1

/

dari

6

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

Q/BQB 402-2009 English PDF

Q/BQB 402-2009 English PDF

Harga reguler

$70.00 USD

Harga reguler

Harga obral

$70.00 USD

Harga satuan

/

per

Biaya pengiriman dihitung saat checkout.

Tidak dapat memuat ketersediaan pengambilan

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click Q/BQB 402-2009

Historical versions: Q/BQB 402-2009

Preview True-PDF (Reload/Scroll if blank)

Q/BQB 402-2009: Cold-rolled carbon steel and steel strip

Q/BQB 402-2009

BQB

ENTERPRISE STANDARD OF

BAOSHAN IRON AND STEEL CO., LTD

Replacing Q/BQB 402-2003, BZJ 491-2004

Continuously-cold-rolled carbon steel sheets and

strips

Table of Contents

1 Scope ... 3

2 Normative references ... 3

3 Classification and code ... 4

4 Information required for ordering ... 5

5 Dimension, shape, weight and allowable deviation ... 6

6 Technical requirements ... 6

7 Inspection and test ... 10

8 Packaging, marking and inspection documents ... 11

9 Numerical rounding rules ... 11

10 Approximate comparison of designation ... 11

Appendix A (Informative) Approximate comparison between the designations of

this standard and domestic and foreign standard ... 12

Additional information: ... 12

Continuously-cold-rolled carbon steel sheets and

strips

1 Scope

This standard specifies the classification and code, size, shape, weight,

technical requirements, inspection and test, packaging, marking and inspection

documents of continuously-cold-rolled carbon steel sheets and strips.

This standard applies to the continuously-cold-rolled carbon steel sheets and

strips (hereinafter referred to as steel sheets and strips) which have a thickness

of 0.17 mm ~ 3.5 mm as produced by Baoshan Iron and Steel Co., Ltd.

2 Normative references

The provisions in following documents become the provisions of this Standard

through reference in this Standard. For the dated references, the subsequent

amendments (excluding corrections) or revisions do not apply to this Standard;

however, parties who reach an agreement based on this Standard are

encouraged to study if the latest versions of these documents are applicable.

For undated references, the latest edition of the referenced document applies.

GB/T 222-2006 Permissible tolerances for chemical composition of steel

products

GB/T 223 Methods for chemical analysis of steel and alloys

GB/T 228-2002 Metallic materials - Tensile testing at ambient temperature

GB/T 230.1-2004 Metallic Rockwell hardness test - Part 1: Test method

(scales A, B, C, D, E, F, G, H, K, N, T)

GB/T 232-1999 Metallic materials - Bend test

GB/T 2523-2008 Measuring method of surface roughness and peak count

for cold-rolled metal sheet (strip)

GB/T 2975-1998 Steel and steel products - Location and preparation of test

pieces for mechanical testing

GB/T 4336-2002 Standard test method for spark discharge atomic emission

spectrometric analysis of carbon and low-alloy steel (routine method)

The steel used for steel sheets and steel strips is smelted by the use of an

oxygen converter.

6.3 Delivery status

6.3.1 Steel sheets and steel strips are supplied by heat treatment after

continuously-cold-rolling. The type of heat treatment shall meet the

requirements in Table 4.

6.3.2 Steel sheets and steel strips are usually supplied after coating oil. The

applied oil film shall be able to be removed by alkaline aqueous solution. Under

normal packaging, transportation, loading and unloading, and storage

conditions, the supplier shall ensure that the surface of the steel sheet and strip

does not rust within 6 months from the date of completion of manufacture.

According to the requirements of the purchaser, through negotiation between

the supplier and the purchaser, as indicated in the contract, it may also be

supplied without oil.

6.4 Mechanical properties

6.4.1 The mechanical properties of annealed and flattened steel sheets and

strips shall meet the requirements of Table 6.

