1

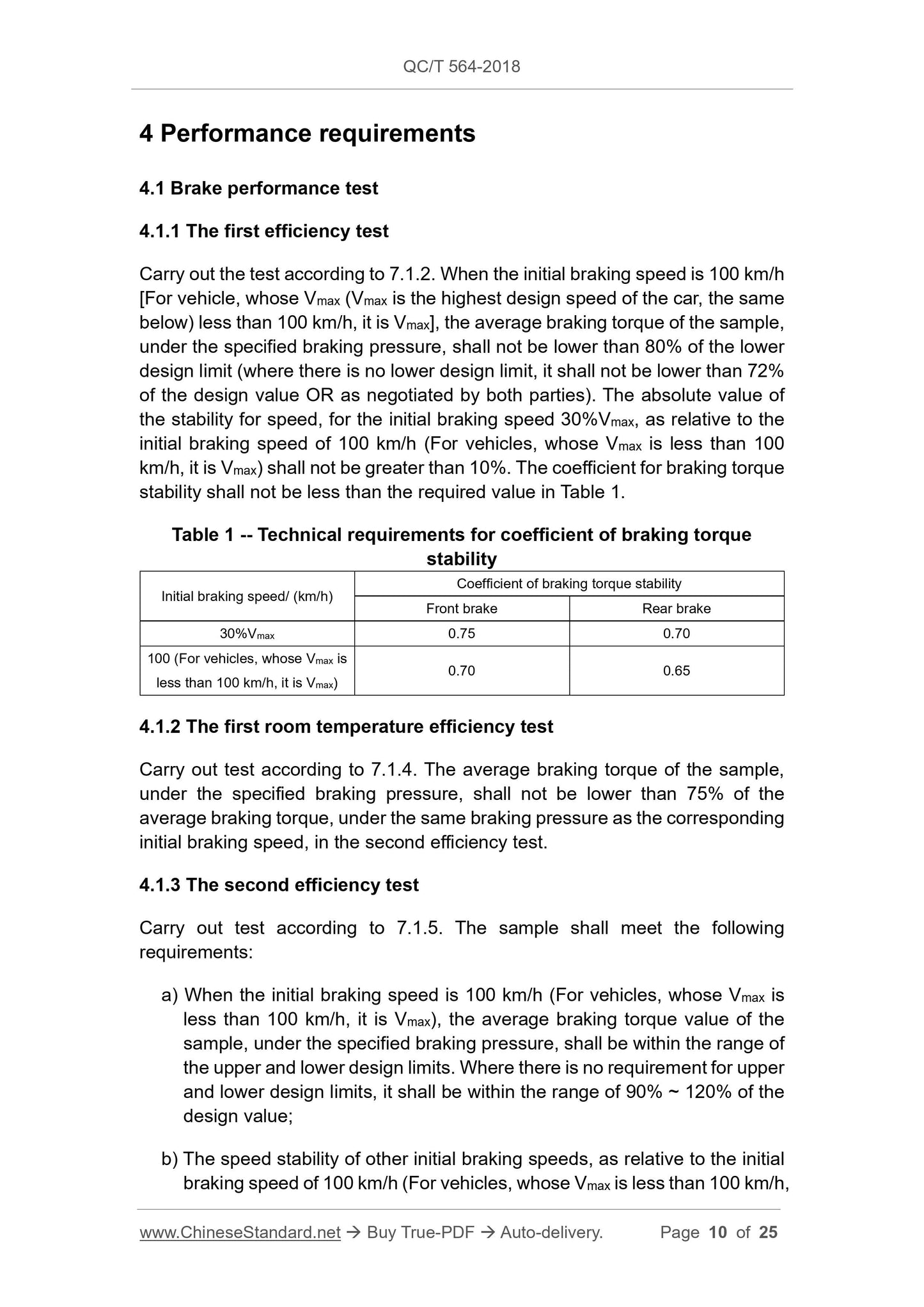

/

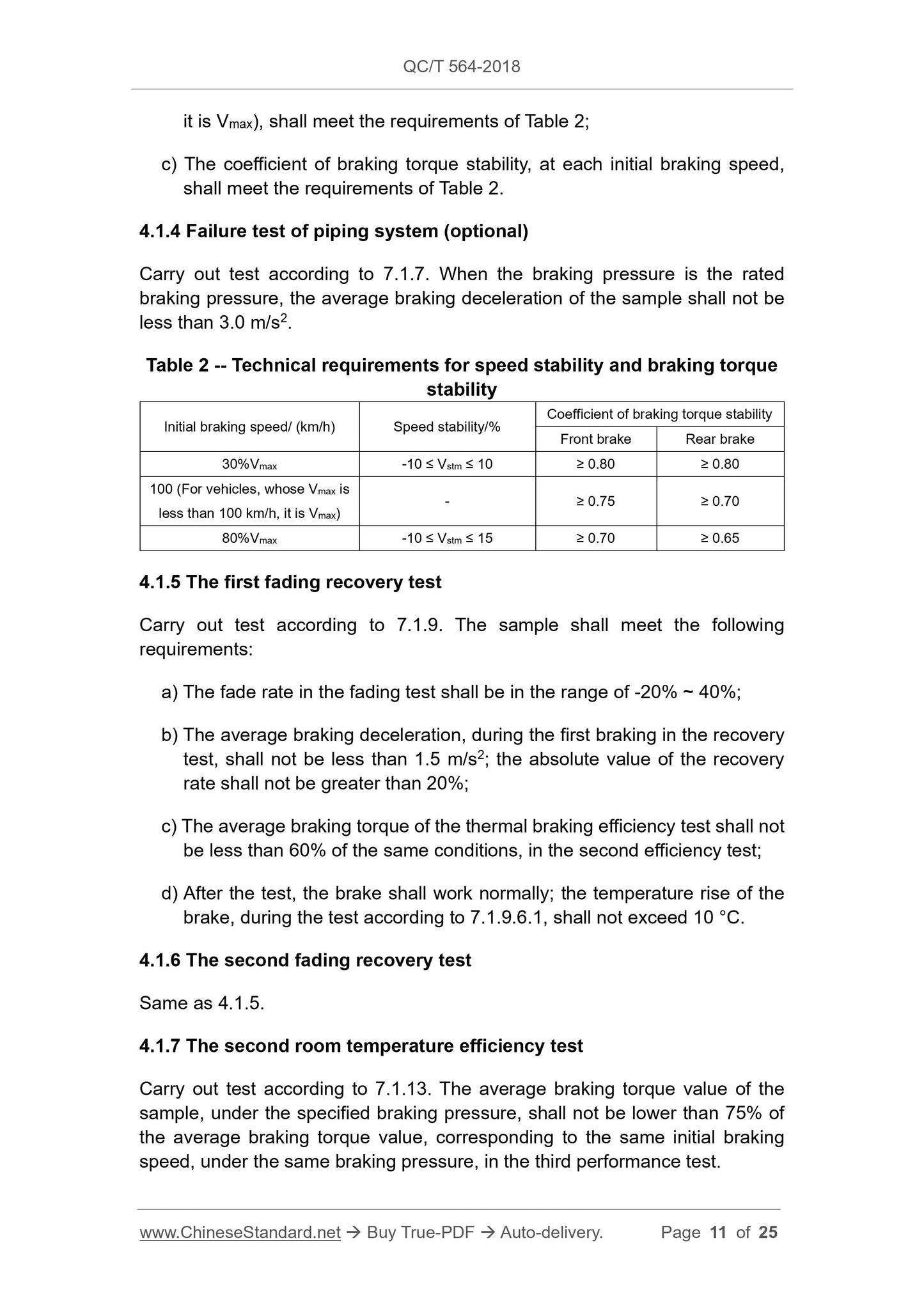

su

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

QC/T 564-2018 English PDF (QCT564-2018)

QC/T 564-2018 English PDF (QCT564-2018)

Prezzo di listino

$285.00 USD

Prezzo di listino

Prezzo scontato

$285.00 USD

Prezzo unitario

/

per

Spese di spedizione calcolate al check-out.

