1

/

su

12

PayPal, credit cards. Download editable-PDF & invoice in 1 second!

YY/T 0328-2015 English PDF (YYT0328-2015)

YY/T 0328-2015 English PDF (YYT0328-2015)

Prezzo di listino

$150.00 USD

Prezzo di listino

Prezzo scontato

$150.00 USD

Prezzo unitario

/

per

Spese di spedizione calcolate al check-out.

Impossibile caricare la disponibilità di ritiro

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click YY/T 0328-2015

Historical versions: YY/T 0328-2015

Preview True-PDF (Reload/Scroll if blank)

YY/T 0328-2015: A.V.fistula needle sets for single use

YY/T 0328-2015

YY

PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.040.20

C 31

Replacing YY/T 0328-2002

A.V. fistula needle sets for single use

ISSUED ON. MARCH 02, 2015

IMPLEMENTED ON. JANUARY 01, 2016

Issued by. China Food and Drug Administration

Table of Contents

Foreword . 3

Introduction .. 5

1 Scope .. 6

2 Normative references . 6

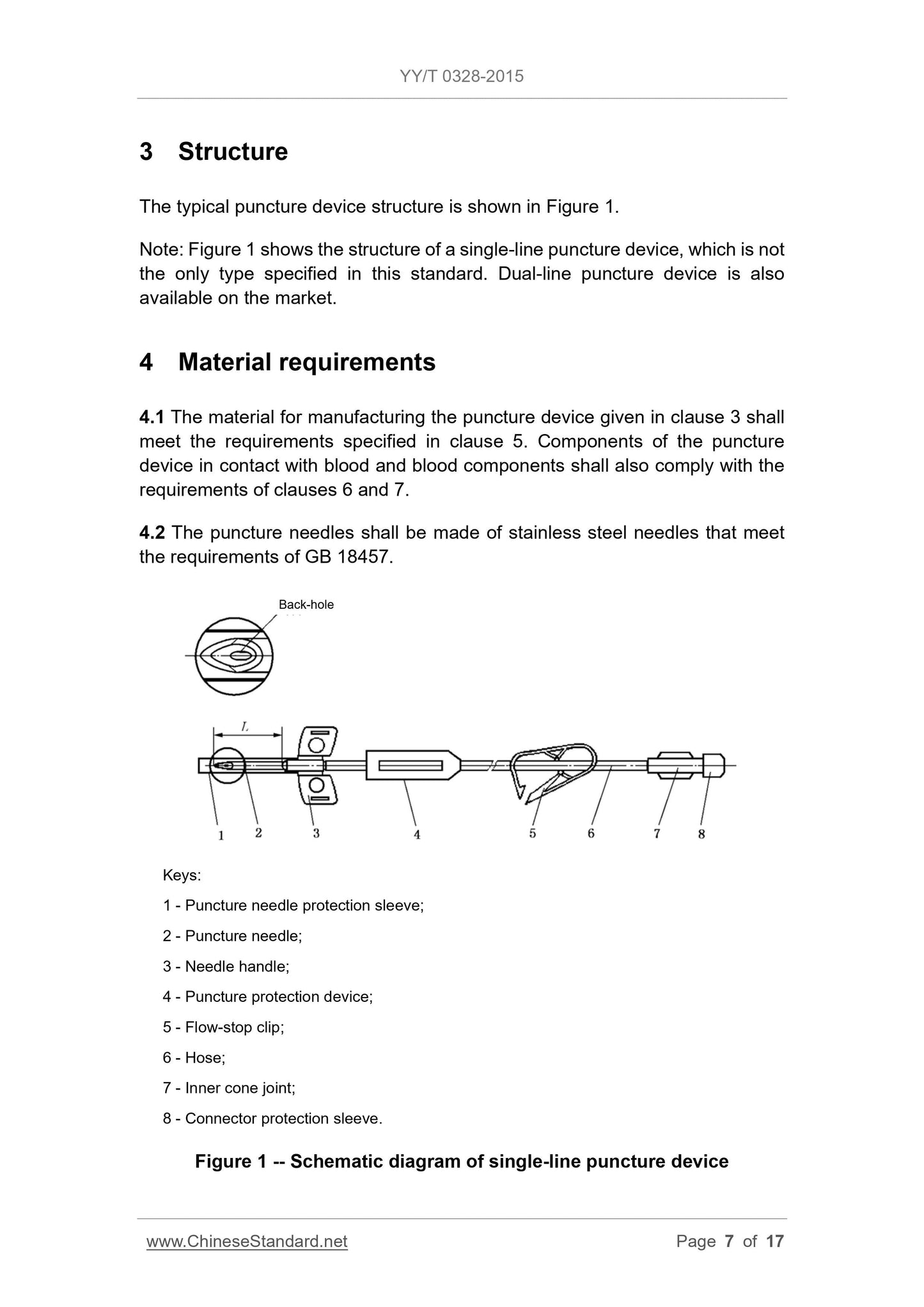

3 Structure . 7

4 Material requirements . 7

5 Physical requirements . 8

6 Chemical requirements . 11

7 Biological requirements . 12

8 Type test. 13

9 Markings . 13

10 Packaging . 15

Appendix A (Normative) Particle contamination test . 16

References . 17

Foreword

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

Please note that some of the contents of this document may involve patents.

The publication institute of this document does not assume responsibility for

identifying these patents.

This standard replaces YY/T 0328-2002 “Single use blood-taking set for blood

processing equipment”. As compared with YY/T 0328-2002, the main technical

changes of this standard are as follows.

- MODIFY the Chinese and English names of this standard;

- ADD a description of the two-way type;

- CANCEL the description of the product mark;

- MODIFY the requirements for particulate pollution;

- MODIFY the sealing requirements;

- MODIFY the flow rate requirements;

- MODIFY the requirements for puncture needles;

- MODIFY the appearance of the needle handle;

- MODIFY the recommended requirements of needle handle color scales;

- ADD the recommended requirements for stop-flow clip color scales;

- ADD recommended requirements for protection against needle puncture;

- MODIFY the requirements of the pH and test methods;

- MODIFY the requirements for total amount of evaporation residues;

- ADD the requirements that the non-single set package shall be marked of

the quantity and recommended maximum positive and negative pressure.

