1

/

of

5

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

JT/T 1029-2016 English PDF (JT/T1029-2016)

JT/T 1029-2016 English PDF (JT/T1029-2016)

Regular price

$70.00 USD

Regular price

Sale price

$70.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click JT/T 1029-2016

Historical versions: JT/T 1029-2016

Preview True-PDF (Reload/Scroll if blank)

JT/T 1029-2016: Technical Specifications for the Maintenance of Hybrid Electric Vehicle

JT/T 1029-2016

JT

TRANSPORTATION INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.180

R 16

Record No..

Technical specifications for the

maintenance of hybrid electric vehicle

ISSUED ON. FEBRUARY 2, 2016

IMPLEMENTED ON. APRIL 10, 2016

Issued by. Ministry of Transport of PRC

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Operational safety ... 5

5 Technical requirements ... 5

Annex A (informative) Completion inspection record sample for secondary

maintenance for electric system-specific equipment ... 11

Technical specifications for the

maintenance of hybrid electric vehicle

1 Scope

This Standard specifies the operational safety and technical requirements of

the maintenance of hybrid electric vehicle.

This Standard is applicable to hybrid electric vehicle with total mass not less

than 3500kg.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB 7258, Steel cylinders for the on-board of compressed natural gas as a

fuel for vehicles

GB/T 18344, Specification for the inspection and maintenance of motor

vehicle

GB/T 19596, Terminology of electric vehicles

GB/T 19751, Hybrid electric vehicles safety specification

GB/T 27876, Technical specification for the maintenance of compressed

natural gas vehicle

JT/T 1009, Technical Specification for the Maintenance of Liquefied Natural

Gas Vehicle

3 Terms and definitions

For the purposes of this document, the terms and definitions defined in GB/T

19596 and GB 7258 apply.