6.4.2 Due to the effects of aging, the mechanical properties of steel sheets and

strips will deteriorate with the increase of storage time, such as the increase in

yield strength and tensile strength, the decrease in elongation at breaking, the

deterioration of formability, the occurrence of tensile strain marks, etc., so it is

recommended for the users to use it as soon as possible

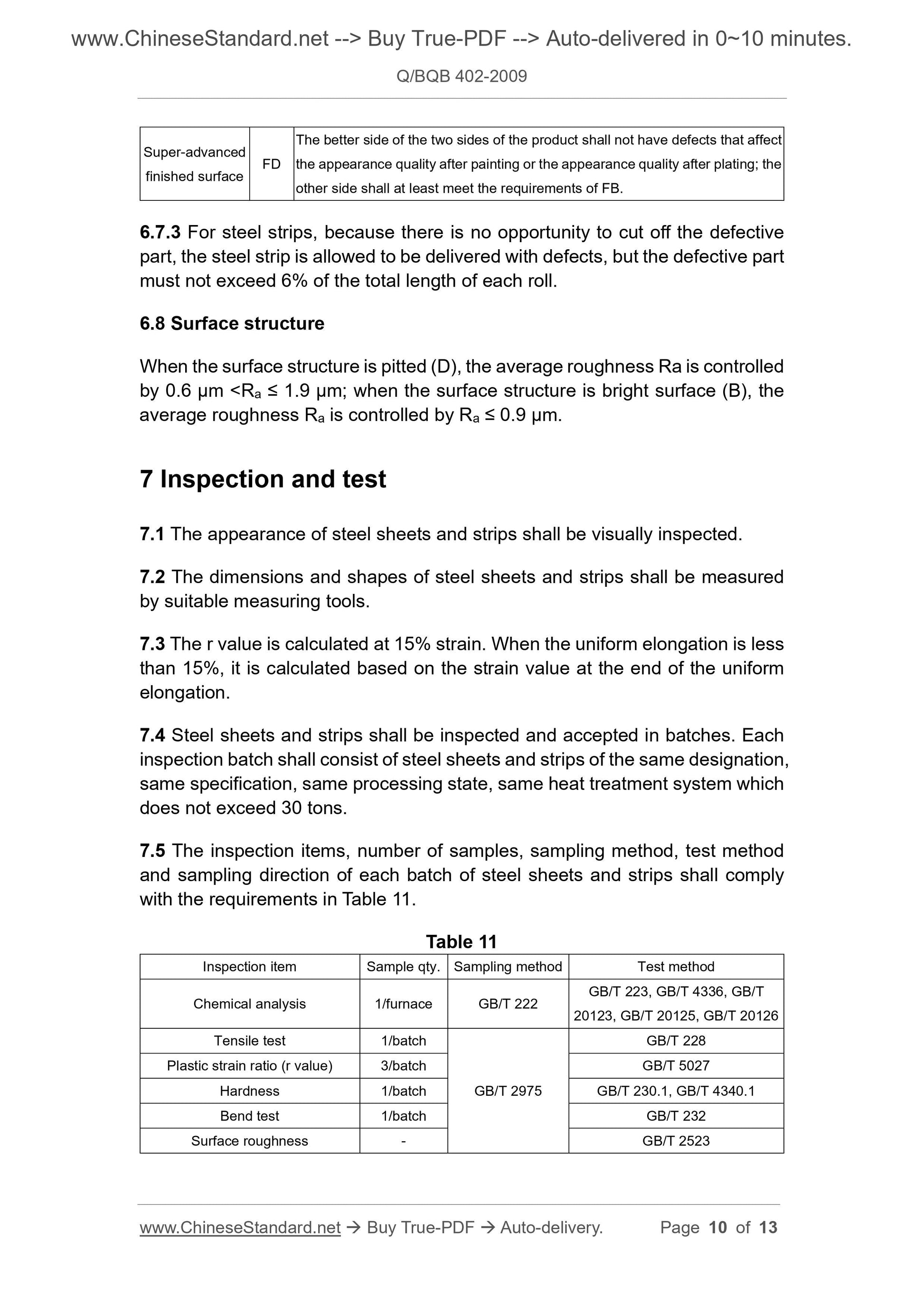

Super-advanced

finished surface FD

The better side of the two sides of the product shall not have defects that affect

the appearance quality after painting or the appearance quality after plating; the

other side shall at least meet the requirements of FB.

6.7.3 For steel strips, because there is no opportunity to cut off the defective

part, the steel strip is allowed to be delivered with defects, but the defective part

must not exceed 6% of the total length of each roll.

6.8 Surface structure

When the surface structure is pitted (D), the average roughness Ra is controlled

by 0.6 µm < Ra ≤ 1.9 µm; when the surface structure is bright surface (B), the

average roughness Ra is controlled by Ra ≤ 0.9 µm.

