1

/

of

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

QC/T 1136-2020 English PDF (QCT1136-2020)

QC/T 1136-2020 English PDF (QCT1136-2020)

Regular price

$275.00 USD

Regular price

Sale price

$275.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click QC/T 1136-2020

Historical versions: QC/T 1136-2020

Preview True-PDF (Reload/Scroll if blank)

QC/T 1136-2020: Environmental test requirements and test methods of insulated-gate bipolar transistors (IGBT) module for electric vehicles

QC/T 1136-2020

QC

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.040

T 35

Environmental test requirements and test methods of

insulated-gate bipolar transistors (IGBT) module for

electric vehicles

ISSUED ON: DECEMBER 09, 2020

IMPLEMENTED ON: APRIL 01, 2021

Issued by: Ministry of Industry and Information Technology of PRC

Environmental test requirements and test methods of

insulated-gate bipolar transistors (IGBT) module for

electric vehicles

1 Scope

This document specifies the environmental test requirements and test methods

of insulated-gate bipolar transistors (IGBT) module for electric vehicles.

This document applies to IGBT modules for electric vehicles. Other

semiconductor device modules may use it as a reference.

2 Normative references

The contents of the following documents constitute the indispensable clauses

of this document through normative references in the text. Among them, for

dated reference documents, only the version corresponding to that date is

applicable to this document; for undated reference documents, the latest

version (including all amendments) is applicable to this document.

GB/T 2423.1-2008 Environmental testing for electric and electronic products

- Part 2: Test methods - Tests A: Cold

GB/T 2423.2-2008 Environmental testing for electric and electronic products

- Part 2: Test methods - Tests B: Dry heat

GB/T 2423.5-2019 Environmental testing for electric and electronic products

- Part 2: Test methods - Test Ea and guidance: Shock

GB/T 2423.10-2019 Environmental testing for electric and electronic

products - Part 2: Test methods - Test Fc: Vibration (sinusoidal)

GB/T 2423.22-2012 Environmental testing for electric and electronic

products - Part 2: Test methods Test N: Change of temperature

GB/T 2423.28-2005 Basic environmental testing procedures for electric and

electronic products - Part 2: Test methods - Test T: Soldering

GB/T 2423.56-2018 Environmental testing - Part 2: Test methods - Test Fh:

Vibration, broadband random and guidance

ICES-ini: Collector leakage current before the test.

VGE(th): Threshold voltage between grid-emitter.

VCEsat: Saturation voltage between collector-emitter.

Rth: Thermal resistance.

VF: Forward DC voltage.

IF: Forward DC current.

IC: Collector current.

ton: Turn-on phase time.

toff: Turn-off phase time.

Tcha: Temperature of test chamber.

VCE: Collector-emitter voltage.

VGE: Grid-emitter voltage.

ICN: Nominal current of collector.

USL: Upper limit in specification manual.

LSL: Lower limit in specification manual.

5 Environmental adaptability requirements

5.1 Appearance requirements

The main inspection items and requirements, before test assembly and after

test disassembly, include:

a) The enclosure of the IGBT module is not damaged;

b) The connecting terminals of the IGBT module are not deformed or oxidized;

c) The connection of the IGBT module is reliable;

d) The fasteners of the IGBT module are not loosening.

