1

/

of

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

YC/T 159-2019 English PDF (YCT159-2019)

YC/T 159-2019 English PDF (YCT159-2019)

Regular price

$160.00 USD

Regular price

Sale price

$160.00 USD

Unit price

/

per

Shipping calculated at checkout.

Couldn't load pickup availability

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click YC/T 159-2019

Historical versions: YC/T 159-2019

Preview True-PDF (Reload/Scroll if blank)

YC/T 159-2019: Tobacco and tobacco products - Determination of water soluble sugars - Continuous flow method

YC/T 159-2019

TOBACCO INDUSTRY STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 65.160

X 85

Replacing YC/T 159-2002

Tobacco and tobacco products - Determination of

water soluble sugars - Continuous flow method

ISSUED ON: DECEMBER 26, 2019

IMPLEMENTED ON: JANUARY 15, 2020

Issued by: State Tobacco Monopoly Administration

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Principle ... 5

4 Reagents ... 5

5 Instruments and materials ... 7

7 Result calculation and expression ... 8

8 Precision and recovery rate ... 9

9 Test report ... 10

Annex A (informative) Flow chart of continuous flow analysis of water-soluble

sugar... 12

Foreword

This Standard was drafted in accordance with the rules given in GB/T 1.1-2009

and GB/T 20001.4-2015.

This Standard replaces YC/T 159-2002 “Tobacco and tobacco products -

Determination of water soluble sugars - Continuous flow method”. Compared

with YC/T 159-2002, in addition to editorial modifications, the main technical

changes are as follows:

- modified green/green pipe sodium hydroxide solution concentration (see

4.2 of this Edition, 4.2 of Edition 2002);

- modified reagent for measuring red/red pipe diameter when reducing sugar

(see 4.6 of this Edition, 4.6 of Edition 2002);

- modified 85°C heating tank volume (see 5.1 of this Edition, 5/1 of Edition

2002);

- added heat-dissipation device (see 5.1 of this Edition, 5.1 of Edition 2002).

Please note that some content of this document may involve patents. The issuer

of this document does not assume responsibility for identifying these patents.

This Standard was proposed by State Tobacco Monopoly Administration.

This Standard shall be under the jurisdiction of Subcommittee on Cigarette of

National Technical Committee on Tobacco of Standardization Administration of

China (SAC/TC 144/SC 1).

The drafting organizations of this Standard: National Tobacco Quality

Supervision and Inspection Center, Shanghai Tobacco Group Beijing Cigarette

Factory, Yunnan China Tobacco Industry Co., Ltd., Yunnan China Tobacco

Recycled Tobacco Co., Ltd., Zhengzhou Tobacco Research Institute, Yunnan

Tobacco Quality Supervision and Inspection Station, Guizhou China Tobacco

Industry Co., Ltd., Henan China Tobacco Industry Co., Ltd., Henan Tobacco

Quality Supervision and Inspection Station, Northwest Tobacco Quality

Supervision and Inspection Station, Guangdong Tobacco Quality Supervision

and Inspection Station, Shandong China Tobacco Industry Co., Ltd.

Main drafters of this Standard: He Shengbao, Zhang Wei, Luo Anna, Liu Nan,

Feng Xiaomin, Wang Yingyuan, Ma Yanjun, Qin Yunhua, Liu Enfen, Wang Ran,

Guo Junwei, Peng Qianrong, Li Wenwei, Peng Lijuan, Ma Li, Du Guorong,

Wang Fei, Wang Kai, Peng Yuntie, Shi Hongyan, Liu Wei, Wang Hongbo,

Zhang Jianfeng, Mao Jian, Ji Houwei, Wu Shouming, Guo Shuwen, Zhao

Haijuan.

Tobacco and tobacco products - Determination of

water soluble sugars - Continuous flow method

1 Scope

This Standard specifies the method to determine water-soluble sugar (including

water-soluble total sugar and water-soluble reducing sugar) in tobacco and

tobacco products.

