1

/

su

4

PayPal, credit cards. Download editable-PDF & invoice In 1 second!

GB 10849-1989 English PDF (GB10849-1989)

GB 10849-1989 English PDF (GB10849-1989)

Prezzo di listino

$165.00 USD

Prezzo di listino

Prezzo scontato

$165.00 USD

Prezzo unitario

/

per

Spese di spedizione calcolate al check-out.

Impossibile caricare la disponibilità di ritiro

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB 10849-1989

Historical versions: GB 10849-1989

Preview True-PDF (Reload/Scroll if blank)

GB 10849-1989: Cast aluminium-silicon alloys--Modification

GB 10849-1989

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

Cast aluminum-silicon alloy modification

APPROVED ON: MARCH 31, 1989

IMPLEMENTED ON: JANUARY 01, 1990

Approved by: State Bureau of Technical Supervision

Table of Contents

1 Subject content and scope of application ... 3

2 Sodium modification of cast aluminum-silicon alloy ... 3

3 Phosphorus modification of cast aluminum-silicon eutectic alloy ... 6

Additional information: ... 8

Cast aluminum-silicon alloy modification

1 Subject content and scope of application

This standard specifies the classification principle and rating method for cast

aluminum-silicon alloy modification.

This standard applies to the evaluation of the metallographic structure of cast

aluminum-silicon alloys that have undergone sodium modification and

phosphorus modification.

2 Sodium modification of cast aluminum-silicon alloy

2.1 Cutting and preparation of specimen

2.1.1 Metallographic specimens are usually cut from a single cast tensile test

bar of the furnace. The metallographic specimens of important castings shall

be cut from the additional casting test bars of the castings or as specified in the

technical documents.

2.1.2 Metallographic specimens are mechanically polished after fine grinding

by the metallographic sandpaper, and manually fine-polished if necessary.

2.1.3 The polished metallographic specimen is etched by the use of a 0.5%

aqueous solution of hydrofluoric acid for 5 s ~ 10 s at room temperature.

2.1.4 During the process of cutting and preparing the metallographic specimen,

it shall be ensured that the structure is not changed.

2.2 Microscopic examination

2.2.1 Use an optical microscopy to evaluate the metallographic structure of the

sodium-modified cast aluminum-silicon alloy; the magnification is 200 times.

2.2.2 During microscopic examination, it shall first look at the entire surface to

be inspected and then evaluate it according to the figure of corresponding

grades of most fields of view.

2.2.3 The sodium modification of cast aluminum-silicon alloy is divided into no

modification, insufficient modification, normal modification, deterioration of

modification, mild over-modification, severe over-modification.

