1

/

su

10

PayPal, credit cards. Download editable-PDF and invoice in 1 second!

YY/T 0346-2022 English PDF (YYT0346-2022)

YY/T 0346-2022 English PDF (YYT0346-2022)

Prezzo di listino

$245.00 USD

Prezzo di listino

Prezzo scontato

$245.00 USD

Prezzo unitario

/

per

Spese di spedizione calcolate al check-out.

Impossibile caricare la disponibilità di ritiro

Delivery: 3 seconds. Download true-PDF + Invoice.

Get QUOTATION in 1-minute: Click YY/T 0346-2022

Historical versions: YY/T 0346-2022

Preview True-PDF (Reload/Scroll if blank)

YY/T 0346-2022: Implants for osteosynthesis - Metallic fixation screw for femur neck

YY/T 0346-2022

YY

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 11.040.40

CCS C 35

Replace YY/T 0346-2002

Implants for osteosynthesis - Metallic fixation screw for

femur neck

ISSUED ON: MAY 18, 2022

IMPLEMENTED ON: JUNE 1, 2023

Issued by: National Medical Products Administration

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Requirements ... 6

5 Test methods ... 9

6 Manufacturing ... 11

7 Sterilization ... 11

8 Packaging ... 11

9 Information provided by the manufacturer ... 11

Appendix A (Informative) List of approved method standards for chemical analysis,

metallographic examination ... 13

Appendix B (Normative) Explanation of the determination method of maximum torque

and breaking angle ... 14

Appendix C (Normative) Measuring method of the axial insert strength of a femur neck

screw ... 15

Appendix D (Normative) Test methods of static compression bending performance and

fatigue compression bending performance of femur neck screws ... 18

References ... 22

Implants for osteosynthesis - Metallic fixation screw for

femur neck

1 Scope

This document specifies the terms and definitions, requirements, test methods,

manufacturing, sterilization, packaging, and information provided by the manufacturer

of metallic fixation screws for the femur neck (hereinafter referred to as femur neck

screws).

This document applies to femoral neck screws, which are used for the internal fixation

of femur neck fractures during orthopedic surgery.

2 Normative references

The following documents contain the provisions which, through normative reference in

this document, constitute the essential provisions of this document. For the dated

referenced documents, only the versions with the indicated dates are applicable to this

document; for the undated referenced documents, only the latest version (including all

the amendments) is applicable to this document.

GB 4234.1 Implants for surgery - Metallic materials - Part 1: Wrought stainless steel