This Standard is applicable to the determination of water-soluble sugar in

tobacco and tobacco products. The detection limit of this method is 0.0063%.

quantitation limit is 0.0210%.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 6682, Water for analytical laboratory use - Specification and test

methods

YC/T 31, Tobacco and tobacco products - Preparation of test sample and

determination of water content - Oven method

3 Principle

Use 5% aqueous acetic acid to extract the sample. The sugar in the extract

reacts with p-hydroxybenzoic acid hydrazide. Produce yellow azo compounds

in alkaline media at 85°C. Its maximum absorption wavelength is 410nm. Use

colorimeter to determine.

4 Reagents

Except for special requirements, analytically pure reagents shall be used. The

water shall comply with the regulations for grade one water in GB/T 6682.

4.1 Polyoxyethylene lauryl ether solution (Brij35 solution)

- 5% p-hydroxybenzoic acid hydrazide solution is yellow;

- It is difficult to dissolve p-hydroxybenzoic acid hydrazide in 0.5mol/L sodium

hydroxide solution;

- There are suspended particles in the solution;

- The baseline is wavy.

4.10 5% p-hydroxybenzoic acid hydrazide solution

Add 250mL of 0.5mol/L hydrochloric acid solution (4.7) to a beaker. Add 25g of

paraben hydrazide (4.9) to make it dissolved. Add 10.5g of citric acid (C6H8O7

• H2O). After dissolution, transfer to a 500mL volumetric flask. Use 0.5mol/L

hydrochloric acid solution to dilute to the scale. Store at 0°C~4°C.

5% p-hydroxybenzoic acid hydrazide solution can also be prepared by the

following method. Add 250mL of 0.5mol/L hydrochloric acid solution (4.7) to the

beaker. Heat to 45°C. Add p-hydroxybenzoic acid hydrazide and citric acid

under continuous stirring. Transfer to volumetric flask after cooling. Use 0.5

mol/L hydrochloric acid solution to dilute to the scale. The p-hydroxybenzoic

acid hydrazide solution prepared in this way can avoid the formation of

precipitates in the pipeline.

4.11 D-glucose, purity ≥99.5%.

4.12 Standard stock solution: Weigh 20.0g of dry D-glucose (4.11) in a beaker,

to the nearest of 0.0001g. Use water to dissolve then transfer into a 500mL

volumetric flask and set volume to the scale. The standard stock solution is

stored in the refrigerator at 0°C~4°C. The validity is 1 month.

4.13 Series standard working solution: Use 5% acetic acid solution (4.4) to

prepare at least 5 standard working solution from stock solution. The

concentration range shall cover the expected sample content. The standard

stock solution is stored in the refrigerator at 0°C~4°C. The validity is 2 weeks.

5 Instruments and materials

5.1 Continuous flow analyzer, consisting of the following parts:

- Sampler;

- Proportional pump;

- Dialyzer;

- Heating tank;

- Spiral tube;

- Colorimeter with 410nm filter;

- Data processing device;

- Heat-dissipation device (radiating fin or equivalent cooling device).

5.2 Balance, with a sensitivity of 0.0001g.

5.3 Oscillator.

5.4 Quantitative filling injector or pipette.

5.5 50mL Erlenmeyer flask with stopper.

5.6 Rapid qualitative filter paper.

6 Analysis steps

6.1 Sample preparation

Prepare sample according to YC/T 31 and measure its moisture content.

6.2 Sample processing

Weigh 0.25g of sample in the 50mL Erlenmeyer flask with stopper (5.5), to the

nearest of 0.0001g. Add 25mL of 5% acetic acid solution (4.4). Cover with a

stopper. Shake on the shaker (5.3) (rotation speed >150r/min) and extract for

30min. Use rapid qualitative filter paper (5.6) to filter the extract. Discard the

first 2mL~3mL of filtrate. Collect subsequent filtrate for analysis.

6.3 Instrument analysis

Operate the series of standard working solution (4.13) and subsequent filtrate

of sample processing (6.2) on the instrument. See Annex A for the analysis

flowchart. If the sample concentration exceeds the standard working solution

concentration range, it shall be diluted before measurement.