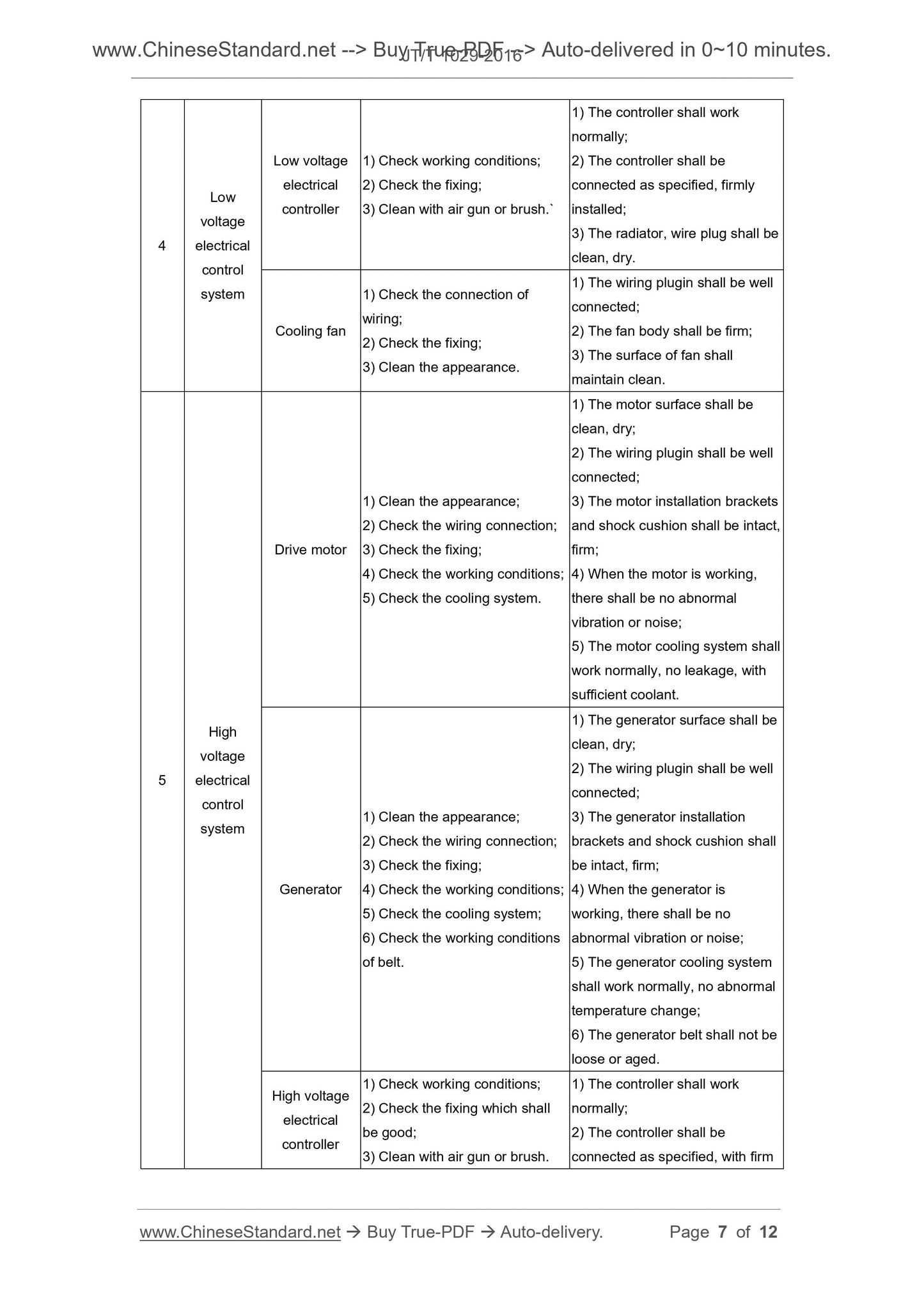

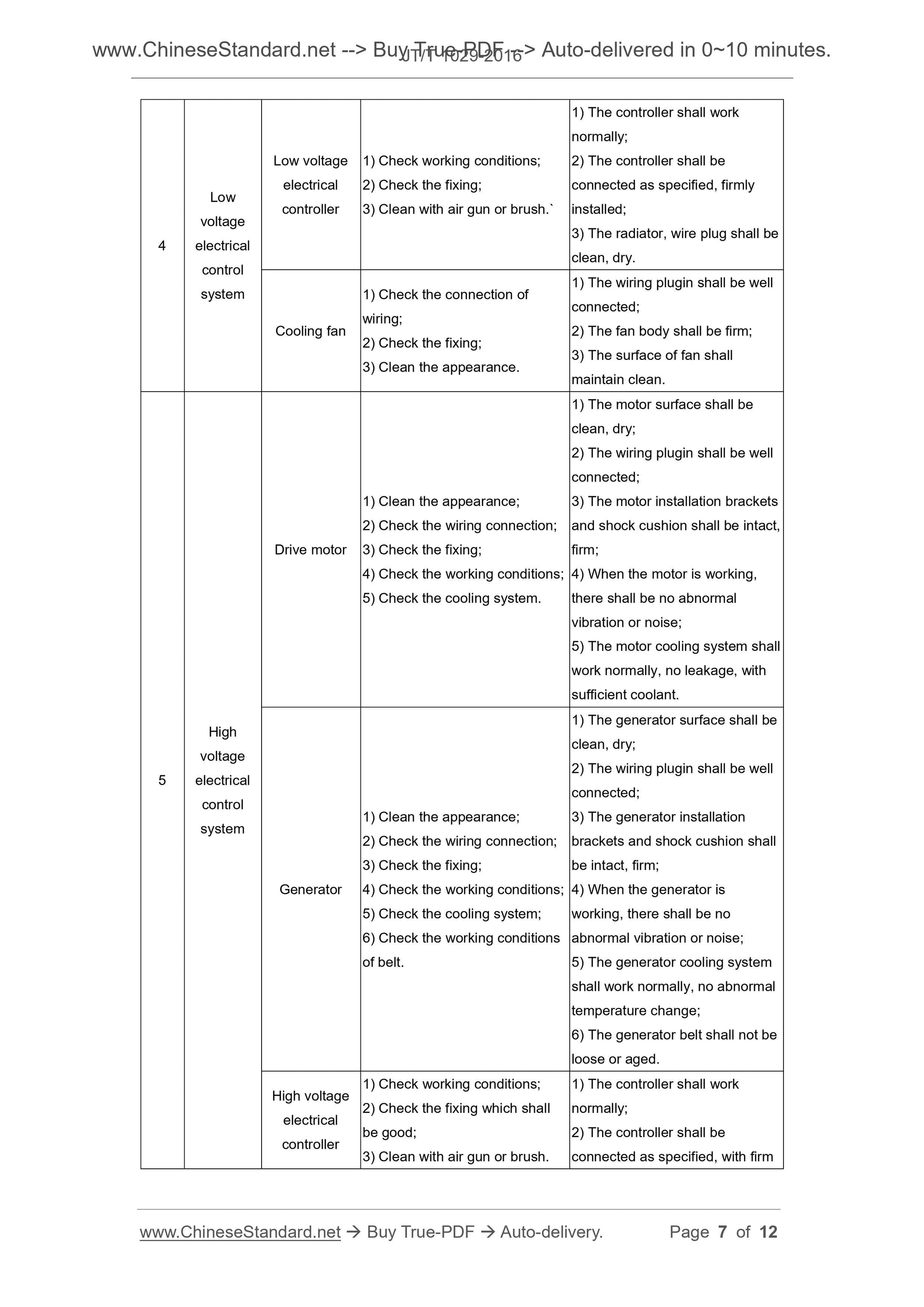

Low

voltage

electrical

control

system

Low voltage

electrical

controller

1) Check working conditions;

2) Check the fixing;

3) Clean with air gun or brush.`

1) The controller shall work

normally;

2) The controller shall be

connected as specified, firmly

installed;

3) The radiator, wire plug shall be

clean, dry.

Cooling fan

1) Check the connection of

wiring;

2) Check the fixing;

3) Clean the appearance.

1) The wiring plugin shall be well

connected;

2) The fan body shall be firm;

3) The surface of fan shall

maintain clean.

High

voltage

electrical

control

system

Drive motor

1) Clean the appearance;

2) Check the wiring connection;

3) Check the fixing;

4) Check the working conditions;

5) Check the cooling system.

1) The motor surface shall be

clean, dry;

2) The wiring plugin shall be well

connected;

3) The motor installation brackets

and shock cushion shall be intact,

firm;

4) When the motor is working,

there shall be no abnormal

vibration or noise;

5) The motor cooling system shall

work normally, no leakage, with

sufficient coolant.

Generator

1) Clean the appearance;

2) Check the wiring connection;

3) Check the fixing;

4) Check the working conditions;

5) Check the cooling system;

6) Check the working conditions

of belt.

1) The generator surface shall be

clean, dry;

2) The wiring plugin shall be well

connected;

3) The generator installation

brackets and shock cushion shall

be intact, firm;

4) When the generator is

working, there shall be no

abnormal vibration or noise;

5) The generator cooling system

shall work normally, no abnormal

temperature change;

6) The generator belt shall not be

loose or aged.

High voltage

electrical

controller

1) Check working conditions;

2) Check the fixing which shall

be good;

3) Clean with air gun or brush.

1) The controller shall work

normally;