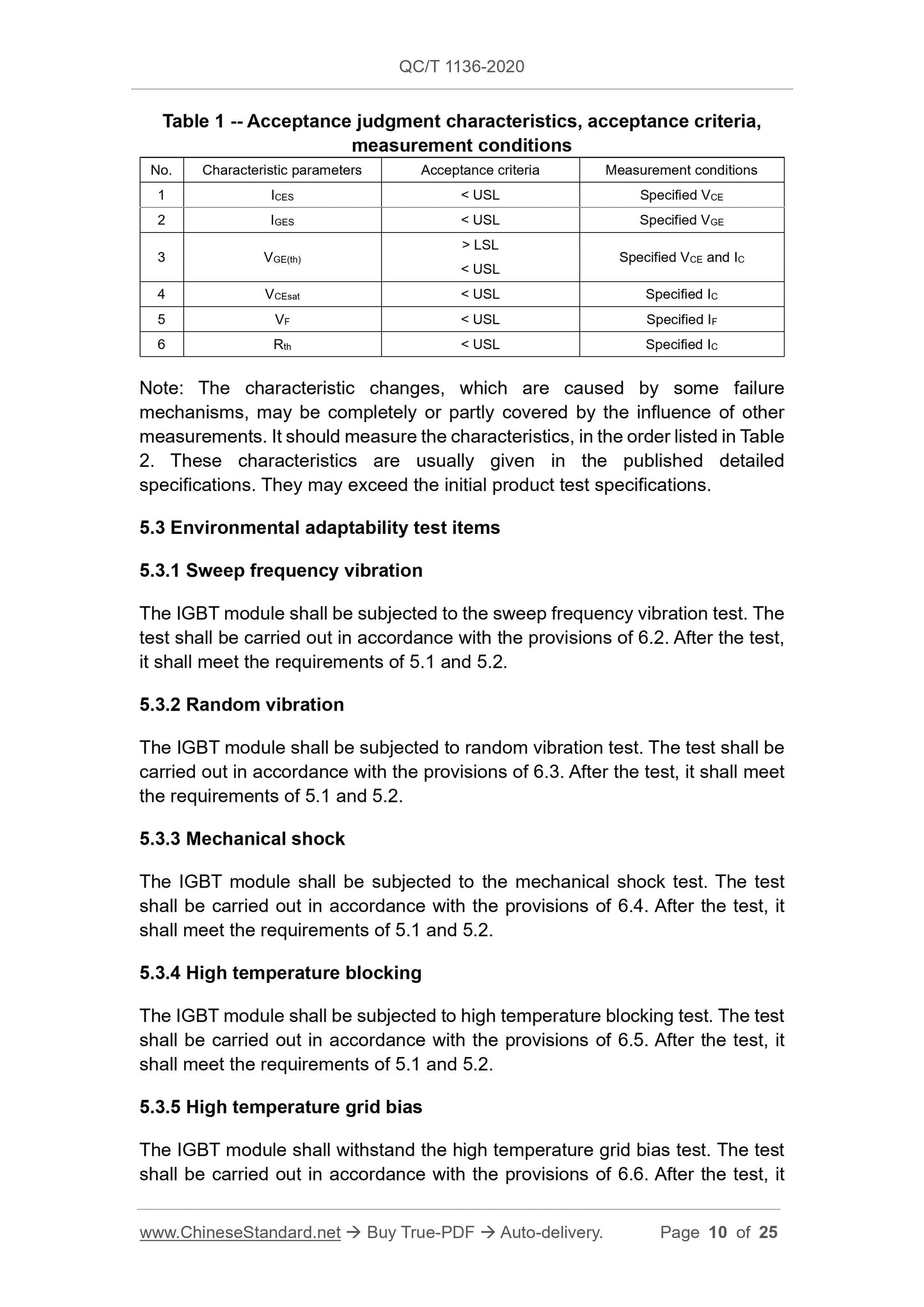

5.2 Characteristic parameter requirements

The acceptance judgment characteristics, acceptance criteria, measurement

conditions are as shown in Table 1.

shall meet the requirements of 5.1 and 5.2.

5.3.6 High temperature and high humidity blocking

The IGBT module shall be subjected to the high temperature and high humidity

blocking test. The test shall be carried out in accordance with the provisions of

6.7. After the test, it shall meet the requirements of 5.1 and 5.2.

5.3.7 Power cycle

The IGBT module shall be subjected to a power cycle test. The test shall be

carried out in accordance with the provisions of 6.8. After the test, it shall meet

the requirements of 5.1 and 5.2.

5.3.8 Temperature shock

The IGBT module shall be subjected to the temperature shock test. The test

shall be carried out in accordance with the provisions of 6.9. After the test, it

shall meet the requirements of 5.1 and 5.2.

5.3.9 Temperature cycle

The IGBT module shall be subjected to a temperature cycle test. The test shall

be carried out in accordance with the provisions of 6.10. After the test, it shall

meet the requirements of 5.1 and 5.2.

5.3.10 High temperature storage

The IGBT module shall be subjected to high temperature storage test. The test

shall be carried out in accordance with the provisions of 6.11. After the test, it

shall meet the requirements of 5.1 and 5.2.

5.3.11 Low temperature storage

The IGBT module shall be subjected to low temperature storage test. The test

shall be carried out in accordance with the provisions of 6.12. After the test, it

shall meet the requirements of 5.1 and 5.2.

5.3.12 Soldering temperature

The IGBT module shall be subjected to the soldering temperature test. The test

shall be carried out in accordance with the provisions of 6.13. After the test, it

shall meet the requirements of 5.1 and 5.2.