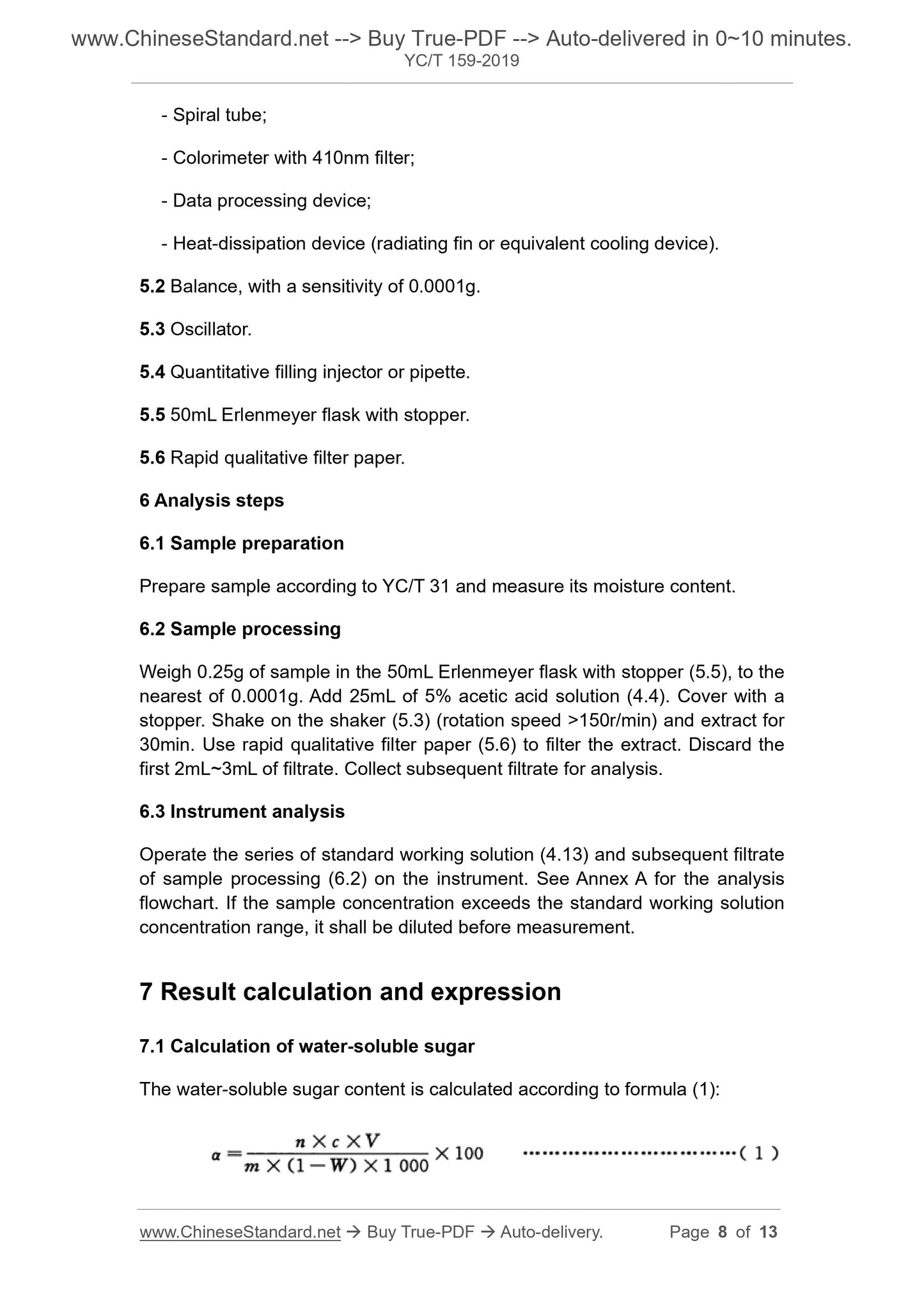

7 Result calculation and expression ...

Get QUOTATION in 1-minute: Click YC/T 159-2019

Historical versions: YC/T 159-2019

Preview True-PDF (Reload/Scroll if blank)