2) The controller shall be

connected as specified, with firm

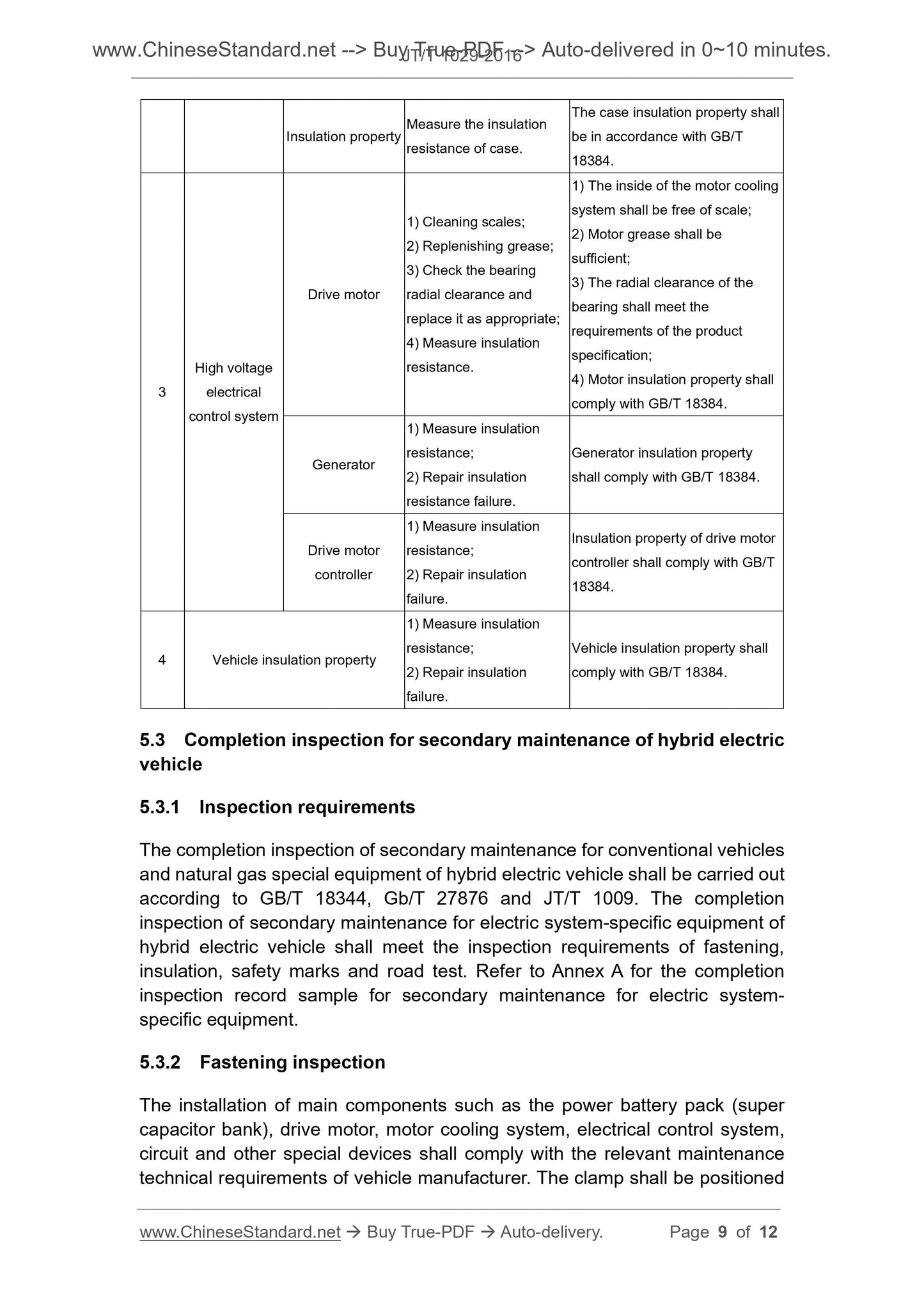

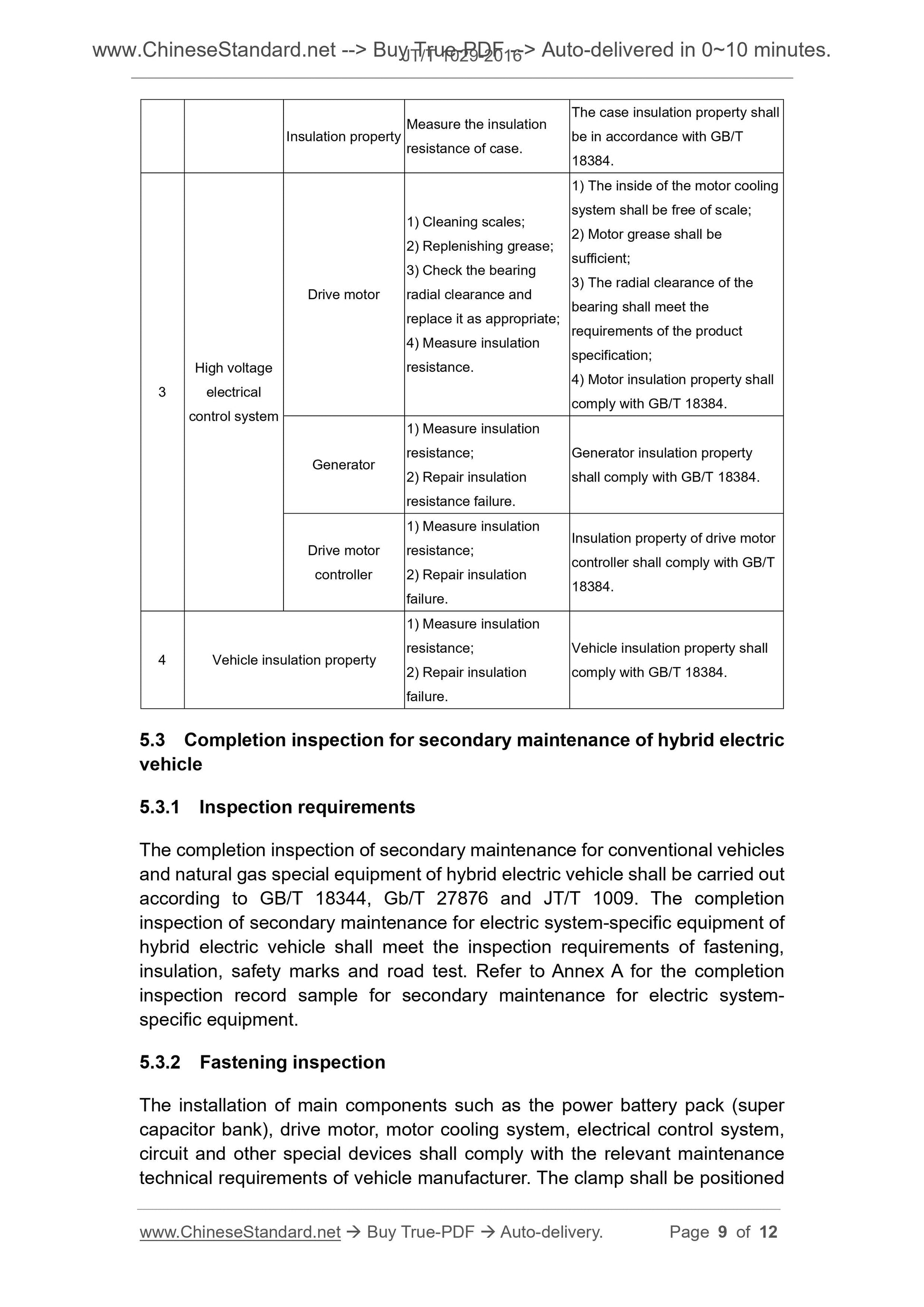

Insulation property Measure the insulation resistance of case.

The case insulation property shall

be in accordance with GB/T

18384.

High voltage

electrical

control system

Drive motor

1) Cleaning scales;

2) Replenishing grease;

3) Check the bearing

radial clearance and

replace it as appropriate;

4) Measure insulation

resistance.

1) The inside of the motor cooling

system shall be free of scale;

2) Motor grease shall be

sufficient;

3) The radial clearance of the

bearing shall meet the

requirements of the product

specification;

4) Motor insulation property shall

comply with GB/T 18384.

Generator

1) Measure insulation

resistance;

2) Repair insulation

resistance failure.

Generator insulation property

shall comply with GB/T 18384.

Drive motor

controller

1) Measure insulation

resistance;

2) Repair insulation

failure.

Insulation property of drive motor

controller shall comply with GB/T

18384.

4 Vehicle insulation property

1) Measure insulation

resistance;

2) Repair insulation

failure.

Vehicle insulation property shall

comply with GB/T 18384.

5.3 Completion inspection for secondary maintenance of hybrid electric

vehicle

5.3.1 Inspection requirements

The completion inspection of secondary maintenance for conventional vehicles

and natural gas special equipment of hybrid electric vehicle shall be carried out

according to GB/T 18344, Gb/T 27876 and JT/T 1009. The completion

inspection of secondary maintenance for electric system-specific equipment of