Impossibile caricare la disponibilità di ritiro

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click QC/T 564-2018

Historical versions: QC/T 564-2018

Preview True-PDF (Reload/Scroll if blank)

QC/T 564-2018: Performance requirements and test methods for passenger car service brake

QC/T 564-2018

QC

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.040.40

T 24

Replacing QC/T 564-2008

Performance requirements and test methods for

passenger car service brake

ISSUED ON: JULY 04, 2018

IMPLEMENTED ON: JANUARY 01, 2019

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Performance requirements ... 10

5 Test-related requirements ... 13

6 Test preparation ... 14

7 Test method ... 16

Appendix A (Normative) Braking torque value method ... 24

Performance requirements and test methods for

passenger car service brake

1 Scope

1.1 This standard specifies the terms and definitions, performance

requirements, test-related requirements, test preparations, test methods for

passenger car service brake assemblies.

1.2 This standard is applicable to the service brake assembly and friction lining

(lining block) assembly, for the category M1 passenger car, which is specified in

GB/T 15089.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) is applicable to this standard.

GB/T 5620 Road vehicles - Braking of automotive vehicles and their trailers

- Vocabulary

GB/T 15089 Classification of power-driven vehicles and trailers

QC/T 556 Automobile brake - Temperature measurement and thermocouple

mounting

3 Terms and definitions

The terms and definitions as defined in GB/T 5620, as well as the following

terms and definitions, apply to this standard.