This standard shall be under the jurisdiction of the National Standardization

Technical Committee for Medical Infusion Devices (SAC/TC 106).

Main drafting organizations of this standard. Shandong Provincial Medical

Device Product Quality Inspection Center.

A.V. fistula needle sets for single use

1 Scope

This standard specifies the requirements for the A.V. fistula needle sets for

single use (hereinafter referred to as puncture devices), to ensure that they are

compatible with the blood flow and blood processing systems that they support.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this standard.

GB/T 1962.2 Conical fittings with a 6% (Luer) taper for syringes, needles and

certain other medical equipment - Part 2. Lock fittings

GB/T 14233.1-2008 Test methods for infusion transfusion injection

equipment for medical use - Part 1. Chemical analysis methods

GB/T 14233.2 Test methods for infusion, transfusion, injection equipment for

medical use - Part 2. Biological test methods

GB/T 16886.1 Biological evaluation of medical devices - Part 1. Evaluation

and testing within a risk management process

GB 18457 Stainless steel needle tubing for the manufacture of medical

devices

GB 18671-2009 Intravenous needles for single use

YY/T 0466.1 Medical devices - Symbols to be used with medical device

labels, labelling and information to be supplied - Part 1. General

requirements

ISO 11607-1.2006 Packaging for terminally sterilized medical devices - Part

1. Requirements for materials, sterile barrier systems and packaging

systems 1)

1 The Chinese standard GB/T 19633.1 equivalent to ISO 11607-1.2006 is currently in the approval stage.

GB 18671-2009 gives the evaluation method of needle tip puncture

performance.

5.6.3 Lubricants

If the needle is coated with a lubricant and observed with the normal or

corrected vision, there shall be no visible accumulation of lubricant on the

outside surface of the needle.

Note. The suitable lubricant is undiluted polydimethylsiloxane in accordance

with national pharmacopoeia. The amount of lubricant per square centimeter of

the surface of the needle shall not exceed 0.25 mg.

5.6.4 Needle handle

5.6.4.1 Appearance

The appearance shall meet the following requirements.

a) The edge of the needle handle shall be complete without burrs;

b) In the appropriate position of the needle handle, it shall have the nominal

outer diameter marking of the needle, the marking shall be clear.

Note. There shall be embossed buckles on the needle edge to facilitate the

fingers to control the angle of the puncture needle.

