1

/

de

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY 0341.2-2020 English PDF (YY0341.2-2020)

YY 0341.2-2020 English PDF (YY0341.2-2020)

Prix habituel

$215.00 USD

Prix habituel

Prix promotionnel

$215.00 USD

Prix unitaire

/

par

Frais d'expédition calculés à l'étape de paiement.

Impossible de charger la disponibilité du service de retrait

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click YY 0341.2-2020

Historical versions: YY 0341.2-2020

Preview True-PDF (Reload/Scroll if blank)

YY 0341.2-2020: Non-active surgical implants -- Osteosynthesis and spinal implants -- Part 2: Particular requirements for spinal implants

YY 0341.2-2020

YY

PHARMACEUTICALS INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.040.40

C 35

Replacing YY 0341-2009

Non-active surgical implants - Osteosynthesis and

spinal implants - Part 2: Particular requirements for

spinal implants

无源外科植入物 骨接合与脊柱植入物

ISSUED ON: SEPTEMBER 27, 2020

IMPLEMENTED ON: JUNE 01, 2022

Issued by: National Medical Products Administration

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Requirements ... 6

5 Test method ... 8

6 Manufacturing ... 11

7 Sterilization ... 11

8 Packaging ... 11

9 Information provided by the manufacturer ... 11

Appendix A (Informative) Relevant material standards acceptable for clinical

use ... 13

Appendix B (Informative) List of approved method standards for chemical

analysis ... 15

Appendix C (Informative) Relevant standards for design evaluation and testing

... 16

Non-active surgical implants - Osteosynthesis and

spinal implants - Part 2: Particular requirements for

spinal implants

1 Scope

This Part of YY 0341 specifies the special requirements for non-active surgical

spinal implants (hereinafter referred to as "spinal implants"). In addition to the

requirements that are specified in YY/T 0640, it also specifies the definition,

requirements, test methods, manufacturing, sterilization, packaging and

information provided by the manufacturer of spinal implants.

This Part of YY 0341 applies to non-active surgical spinal implants other than

artificial intervertebral disc implants.

2 Normative references

The following documents are indispensable for the application of this document.

For dated references, only the dated version applies to this document. For

undated references, the latest edition (including all amendments) applies to this

document.

GB/T 4340.1, Metallic materials - Vickers hardness test - Part 1: Test method

GB/T 10610, Geometrical product specifications (GPS) - Surface texture:

Profile method - Rules and procedures for the assessment of surface texture

GB/T 14233.2, Test methods for infusion, transfusion, injection equipment

for medical use - Part 2: Biological test methods

GB/T 16886.7, Biological evaluation of medical devices - Part 7: Ethylene

oxide sterilization residuals

GB 23101.2, Implants for surgery - Hydroxyapatite - Part 2: Coatings of

hydroxyapatite

YY/T 0343, Liquid penetrant inspection of metallic surgical implants

YY/T 0640-2016, Non-active surgical implants - General requirements

Note: Some material standards for spinal implants that have been proven

acceptable through clinical applications can be found in the informative

list that is given in Appendix A.

4.2 Hardness

The hardness of metal spinal implants shall meet the requirements of the

corresponding product standards.

4.3 Static and/or dynamic mechanical properties

The manufacturer shall combine the characteristics of the spinal implant and its

clinical use to specify its static and/or dynamic mechanical properties. If there

are relevant product standards, the mechanical properties of spinal implants

shall meet the requirements of the corresponding standards. Due to the

different characteristics of spinal implants, the test standards may not yet exist

or the existing test standards may be modified as needed.

4.4 Corrosion resistance

The pitting potential (Eb) on the surface of the final product of the stainless-steel

spinal implant shall not be less than 800 mV.

4.5 Surface quality

4.5.1 Surface defects

The surface of the non-coated metal spinal implant shall not have any

discontinuity defects.

4.5.2 Surface roughness

The manufacturer shall specify the roughness Rα value of the main surface of

the spinal implant.

If there are relevant product standards, the roughness Rα value of spinal

implants shall meet the requirements of the corresponding standards.

4.5.3 Appearance

The surface of the spinal implant shall be free of defects that affect the function

of the implant, as well as inlays, final processing deposits or other contaminants.

Note: Defects that affect the function include oxide skin, knife marks, small

nicks, scratches, cracks, depressions, sharp edges (except for cutting

edges), burrs and other defects.