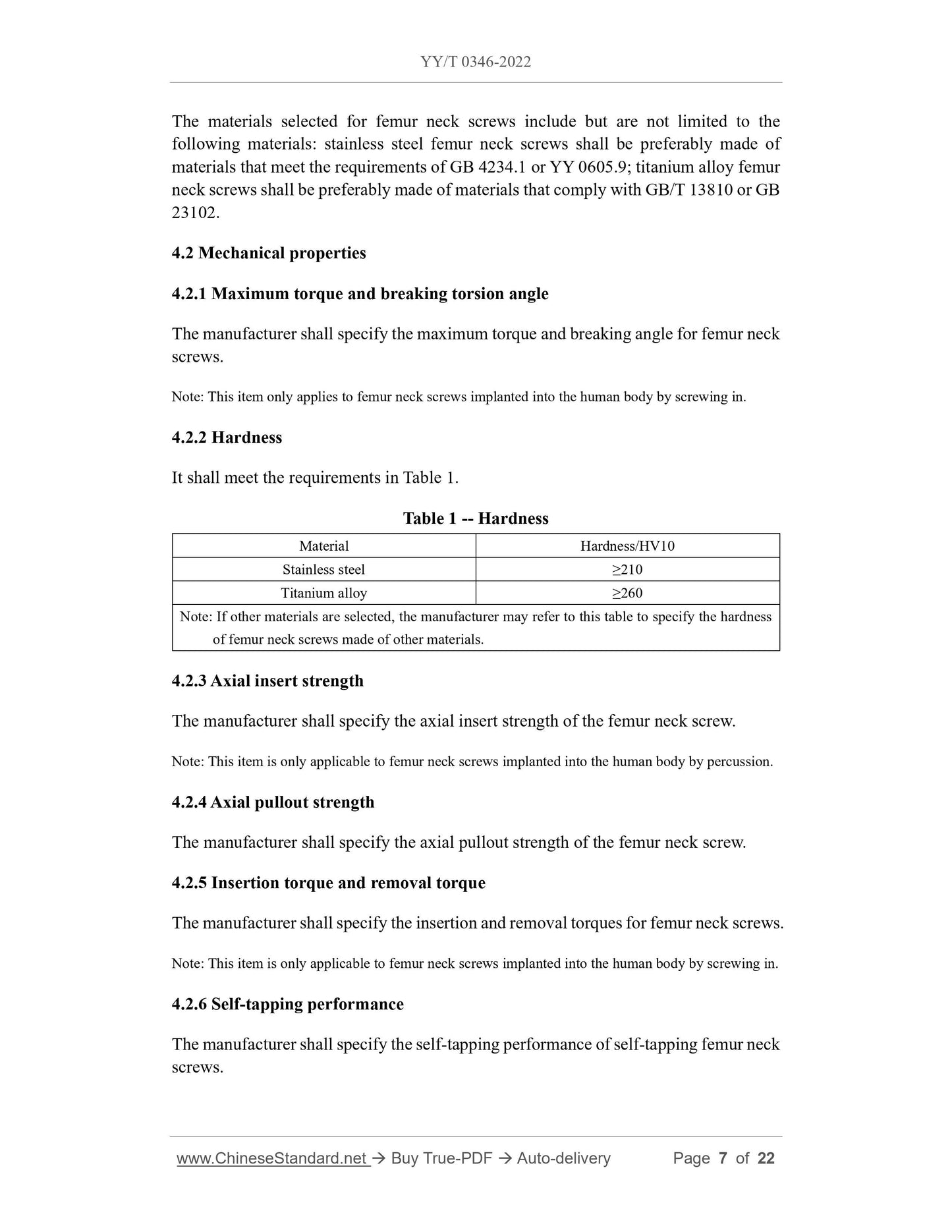

GB/T 4340.1 Metallic materials - Vickers hardness test - Part 1: Test method

GB/T 10610 Geometrical product specifications (GPS) - Surface texture: Profile

method - Rules and procedures for the assessment of surface texture

GB/T 13810 Wrought titanium and titanium alloy for surgical implants

GB/T 16886.5 Biological evaluation of medical devices - Part 5: Tests for in vitro

cytotoxicity

GB 23102 Implants for surgery - Metallic materials - Wrought titanium -

6aluminium-7niobium alloy

YY 0018 Implants for osteosynthesis - Metallic bone screws

YY/T 0343 Liquid penetrant inspection of metallic surgical implants

YY 0605.9 Implants for surgery - Metallic materials - Part 9: Wrought high nitrogen

stainless steel

YY/T 0640 Non-active surgical implants - General requirements

YY/T 0662 Implants for surgery - Metal bone screws with asymmetrical thread and

spherical under-surface - Mechanical requirements and test methods

YY/T 0856 Implants for orthosynthesis - Metallic angled fixation device

YY/T 1074 Implants for surgery - Measuring method for pitting corrosion potential

on stainless products

YY/T 1504 Implants for surgery - Test method for determining the axial pullout

strength of metallic bone screws

YY/T 1505 Implant for surgery - Test method for determining the self-tapping

performance of metallic bone screws

YY/T 1506 Implants for surgery - Test method for driving torque of metallic bone

screws

3 Terms and definitions

The terms and definitions defined in YY 0018, YY/T 0856, and the followings apply to

this document.

3.1 metallic fixation screw for femur neck

An implant that is made of metallic materials, used alone or in conjunction with other

implants (such as angle fixers, intramedullary nails, and internal fixation plates) during

femur neck fracture surgery, and implanted in the femur neck.

3.2 axial insert strength

The maximum pressure required to fully insert the working part of the femur neck screw,

which is implanted into the human body by percussion (see Figure C.1 in Appendix C),

into the test block, and the unit is Newton (N).

4 Requirements

4.1 Materials

Femur neck screws shall be preferably made of surgical implant materials specified by

international standards, national standards, and industry standards.

Note: This item is only applicable to self-tapping femur neck screws implanted into the human body by

screwing in.

4.2.7 Static compression bending performance

The manufacturer shall specify the compression bending strength and compression

bending stiffness of femur neck screws.

4.2.8 Fatigue compression bending performance

The manufacturer shall specify the fatigue compression bending performance of femur

neck screws.

4.3 Corrosion resistance

The pitting potential (Eb) of the stainless-steel femur neck screw shall not be less than

800 mV.

4.4 Surface quality

4.4.1 Surface defects

The surface of the femur neck screw must have no discontinuities.