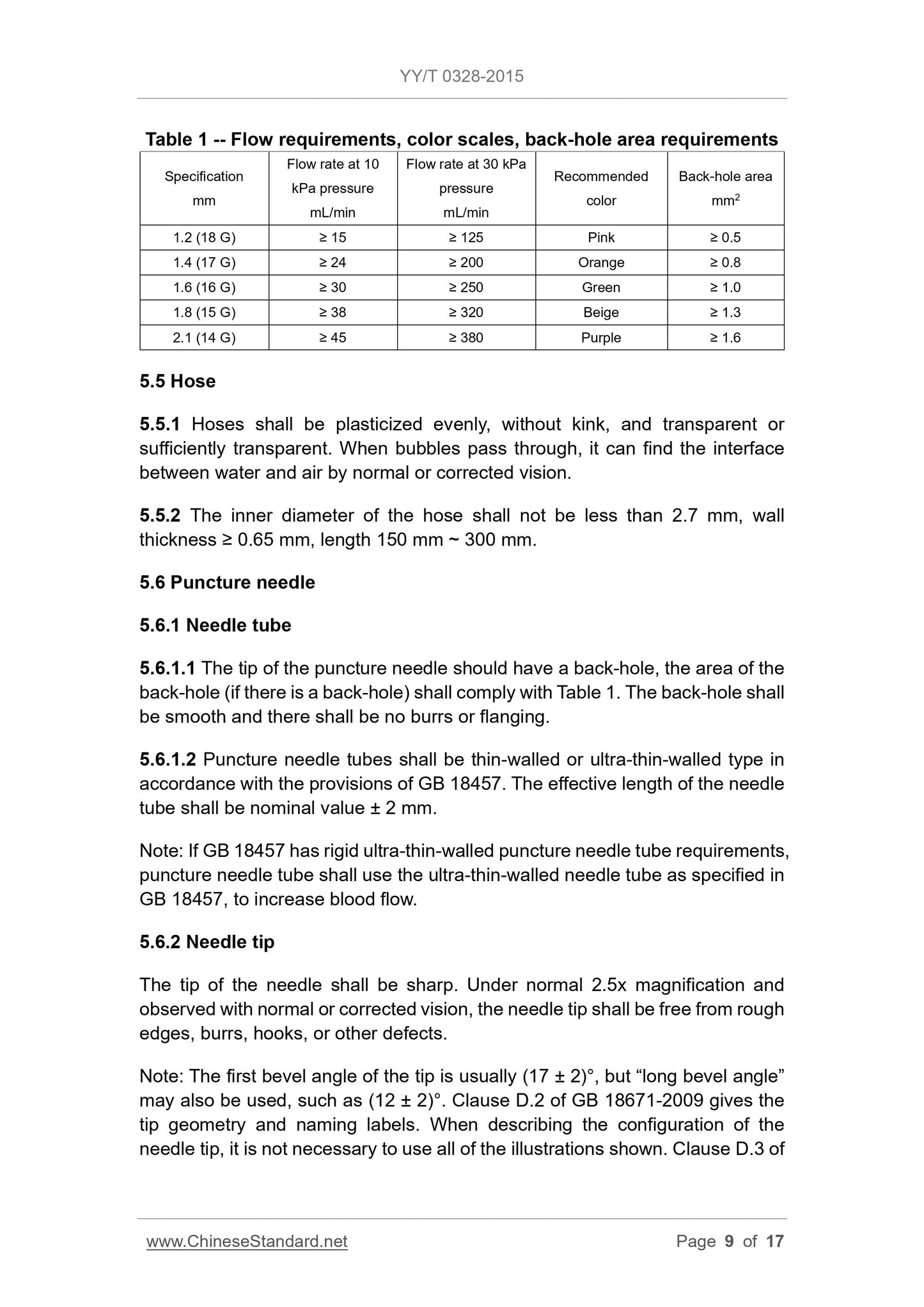

5.6.4.2 Color scales

The needle handle color should be used to indicate the outer diameter of the

puncture needle. It is recommended to use the color specified in Table 1.

5.6.4.3 Needle handle direction

The needle handle shall be in the same direction as the needle bevel (as shown

in Figure 1).

Note. Movable needles that can rotate axially around the needle handle are not

subject to this requirement, but additional indications of the direction of the

bevel of the needle tip must be provided on the needle handle.

5.7 Flow-stop clip

5.7.1 The flow-stop clip on the puncture device should be a locking pin. The

flow-stop clip shall be able to effectively open and close the hose. When closed,

it shall be able to block the gas that is 50 kPa above atmospheric pressure for

1 min without leakage.

chromium, copper, lead, and tin in the puncture test solution shall not exceed 1

μg/mL. The content of cadmium shall not exceed 0.1 μg/mL.

