1

/

de

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY 0304-2009 English PDF (YY0304-2009)

YY 0304-2009 English PDF (YY0304-2009)

Prix habituel

$110.00 USD

Prix habituel

Prix promotionnel

$110.00 USD

Prix unitaire

/

par

Frais d'expédition calculés à l'étape de paiement.

Impossible de charger la disponibilité du service de retrait

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click YY 0304-2009

Historical versions: YY 0304-2009

Preview True-PDF (Reload/Scroll if blank)

YY 0304-2009: Plasma sprayed hydroxyapatite coated-titanium dental implant

YY 0304-2009

YY

NATIONAL PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.060.10

C 33

Replacing YY 0304-1998

Plasma sprayed hydroxyapatite coated –

titanium dental implant

羟基磷灰石涂层 - 钛基牙种植体

ISSUED ON. DECEMBER 30, 2009

IMPLEMENTED ON. JUNE 1, 2011

Issued by. China Food and Drug Administration

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Requirements ... 6

5 Test methods ... 9

6 Marks, labels, packaging, transport, storage ... 11

Foreword

This Standard mainly supplemented and modified the original standard content

according to the latest version of the relevant standard. The technical content

that this Standard shall contain is verified and supplemented in full compliance

with the provisions of International Standard ISO 10451-2002 "Dental implant

systems - Contents of technical file". All contents relating to plasma sprayed

hydroxyapatite coated - titanium dental implant are written in this new edition

according to the requirements of the international standard. The performance

requirements and test method of plasma sprayed hydroxyapatite coated

respectively and equivalently adopt ISO 13779.2-2000 "Implants for surgery-

Hydroxyapatite - Part 2. Coatings of hydroxyapatite", ISO 13779.3-2008

"Implants for surgery-Hydroxyapatite - Part 3. Chemical analysis and

characterization of crystallinity and phase purity" and ISO 13779.4-2002

"Implants for surgery-Hydroxyapatite - Part 4. Determination of coating

adhesive strength".

This Standard replaces the previous edition YY 0304-1998 "Plasma sprayed

hydroxyapatite coated titanium dental implant". Compared with the previous

edition, the main changes and reasons in this edition are as follows.

- in definitions, "dental implant" was specified as "plasma sprayed

hydroxyapatite coated - titanium dental implant" directly related in this

Standard, and added the definition of "endosseous implant"; their

definition are based on ISO/TR 11175.1993;

- the biological evaluation stated that the selection and evaluation of test

items were conducted in accordance with the relevant national standards

GB/T 16886 and the pharmaceutical industry standard YY/T 0268, and the

main requirements items and test methods were not listed item by item;

correspondingly, Annex A on biological testing method were also deleted;

- in the geometrical accuracy, added two items. neck surface roughness

and main important connection dimensions and tolerances; the testing

method of the geometric dimension accuracy part shall be no longer

specified, so as to adapt to the differences in the detection equipment

configuration of various production plants and the advanced methods and

instruments that are continuously emerging.

Chemical composition has the following changes.

- the HA content in the coating and the index of crystallinity were changed

to 95% and 45% according to the requirements of ISO 13779.2; added

"4.3.2.1.3 Atomic ratio of calcium and phosphorus";

- "4.3.2.2 Titanium chemical composition " was changed to "Chemical

Plasma sprayed hydroxyapatite coated –

titanium dental implant

1 Scope

This Standard specifies the technical requirements, test methods, product

classification, marks, labels, packaging, transport and storage for plasma

sprayed hydroxyapatite coated - titanium dental implant.

This Standard is applicable to the plasma sprayed hydroxyapatite coated -

titanium dental implant that is implanted in jawbone after the loss of a teeth.

2 Normative references

The following standards contain the provisions which, through reference in this

Standard, constitute the provisions of this Standard. For dated references,

subsequent amendments (excluding corrections) or revisions do not apply to

this Standard. However, the parties who enter into agreement based on this

Standard are encouraged to investigate whether the latest versions of these

documents are applicable. For undated reference documents, the latest

versions apply to this Standard.

GB/T 13810-2007, Wrought titanium and titanium alloy for surgical implants

GB/T 16886.1, Biological evaluation of medical devices - Part 1. Evaluation

and testing within a risk management process (GB/T 16886.1-2001,ISO

10993-1.1997, IDT)

YY/T 0268, Dentistry - Biological evaluation of medical devices used in

dentistry Part 1. Evaluation and test (YY/T 0268-2008, ISO/FDIS 7405.2008,

NEQ)

YY/T 0313-1998, Package, label, transport and storage for medical polymer

products

Pharmacopoeia of the People's Republic of China, 2005 Edition, Part II,

Annex XI "H sterility test method", Annex VIII "H heavy metal test method"

ISO 13779. 3-2008, Implants for surgery - Hydroxyapatite - Part 3. Chemical

analysis and characterization of crystallinity and phase purity

ISO 13779. 4-2002, Implants for surgery - Hydroxyapatite - Part 4.