YC/T 159-2019: Tobacco and tobacco products - Determination of water soluble sugars - Continuous flow method

YC/T 159-2019

TOBACCO INDUSTRY STANDARD OF

THE PEOPLE’S REPUBLIC OF CHINA

ICS 65.160

X 85

Replacing YC/T 159-2002

Tobacco and tobacco products - Determination of

water soluble sugars - Continuous flow method

ISSUED ON: DECEMBER 26, 2019

IMPLEMENTED ON: JANUARY 15, 2020

Issued by: State Tobacco Monopoly Administration

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Principle ... 5

4 Reagents ... 5

5 Instruments and materials ... 7

7 Result calculation and expression ... 8

8 Precision and recovery rate ... 9

9 Test report ... 10

Annex A (informative) Flow chart of continuous flow analysis of water-soluble

sugar... 12

Foreword

This Standard was drafted in accordance with the rules given in GB/T 1.1-2009

and GB/T 20001.4-2015.

This Standard replaces YC/T 159-2002 “Tobacco and tobacco products -

Determination of water soluble sugars - Continuous flow method”. Compared

with YC/T 159-2002, in addition to editorial modifications, the main technical

changes are as follows:

- modified green/green pipe sodium hydroxide solution concentration (see

4.2 of this Edition, 4.2 of Edition 2002);

- modified reagent for measuring red/red pipe diameter when reducing sugar

(see 4.6 of this Edition, 4.6 of Edition 2002);

- modified 85°C heating tank volume (see 5.1 of this Edition, 5/1 of Edition

2002);

- added heat-dissipation device (see 5.1 of this Edition, 5.1 of Edition 2002).

Please note that some content of this document may involve patents. The issuer

of this document does not assume responsibility for identifying these patents.

This Standard was proposed by State Tobacco Monopoly Administration.

This Standard shall be under the jurisdiction of Subcommittee on Cigarette of

National Technical Committee on Tobacco of Standardization Administration of

China (SAC/TC 144/SC 1).

The drafting organizations of this Standard: National Tobacco Quality

Supervision and Inspection Center, Shanghai Tobacco Group Beijing Cigarette

Factory, Yunnan China Tobacco Industry Co., Ltd., Yunnan China Tobacco

Recycled Tobacco Co., Ltd., Zhengzhou Tobacco Research Institute, Yunnan

Tobacco Quality Supervision and Inspection Station, Guizhou China Tobacco

Industry Co., Ltd., Henan China Tobacco Industry Co., Ltd., Henan Tobacco

Quality Supervision and Inspection Station, Northwest Tobacco Quality

Supervision and Inspection Station, Guangdong Tobacco Quality Supervision

and Inspection Station, Shandong China Tobacco Industry Co., Ltd.

Main drafters of this Standard: He Shengbao, Zhang Wei, Luo Anna, Liu Nan,

Feng Xiaomin, Wang Yingyuan, Ma Yanjun, Qin Yunhua, Liu Enfen, Wang Ran,

Guo Junwei, Peng Qianrong, Li Wenwei, Peng Lijuan, Ma Li, Du Guorong,

Wang Fei, Wang Kai, Peng Yuntie, Shi Hongyan, Liu Wei, Wang Hongbo,

Zhang Jianfeng, Mao Jian, Ji Houwei, Wu Shouming, Guo Shuwen, Zhao

Haijuan.

Tobacco and tobacco products - Determination of

water soluble sugars - Continuous flow method

1 Scope

This Standard specifies the method to determine water-soluble sugar (including

water-soluble total sugar and water-soluble reducing sugar) in tobacco and

tobacco products.

This Standard is applicable to the determination of water-soluble sugar in

tobacco and tobacco products. The detection limit of this method is 0.0063%.

quantitation limit is 0.0210%.

2 Normative references

The following referenced documents are indispensable for the application of

this document. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any

amendments) applies.

