1

/

su

12

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

GB/T 19494.1-2023 English PDF (GBT19494.1-2023)

GB/T 19494.1-2023 English PDF (GBT19494.1-2023)

Prezzo di listino

$440.00 USD

Prezzo di listino

Prezzo scontato

$440.00 USD

Prezzo unitario

/

per

Spese di spedizione calcolate al check-out.

Impossibile caricare la disponibilità di ritiro

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click GB/T 19494.1-2023

Historical versions: GB/T 19494.1-2023

Preview True-PDF (Reload/Scroll if blank)

GB/T 19494.1-2023: Mechanical sampling of coal -- Part 1: Method for sampling

GB/T 19494.1-2023

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 73.040

CCS D 21

Replacing GB/T 19494.1-2004

Mechanical Sampling of Coal - Part 1: Method for Sampling

(ISO 13909-1:2016, Hard coal and coke - Mechanical sampling - Part 1: General

introduction; ISO 13909-2:2016, Hard coal and coke - Mechanical sampling - Part 2:

Coal - Sampling from moving streams; ISO 13909-3:2016, Hard coal and coke -

Mechanical sampling - Part 3: Coal - Sampling from stationary lots, NEQ)

ISSUED ON: NOVEMBER 27, 2023

IMPLEMENTED ON: MARCH 1, 2024

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword ... 3

Introduction ... 4

1 Scope ... 5

2 Normative References ... 5

3 Terms and Definitions ... 5

4 General Requirements and Precision of Sampling ... 9

5 Establishment of Sampling Schemes ... 10

6 Moving Coal Flow Sampling Method ... 19

7 Stationary Coal Sampling Method ... 27

8 Packaging and Marking of Coal Sample ... 33

9 Sampling Report ... 34

Appendix A (informative) Examples of Calculation of the Number of Sampling Units

and the Number of Increments in Each Sampling Unit ... 35

Appendix B (normative) Evaluation of Mass-basis Sampling Equipment ... 37

Mechanical Sampling of Coal - Part 1: Method for Sampling

1 Scope

This document specifies the general requirements and precision of mechanized coal sampling,

the establishment of sampling schemes, the moving coal flow sampling method and stationary

coal sampling method, as well as packaging and marking of coal samples, and sampling reports.

This document is applicable to lignite, bituminous coal and anthracite coal.

2 Normative References

The contents of the following documents constitute indispensable clauses of this document

through the normative references in the text. In terms of references with a specified date, only

versions with a specified date are applicable to this document. In terms of references without a

specified date, the latest version (including all the modifications) is applicable to this document.

GB/T 3715 Terms Relating to Properties and Analysis of Coal

GB/T 19494.2 Mechanical Sampling of Coal - Part 2: Method for Sample Preparation

GB/T 19494.3 Mechanical Sampling of Coal - Part 3: Determination of Precision and Bias Test

3 Terms and Definitions

What is defined in GB/T 3715, and the following terms and definitions are applicable to this

document.

3.1 coal sample

A representative portion of coal taken for the purpose of determining certain properties.

3.2 test sample of coal

Sample prepared to satisfy specific test requirements.

NOTE: specimen for short.

3.3 common sample of coal

Coal sample taken for multiple tests.

3.4 moisture sample of coal

Coal sample specially taken for the determination of total moisture.

4 General Requirements and Precision of Sampling

4.1 General Requirements for Sampling

The purpose of coal sampling and sample preparation is to obtain a test sample of coal whose

test results can represent the entire lot of sampled coal.

The basic process of sampling and sample preparation is to first collect a considerable amount

of coal from many points distributed throughout the entire lot of coal, that is, primary

increments, then, directly merge (or merge after division) the various primary increments into

a gross sample, and finally, prepare the gross sample into the required number and type of test

samples of coal through a series of sample preparation procedures.

The basic requirement for sampling is that all particles of the sampled lot of coal can enter the

sampling equipment, and each particle has an equal probability of being collected into the coal

sample.

In all sampling, sample preparation and assay methods, errors always exist, and meanwhile, the

test results of any specified parameter obtained by such a method will also deviate from the true

value of this parameter. It is impossible to determine the absolute bias of a single result from

the “true value”, but only to estimate the precision of the test result. The degree of coincidence

between the results obtained from a series of determinations on the same coal is precision, and

the deviation of the average value of this series of determination results from an acceptable

reference value is bias (see GB/T 19494.3).