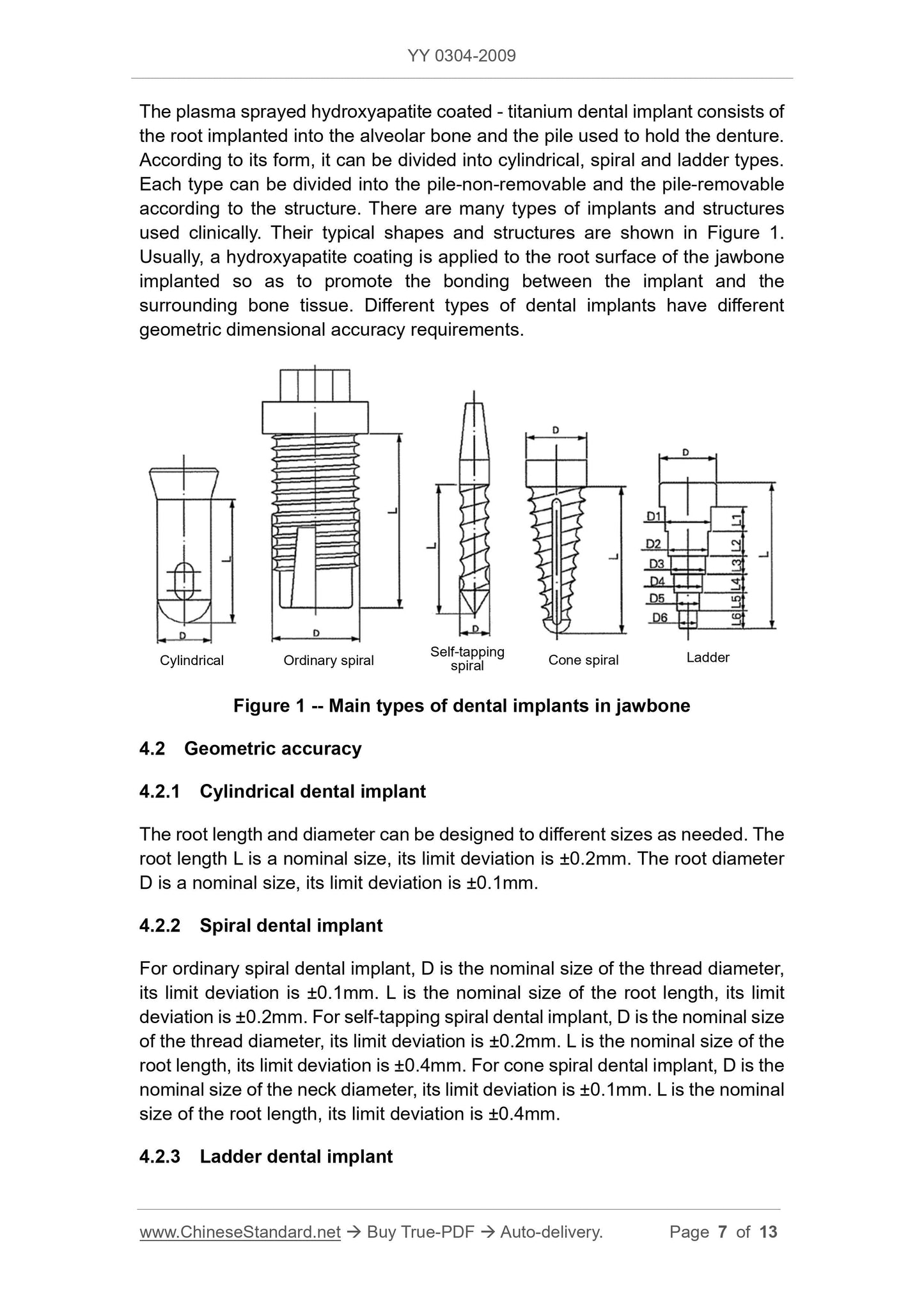

D is the nominal size of the neck diameter, its limit deviation is ±0.1mm. L is the

nominal size of the root length, its limit deviation is ±0.2mm. The diameter and

length of each ladder segment shall also meet the limit deviation specified in

the design requirements.

