB 6103 Dimensional tolerances of castings

HB 6573 Standard reference radiographs for investment steel castings

3 Requirements

3.1 Master alloy

process for not more than 10 smelting furnaces.

5.2 Chemical analysis

5.2.1 Specimens can be cut from cast test bars, casting systems or castings.

5.2.2 Take a specimen from each batch of castings for analysis. When the analysis result

is unqualified, it is allowed to retake the specimen, from the test bar, casting system or

casting that is sampled for the first time, to retest the unqualified elements. If the re-test

results are still unqualified, samples shall be taken from furnace one by one for analysis

of all items. The castings of unqualified furnace numbers shall be disqualified.

5.3 Mechanical properties

5.3.1 The mechanical properties of castings can be tested, by using the attached casting

specimens OR cutting specimens from castings. It shall be inspected according to the

requirements of 3.5.

5.3.2 Take two tensile specimens from each furnace batch of castings; inspect them

according to the requirements in Table 2.

5.3.3 When one specimen is unqualified in the test results, it is allowed to take double

quantity of specimens from the same batch of castings for re-inspection. If the re-

inspection result still has one disqualified piece, it is allowed to take specimen from

each furnace for test. The castings from unqualified furnaces are disqualified.

5.3.4 Tensile specimens for mechanical performance testing shall, according to the

provisions of GB/T 228, select a proportioned specimen, which has a diameter of Φ5

mm and a gauge length of 25 mm.

5.4 Surface quality

Castings shall be 100% inspected for surface quality, according to the requirements of

3.6.

5.5 Internal quality

5.5.1 Castings shall be 100% X-ray inspected, according to the requirements in Table

4.

5.5.2 When the buyer requires metallographic inspection, the inspection shall be carried

out, according to the special technical documents as negotiated by the supplier and the

buyer.

5.6 Casting shape and size

The shape and size of castings are 100% inspected, according to the requirements of

3.8.

5.7 Correction and repair welding

See Appendix A, for the correction and repair welding inspection requirements of

casting defects. It is carried out, according to the special technical documents, as

negotiated between the supplier and the purchaser.

6 Quality certificate

Each batch (number) of castings shall be accompanied by a quality inspection report.

The report shall state the following: supplier name, casting name (code), alloy

designation, furnace batch number of castings, supply status of castings, quantity of

castings, inspection results of casting numbers, this standard number, date of exit-

factory, etc.

7 Marking, packaging, transportation, storage

7.1 Marking

Steel stamps are not allowed on the castings; however, the steel number (referring to

the casting number) can be printed on the gate or riser of the casting.

7.2 Packaging, transportation, storage

7.2.1 Castings shall be packed well. The same batch of castings shall be packaged in

the same package, to prevent mechanical damage, surface pollution, deformation and

other influences, during transportation. The package shall indicate the making

organization, address, zip code, casting name, material designation, furnace batch

number, casting quantity, etc.

7.2.2 The requirements for preventing mechanical damage shall be indicated during the

transportation of castings.

7.2.3 Pollution, corrosion and rust shall be prevented during the storage of castings; it

shall be stored in a neat and orderly manner.

Share