2.2.4 For the sodium modification of cast aluminum-silicon alloy, the grading of

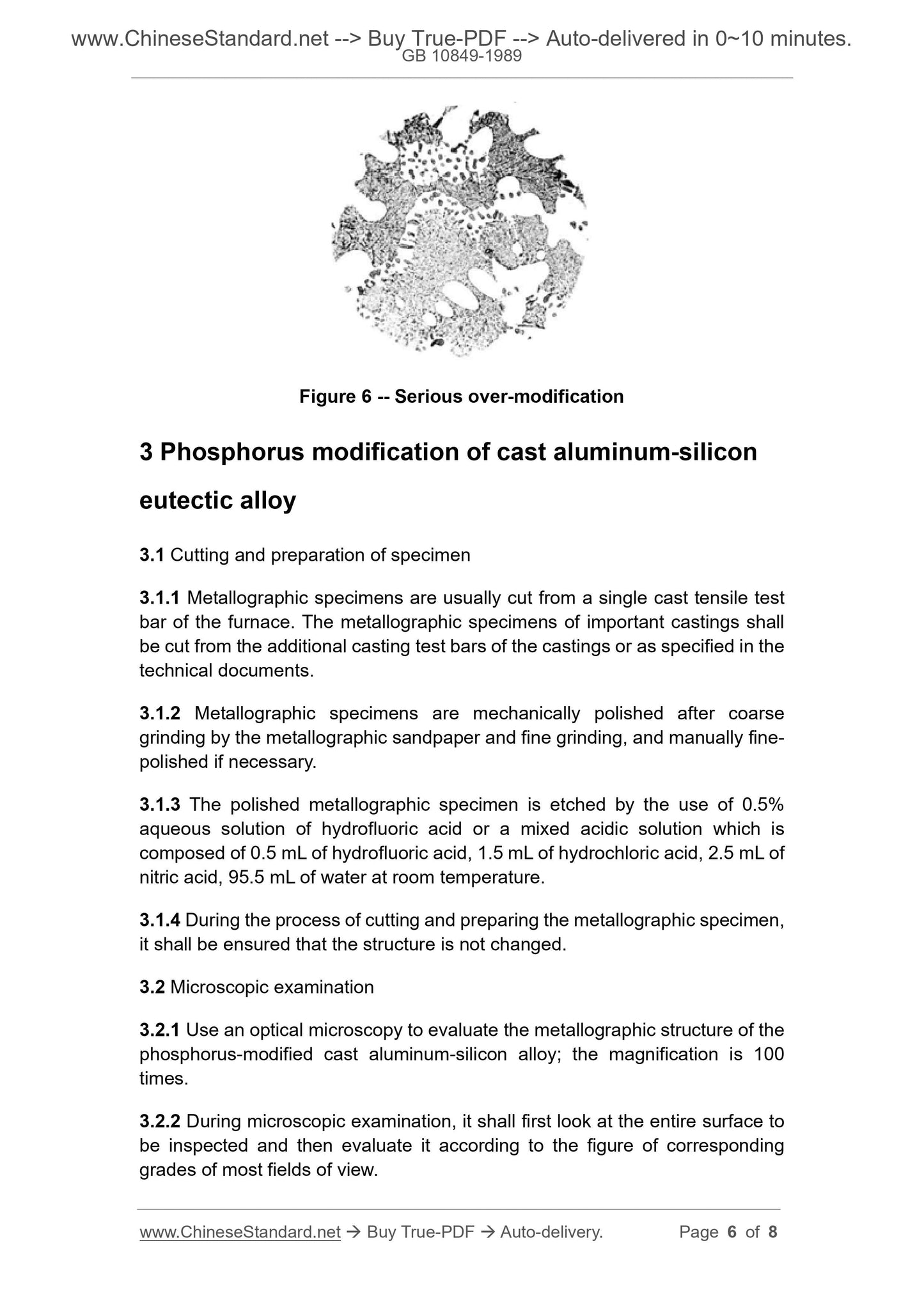

Figure 6 -- Serious over-modification

3 Phosphorus modification of cast aluminum-silicon

eutectic alloy

3.1 Cutting and preparation of specimen

3.1.1 Metallographic specimens are usually cut from a single cast tensile test

bar of the furnace. The metallographic specimens of important castings shall

be cut from the additional casting test bars of the castings or as specified in the

technical documents.

3.1.2 Metallographic specimens are mechanically polished after coarse

grinding by the metallographic sandpaper and fine grinding, and manually fine-

polished if necessary.

3.1.3 The polished metallographic specimen is etched by the use of 0.5%

aqueous solution of hydrofluoric acid or a mixed acidic solution which is

composed of 0.5 mL of hydrofluoric acid, 1.5 mL of hydrochloric acid, 2.5 mL of

nitric acid, 95.5 mL of water at room temperature.

3.1.4 During the process of cutting and preparing the metallographic specimen,

it shall be ensured that the structure is not changed.

3.2 Microscopic examination

3.2.1 Use an optical microscopy to evaluate the metallographic structure of the

phosphorus-modified cast aluminum-silicon alloy; the magnification is 100

times.

3.2.2 During microscopic examination, it shall first look at the entire surface to

be inspected and then evaluate it according to the figure of corresponding

grades of most fields of view.

Get QUOTATION in 1-minute: Click GB 10849-1989

Historical versions: GB 10849-1989

Preview True-PDF (Reload/Scroll if blank)

GB 10849-1989: Cast aluminium-silicon alloys--Modification

GB 10849-1989

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

Cast aluminum-silicon alloy modification

APPROVED ON: MARCH 31, 1989

IMPLEMENTED ON: JANUARY 01, 1990

Approved by: State Bureau of Technical Supervision

Table of Contents

1 Subject content and scope of application ... 3

2 Sodium modification of cast aluminum-silicon alloy ... 3

3 Phosphorus modification of cast aluminum-silicon eutectic alloy ... 6

Additional information: ... 8

Cast aluminum-silicon alloy modification

1 Subject content and scope of application

This standard specifies the classification principle and rating method for cast

aluminum-silicon alloy modification.

This standard applies to the evaluation of the metallographic structure of cast

aluminum-silicon alloys that have undergone sodium modification and

phosphorus modification.

2 Sodium modification of cast aluminum-silicon alloy

2.1 Cutting and preparation of specimen

2.1.1 Metallographic specimens are usually cut from a single cast tensile test

bar of the furnace. The metallographic specimens of important castings shall

be cut from the additional casting test bars of the castings or as specified in the

technical documents.

2.1.2 Metallographic specimens are mechanically polished after fine grinding

by the metallographic sandpaper, and manually fine-polished if necessary.

2.1.3 The polished metallographic specimen is etched by the use of a 0.5%

aqueous solution of hydrofluoric acid for 5 s ~ 10 s at room temperature.

2.1.4 During the process of cutting and preparing the metallographic specimen,

it shall be ensured that the structure is not changed.

2.2 Microscopic examination

2.2.1 Use an optical microscopy to evaluate the metallographic structure of the

sodium-modified cast aluminum-silicon alloy; the magnification is 200 times.

2.2.2 During microscopic examination, it shall first look at the entire surface to

be inspected and then evaluate it according to the figure of corresponding

grades of most fields of view.

2.2.3 The sodium modification of cast aluminum-silicon alloy is divided into no

modification, insufficient modification, normal modification, deterioration of

modification, mild over-modification, severe over-modification.

2.2.4 For the sodium modification of cast aluminum-silicon alloy, the grading of

Figure 6 -- Serious over-modification

3 Phosphorus modification of cast aluminum-silicon

eutectic alloy

3.1 Cutting and preparation of specimen

3.1.1 Metallographic specimens are usually cut from a single cast tensile test

bar of the furnace. The metallographic specimens of important castings shall

be cut from the additional casting test bars of the castings or as specified in the

technical documents.

3.1.2 Metallographic specimens are mechanically polished after coarse

grinding by the metallographic sandpaper and fine grinding, and manually fine-

polished if necessary.

3.1.3 The polished metallographic specimen is etched by the use of 0.5%

aqueous solution of hydrofluoric acid or a mixed acidic solution which is

composed of 0.5 mL of hydrofluoric acid, 1.5 mL of hydrochloric acid, 2.5 mL of

nitric acid, 95.5 mL of water at room temperature.

3.1.4 During the process of cutting and preparing the metallographic specimen,

it shall be ensured that the structure is not changed.

3.2 Microscopic examination

3.2.1 Use an optical microscopy to evaluate the metallographic structure of the

phosphorus-modified cast aluminum-silicon alloy; the magnification is 100

times.

3.2.2 During microscopic examination, it shall first look at the entire surface to

be inspected and then evaluate it according to the figure of corresponding

grades of most fields of view.

Share