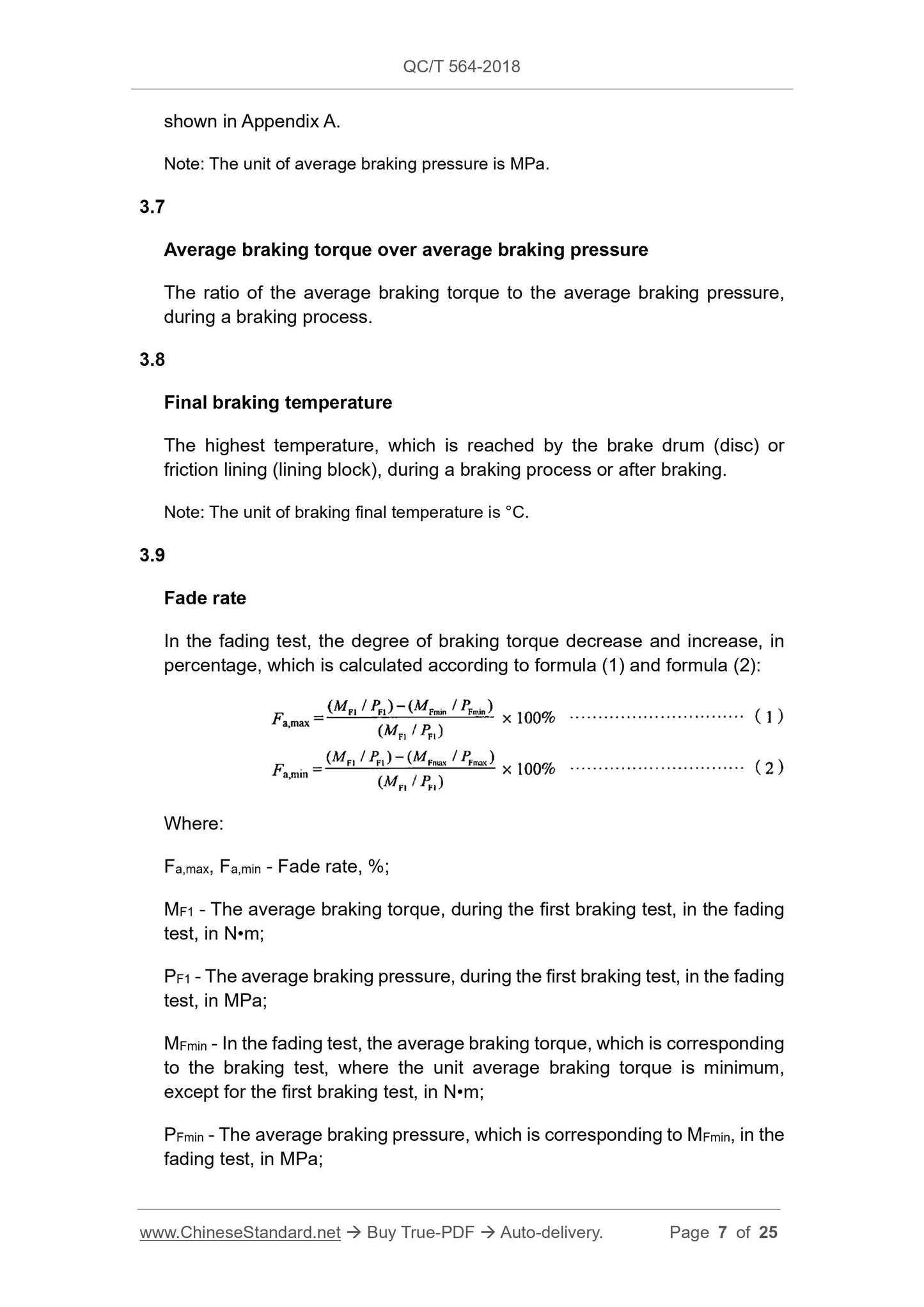

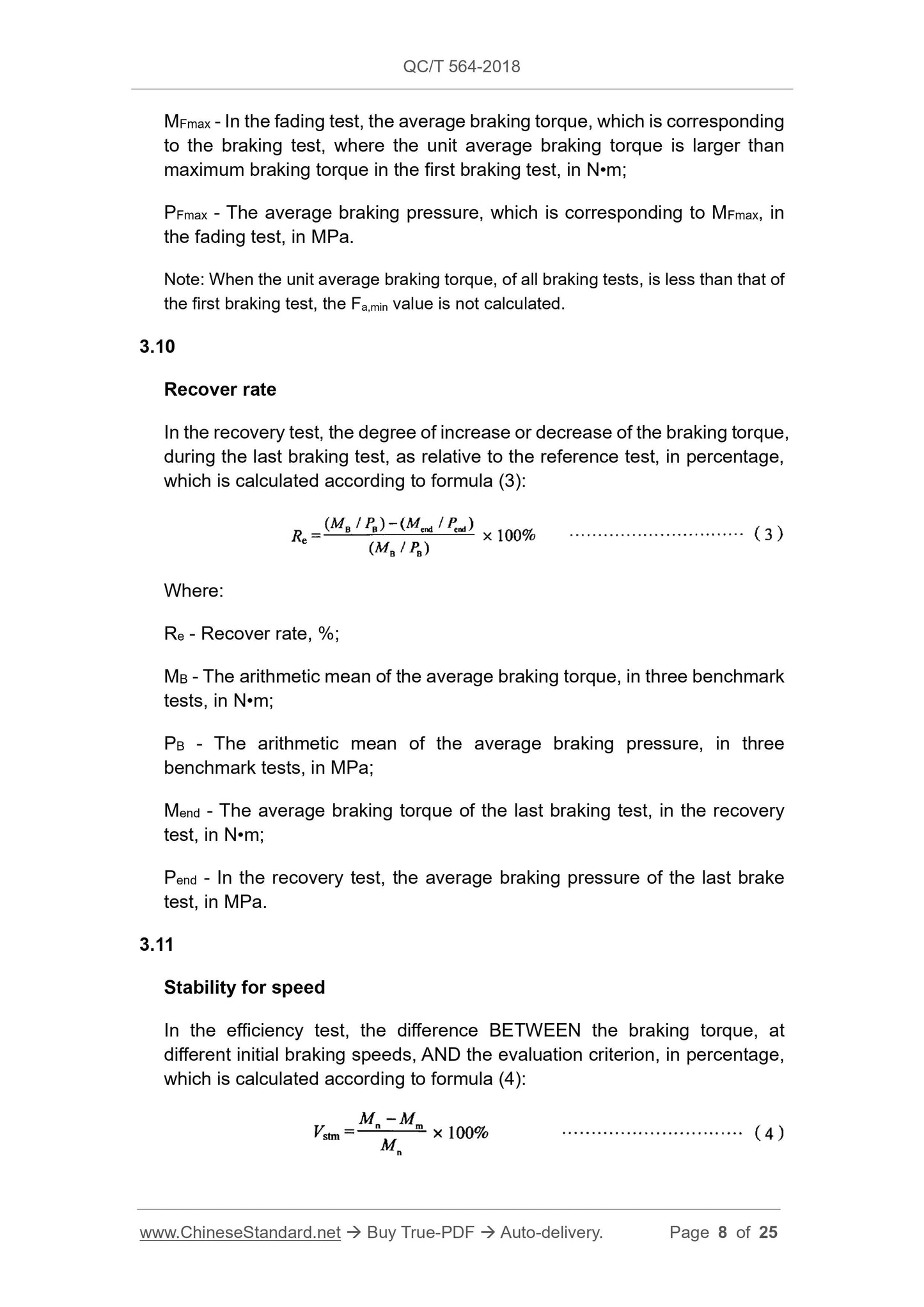

3.1

Braking period

In the continuous braking process, the elapsed time, from the beginning of

this braking to the beginning of the next braking.

Note: The unit of braking period is s.

4.1.8 The third efficiency test

Same as 4.1.3.

4.1.9 Braking noise

During the test process of 7.1, the braking noise value of the sample shall be

less than 76dB (A).

4.1.10 Sample requirements after test

After completing the test of 7.1, the brake shall work normally AND meet the

following requirements:

a) There shall be no scratches on the working surface of the brake drum or

brake disc;

b) There shall be no deformation on the brake base plate (brake caliper), that

affects the braking performance;

c) The surface of the friction lining (lining block) shall be intact; there shall be

no defects such as peeling off, scorching, etc.; but slight cracks are

allowed;

d) There shall be no separation of friction lining (lining block) from brake shoe

(back plate);

e) The brake wheel cylinder (brake caliper) shall have no leakage.

4.2 Abrasion test of brake

4.2.1 Abrasion requirements

4.2.1.1 The abrasion of brake friction linings (lining block) and brake drums

(disks) shall be negotiated between the supplier and the buyer.

4.2.1.2 After all abrasion tests are completed, the friction lining (lining block)

and the brake drum (disc) shall meet the following requirements:

a) There shall be no obvious scratches on the working surface of the brake

drum or brake disc;

b) The surface of the friction lining (lining block) shall be complete; there shall

be no obvious defects, such as missing edges, bumps, pits, peeling off,

cracks;

c) There shall be no separation of the friction lining (lining block) from the

brake shoe (back plate);

d) The surface of the friction lining (lining block) shall not have cracks, which