6.3.2 When tested in accordance with the method of 5.6.1 of GB/T 14233.1-

2008, the color of the puncture device test solution shall not exceed the

standard control solution which has a mass concentration ρ(Pb2+) = 1 μg/mL.

6.4 pH

When tested in accordance with the method of 5.4.2 of GB/T 14233.1-2008,

any standard solution required for graying the indicator shall not exceed 1 mL.

6.5 Evaporation residue

When tested in accordance with them method of 5.5 in GB/T 14233.1-2008, the

total amount of evaporation residues shall not exceed 5 mg.

6.6 UV absorbance

When tested in accordance with the method of 5.7 in GB/T 14233.1-2008, the

absorbance of the puncture test solution in the range of 250 nm ~ 320 nm shall

not exceed 0.1.

6.7 Ethylene oxide residues

When tested in accordance with the methods of clause 9 or clause 10 of GB/T

14233.1-2008, the residual ethylene oxide of each puncture device shall not

exceed 0.5 mg.

7 Biological requirements

7.1 Biocompatibility

The puncture device shall be evaluated biologically in accordance with the

requirements of GB/T 16886.1.

7.2 Asepsis

The puncture device shall undergo a confirmed sterilization process to make

the product sterile.

Note 1. Refer to the reference for suitable sterilization methods.

Note 2. GB/T 14233.2 specifies a sterile test method, but this method should

not be used for exit-factory inspection.

expressed in kPa.

Note. The graphic symbols given in YY/T 0466.1 may be used to satisfy the

above requirements.

9.2 Middle packaging

The middle packaging shall have at least the following clearly identified

informati...

Get QUOTATION in 1-minute: Click YY/T 0328-2015

Historical versions: YY/T 0328-2015

Preview True-PDF (Reload/Scroll if blank)

YY/T 0328-2015: A.V.fistula needle sets for single use

YY/T 0328-2015

YY

PHARMACEUTICAL INDUSTRY STANDARD

OF THE PEOPLE’S REPUBLIC OF CHINA

ICS 11.040.20

C 31

Replacing YY/T 0328-2002

A.V. fistula needle sets for single use

ISSUED ON. MARCH 02, 2015

IMPLEMENTED ON. JANUARY 01, 2016

Issued by. China Food and Drug Administration

Table of Contents

Foreword . 3

Introduction .. 5

1 Scope .. 6

2 Normative references . 6

3 Structure . 7

4 Material requirements . 7

5 Physical requirements . 8

6 Chemical requirements . 11

7 Biological requirements . 12

8 Type test. 13

9 Markings . 13

10 Packaging . 15

Appendix A (Normative) Particle contamination test . 16

References . 17

Foreword

This standard was drafted in accordance with the rules given in GB/T 1.1-2009.

Please note that some of the contents of this document may involve patents.

The publication institute of this document does not assume responsibility for

identifying these patents.

This standard replaces YY/T 0328-2002 “Single use blood-taking set for blood

processing equipment”. As compared with YY/T 0328-2002, the main technical

changes of this standard are as follows.

- MODIFY the Chinese and English names of this standard;

- ADD a description of the two-way type;

- CANCEL the description of the product mark;

- MODIFY the requirements for particulate pollution;

- MODIFY the sealing requirements;

- MODIFY the flow rate requirements;

- MODIFY the requirements for puncture needles;

- MODIFY the appearance of the needle handle;

- MODIFY the recommended requirements of needle handle color scales;

- ADD the recommended requirements for stop-flow clip color scales;

- ADD recommended requirements for protection against needle puncture;

- MODIFY the requirements of the pH and test methods;

- MODIFY the requirements for total amount of evaporation residues;

- ADD the requirements that the non-single set package shall be marked of

the quantity and recommended maximum positive and negative pressure.

This standard shall be under the jurisdiction of the National Standardization

Technical Committee for Medical Infusion Devices (SAC/TC 106).

Main drafting organizations of this standard. Shandong Provincial Medical

Device Product Quality Inspection Center.

A.V. fistula needle sets for single use

1 Scope

This standard specifies the requirements for the A.V. fistula needle sets for

single use (hereinafter referred to as puncture devices), to ensure that they are

compatible with the blood flow and blood processing systems that they support.

2 Normative references

The following documents are essential to the application of this document. For

the dated documents, only the versions with the dates indicated are applicable

to this document; for the undated documents, only the latest version (including

all the amendments) are applicable to this standard.