7 Inspection and test

7.1 The appearance of steel sheets and strips shall be visually inspected.

7.2 The dimensions and shapes of steel sheets and strips shall be measured

by suitable measuring tools.

7.3 The r value is calculated at 15% strain. When the uniform elongation is less

than 15%, it is calculated based on the strain value at the end of the uniform

elongation.

7.4 Steel sheets and strips shall be inspected and accepted in batches. Each

inspection batch shall consist of steel sheets and strips of the same designation,

same specification, same processing state, same heat treatment system which

does not exceed 30 tons.

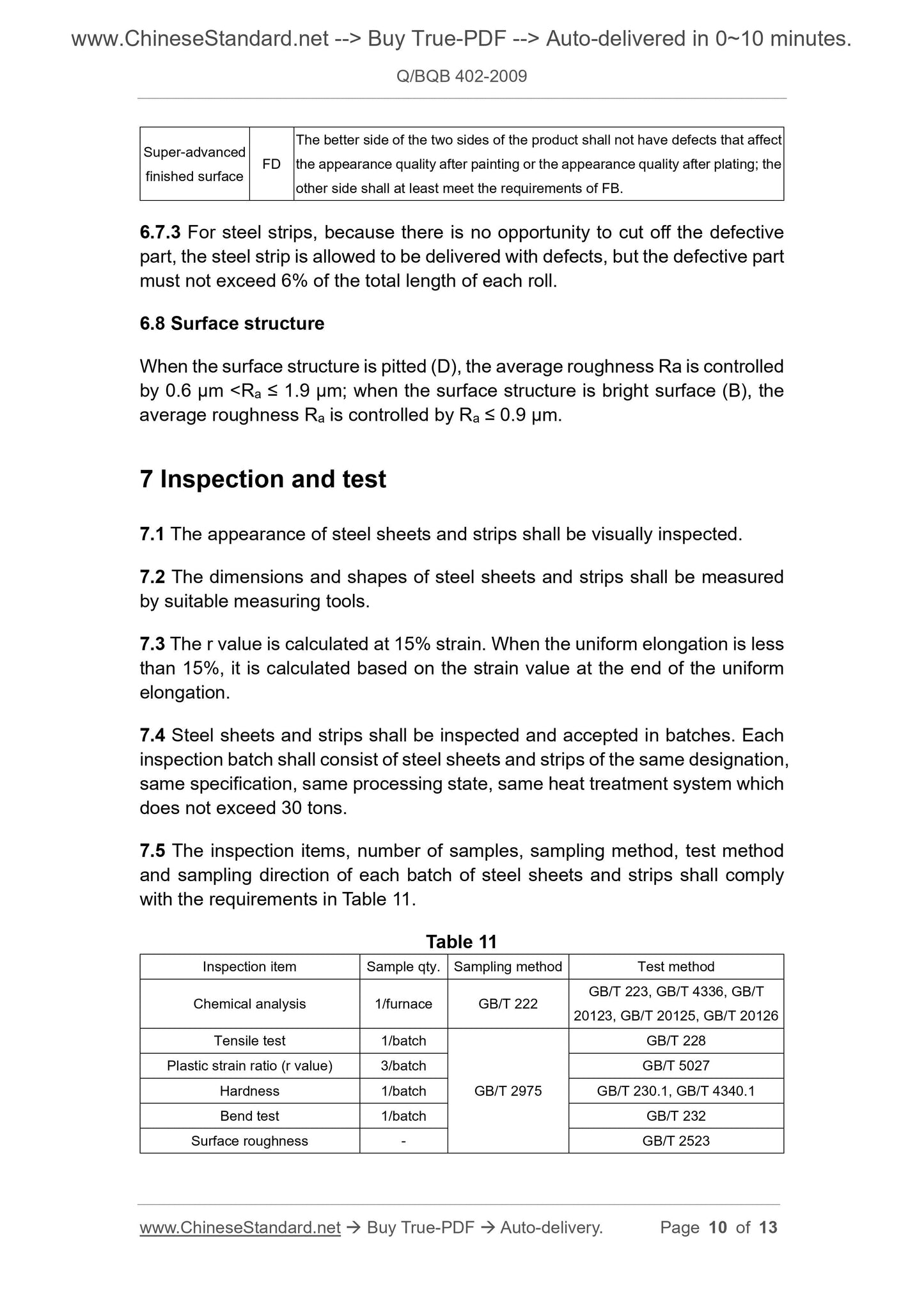

7.5 The inspection items, number of samples, sampling method, test method

and sampling direction of each batch of steel sheets and strips shall comply

with the requirements in Table 11.