4.2.4 Connection thread

For pile-removable dental implant, the connection thread shall give thread code

and thread tolerance zone code. The processing accuracy and the tolerance

zone shall ensure that the root and crown pile connection threads of crown-pile-

removable implant shall cooperate well.

4.2.5 Neck surface roughness

For a dental implant with a malleolus neck design, neck surface roughness.

Ra≤1.6µm.

4.2.6 Size and tolerance of important connection site

For pile-removable dental implant, the connection and structure of the

connection site shall be specified and comply with the specified concentricity,

size and tolerance requirements.

4.3 Physical and chemical properties

4.3.1 Appearance

The uncoated titanium surface of the dental implant shall be free from defects

such as cracks, hairless flaws, and scratches due to mechanical processing.

The root and crown pile of two-stage implant shall be well balanced. No visible

gaps and offsets between mating faces.

Hydroxyapatite coating is gray and white porous layer. The surface of the

coating is evenly covered and tightly covered with hydroxyl groups, without any

spots or cracks.

4.3.2 Chemical composition

4.3.2.1 Chemical composition of HA coating

4.3.2.1.1 HA content and crystallinity in coating

HA content ≥95%, HA crystallinity ≥45%.

4.3.2.1.2 Impurity element limit

Arsenic ≤ 3mg/kg, cadmium ≤ 5mg/kg, mercury ≤ 5mg/kg, lead ≤ 30mg/kg.

The total amount of heavy metals (in terms of lead) ≤ 50mg/kg.

also be different. This Standard does not make specific provisions so as to

adapt to different designs and advanced detection methods and detection

instruments that are constantly emerging.

5.2 Physical and chemical properties

5.2.1 Appearance

Visually inspected.

5.2.2 Chemical composition

5.2.2.1 Chemical composition of hydroxyapatite coating

5.2.2.1.1 HA content and crystallinity

The testing of HA content and crystallinity are performed in accordance with the

methods specified in ISO 13779.3.

5.2.2.1.2 Impurity element limit

The test method of trace impurities is in accordance with ISO 13779.3. The total

content of heavy metal elements is performed according to Pharmacopoeia of

the People's Republic of China, 2005 Edition, Par...

Get QUOTATION in 1-minute: Click YY 0304-2009

Historical versions: YY 0304-2009

Preview True-PDF (Reload/Scroll if blank)

YY 0304-2009: Plasma sprayed hydroxyapatite coated-titanium dental implant

YY 0304-2009

YY

NATIONAL PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.060.10

C 33

Replacing YY 0304-1998

Plasma sprayed hydroxyapatite coated –

titanium dental implant

羟基磷灰石涂层 - 钛基牙种植体

ISSUED ON. DECEMBER 30, 2009

IMPLEMENTED ON. JUNE 1, 2011

Issued by. China Food and Drug Administration

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Requirements ... 6

5 Test methods ... 9

6 Marks, labels, packaging, transport, storage ... 11

Foreword

This Standard mainly supplemented and modified the original standard content

according to the latest version of the relevant standard. The technical content

that this Standard shall contain is verified and supplemented in full compliance

with the provisions of International Standard ISO 10451-2002 "Dental implant

systems - Contents of technical file". All contents relating to plasma sprayed

hydroxyapatite coated - titanium dental implant are written in this new edition

according to the requirements of the international standard. The performance

requirements and test method of plasma sprayed hydroxyapatite coated

respectively and equivalently adopt ISO 13779.2-2000 "Implants for surgery-

Hydroxyapatite - Part 2. Coatings of hydroxyapatite", ISO 13779.3-2008

"Implants for surgery-Hydroxyapatite - Part 3. Chemical analysis and

characterization of crystallinity and phase purity" and ISO 13779.4-2002

"Implants for surgery-Hydroxyapatite - Part 4. Determination of coating

adhesive strength".

This Standard replaces the previous edition YY 0304-1998 "Plasma sprayed

hydroxyapatite coated titanium dental implant". Compared with the previous

edition, the main changes and reasons in this edition are as follows.

- in definitions, "dental implant" was specified as "plasma sprayed

hydroxyapatite coated - titanium dental implant" directly related in this

Standard, and added the definition of "endosseous implant"; their

definition are based on ISO/TR 11175.1993;

- the biological evaluation stated that the selection and evaluation of test

items were conducted in accordance with the relevant national standards

GB/T 16886 and the pharmaceutical industry standard YY/T 0268, and the

main requirements items and test methods were not listed item by item;

correspondingly, Annex A on biological testing method were also deleted;

- in the geometrical accuracy, added two items. neck surface roughness

and main important connection dimensions and tolerances; the testing

method of the geometric dimension accuracy part shall be no longer

specified, so as to adapt to the differences in the detection equipment

configuration of various production plants and the advanced methods and

instruments that are continuously emerging.