4.5.4 Anodized surface treatment

implants, as well as the physical and chemical properties of polymer materials,

are tested according to the method that is specified in the material standard or

the recommended method in Appendix B.

Note: If the final product cannot be sampled due to structure or size, samples

of the same batch of raw materials and the same manufacturing process

can also be used.

5.2 Hardness

It is performed according to the method of GB/T 4340.1.

Note: Other validated methods are also acceptable.

5.3 Static and/or dynamic mechanical properties

When using static and/or dynamic load tests to evaluate spinal implants,

existing inspection standards can be used (see Appendix C for related

information), or a custom test model that considers the characteristics of the

implant can be used; the quantity of the samples required for tests shall be

determined according to the selected test method standard.

Note 1: The test method can be selected according to different test levels.

Note 2: Preclinical evaluation shall consider the existing data of similar implants

or design characteristics.

Note 3: Tests can be performed on specific implants under specific loads and/or

specific environmental conditions to evaluate their performance.

5.4 Corrosion resistance

It is performed according to the method that is specified in YY/T 1074. The

number of samples shall be no less than 3.

Note: If the final product cannot be sampled due to structure or size, samples

of the same batch of raw materials and the same manufacturing process

can also be used.

5.5 Surface quality

5.5.1 Surface defects

It is performed according to the method that is specified in YY/T 0343. The

number of samples shall be no less than 3.

Note: Other validated methods are also acceptable.

5.9.1 The sterility test shall be carried out according to the method that is

specified in GB/T 14233.2.

Note: Other validated methods are also acceptable.

5.9.2 The residual amount of ethylene oxide shall be carried out according to

the method that is specified in GB/T 16886.7.

Note: Other validated methods are also acceptable.

6 Manufacturing

It shall meet the requirements of Chapter 8 in YY/T 0640-2016.

7 Sterilization

It shall meet the requirements of Chapter 9 in YY/T 0640-2016.

8 Packaging

It shall meet the requirements of Chapter 10 in YY/T 0640-2016.

9 Information provided by the manufacturer

9.1 General principles

Chapter 11 of YY/T 0640-2016 and the following specific terms apply.

9.2 Instruction manual

It shall comply with the provisions of 11.3 in YY/T 0640-2016; the manufacturer

should also provide the following information:

Restrictions on any modification after delivery of the implant: size, shape,

surface condition.