penetrate through the entire friction surface.

4.2.2 Inspection of braking performance

Compared with before the abrasion test, the change of average braking torque,

under the specified braking pressure, shall not exceed ±15%.

5 Test-related requirements

5.1 Test equipment

5.1.1 The test equipment is an inertial brake test bench (both single and double

wheels are acceptable). Its performance indicators shall meet the test

requirements of this standard.

5.1.2 The brake line pressure supply system of the test equipment shall meet

the requirements of various brake working conditions, for the brake line

pressure, AND be stable. The rate of pressure rise and fall of the brake line

shall be controlled within the range of (25 ± 5) MPa/s.

5.1.3 The brake cooling device of the test equipment shall make the wind speed

at the brake under test reach 11 m/s, AND cover the entire brake assembly.

5.1.4 The control error of brake pipeline pressure, braking torque, test bench's

spindle speed shall not exceed ±3%. The relative error of the rotation moment

of inertia (including the inertia of the rotating part of the test bench) shall not

exceed ±5%.

5.1.5 The test equipment shall be able to continuously record the following

parameters. The measurement error shall meet the following requirements:

a) The braking output torque is ±1.0%;

b) The braking pressure is ±1.0%;

c) The spindle speed of the test bench is ±1.0%;

d) The braking time is ±0.01 s;

e) The temperature of the brake drum (disc) and brake lining (lining block) is

±3 °C, when the temperature is not higher than 300 °C; it is ±1.0%, when

the temperature is higher than 300 °C.

5.1.6 The device and thermocouple, which are used for measuring the

temperature of the brake drum (disc) and friction lining (lining block), shall

comply with the relevant requirements in QC/T 556.