Chemical composition has the following changes.

- the HA content in the coating and the index of crystallinity were changed

to 95% and 45% according to the requirements of ISO 13779.2; added

"4.3.2.1.3 Atomic ratio of calcium and phosphorus";

- "4.3.2.2 Titanium chemical composition " was changed to "Chemical

Plasma sprayed hydroxyapatite coated –

titanium dental implant

1 Scope

This Standard specifies the technical requirements, test methods, product

classification, marks, labels, packaging, transport and storage for plasma

sprayed hydroxyapatite coated - titanium dental implant.

This Standard is applicable to the plasma sprayed hydroxyapatite coated -

titanium dental implant that is implanted in jawbone after the loss of a teeth.

2 Normative references

The following standards contain the provisions which, through reference in this

Standard, constitute the provisions of this Standard. For dated references,

subsequent amendments (excluding corrections) or revisions do not apply to

this Standard. However, the parties who enter into agreement based on this

Standard are encouraged to investigate whether the latest versions of these

documents are applicable. For undated reference documents, the latest

versions apply to this Standard.

GB/T 13810-2007, Wrought titanium and titanium alloy for surgical implants

GB/T 16886.1, Biological evaluation of medical devices - Part 1. Evaluation

and testing within a risk management process (GB/T 16886.1-2001,ISO

10993-1.1997, IDT)

YY/T 0268, Dentistry - Biological evaluation of medical devices used in

dentistry Part 1. Evaluation and test (YY/T 0268-2008, ISO/FDIS 7405.2008,

NEQ)

YY/T 0313-1998, Package, label, transport and storage for medical polymer

products

Pharmacopoeia of the People's Republic of China, 2005 Edition, Part II,

Annex XI "H sterility test method", Annex VIII "H heavy metal test method"

ISO 13779. 3-2008, Implants for surgery - Hydroxyapatite - Part 3. Chemical

analysis and characterization of crystallinity and phase purity

ISO 13779. 4-2002, Implants for surgery - Hydroxyapatite - Part 4.

D is the nominal size of the neck diameter, its limit deviation is ±0.1mm. L is the

nominal size of the root length, its limit deviation is ±0.2mm. The diameter and

length of each ladder segment shall also meet the limit deviation specified in

the design requirements.

4.2.4 Connection thread

For pile-removable dental implant, the connection thread shall give thread code

and thread tolerance zone code. The processing accuracy and the tolerance

zone shall ensure that the root and crown pile connection threads of crown-pile-

removable implant shall cooperate well.

4.2.5 Neck surface roughness

For a dental implant with a malleolus neck design, neck surface roughness.

Ra≤1.6µm.

4.2.6 Size and tolerance of important connection site

For pile-removable dental implant, the connection and structure of the

connection site shall be specified and comply with the specified concentricity,

size and tolerance requirements.

4.3 Physical and chemical properties

4.3.1 Appearance

The uncoated titanium surface of the dental implant shall be free from defects

such as cracks, hairless flaws, and scratches due to mechanical processing.

The root and crown pile of two-stage implant shall be well balanced. No visible

gaps and offsets between mating faces.

Hydroxyapatite coating is gray and white porous layer. The surface of the

coating is evenly covered and tightly covered with hydroxyl groups, without any

spots or cracks.

4.3.2 Chemical composition

4.3.2.1 Chemical composition of HA coating

4.3.2.1.1 HA content and crystallinity in coating

HA content ≥95%, HA crystallinity ≥45%.

4.3.2.1.2 Impurity element limit

Arsenic ≤ 3mg/kg, cadmium ≤ 5mg/kg, mercury ≤ 5mg/kg, lead ≤ 30mg/kg.

The total amount of heavy metals (in terms of lead) ≤ 50mg/kg.

also be different. This Standard does not make specific provisions so as to

adapt to different designs and advanced detection methods and detection

instruments that are constantly emerging.

5.2 Physical and chemical properties

5.2.1 Appearance

Visually inspected.

5.2.2 Chemical composition

5.2.2.1 Chemical composition of hydroxyapatite coating

5.2.2.1.1 HA content and crystallinity

The testing of HA content and crystallinity are performed in accordance with the

methods specified in ISO 13779.3.

5.2.2.1.2 Impurity element limit

The test method of trace impurities is in accordance with ISO 13779.3. The total

content of heavy metal elements is performed according to Pharmacopoeia of

the People's Republic of China, 2005 Edition, Par...

Share