Table 11

Inspection item Sample qty. Sampling method Test method

Chemical analysis 1/furnace GB/T 222 GB/T 223, GB/T 4336, GB/T 20123, GB/T 20125, GB/T 20126

Tensile test 1/batch

GB/T 2975

GB/T 228

Plastic strain ratio (r value) 3/batch GB/T 5027

Hardness 1/batch GB/T 230.1, GB/T 4340.1

Bend test 1/batch GB/T 232

Surface roughness - GB/T 2523

7.6 For the tensile, plastic strain ratio (r value), hardness, bend tests, if any test

results do not meet the standard requirements, it shall double the number of

samples from the same batch and re-test the unqualified item. If the retest

results (including all indicators required for the test of this item) are qualified,

the entire batch is qualified. Even though one indicator of the retest results

(including all indicators required for the test of the item) fails, the retest is

unqualified. If the retest is unqualified, the single piece that had been subjected

to the test and the test result is unqualified shall not be accepted, but single

piece in this batch of materials that does not subject to test may be submitted

again for test and acceptance.

8 Packaging, marking and inspection documents

The packaging, marking and inspection documents of steel sheets and strips

shall comply with Q/BQB 400. If the purchaser has special requirements for the

weight of the package, it shall be specified in the contract.

9 Numerical rounding rules

Numerical rounding rules shall comply with the provisions of GB/T 8170.

10 Approximate comparison of designation

The approximate comparison between the designations of this standard and

domestic and foreign standard is as shown in Appendix A.

Get QUOTATION in 1-minute: Click Q/BQB 402-2009

Historical versions: Q/BQB 402-2009

Preview True-PDF (Reload/Scroll if blank)

Q/BQB 402-2009: Cold-rolled carbon steel and steel strip

Q/BQB 402-2009

BQB

ENTERPRISE STANDARD OF

BAOSHAN IRON AND STEEL CO., LTD

Replacing Q/BQB 402-2003, BZJ 491-2004

Continuously-cold-rolled carbon steel sheets and

strips

Table of Contents

1 Scope ... 3

2 Normative references ... 3

3 Classification and code ... 4

4 Information required for ordering ... 5

5 Dimension, shape, weight and allowable deviation ... 6

6 Technical requirements ... 6

7 Inspection and test ... 10

8 Packaging, marking and inspection documents ... 11

9 Numerical rounding rules ... 11

10 Approximate comparison of designation ... 11

Appendix A (Informative) Approximate comparison between the designations of

this standard and domestic and foreign standard ... 12

Additional information: ... 12

Continuously-cold-rolled carbon steel sheets and

strips

1 Scope

This standard specifies the classification and code, size, shape, weight,

technical requirements, inspection and test, packaging, marking and inspection

documents of continuously-cold-rolled carbon steel sheets and strips.

This standard applies to the continuously-cold-rolled carbon steel sheets and

strips (hereinafter referred to as steel sheets and strips) which have a thickness

of 0.17 mm ~ 3.5 mm as produced by Baoshan Iron and Steel Co., Ltd.

2 Normative references

The provisions in following documents become the provisions of this Standard

through reference in this Standard. For the dated references, the subsequent

amendments (excluding corrections) or revisions do not apply to this Standard;

however, parties who reach an agreement based on this Standard are

encouraged to study if the latest versions of these documents are applicable.

For undated references, the latest edition of the referenced document applies.

GB/T 222-2006 Permissible tolerances for chemical composition of steel

products

GB/T 223 Methods for chemical analysis of steel and alloys

GB/T 228-2002 Metallic materials - Tensile testing at ambient temperature

GB/T 230.1-2004 Metallic Rockwell hardness test - Part 1: Test method

(scales A, B, C, D, E, F, G, H, K, N, T)

GB/T 232-1999 Metallic materials - Bend test

GB/T 2523-2008 Measuring method of surface roughness and peak count

for cold-rolled metal sheet (strip)

GB/T 2975-1998 Steel and steel products - Location and preparation of test

pieces for mechanical testing

GB/T 4336-2002 Standard test method for spark discharge atomic emission

spectrometric analysis of carbon and low-alloy steel (routine method)

The steel used for steel sheets and steel strips is smelted by the use of an

oxygen converter.