hybrid electric vehicle shall meet the inspection requirements of fastening,

insulation, safety marks and road test. Refer to Annex A for the completion

inspection record sample for secondary maintenance for electric system-

specific equipment.

5.3.2 Fastening inspection

The installation of main components such as the power battery pack (super

capacitor bank), drive motor, motor cooling system, electrical control system,

circuit and other special devices shall comply with the relevant maintenance

technical requirements of vehicle manufacturer. The clamp shall be positioned

Get QUOTATION in 1-minute: Click JT/T 1029-2016

Historical versions: JT/T 1029-2016

Preview True-PDF (Reload/Scroll if blank)

JT/T 1029-2016: Technical Specifications for the Maintenance of Hybrid Electric Vehicle

JT/T 1029-2016

JT

TRANSPORTATION INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.180

R 16

Record No..

Technical specifications for the

maintenance of hybrid electric vehicle

ISSUED ON. FEBRUARY 2, 2016

IMPLEMENTED ON. APRIL 10, 2016

Issued by. Ministry of Transport of PRC

Table of Contents

Foreword ... 3

1 Scope ... 4

2 Normative references ... 4

3 Terms and definitions ... 4

4 Operational safety ... 5

5 Technical requirements ... 5

Annex A (informative) Completion inspection record sample for secondary

maintenance for electric system-specific equipment ... 11

Technical specifications for the

maintenance of hybrid electric vehicle

1 Scope

This Standard specifies the operational safety and technical requirements of

the maintenance of hybrid electric vehicle.