5.3.13 Solderability

The IGBT module shall be subjected to the solderability test. The test shall be

carried out in accordance with the provisions of 6.14. After the test, it shall meet

provisions of GB/T 2423.10. The test procedure is as follows:

a) Number the samples before the test. Follow the requirements of GB/T

29332-2012, to test the characteristic parameters in Table 2 AND record

the data;

b) Select the vibration direction. Fix the sample on the installation fixture,

according to the installation requirements of the data manual;

c) According to the vibration conditions, set the parameters such as vibration

frequency, acceleration, duration;

d) Start the vibrating table. Let the sample start to vibrate in one direction;

e) After the vibration in the first direction is over, change the installation

direction of the sample. Repeat the steps b) ~ d), until the test in the three

directions X, Y, Z is over;

f) Within 24h ~ 48h, follow the requirements of GB/T 29332-2012 to test the

characteristic parameters in Table 2. Organize the report. The

corresponding report record is as shown in Appendix A.

6.3 Random vibration test

6.3.1 Test conditions

The IGBT module shall be subjected to random vibration tests in three

directions X, Y, Z. If there are no special requirements, according to the

installation location, the random vibration severity and test duration of the IGBT

module shall refer to the requirements in GB/T 28046.3-2011.

6.3.2 Test procedure

The random vibration test shall be carried out in accordance with the provisions

of GB/T 2423.56. The test procedure is as follows:

a) Number the samples before the test. Follow the requirements of GB/T

29332-2012, to test the characteristic parameters in Table 1 AND record

the data;

b) Select the impact direction. Fix the sample on the installation fixture;

c) According to random vibration conditions, set the parameters such as

frequency, acceleration, duration;

d) Start the vibrating table. Let the sample start to vibrate randomly in one

direction;

- Voltage: VCE ≥ 0.8 VCES, VGE = 0V;

- Temperature: Tj = Tjop_max;

- Time: ≥ 1000h;

- Termination judgement: 5ICES_ini < ICES < USL.

6.5.2 Test procedure

The high temperature blocking test shall be carried out in accordance with the

provisions of GB/T 29332. The test procedure is as follows:

a) Number the samples before the test. Follow the requirements of GB/T

29332-2012, to test the characteristic parameters in Table 1 AND record

the data;

b) Short-circuit the grid and emitter o...

Get QUOTATION in 1-minute: Click QC/T 1136-2020

Historical versions: QC/T 1136-2020

Preview True-PDF (Reload/Scroll if blank)

QC/T 1136-2020: Environmental test requirements and test methods of insulated-gate bipolar transistors (IGBT) module for electric vehicles

QC/T 1136-2020

QC

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.040

T 35

Environmental test requirements and test methods of

insulated-gate bipolar transistors (IGBT) module for

electric vehicles

ISSUED ON: DECEMBER 09, 2020

IMPLEMENTED ON: APRIL 01, 2021

Issued by: Ministry of Industry and Information Technology of PRC

Environmental test requirements and test methods of

insulated-gate bipolar transistors (IGBT) module for

electric vehicles

1 Scope

This document specifies the environmental test requirements and test methods

of insulated-gate bipolar transistors (IGBT) module for electric vehicles.

This document applies to IGBT modules for electric vehicles. Other

semiconductor device modules may use it as a reference.

2 Normative references

The contents of the following documents constitute the indispensable clauses

of this document through normative references in the text. Among them, for

dated reference documents, only the version corresponding to that date is

applicable to this document; for undated reference documents, the latest

version (including all amendments) is applicable to this document.

GB/T 2423.1-2008 Environmental testing for electric and electronic products

- Part 2: Test methods - Tests A: Cold

GB/T 2423.2-2008 Environmental testing for electric and electronic products

- Part 2: Test methods - Tests B: Dry heat

GB/T 2423.5-2019 Environmental testing for electric and electronic products

- Part 2: Test methods - Test Ea and guidance: Shock

GB/T 2423.10-2019 Environmental testing for electric and electronic

products - Part 2: Test methods - Test Fc: Vibration (sinusoidal)

GB/T 2423.22-2012 Environmental testing for electric and electronic

products - Part 2: Test methods Test N: Change of temperature

GB/T 2423.28-2005 Basic environmental testing procedures for electric and

electronic products - Part 2: Test methods - Test T: Soldering

GB/T 2423.56-2018 Environmental testing - Part 2: Test methods - Test Fh:

Vibration, broadband random and guidance

ICES-ini: Collector leakage current before the test.

VGE(th): Threshold voltage between grid-emitter.

VCEsat: Saturation voltage between collector-emitter.

Rth: Thermal resistance.

VF: Forward DC voltage.

IF: Forward DC current.

IC: Collector current.

ton: Turn-on phase time.

toff: Turn-off phase time.

Tcha: Temperature of test chamber.