In order to ensure that the precision of the obtained test results of the specimens complies with

the requirements, the following factors shall be considered during sampling:

a) Variability of coal;

b) Number of gross samples taken from this lot of coal;

c) Number of increments for each gross sample;

d) Mass of specimen corresponding to the nominal maximum particle size.

It is of great importance to prevent bias in sampling, which may arise from:

a) Incorrect increment collection location or collection time;

b) Incorrect delimitation and / or collection of increments;

c) The collected coal sample loses its integrity.

In order to satisfy the basic requirements of sampling, the mechanized sampling method of

moving coal flow should be adopted; in places where conditions are unavailable, the

mechanized sampling method of stationary coal may also be adopted. However, no matter

variability of the sampled coal has increased, the sampling precision shall also be verified.

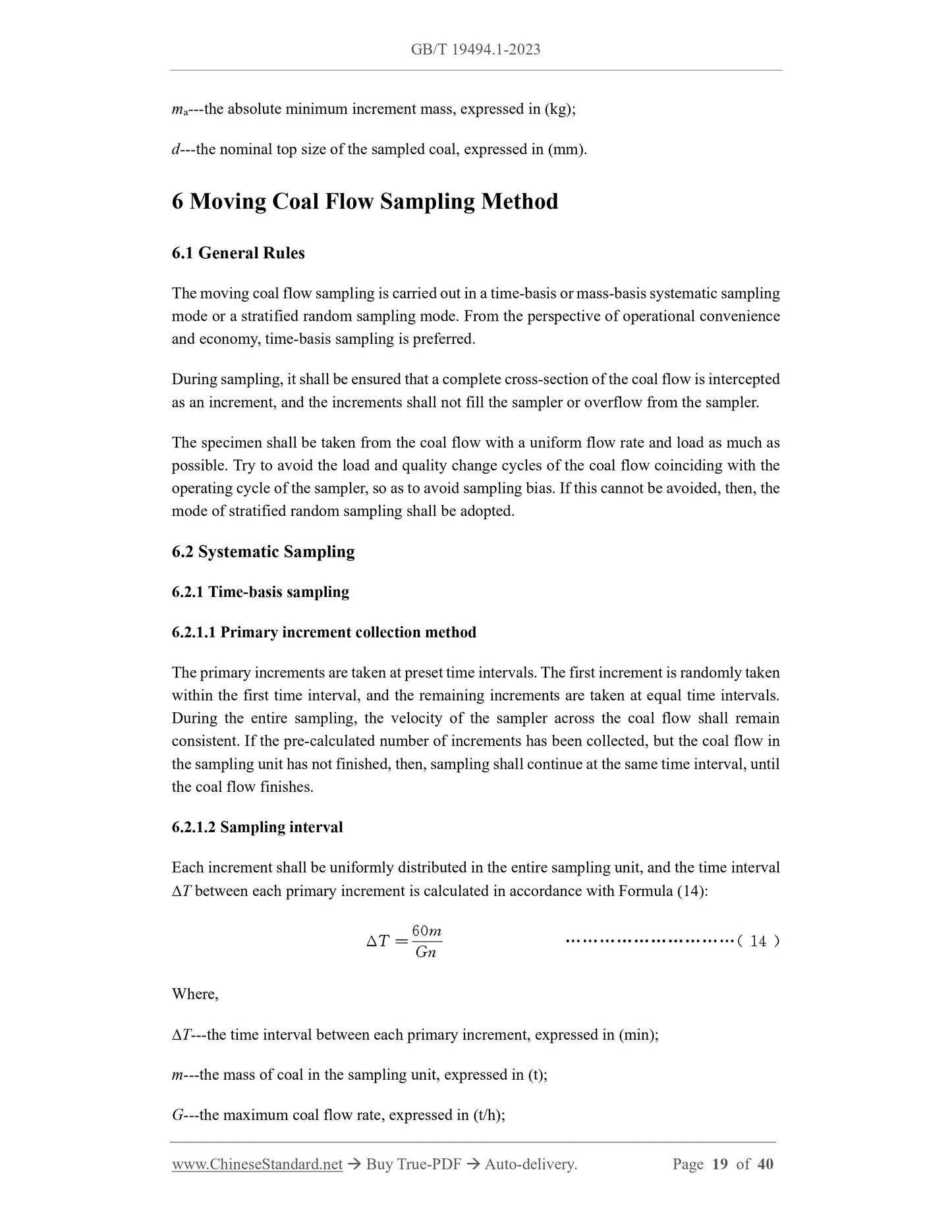

5.2.3 Determination of coal variability

5.2.3.1 Determination of variance of primary increments

The variance of primary increments depends on the variety of coal, the nominal top size, the

degree of processing and mixing, the absolute value of the parameter to be measured and the

mass of increments.