4.4.2 Surface roughness

The manufacturer shall specify the requirements for the surface roughness (Ra) value

according to the product design characteristics.

4.4.3 Appearance

The surface of the femur neck screw shall be free from defects such as oxide scale,

knife marks, small notches, scratches, cracks, depressions, sharp edges (except cutting

edges), burrs, and shall also be free from inlays, final processing deposits, and other

pollutants.

4.4.4 Anodic oxidation surface treatment

After anodic oxidation surface treatment, femur neck screws shall at least be conducted

a qualitative analysis of surface elements and evaluation of cytotoxicity.

4.5 Dimensions

The manufacturer shall specify the dimensions and tolerances of the product according

to the product design characteristics.

4.6 Coordination performance

Where the femur neck screw has a connection, the coordination performance shall be

good, and there must be no looseness or jamming.

5 Test methods

5.1 Materials

The chemical composition and microstructure shall be sampled on the final product,

and inspected according to the method specified in the selected material standard or the

method in the standard recommended in Appendix A.

5.2 Mechanical properties

5.2.1 Maximum torque and breaking angle

The test shall be carried out according to the method of YY/T 0662 and the instructions

in Appendix B. If an electronic torsion testing machine is used for the torsion test, the

range shall be selected to ensure that the recorded maximum torque and breaking angle

are within the effective range of the testing machine. If possible, counting from the

thread close to the screw head, there shall be 5 complete threads exposed; if less than 5

threads are completely exposed, it shall be indicated in the report. It is recommended to

use a fixed angular velocity of 3 r/min, rotate the femur neck screw in the direction of

insertion until the femur neck screw breaks, and record the maximum torque and

breaking angle. The samples shall not be less than 5 pieces.

5.2.2 Hardness

The test shall be carried out according to the method specified in GB/T 4340.1, and the

number of samples shall not be less than 3 pieces.

5.2.3 Axial insert strength

The test shall be carried out according to the method specified in Appendix C, and the

number of samples shall not be less than 3 pieces.

Note: The test method in Appen...

Get QUOTATION in 1-minute: Click YY/T 0346-2022

Historical versions: YY/T 0346-2022

Preview True-PDF (Reload/Scroll if blank)

YY/T 0346-2022: Implants for osteosynthesis - Metallic fixation screw for femur neck

YY/T 0346-2022

YY

NATIONAL STANDARD OF THE

PEOPLE’S REPUBLIC OF CHINA

ICS 11.040.40

CCS C 35

Replace YY/T 0346-2002

Implants for osteosynthesis - Metallic fixation screw for

femur neck

ISSUED ON: MAY 18, 2022

IMPLEMENTED ON: JUNE 1, 2023

Issued by: National Medical Products Administration

Table of Contents

Foreword ... 3

1 Scope ... 5

2 Normative references ... 5

3 Terms and definitions ... 6

4 Requirements ... 6

5 Test methods ... 9

6 Manufacturing ... 11

7 Sterilization ... 11

8 Packaging ... 11

9 Information provided by the manufacturer ... 11

Appendix A (Informative) List of approved method standards for chemical analysis,

metallographic examination ... 13

Appendix B (Normative) Explanation of the determination method of maximum torque

and breaking angle ... 14

Appendix C (Normative) Measuring method of the axial insert strength of a femur neck

screw ... 15

Appendix D (Normative) Test methods of static compression bending performance and

fatigue compression bending performance of femur neck screws ... 18

References ... 22

Implants for osteosynthesis - Metallic fixation screw for

femur neck

1 Scope

This document specifies the terms and definitions, requirements, test methods,

manufacturing, sterilization, packaging, and information provided by the manufacturer

of metallic fixation screws for the femur neck (hereinafter referred to as femur neck

screws).

This document applies to femoral neck screws, which are used for the internal fixation

of femur neck fractures during orthopedic surgery.

2 Normative references

The following documents contain the provisions which, through normative reference in

this document, constitute the essential provisions of this document. For the dated

referenced documents, only the versions with the indicated dates are applicable to this

document; for the undated referenced documents, only the latest version (including all

the amendments) is applicable to this document.