5.1.7 The accuracy grade of the instrument or meter, which indicates each

parameter, shall not be lower than grade 2.5.

5.2 Other requirements

5.2.1 All test vehicle speeds shall be rounded off to an integral multiple of 5.

5.2.2 Except for the fading test AND unless otherwise specified, during the test,

the cooling wind speed is 11 m/s; the temperature of the cooling air is room

temperature.

5.2.3 Unless otherwise specified, the vehicle speed, at the end of all braking

tests, shall be less than 5 km/h

5.2.4 When measuring braking noise, the pickup head of the sound level meter

shall be placed in the rotating plane of the brake to be tested, 500 mm right

above the axis of rotation of the brake; the pickup head shall be equipped with

a wind protection ball.

5.2.5 For all tests, which are carried out according to the brake deceleration

control, it shall use the formula (12) to convert the brake deceleration into the

braking torque control value of the test bench.

5.2.6 The radial runout of the brake drum, after installation (measured at the

middle of the width direction of the friction surface of the brake drum), shall not

be greater than 0.2 mm. The axial runout of the friction surface of the brake disc,

after installation (measured at the effective radius of the brake disc), shall not

be greater than 0.15 mm.

6 Test preparation

6.1 Thermocouple installation

Install the thermocouple, according to the relevant requirements in QC/T 556.

6.2 Determination of the spindle speed of test bench

The spindle speed of the test bench is determined according to formula (6):

Where:

n - Spindle speed of the test bench, r/min;

V - Test vehicle speed, km /h;

7.1.2.3 Take no less than 5 points for the test, within the specified braking

pressure range. The interval between the test points shall be as equal as

possible. The maximum increase in braking pressure shall not be higher tha...

Get QUOTATION in 1-minute: Click QC/T 564-2018

Historical versions: QC/T 564-2018

Preview True-PDF (Reload/Scroll if blank)

QC/T 564-2018: Performance requirements and test methods for passenger car service brake

QC/T 564-2018

QC

AUTOMOBILE INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 43.040.40

T 24

Replacing QC/T 564-2008

Performance requirements and test methods for

passenger car service brake

ISSUED ON: JULY 04, 2018

IMPLEMENTED ON: JANUARY 01, 2019

Issued by: Ministry of Industry and Information Technology of PRC

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 5

4 Performance requirements ... 10

5 Test-related requirements ... 13

6 Test preparation ... 14

7 Test method ... 16

Appendix A (Normative) Braking torque value method ... 24

Performance requirements and test methods for

passenger car service brake

1 Scope

1.1 This standard specifies the terms and definitions, performance

requirements, test-related requirements, test preparations, test methods for

passenger car service brake assemblies.

1.2 This standard is applicable to the service brake assembly and friction lining

(lining block) assembly, for the category M1 passenger car, which is specified in

GB/T 15089.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) is applicable to this standard.

GB/T 5620 Road vehicles - Braking of automotive vehicles and their trailers

- Vocabulary

GB/T 15089 Classification of power-driven vehicles and trailers

QC/T 556 Automobile brake - Temperature measurement and thermocouple

mounting

3 Terms and definitions

The terms and definitions as defined in GB/T 5620, as well as the following

terms and definitions, apply to this standard.

3.1

Braking period

In the continuous braking process, the elapsed time, from the beginning of

this braking to the beginning of the next braking.

Note: The unit of braking period is s.

4.1.8 The third efficiency test

Same as 4.1.3.

4.1.9 Braking noise

During the test process of 7.1, the braking noise value of the sample shall be

less than 76dB (A).

4.1.10 Sample requirements after test

After completing the test of 7.1, the brake shall work normally AND meet the

following requirements:

a) There shall be no scratches on the working surface of the brake drum or

brake disc;

b) There shall be no deformation on the brake base plate (brake caliper), that

affects the braking performance;

c) The surface of the friction lining (lining block) shall be intact; there shall be

no defects such as peeling off, scorching, etc.; but slight cracks are

allowed;

d) There shall be no separation of friction lining (lining block) from brake shoe

(back plate);

e) The brake wheel cylinder (brake caliper) shall have no leakage.