GB/T 6682, Water for analytical laboratory use - Specification and test

methods

YC/T 31, Tobacco and tobacco products - Preparation of test sample and

determination of water content - Oven method

3 Principle

Use 5% aqueous acetic acid to extract the sample. The sugar in the extract

reacts with p-hydroxybenzoic acid hydrazide. Produce yellow azo compounds

in alkaline media at 85°C. Its maximum absorption wavelength is 410nm. Use

colorimeter to determine.

4 Reagents

Except for special requirements, analytically pure reagents shall be used. The

water shall comply with the regulations for grade one water in GB/T 6682.

4.1 Polyoxyethylene lauryl ether solution (Brij35 solution)

- 5% p-hydroxybenzoic acid hydrazide solution is yellow;

- It is difficult to dissolve p-hydroxybenzoic acid hydrazide in 0.5mol/L sodium

hydroxide solution;

- There are suspended particles in the solution;

- The baseline is wavy.

4.10 5% p-hydroxybenzoic acid hydrazide solution

Add 250mL of 0.5mol/L hydrochloric acid solution (4.7) to a beaker. Add 25g of

paraben hydrazide (4.9) to make it dissolved. Add 10.5g of citric acid (C6H8O7

• H2O). After dissolution, transfer to a 500mL volumetric flask. Use 0.5mol/L

hydrochloric acid solution to dilute to the scale. Store at 0°C~4°C.

5% p-hydroxybenzoic acid hydrazide solution can also be prepared by the

following method. Add 250mL of 0.5mol/L hydrochloric acid solution (4.7) to the

beaker. Heat to 45°C. Add p-hydroxybenzoic acid hydrazide and citric acid

under continuous stirring. Transfer to volumetric flask after cooling. Use 0.5

mol/L hydrochloric acid solution to dilute to the scale. The p-hydroxybenzoic

acid hydrazide solution prepared in this way can avoid the formation of

precipitates in the pipeline.

4.11 D-glucose, purity ≥99.5%.

4.12 Standard stock solution: Weigh 20.0g of dry D-glucose (4.11) in a beaker,

to the nearest of 0.0001g. Use water to dissolve then transfer into a 500mL

volumetric flask and set volume to the scale. The standard stock solution is

stored in the refrigerator at 0°C~4°C. The validity is 1 month.

4.13 Series standard working solution: Use 5% acetic acid solution (4.4) to

prepare at least 5 standard working solution from stock solution. The

concentration range shall cover the expected sample content. The standard

stock solution is stored in the refrigerator at 0°C~4°C. The validity is 2 weeks.

5 Instruments and materials

5.1 Continuous flow analyzer, consisting of the following parts:

- Sampler;

- Proportional pump;

- Dialyzer;

- Heating tank;

- Spiral tube;

- Colorimeter with 410nm filter;

- Data processing device;

- Heat-dissipation device (radiating fin or equivalent cooling device).

5.2 Balance, with a sensitivity of 0.0001g.

5.3 Oscillator.

5.4 Quantitative filling injector or pipette.

5.5 50mL Erlenmeyer flask with stopper.

5.6 Rapid qualitative filter paper.

6 Analysis steps

6.1 Sample preparation

Prepare sample according to YC/T 31 and measure its moisture content.

6.2 Sample processing

Weigh 0.25g of sample in the 50mL Erlenmeyer flask with stopper (5.5), to the

nearest of 0.0001g. Add 25mL of 5% acetic acid solution (4.4). Cover with a

stopper. Shake on the shaker (5.3) (rotation speed >150r/min) and extract for

30min. Use rapid qualitative filter paper (5.6) to filter the extract. Discard the

first 2mL~3mL of filtrate. Collect subsequent filtrate for analysis.

6.3 Instrument analysis

Operate the series of standard working solution (4.13) and subsequent filtrate

of sample processing (6.2) on the instrument. See Annex A for the analysis

flowchart. If the sample concentration exceeds the standard working solution

concentration range, it shall be diluted before measurement.

7 Result calculation and expression ...

Share