GB 4234.1 Implants for surgery - Metallic materials - Part 1: Wrought stainless steel

GB/T 4340.1 Metallic materials - Vickers hardness test - Part 1: Test method

GB/T 10610 Geometrical product specifications (GPS) - Surface texture: Profile

method - Rules and procedures for the assessment of surface texture

GB/T 13810 Wrought titanium and titanium alloy for surgical implants

GB/T 16886.5 Biological evaluation of medical devices - Part 5: Tests for in vitro

cytotoxicity

GB 23102 Implants for surgery - Metallic materials - Wrought titanium -

6aluminium-7niobium alloy

YY 0018 Implants for osteosynthesis - Metallic bone screws

YY/T 0343 Liquid penetrant inspection of metallic surgical implants

YY 0605.9 Implants for surgery - Metallic materials - Part 9: Wrought high nitrogen

stainless steel

YY/T 0640 Non-active surgical implants - General requirements

YY/T 0662 Implants for surgery - Metal bone screws with asymmetrical thread and

spherical under-surface - Mechanical requirements and test methods

YY/T 0856 Implants for orthosynthesis - Metallic angled fixation device

YY/T 1074 Implants for surgery - Measuring method for pitting corrosion potential

on stainless products

YY/T 1504 Implants for surgery - Test method for determining the axial pullout

strength of metallic bone screws

YY/T 1505 Implant for surgery - Test method for determining the self-tapping

performance of metallic bone screws

YY/T 1506 Implants for surgery - Test method for driving torque of metallic bone

screws

3 Terms and definitions

The terms and definitions defined in YY 0018, YY/T 0856, and the followings apply to

this document.

3.1 metallic fixation screw for femur neck

An implant that is made of metallic materials, used alone or in conjunction with other

implants (such as angle fixers, intramedullary nails, and internal fixation plates) during

femur neck fracture surgery, and implanted in the femur neck.

3.2 axial insert strength

The maximum pressure required to fully insert the working part of the femur neck screw,

which is implanted into the human body by percussion (see Figure C.1 in Appendix C),

into the test block, and the unit is Newton (N).

4 Requirements

4.1 Materials

Femur neck screws shall be preferably made of surgical implant materials specified by

international standards, national standards, and industry standards.

Note: This item is only applicable to self-tapping femur neck screws implanted into the human body by

screwing in.

4.2.7 Static compression bending performance

The manufacturer shall specify the compression bending strength and compression

bending stiffness of femur neck screws.

4.2.8 Fatigue compression bending performance

The manufacturer shall specify the fatigue compression bending performance of femur

neck screws.

4.3 Corrosion resistance

The pitting potential (Eb) of the stainless-steel femur neck screw shall not be less than

800 mV.

4.4 Surface quality

4.4.1 Surface defects

The surface of the femur neck screw must have no discontinuities.

4.4.2 Surface roughness

The manufacturer shall specify the requirements for the surface roughness (Ra) value

according to the product design characteristics.

4.4.3 Appearance

The surface of the femur neck screw shall be free from defects such as oxide scale,

knife marks, small notches, scratches, cracks, depressions, sharp edges (except cutting

edges), burrs, and shall also be free from inlays, final processing deposits, and other

pollutants.

4.4.4 Anodic oxidation surface treatment

After anodic oxidation surface treatment, femur neck screws shall at least be conducted

a qualitative analysis of surface elements and evaluation of cytotoxicity.

4.5 Dimensions

The manufacturer shall specify the dimensions and tolerances of the product according

to the product design characteristics.

4.6 Coordination performance

Where the femur neck screw has a connection, the coordination performance shall be

good, and there must be no looseness or jamming.

5 Test methods

5.1 Materials

The chemical composition and microstructure shall be sampled on the final product,

and inspected according to the method specified in the selected material standard or the

method in the standard recommended in Appendix A.

5.2 Mechanical properties

5.2.1 Maximum torque and breaking angle

The test shall be carried out according to the method of YY/T 0662 and the instructions

in Appendix B. If an electronic torsion testing machine is used for the torsion test, the

range shall be selected to ensure that the recorded maximum torque and breaking angle

are within the effective range of the testing machine. If possible, counting from the

thread close to the screw head, there shall be 5 complete threads exposed; if less than 5

threads are completely exposed, it shall be indicated in the report. It is recommended to

use a fixed angular velocity of 3 r/min, rotate the femur neck screw in the direction of

insertion until the femur neck screw breaks, and record the maximum torque and

breaking angle. The samples shall not be less than 5 pieces.

5.2.2 Hardness

The test shall be carried out according to the method specified in GB/T 4340.1, and the

number of samples shall not be less than 3 pieces.

5.2.3 Axial insert strength

The test shall be carried out according to the method specified in Appendix C, and the

number of samples shall not be less than 3 pieces.

Note: The test method in Appen...

Share