This Standard is applicable to hybrid electric vehicle with total mass not less

than 3500kg.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB 7258, Steel cylinders for the on-board of compressed natural gas as a

fuel for vehicles

GB/T 18344, Specification for the inspection and maintenance of motor

vehicle

GB/T 19596, Terminology of electric vehicles

GB/T 19751, Hybrid electric vehicles safety specification

GB/T 27876, Technical specification for the maintenance of compressed

natural gas vehicle

JT/T 1009, Technical Specification for the Maintenance of Liquefied Natural

Gas Vehicle

3 Terms and definitions

For the purposes of this document, the terms and definitions defined in GB/T

19596 and GB 7258 apply.

Low

voltage

electrical

control

system

Low voltage

electrical

controller

1) Check working conditions;

2) Check the fixing;

3) Clean with air gun or brush.`

1) The controller shall work

normally;

2) The controller shall be

connected as specified, firmly

installed;

3) The radiator, wire plug shall be

clean, dry.

Cooling fan

1) Check the connection of

wiring;

2) Check the fixing;

3) Clean the appearance.

1) The wiring plugin shall be well

connected;

2) The fan body shall be firm;

3) The surface of fan shall

maintain clean.

High

voltage

electrical

control

system

Drive motor

1) Clean the appearance;

2) Check the wiring connection;

3) Check the fixing;

4) Check the working conditions;

5) Check the cooling system.

1) The motor surface shall be

clean, dry;

2) The wiring plugin shall be well

connected;

3) The motor installation brackets

and shock cushion shall be intact,

firm;

4) When the motor is working,

there shall be no abnormal

vibration or noise;

5) The motor cooling system shall

work normally, no leakage, with

sufficient coolant.

Generator

1) Clean the appearance;

2) Check the wiring connection;

3) Check the fixing;

4) Check the working conditions;

5) Check the cooling system;

6) Check the working conditions

of belt.

1) The generator surface shall be

clean, dry;

2) The wiring plugin shall be well

connected;

3) The generator installation

brackets and shock cushion shall

be intact, firm;

4) When the generator is

working, there shall be no

abnormal vibration or noise;

5) The generator cooling system

shall work normally, no abnormal

temperature change;

6) The generator belt shall not be

loose or aged.

High voltage

electrical

controller

1) Check working conditions;

2) Check the fixing which shall

be good;

3) Clean with air gun or brush.

1) The controller shall work

normally;

2) The controller shall be

connected as specified, with firm

Insulation property Measure the insulation resistance of case.

The case insulation property shall

be in accordance with GB/T

18384.

High voltage

electrical

control system

Drive motor

1) Cleaning scales;

2) Replenishing grease;

3) Check the bearing

radial clearance and

replace it as appropriate;

4) Measure insulation

resistance.

1) The inside of the motor cooling

system shall be free of scale;

2) Motor grease shall be

sufficient;

3) The radial clearance of the

bearing shall meet the

requirements of the product

specification;

4) Motor insulation property shall

comply with GB/T 18384.

Generator

1) Measure insulation

resistance;

2) Repair insulation

resistance failure.

Generator insulation property

shall comply with GB/T 18384.

Drive motor

controller

1) Measure insulation

resistance;

2) Repair insulation

failure.

Insulation property of drive motor

controller shall comply with GB/T

18384.

4 Vehicle insulation property

1) Measure insulation

resistance;

2) Repair insulation

failure.

Vehicle insulation property shall

comply with GB/T 18384.

5.3 Completion inspection for secondary maintenance of hybrid electric

vehicle

5.3.1 Inspection requirements

The completion inspection of secondary maintenance for conventional vehicles

and natural gas special equipment of hybrid electric vehicle shall be carried out

according to GB/T 18344, Gb/T 27876 and JT/T 1009. The completion

inspection of secondary maintenance for electric system-specific equipment of

hybrid electric vehicle shall meet the inspection requirements of fastening,

insulation, safety marks and road test. Refer to Annex A for the completion

inspection record sample for secondary maintenance for electric system-

specific equipment.

5.3.2 Fastening inspection

The installation of main components such as the power battery pack (super

capacitor bank), drive motor, motor cooling system, electrical control system,

circuit and other special devices shall comply with the relevant maintenance

technical requirements of vehicle manufacturer. The clamp shall be positioned

Share