9.3 Marking

9.3.1 The 11.5, 11.6 in YY/T 0640-2016 or the following terms apply.

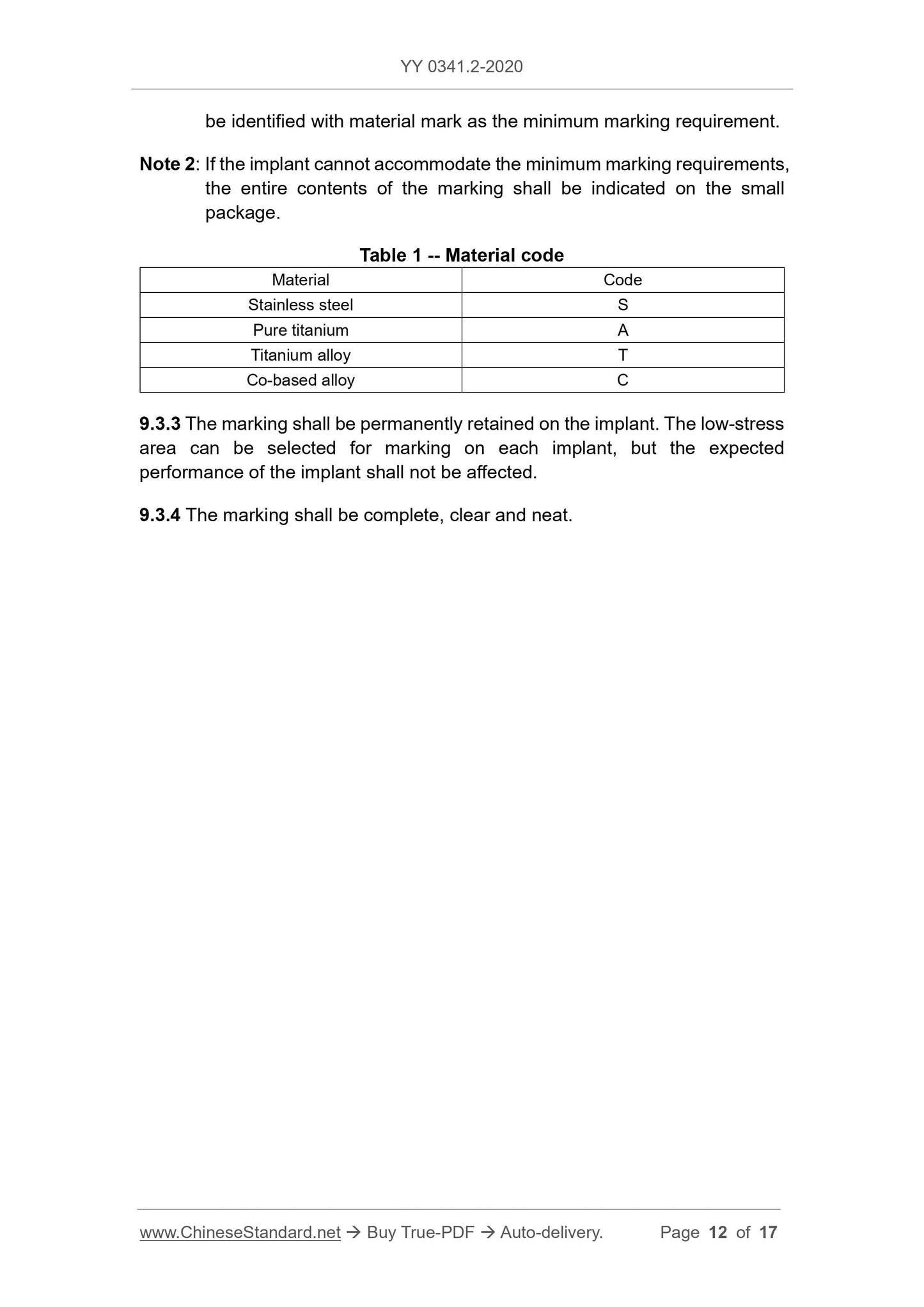

9.3.2 The spinal implant’s marking consists of material code, manufacturer

name code, production batch number, etc. The material code is as specified in

Table 1, or expressed by the element symbol of the substrate.

Note 1: Implants that cannot completely c...

Get QUOTATION in 1-minute: Click YY 0341.2-2020

Historical versions: YY 0341.2-2020

Preview True-PDF (Reload/Scroll if blank)

YY 0341.2-2020: Non-active surgical implants -- Osteosynthesis and spinal implants -- Part 2: Particular requirements for spinal implants

YY 0341.2-2020

YY

PHARMACEUTICALS INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.040.40

C 35

Replacing YY 0341-2009

Non-active surgical implants - Osteosynthesis and

spinal implants - Part 2: Particular requirements for

spinal implants

无源外科植入物 骨接合与脊柱植入物

ISSUED ON: SEPTEMBER 27, 2020

IMPLEMENTED ON: JUNE 01, 2022

Issued by: National Medical Products Administration

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Requirements ... 6

5 Test method ... 8

6 Manufacturing ... 11

7 Sterilization ... 11

8 Packaging ... 11

9 Information provided by the manufacturer ... 11

Appendix A (Informative) Relevant material standards acceptable for clinical

use ... 13

Appendix B (Informative) List of approved method standards for chemical

analysis ... 15

Appendix C (Informative) Relevant standards for design evaluation and testing

... 16

Non-active surgical implants - Osteosynthesis and

spinal implants - Part 2: Particular requirements for

spinal implants

1 Scope

This Part of YY 0341 specifies the special requirements for non-active surgical

spinal implants (hereinafter referred to as "spinal implants"). In addition to the

requirements that are specified in YY/T 0640, it also specifies the definition,

requirements, test methods, manufacturing, sterilization, packaging and

information provided by the manufacturer of spinal implants.

This Part of YY 0341 applies to non-active surgical spinal implants other than

artificial intervertebral disc implants.

2 Normative references

The following documents are indispensable for the application of this document.

For dated references, only the dated version applies to this document. For

undated references, the latest edition (including all amendments) applies to this

document.