The variance of primary increments VI is obtained through one of the following methods:

a) Directly determine in accordance with one of the methods specified in GB/T 19494.3;

b) Determine based on the variance of increments determined for similar coals in similar

sampling systems;

c) In the absence of increment variance data, it can be assumed that VI = 20, then, verify

in accordance with one of the methods specified in GB/T 19494.3 after sampling.

5.2.3.2 Sample preparation and assay variance

The variance of sample preparation and assay VPT is obtained through one of the following

methods:

a) Directly determine in accordance with one of the methods specified in GB/T 19494.3;

b) Determine based on values measured for similar coal using similar sample preparation

procedures;

c) In the absence of sample preparation and assay variance data, it can be assumed that

VPT = 0.2, then, verify in accordance with one of the methods specified in GB/T

19494.3 after sample preparation and assay.

5.2.4 Number of sampling units and number of increments

5.2.4.1 Overview

Theoretically speaking, the number of increments taken from a lot of coal to obtain a specific

sampling precision is a function of the quality variability of that lot of coal, which has nothing

to do with the size of that lot of coal. However, in practice, due to the serial correlation of coal,

it is related to the quantity of coal. A lot of coal can be used as a whole sampling unit, or it can

be divided into several sampling units, and a gross sample is taken from each sampling unit.

For the following purposes, a lot of coal should be divided into several sampling units:

a) Improve the sampling precision to achieve the required value;

b) Maintain the integrity of the specimen, that is, avoid bias after the specimen is <...

Get QUOTATION in 1-minute: Click GB/T 19494.1-2023

Historical versions: GB/T 19494.1-2023

Preview True-PDF (Reload/Scroll if blank)

GB/T 19494.1-2023: Mechanical sampling of coal -- Part 1: Method for sampling

GB/T 19494.1-2023

GB

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 73.040

CCS D 21

Replacing GB/T 19494.1-2004

Mechanical Sampling of Coal - Part 1: Method for Sampling

(ISO 13909-1:2016, Hard coal and coke - Mechanical sampling - Part 1: General

introduction; ISO 13909-2:2016, Hard coal and coke - Mechanical sampling - Part 2:

Coal - Sampling from moving streams; ISO 13909-3:2016, Hard coal and coke -

Mechanical sampling - Part 3: Coal - Sampling from stationary lots, NEQ)

ISSUED ON: NOVEMBER 27, 2023

IMPLEMENTED ON: MARCH 1, 2024

Issued by: State Administration for Market Regulation;

Standardization Administration of the People’s Republic of China.

Table of Contents

Foreword ... 3

Introduction ... 4

1 Scope ... 5

2 Normative References ... 5

3 Terms and Definitions ... 5

4 General Requirements and Precision of Sampling ... 9

5 Establishment of Sampling Schemes ... 10

6 Moving Coal Flow Sampling Method ... 19

7 Stationary Coal Sampling Method ... 27

8 Packaging and Marking of Coal Sample ... 33

9 Sampling Report ... 34

Appendix A (informative) Examples of Calculation of the Number of Sampling Units

and the Number of Increments in Each Sampling Unit ... 35

Appendix B (normative) Evaluation of Mass-basis Sampling Equipment ... 37

Mechanical Sampling of Coal - Part 1: Method for Sampling

1 Scope

This document specifies the general requirements and precision of mechanized coal sampling,

the establishment of sampling schemes, the moving coal flow sampling method and stationary

coal sampling method, as well as packaging and marking of coal samples, and sampling reports.

This document is applicable to lignite, bituminous coal and anthracite coal.

2 Normative References

The contents of the following documents constitute indispensable clauses of this document

through the normative references in the text. In terms of references with a specified date, only

versions with a specified date are applicable to this document. In terms of references without a

specified date, the latest version (including all the modifications) is applicable to this document.