6.3 Delivery status

6.3.1 Steel sheets and steel strips are supplied by heat treatment after

continuously-cold-rolling. The type of heat treatment shall meet the

requirements in Table 4.

6.3.2 Steel sheets and steel strips are usually supplied after coating oil. The

applied oil film shall be able to be removed by alkaline aqueous solution. Under

normal packaging, transportation, loading and unloading, and storage

conditions, the supplier shall ensure that the surface of the steel sheet and strip

does not rust within 6 months from the date of completion of manufacture.

According to the requirements of the purchaser, through negotiation between

the supplier and the purchaser, as indicated in the contract, it may also be

supplied without oil.

6.4 Mechanical properties

6.4.1 The mechanical properties of annealed and flattened steel sheets and

strips shall meet the requirements of Table 6.

6.4.2 Due to the effects of aging, the mechanical properties of steel sheets and

strips will deteriorate with the increase of storage time, such as the increase in

yield strength and tensile strength, the decrease in elongation at breaking, the

deterioration of formability, the occurrence of tensile strain marks, etc., so it is

recommended for the users to use it as soon as possible

Super-advanced

finished surface FD

The better side of the two sides of the product shall not have defects that affect

the appearance quality after painting or the appearance quality after plating; the

other side shall at least meet the requirements of FB.

6.7.3 For steel strips, because there is no opportunity to cut off the defective

part, the steel strip is allowed to be delivered with defects, but the defective part

must not exceed 6% of the total length of each roll.

6.8 Surface structure

When the surface structure is pitted (D), the average roughness Ra is controlled

by 0.6 µm < Ra ≤ 1.9 µm; when the surface structure is bright surface (B), the

average roughness Ra is controlled by Ra ≤ 0.9 µm.

7 Inspection and test

7.1 The appearance of steel sheets and strips shall be visually inspected.

7.2 The dimensions and shapes of steel sheets and strips shall be measured

by suitable measuring tools.

7.3 The r value is calculated at 15% strain. When the uniform elongation is less

than 15%, it is calculated based on the strain value at the end of the uniform

elongation.

7.4 Steel sheets and strips shall be inspected and accepted in batches. Each

inspection batch shall consist of steel sheets and strips of the same designation,

same specification, same processing state, same heat treatment system which

does not exceed 30 tons.

7.5 The inspection items, number of samples, sampling method, test method

and sampling direction of each batch of steel sheets and strips shall comply

with the requirements in Table 11.

Table 11

Inspection item Sample qty. Sampling method Test method

Chemical analysis 1/furnace GB/T 222 GB/T 223, GB/T 4336, GB/T 20123, GB/T 20125, GB/T 20126

Tensile test 1/batch

GB/T 2975

GB/T 228

Plastic strain ratio (r value) 3/batch GB/T 5027

Hardness 1/batch GB/T 230.1, GB/T 4340.1

Bend test 1/batch GB/T 232

Surface roughness - GB/T 2523

7.6 For the tensile, plastic strain ratio (r value), hardness, bend tests, if any test

results do not meet the standard requirements, it shall double the number of

samples from the same batch and re-test the unqualified item. If the retest

results (including all indicators required for the test of this item) are qualified,

the entire batch is qualified. Even though one indicator of the retest results

(including all indicators required for the test of the item) fails, the retest is

unqualified. If the retest is unqualified, the single piece that had been subjected

to the test and the test result is unqualified shall not be accepted, but single

piece in this batch of materials that does not subject to test may be submitted

again for test and acceptance.

8 Packaging, marking and inspection documents

The packaging, marking and inspection documents of steel sheets and strips

shall comply with Q/BQB 400. If the purchaser has special requirements for the

weight of the package, it shall be specified in the contract.

9 Numerical rounding rules

Numerical rounding rules shall comply with the provisions of GB/T 8170.

10 Approximate comparison of designation

The approximate comparison between the designations of this standard and

domestic and foreign standard is as shown in Appendix A.

Share