GB/T 4340.1, Metallic materials - Vickers hardness test - Part 1: Test method

GB/T 10610, Geometrical product specifications (GPS) - Surface texture:

Profile method - Rules and procedures for the assessment of surface texture

GB/T 14233.2, Test methods for infusion, transfusion, injection equipment

for medical use - Part 2: Biological test methods

GB/T 16886.7, Biological evaluation of medical devices - Part 7: Ethylene

oxide sterilization residuals

GB 23101.2, Implants for surgery - Hydroxyapatite - Part 2: Coatings of

hydroxyapatite

YY/T 0343, Liquid penetrant inspection of metallic surgical implants

YY/T 0640-2016, Non-active surgical implants - General requirements

Note: Some material standards for spinal implants that have been proven

acceptable through clinical applications can be found in the informative

list that is given in Appendix A.

4.2 Hardness

The hardness of metal spinal implants shall meet the requirements of the

corresponding product standards.

4.3 Static and/or dynamic mechanical properties

The manufacturer shall combine the characteristics of the spinal implant and its

clinical use to specify its static and/or dynamic mechanical properties. If there

are relevant product standards, the mechanical properties of spinal implants

shall meet the requirements of the corresponding standards. Due to the

different characteristics of spinal implants, the test standards may not yet exist

or the existing test standards may be modified as needed.

4.4 Corrosion resistance

The pitting potential (Eb) on the surface of the final product of the stainless-steel

spinal implant shall not be less than 800 mV.

4.5 Surface quality

4.5.1 Surface defects

The surface of the non-coated metal spinal implant shall not have any

discontinuity defects.

4.5.2 Surface roughness

The manufacturer shall specify the roughness Rα value of the main surface of

the spinal implant.

If there are relevant product standards, the roughness Rα value of spinal

implants shall meet the requirements of the corresponding standards.

4.5.3 Appearance

The surface of the spinal implant shall be free of defects that affect the function

of the implant, as well as inlays, final processing deposits or other contaminants.

Note: Defects that affect the function include oxide skin, knife marks, small

nicks, scratches, cracks, depressions, sharp edges (except for cutting

edges), burrs and other defects.

4.5.4 Anodized surface treatment

implants, as well as the physical and chemical properties of polymer materials,

are tested according to the method that is specified in the material standard or

the recommended method in Appendix B.

Note: If the final product cannot be sampled due to structure or size, samples

of the same batch of raw materials and the same manufacturing process

can also be used.

5.2 Hardness

It is performed according to the method of GB/T 4340.1.

Note: Other validated methods are also acceptable.

5.3 Static and/or dynamic mechanical properties

When using static and/or dynamic load tests to evaluate spinal implants,

existing inspection standards can be used (see Appendix C for related

information), or a custom test model that considers the characteristics of the

implant can be used; the quantity of the samples required for tests shall be

determined according to the selected test method standard.

Note 1: The test method can be selected according to different test levels.

Note 2: Preclinical evaluation shall consider the existing data of similar implants

or design characteristics.

Note 3: Tests can be performed on specific implants under specific loads and/or

specific environmental conditions to evaluate their performance.

5.4 Corrosion resistance

It is performed according to the method that is specified in YY/T 1074. The

number of samples shall be no less than 3.

Note: If the final product cannot be sampled due to structure or size, samples

of the same batch of raw materials and the same manufacturing process

can also be used.

5.5 Surface quality

5.5.1 Surface defects

It is performed according to the method that is specified in YY/T 0343. The

number of samples shall be no less than 3.

Note: Other validated methods are also acceptable.

5.9.1 The sterility test shall be carried out according to the method that is

specified in GB/T 14233.2.

Note: Other validated methods are also acceptable.

5.9.2 The residual amount of ethylene oxide shall be carried out according to

the method that is specified in GB/T 16886.7.

Note: Other validated methods are also acceptable.

6 Manufacturing

It shall meet the requirements of Chapter 8 in YY/T 0640-2016.

7 Sterilization

It shall meet the requirements of Chapter 9 in YY/T 0640-2016.

8 Packaging

It shall meet the requirements of Chapter 10 in YY/T 0640-2016.

9 Information provided by the manufacturer

9.1 General principles

Chapter 11 of YY/T 0640-2016 and the following specific terms apply.

9.2 Instruction manual

It shall comply with the provisions of 11.3 in YY/T 0640-2016; the manufacturer

should also provide the following information:

Restrictions on any modification after delivery of the implant: size, shape,

surface condition.

9.3 Marking

9.3.1 The 11.5, 11.6 in YY/T 0640-2016 or the following terms apply.

9.3.2 The spinal implant’s marking consists of material code, manufacturer

name code, production batch number, etc. The material code is as specified in

Table 1, or expressed by the element symbol of the substrate.

Note 1: Implants that cannot completely c...

Share