VCE: Collector-emitter voltage.

VGE: Grid-emitter voltage.

ICN: Nominal current of collector.

USL: Upper limit in specification manual.

LSL: Lower limit in specification manual.

5 Environmental adaptability requirements

5.1 Appearance requirements

The main inspection items and requirements, before test assembly and after

test disassembly, include:

a) The enclosure of the IGBT module is not damaged;

b) The connecting terminals of the IGBT module are not deformed or oxidized;

c) The connection of the IGBT module is reliable;

d) The fasteners of the IGBT module are not loosening.

5.2 Characteristic parameter requirements

The acceptance judgment characteristics, acceptance criteria, measurement

conditions are as shown in Table 1.

shall meet the requirements of 5.1 and 5.2.

5.3.6 High temperature and high humidity blocking

The IGBT module shall be subjected to the high temperature and high humidity

blocking test. The test shall be carried out in accordance with the provisions of

6.7. After the test, it shall meet the requirements of 5.1 and 5.2.

5.3.7 Power cycle

The IGBT module shall be subjected to a power cycle test. The test shall be

carried out in accordance with the provisions of 6.8. After the test, it shall meet

the requirements of 5.1 and 5.2.

5.3.8 Temperature shock

The IGBT module shall be subjected to the temperature shock test. The test

shall be carried out in accordance with the provisions of 6.9. After the test, it

shall meet the requirements of 5.1 and 5.2.

5.3.9 Temperature cycle

The IGBT module shall be subjected to a temperature cycle test. The test shall

be carried out in accordance with the provisions of 6.10. After the test, it shall

meet the requirements of 5.1 and 5.2.

5.3.10 High temperature storage

The IGBT module shall be subjected to high temperature storage test. The test

shall be carried out in accordance with the provisions of 6.11. After the test, it

shall meet the requirements of 5.1 and 5.2.

5.3.11 Low temperature storage

The IGBT module shall be subjected to low temperature storage test. The test

shall be carried out in accordance with the provisions of 6.12. After the test, it

shall meet the requirements of 5.1 and 5.2.

5.3.12 Soldering temperature

The IGBT module shall be subjected to the soldering temperature test. The test

shall be carried out in accordance with the provisions of 6.13. After the test, it

shall meet the requirements of 5.1 and 5.2.

5.3.13 Solderability

The IGBT module shall be subjected to the solderability test. The test shall be

carried out in accordance with the provisions of 6.14. After the test, it shall meet

provisions of GB/T 2423.10. The test procedure is as follows:

a) Number the samples before the test. Follow the requirements of GB/T

29332-2012, to test the characteristic parameters in Table 2 AND record

the data;

b) Select the vibration direction. Fix the sample on the installation fixture,

according to the installation requirements of the data manual;

c) According to the vibration conditions, set the parameters such as vibration

frequency, acceleration, duration;

d) Start the vibrating table. Let the sample start to vibrate in one direction;

e) After the vibration in the first direction is over, change the installation

direction of the sample. Repeat the steps b) ~ d), until the test in the three

directions X, Y, Z is over;

f) Within 24h ~ 48h, follow the requirements of GB/T 29332-2012 to test the

characteristic parameters in Table 2. Organize the report. The

corresponding report record is as shown in Appendix A.

6.3 Random vibration test

6.3.1 Test conditions

The IGBT module shall be subjected to random vibration tests in three

directions X, Y, Z. If there are no special requirements, according to the

installation location, the random vibration severity and test duration of the IGBT

module shall refer to the requirements in GB/T 28046.3-2011.

6.3.2 Test procedure

The random vibration test shall be carried out in accordance with the provisions

of GB/T 2423.56. The test procedure is as follows:

a) Number the samples before the test. Follow the requirements of GB/T

29332-2012, to test the characteristic parameters in Table 1 AND record

the data;

b) Select the impact direction. Fix the sample on the installation fixture;

c) According to random vibration conditions, set the parameters such as

frequency, acceleration, duration;

d) Start the vibrating table. Let the sample start to vibrate randomly in one

direction;

- Voltage: VCE ≥ 0.8 VCES, VGE = 0V;

- Temperature: Tj = Tjop_max;

- Time: ≥ 1000h;

- Termination judgement: 5ICES_ini < ICES < USL.

6.5.2 Test procedure

The high temperature blocking test shall be carried out in accordance with the

provisions of GB/T 29332. The test procedure is as follows:

a) Number the samples before the test. Follow the requirements of GB/T

29332-2012, to test the characteristic parameters in Table 1 AND record

the data;

b) Short-circuit the grid and emitter o...

Share