GB/T 3715 Terms Relating to Properties and Analysis of Coal

GB/T 19494.2 Mechanical Sampling of Coal - Part 2: Method for Sample Preparation

GB/T 19494.3 Mechanical Sampling of Coal - Part 3: Determination of Precision and Bias Test

3 Terms and Definitions

What is defined in GB/T 3715, and the following terms and definitions are applicable to this

document.

3.1 coal sample

A representative portion of coal taken for the purpose of determining certain properties.

3.2 test sample of coal

Sample prepared to satisfy specific test requirements.

NOTE: specimen for short.

3.3 common sample of coal

Coal sample taken for multiple tests.

3.4 moisture sample of coal

Coal sample specially taken for the determination of total moisture.

4 General Requirements and Precision of Sampling

4.1 General Requirements for Sampling

The purpose of coal sampling and sample preparation is to obtain a test sample of coal whose

test results can represent the entire lot of sampled coal.

The basic process of sampling and sample preparation is to first collect a considerable amount

of coal from many points distributed throughout the entire lot of coal, that is, primary

increments, then, directly merge (or merge after division) the various primary increments into

a gross sample, and finally, prepare the gross sample into the required number and type of test

samples of coal through a series of sample preparation procedures.

The basic requirement for sampling is that all particles of the sampled lot of coal can enter the

sampling equipment, and each particle has an equal probability of being collected into the coal

sample.

In all sampling, sample preparation and assay methods, errors always exist, and meanwhile, the

test results of any specified parameter obtained by such a method will also deviate from the true

value of this parameter. It is impossible to determine the absolute bias of a single result from

the “true value”, but only to estimate the precision of the test result. The degree of coincidence

between the results obtained from a series of determinations on the same coal is precision, and

the deviation of the average value of this series of determination results from an acceptable

reference value is bias (see GB/T 19494.3).

In order to ensure that the precision of the obtained test results of the specimens complies with

the requirements, the following factors shall be considered during sampling:

a) Variability of coal;

b) Number of gross samples taken from this lot of coal;

c) Number of increments for each gross sample;

d) Mass of specimen corresponding to the nominal maximum particle size.

It is of great importance to prevent bias in sampling, which may arise from:

a) Incorrect increment collection location or collection time;

b) Incorrect delimitation and / or collection of increments;

c) The collected coal sample loses its integrity.

In order to satisfy the basic requirements of sampling, the mechanized sampling method of

moving coal flow should be adopted; in places where conditions are unavailable, the

mechanized sampling method of stationary coal may also be adopted. However, no matter

variability of the sampled coal has increased, the sampling precision shall also be verified.

5.2.3 Determination of coal variability

5.2.3.1 Determination of variance of primary increments

The variance of primary increments depends on the variety of coal, the nominal top size, the

degree of processing and mixing, the absolute value of the parameter to be measured and the

mass of increments.

The variance of primary increments VI is obtained through one of the following methods:

a) Directly determine in accordance with one of the methods specified in GB/T 19494.3;

b) Determine based on the variance of increments determined for similar coals in similar

sampling systems;

c) In the absence of increment variance data, it can be assumed that VI = 20, then, verify

in accordance with one of the methods specified in GB/T 19494.3 after sampling.

5.2.3.2 Sample preparation and assay variance

The variance of sample preparation and assay VPT is obtained through one of the following

methods:

a) Directly determine in accordance with one of the methods specified in GB/T 19494.3;

b) Determine based on values measured for similar coal using similar sample preparation

procedures;

c) In the absence of sample preparation and assay variance data, it can be assumed that

VPT = 0.2, then, verify in accordance with one of the methods specified in GB/T

19494.3 after sample preparation and assay.

5.2.4 Number of sampling units and number of increments

5.2.4.1 Overview

Theoretically speaking, the number of increments taken from a lot of coal to obtain a specific

sampling precision is a function of the quality variability of that lot of coal, which has nothing

to do with the size of that lot of coal. However, in practice, due to the serial correlation of coal,

it is related to the quantity of coal. A lot of coal can be used as a whole sampling unit, or it can

be divided into several sampling units, and a gross sample is taken from each sampling unit.

For the following purposes, a lot of coal should be divided into several sampling units:

a) Improve the sampling precision to achieve the required value;

b) Maintain the integrity of the specimen, that is, avoid bias after the specimen is <...

Share