4.2 Abrasion test of brake

4.2.1 Abrasion requirements

4.2.1.1 The abrasion of brake friction linings (lining block) and brake drums

(disks) shall be negotiated between the supplier and the buyer.

4.2.1.2 After all abrasion tests are completed, the friction lining (lining block)

and the brake drum (disc) shall meet the following requirements:

a) There shall be no obvious scratches on the working surface of the brake

drum or brake disc;

b) The surface of the friction lining (lining block) shall be complete; there shall

be no obvious defects, such as missing edges, bumps, pits, peeling off,

cracks;

c) There shall be no separation of the friction lining (lining block) from the

brake shoe (back plate);

d) The surface of the friction lining (lining block) shall not have cracks, which

penetrate through the entire friction surface.

4.2.2 Inspection of braking performance

Compared with before the abrasion test, the change of average braking torque,

under the specified braking pressure, shall not exceed ±15%.

5 Test-related requirements

5.1 Test equipment

5.1.1 The test equipment is an inertial brake test bench (both single and double

wheels are acceptable). Its performance indicators shall meet the test

requirements of this standard.

5.1.2 The brake line pressure supply system of the test equipment shall meet

the requirements of various brake working conditions, for the brake line

pressure, AND be stable. The rate of pressure rise and fall of the brake line

shall be controlled within the range of (25 ± 5) MPa/s.

5.1.3 The brake cooling device of the test equipment shall make the wind speed

at the brake under test reach 11 m/s, AND cover the entire brake assembly.

5.1.4 The control error of brake pipeline pressure, braking torque, test bench's

spindle speed shall not exceed ±3%. The relative error of the rotation moment

of inertia (including the inertia of the rotating part of the test bench) shall not

exceed ±5%.

5.1.5 The test equipment shall be able to continuously record the following

parameters. The measurement error shall meet the following requirements:

a) The braking output torque is ±1.0%;

b) The braking pressure is ±1.0%;

c) The spindle speed of the test bench is ±1.0%;

d) The braking time is ±0.01 s;

e) The temperature of the brake drum (disc) and brake lining (lining block) is

±3 °C, when the temperature is not higher than 300 °C; it is ±1.0%, when

the temperature is higher than 300 °C.

5.1.6 The device and thermocouple, which are used for measuring the

temperature of the brake drum (disc) and friction lining (lining block), shall

comply with the relevant requirements in QC/T 556.

5.1.7 The accuracy grade of the instrument or meter, which indicates each

parameter, shall not be lower than grade 2.5.

5.2 Other requirements

5.2.1 All test vehicle speeds shall be rounded off to an integral multiple of 5.

5.2.2 Except for the fading test AND unless otherwise specified, during the test,

the cooling wind speed is 11 m/s; the temperature of the cooling air is room

temperature.

5.2.3 Unless otherwise specified, the vehicle speed, at the end of all braking

tests, shall be less than 5 km/h

5.2.4 When measuring braking noise, the pickup head of the sound level meter

shall be placed in the rotating plane of the brake to be tested, 500 mm right

above the axis of rotation of the brake; the pickup head shall be equipped with

a wind protection ball.

5.2.5 For all tests, which are carried out according to the brake deceleration

control, it shall use the formula (12) to convert the brake deceleration into the

braking torque control value of the test bench.

5.2.6 The radial runout of the brake drum, after installation (measured at the

middle of the width direction of the friction surface of the brake drum), shall not

be greater than 0.2 mm. The axial runout of the friction surface of the brake disc,

after installation (measured at the effective radius of the brake disc), shall not

be greater than 0.15 mm.

6 Test preparation

6.1 Thermocouple installation

Install the thermocouple, according to the relevant requirements in QC/T 556.

6.2 Determination of the spindle speed of test bench

The spindle speed of the test bench is determined according to formula (6):

Where:

n - Spindle speed of the test bench, r/min;

V - Test vehicle speed, km /h;

7.1.2.3 Take no less than 5 points for the test, within the specified braking

pressure range. The interval between the test points shall be as equal as

possible. The maximum increase in braking pressure shall not be higher tha...

Share