GB/T 1962.2 Conical fittings with a 6% (Luer) taper for syringes, needles and

certain other medical equipment - Part 2. Lock fittings

GB/T 14233.1-2008 Test methods for infusion transfusion injection

equipment for medical use - Part 1. Chemical analysis methods

GB/T 14233.2 Test methods for infusion, transfusion, injection equipment for

medical use - Part 2. Biological test methods

GB/T 16886.1 Biological evaluation of medical devices - Part 1. Evaluation

and testing within a risk management process

GB 18457 Stainless steel needle tubing for the manufacture of medical

devices

GB 18671-2009 Intravenous needles for single use

YY/T 0466.1 Medical devices - Symbols to be used with medical device

labels, labelling and information to be supplied - Part 1. General

requirements

ISO 11607-1.2006 Packaging for terminally sterilized medical devices - Part

1. Requirements for materials, sterile barrier systems and packaging

systems 1)

1 The Chinese standard GB/T 19633.1 equivalent to ISO 11607-1.2006 is currently in the approval stage.

GB 18671-2009 gives the evaluation method of needle tip puncture

performance.

5.6.3 Lubricants

If the needle is coated with a lubricant and observed with the normal or

corrected vision, there shall be no visible accumulation of lubricant on the

outside surface of the needle.

Note. The suitable lubricant is undiluted polydimethylsiloxane in accordance

with national pharmacopoeia. The amount of lubricant per square centimeter of

the surface of the needle shall not exceed 0.25 mg.

5.6.4 Needle handle

5.6.4.1 Appearance

The appearance shall meet the following requirements.

a) The edge of the needle handle shall be complete without burrs;

b) In the appropriate position of the needle handle, it shall have the nominal

outer diameter marking of the needle, the marking shall be clear.

Note. There shall be embossed buckles on the needle edge to facilitate the

fingers to control the angle of the puncture needle.

5.6.4.2 Color scales

The needle handle color should be used to indicate the outer diameter of the

puncture needle. It is recommended to use the color specified in Table 1.

5.6.4.3 Needle handle direction

The needle handle shall be in the same direction as the needle bevel (as shown

in Figure 1).

Note. Movable needles that can rotate axially around the needle handle are not

subject to this requirement, but additional indications of the direction of the

bevel of the needle tip must be provided on the needle handle.

5.7 Flow-stop clip

5.7.1 The flow-stop clip on the puncture device should be a locking pin. The

flow-stop clip shall be able to effectively open and close the hose. When closed,

it shall be able to block the gas that is 50 kPa above atmospheric pressure for

1 min without leakage.

chromium, copper, lead, and tin in the puncture test solution shall not exceed 1

μg/mL. The content of cadmium shall not exceed 0.1 μg/mL.

6.3.2 When tested in accordance with the method of 5.6.1 of GB/T 14233.1-

2008, the color of the puncture device test solution shall not exceed the

standard control solution which has a mass concentration ρ(Pb2+) = 1 μg/mL.

6.4 pH

When tested in accordance with the method of 5.4.2 of GB/T 14233.1-2008,

any standard solution required for graying the indicator shall not exceed 1 mL.

6.5 Evaporation residue

When tested in accordance with them method of 5.5 in GB/T 14233.1-2008, the

total amount of evaporation residues shall not exceed 5 mg.

6.6 UV absorbance

When tested in accordance with the method of 5.7 in GB/T 14233.1-2008, the

absorbance of the puncture test solution in the range of 250 nm ~ 320 nm shall

not exceed 0.1.

6.7 Ethylene oxide residues

When tested in accordance with the methods of clause 9 or clause 10 of GB/T

14233.1-2008, the residual ethylene oxide of each puncture device shall not

exceed 0.5 mg.

7 Biological requirements

7.1 Biocompatibility

The puncture device shall be evaluated biologically in accordance with the

requirements of GB/T 16886.1.

7.2 Asepsis

The puncture device shall undergo a confirmed sterilization process to make

the product sterile.

Note 1. Refer to the reference for suitable sterilization methods.

Note 2. GB/T 14233.2 specifies a sterile test method, but this method should

not be used for exit-factory inspection.

expressed in kPa.

Note. The graphic symbols given in YY/T 0466.1 may be used to satisfy the

above requirements.

9.2 Middle packaging

The middle packaging shall have at least the following clearly identified

informati...

Share